Senix CSX5-M User manual

2WWW.SENIXTOOLS.COM

SAFETY SYMBOLS................................................2

TECHNICAL DATA..................................................3

GENERAL POWER TOOL SAFETY WARNINGS....4

VIBRATION AND NOISE REDUCTION...................7

EMERGENCY..........................................................8

RESIDUAL RISKS.................................................8

To reduce the risk of injury, user must

read instruction manual.

Wear ear protection.

Wear eye protection.

Wear dust mask.

Wear hand protection.

Wear non-slip safety footwear.

Failure to keep your hands away

from the blade will result in serious

personal injury .

Avoid power lines, use in dry

conditions .

Do not expose to rain.

DANGER!

Risk of electrocution!

Thrown objects can ricochet and result

in personal injury or property damage.

Keep all bystanders at least 50 ft.

away.

Indicates danger, warning or caution.

Precautions that involve your safety.

Contact of the guide bar tip with any

object should be avoided.

Tip contact can cause the guide bar

to to move suddenly upward and

backward,which can cause serious

injury.

FELLING A TREE..................................................9

FELLING BACK A CUT..........................................10

LIMBING A TREE..................................................10

BUCKING A LOG..................................................10

ATTACH /REMOVE THE BATTERY......................15

PREPARATION......................................................15

DURING OPERATION...........................................15

SAFETY WARNIGS...............................................15

ON/OFF SWITCH..................................................15

CHAIN BRAKE......................................................16

CLEANING.............................................................17

REPLACING THE CHAIN.......................................17

FILLING THE AUTO OIL SYSTEM..........................18

SPROCKET WHEEL MAINTENANCE..................18

GUIDE BAR AND CHAIN MAINTENANCE..............18

STORAGE.............................................................19

PARTS...................................................................20

Troubleshooting Table............................................21

Troubleshooting Table............................................23

KNOW YOUR CHAINSAW.....................................12

TENSIONING THE CHAIN.....................................13

ASSEMBLY OF GUIDE BAR AND SAW CHAIN.....13

FILLING THE OIL TANK........................................14

Always use two hands when

operating the chain saw.

3

WWW.SENIXTOOLS.COM

Model Number:

Motor:

No Load Speed:

Max. Chain Speed:

Oil Tank Capacity:

Guide Bar Model:

Battery/Charger:

Battery:

Weight (w/Battery):

Product Dimensions:

Model Number:

Motor:

No Load Speed:

Max. Chain Speed:

Oil Tank Capacity:

Guide Bar Model:

Battery/Charger:

Battery:

Weight (w/o Battery):

Product Dimensions:

CSX5-M

58V Brushless Motor

7300 RPM

49 FPS (Feet Per Second)

4.1 oz. (120 ml)

140SDEA041

Senix B25X5/CHX5

58V Max Lithium Ion, 2.5 Ah

10.88 lbs.

30.6 x 8.4 x 9.6 in.

356 mm (14 inch)

Some dust created by power sanding, sawing, grinding, drilling and other

construction activities contains chemicals known to the state of California

to cause cancer, birth defects or other reproductive harm. Some examples

of these chemicals are: Lead from lead-based paints, crystalline silica from

bricks and cement and other masonry products, and arsenic and chromium

from chemically treated lumber.

Your risk from these exposures varies, depending on how often you do this

type of work. To reduce your exposure to these chemicals, work in a well

ventilated area with approved safety equipment such as dust masks that are

This product can expose you to chemicals including lead, a chemical

known to the State of California to cause cancer and birth defects or other

reproductive harm. For more information go to www.P65Warnings.ca.gov.

140SDEA041 91P052X Oregon Cutting System

CSX5-M-O

58V Brushless Motor

7300 RPM

49 FPS (Feet Per Second)

4.1 oz. (120 ml)

140SDEA041

battery and charger not included

58V Max Lithium Ion, 2.5 Ah

8.68 lbs.

30.6 x 8.4 x 9.6 in.

4WWW.SENIXTOOLS.COM

The term “power tool” in the

warnings refers to your mains-

operated (corded) power tool or

battery-operated (cordless) power

tool.

Cluttered or dark areas invite

accidents.

Power tools create sparks

which may ignite the dust or

fumes.

Distractions can cause you

to lose control.

