p WARNING!Disconnect air supply before changing accessories, servicing or performing maintenance.

Replace or repair damaged parts. Use genuine parts only. Non-authorised parts may be dangerous and

will invalidate the warranty.

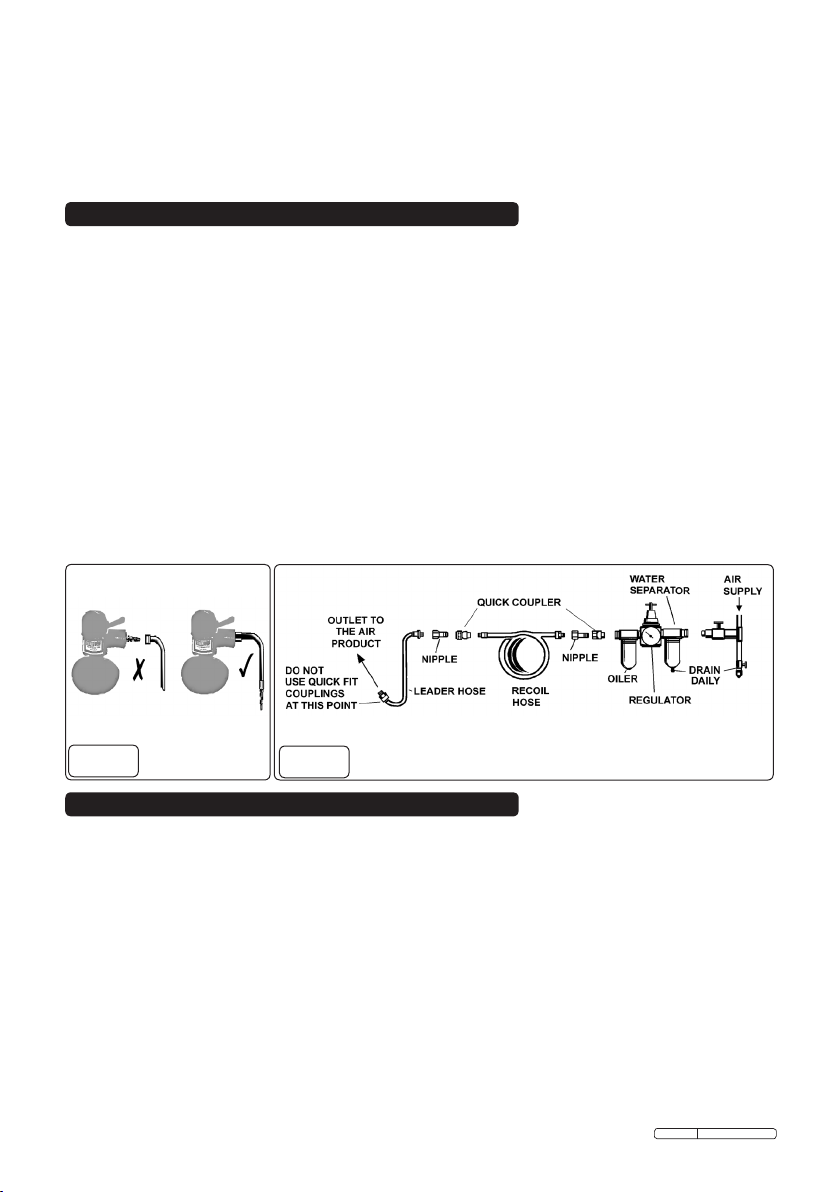

5.1. If there is no oiler in the air supply system, lubricate the tool daily with a few drops of good grade air tool

oil such as Sealey ATO/500 or ATO1000, dripped into the air inlet before use.

5.2. Clean the sander after use and change pad when required.

5.3. Loss of power or erratic action may be due to the following:

a) Excessive drain on the air system. Moisture or restriction in the air line. Incorrect size or type of hose

connectors. To remedy check the air supply and follow instructions in Section 3.

b) Grit or gum deposits in the tool may also reduce performance. If your model has an air strainer

(located in the area of the air inlet), remove the strainer and clean it. Flush the tool out with gum

solvent oil or an equal mixture of SAE 10 oil and kerosene. Allow to dry before use.

If you continue to experience problems, contact your local Sealey service agent.

5.4. For a full service contact your local Sealey service agent.

5.5. When not in use, disconnect from air supply, clean and store in a safe, dry, childproof location.

5. MAINTENANCE

4.2. Operating

4.2.1. DO NOT apply excessive pressure, let the tool do the work. Start the tool and bring the edge of the

pad to the work surface smoothly and slowly. Move the tool back and forth in overlapping areas to

remove the stripe. Lift the pad from the work surface before stopping the tool. Regularly check the

pad for wear - note minimum diameter marking - and always change a damaged pad.

4.2.2. DO NOT allow tool to run in “idle rotation” for an extended period of time as this will damage the

bearings.

4.2.3. A new pad should be run on a hidden or scrap panel to buff the surface before being used for pinstripe

removal.

4.2.4. Before starting each job run the pad on a patch of hidden paintwork to check that no damage is caused.

4.2.5. When used on two pack paints the surface finish may be slightly marked or hazy. Use a high grade

cutting compound to restore the surface finish.

4.2.6. When used on cellulose paints, greater care and time are required to ensure that the minimum of heat is

generated. If this care is not taken, heat will damage the surface finish.

4.2.7. The tool will also remove the double sided tape used to attach body trim. This process is slower than

stripe removal and may produce an unpleasant odour.

NOTE: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

IMPORTANT: No liability is accepted for incorrect use of this product.

WARRANTY: Guarantee is 12 months from purchase date, proof of which will be required for any claim.

INFORMATION: For a copy of our latest catalogue and promotions call us on 01284 757525 and leave your full name and address, including postcode.

01284 757500

01284 703534

sales@sealey.co.uk

Sole UK Distributor, Sealey Group,

Kempson Way, Suffolk Business Park,

Bury St. Edmunds, Suffolk,

IP32 7AR

www.sealey.co.uk

Web

email

Original Language Version SA95.V3 Issue: 1 - 22/09/11

Risk of Hand Arm Vibration Injury.

The SA95.V3 Air Adhesive Stripe Removing Tool Premier when operated in accordance with these instructions and tested in

accordance with BS EN ISO 8662-13:1997 results in the following vibration emission declared in accordance with BS

EN12096:1996.

Measured vibration emission value: ...................... 1.9m/s² Uncertainty: ........................................... 0.76m/s²

These values are suitable for comparison with emission levels of other tools that have been subject to the same test.

This tool may cause hand-arm vibration syndrome if its use is inadequately managed.

Recommended Measures to reduce risk of hand-arm vibration syndrome: This item represents a low Hand Arm Vibration risk

to users. The calculated maximum usage period exceeds 8 hours. We recommend appropriate safety equipment is utilised and

regular breaks for the operator are employed to reduce any residual risk of fatigue or repetitive strain injury.

Parts support is available for this product. To obtain a parts listing and/or diagram, please log on to www.sealey.co.uk,

email sales@sealey.co.uk or phone 01284 757500.