Unmodified plugs and matching

outlets will reduce risk of electric

shock.

There

is an increased risk of electric

shock if your body is earthed or

grounded.

Water entering a power tool

will increase the risk of electric

shock.

Damaged or

entangled cords increase the risk

of electric shock.

Use of a cord suitable for outdoor

use reduces the risk of electric

shock.

Use

of an RCD reduces the risk of

electric shock.

A moment of

inattention while operating

power tools may result in serious

personal injury.

Protective equipment

such as dust mask, non-skid

safety shoes, hard hat, or hearing

protection used for appropriate

conditions will reduce personal

injuries.

Carrying power tools

with your finger on theswitch or

5

WWW.SENIXTOOLS.COM

energising power tools that have

the switch on invites accidents.

A wrench or a

key left attached to a rotating part

of the power tool may result in

personal injury.

This enables better

control of the power tool in

unexpected situations.

Loose clothes, jewellery

or long hair can be caught in

moving parts.

Use of

dust collection can reduce dust-

related hazards.

The correct

power tool will do the job better

and safer at the rate for which it

was designed.

Any power tool that cannot

be controlled with the switch is

dangerous and must be repaired.

Such preventive

safety measures reduce the

risk of starting the power tool

accidentally.

Power tools are

dangerous in the hands of

untrained users.

Many accidents are caused

by poorly maintained power tools.

Properly maintained

cutting tools with sharp cutting

edges are less likely to bind and

are easier to control.

g.

Use of the power

tool for operations different from

those intended could result in a

hazardous situation.

A charger that is suitable for one

type of battery pack may create

a risk of fire when used with

another battery pack.

Use of any other battery

packs may create a risk of injury

and fire.

Shorting the battery terminals

together may cause burns or a

fire.

6WWW.SENIXTOOLS.COM

Liquid

ejected from the battery may

cause irritation or burns.

This will

ensure that the safety of the

power tool is maintained.

A moment of inattention while

operating chain saws may cause

entanglement of your clothing or

body with the saw chain.

Holding the

chain saw with a reversed hand

configuration increases the risk of

personal injury and should never

be done.

For chain saws designed with

the guide bar on the left side, the

reference to “right hand” and “left

hand” positioning is reversed.

may make exposed metal parts

give the operator an electric

shock.

Adequate

protective clothing will reduce

personal injury by flying debris or

accidental contact with the saw

chain.

Operation of a chain saw

while up in a tree may result in

personal injury.

Slippery

or unstable surfaces such as

ladders may cause a loss of

balance or control of the chain

saw.

When the tension

in the wood fibres is released the

spring loaded limb may strike the

operator and/or throw the chain

saw out of control.

The slender material may catch

the saw chain and be whipped

toward you or pull you off

balance.

Proper handling of the chain

saw will reduce the likelihood

of accidental contact with the

moving saw chain.

Improperly tensioned or

lubricated chain may either

break or increase the chance for

kickback.

7

WWW.SENIXTOOLS.COM

Greasy, oily handles are slippery

causing loss of control.

Use of the

chain saw for operations different

than intended could result in a

hazardous situation.

Kickback may occur when the nose

or tip of the guide bar touches an

object, or when the wood closes in

and pinches the saw chain in the

cut.

Tip contact in some cases may

cause a sudden reverse reaction,

kicking the guide bar up and back

towards the operator.

Pinching the saw chain along the

top of the guide bar may push the

guide bar rapidly back towards the

operator.

Either of these reactions may cause

you to lose control of the saw which

could result in serious personal

injury. Do not rely exclusively upon

the safety devices built into your

saw. As a chain saw user, you

should take several steps to keep

your cutting jobs free from accident

or injury.

Kickback is the result of tool

misuse and/or incorrect operating

procedures or conditions and

can be avoided by taking proper

precautions as given below:

Kickback

forces can be controlled by the

operator, if proper precautions are

taken. Do not let go of the chain

saw.

This helps prevent unintended tip

contact and enables better control

of the chain saw in unexpected

situations.

Incorrect

replacement bars and chains may

cause chain breakage and/or

kickback.

Decreasing the depth gauge

height can lead to increased

kickback.

To reduce the impact of noise and

vibration emission, limit the time of

operation, use low-vibration and low-

noise operating modes as well as

wear personal protective equipment.

Take the following points into

account to minimize the vibration

and noise exposure risks:

• Only use the product as

intended by its design and these

instructions.

• Ensure that the product is in good

condition and well maintained.

• Use correct attachments for the

product and ensure they are in

good condition.

• Keep tight grip on the handles/

gripping surface.

• Maintain this product in

accordance with these instructions

and keep it well lubricated (where

appropriate).

• Plan your work schedule to spread

any high vibration tool use across

a longer period of time.

• Prolonged use of the product

exposes the user to vibrations that

can cause a range of conditions

collectively known as hand-arm

vibration syndrome (HAVS) e.g.

fingers going white; as well as

8WWW.SENIXTOOLS.COM

specific diseases such as carpal

tunnel syndrome.

• To reduce this risk when using the

product, always wear protective

gloves and keep your hands

warm.

• The symptoms of HAVS include

any combination of the following:

Tingling and numbness in the

fingers; Not being able to feel

things properly; Loss of strength

in the hands; Fingers going white

(blanching) and becoming red and

painful on recovery (particularly

in the cold and wet, and probably

only in the tips at first).

Seek medical advice immediately if

such symptoms are experienced.

• Familiarize yourself with the use

of this product by means of this

instruction manual. Memorize

the safety directions and follow

them to the letter. This will help to

prevent risks and hazards.

• Always be alert when using this

product, so that you can recognize

and handle risks early. Fast

intervention can prevent serious

injury and damage to property.

• Switch off the product and

remove the battery pack if there

are malfunctions. Have the

product checked by a qualified

professional and repaired, if

necessary, before you operate it

again.

Even if you are operating this

product in accordance with all

the safety requirements, potential

risks of injury and damage remain.

The following dangers can arise in

connection with the structure and

design of this product:

• Health defects resulting from

vibration emission if the product

is being used over long periods of

time or not adequately managed

and properly maintained.

• Injuries and damage to property

due to broken attachments or the

sudden impact of hidden objects

during use.

• Danger of injury and property

damage caused by flying objects.

• Prolonged use of this product

expose the operator to vibrations

and may produce ‘whitefinger’

disease. In order to reduce the

risk, please wear gloves and keep

your hands warm. If any of the

‘whitefinger’ symptoms appear,

seek medical advice immediately.

‘Whitefinger’ symptoms include:

numbness, loss of feeling,

tingling, pricking, pain, loss of

strength, changes in skin colour

or condition. These symptoms

normally appear in the fingers,

hands or wrists. The risk increases

at low temperatures.

This product produces an

electromagnetic field during

operation! This field may under

some circumstances interfere with

active or passive medical implants!

To reduce the risk of serious or fatal

injury, we recommend persons with

medical implants to consult their

doctor and the medical implant

manufacturer before operating this

product!

9

WWW.SENIXTOOLS.COM

By doing so, it is easier for the cut branches

to fall to the ground.

• At the end of the cut, the weight of the saw

suddenly increases for the user since it is no

longer being supported by a branch. There

is a risk of losing control of the saw, so make

sure to stay alert during the entire sawing

operation.

• Only pull the saw out of a cut while the saw is

running. By doing so, you prevent the chain

from jamming in the wood.

• Do not saw with the tip of the guide bar. Do

not saw into the branch formations (where the

tree branches outwards). This will impede the

tree’s ability to heal.

• For sawing off smaller branches, place the

stop face of the saw on the branch. This

prevents unwanted movements of the saw at

the beginning of the cut. While applying light

pressure, guide the saw through the branch

from top to bottom.

a relief cut. Saw through 1/3 of the branch

diameter from the bottom to top using the top

side of the guide bar. Then saw from top to

bottom for the other 2/3 using the bottom side

of the guide bar.

• Saw off longer branches in sections in order

to maintain control over the location of impact.

When bucking and felling operations are being

performed by two or more persons at the same

time, the felling operations should be separated

from the bucking operation by a distance of at

least twice the height of the tree being felled.

Trees should not be felled in a manner that

would endanger any person, strike any utility

line or cause any property damage. If the tree

does make contact with any utility line, the

The chain saw operator should keep on the

uphill side of the terrain as the tree is likely to

roll or slide downhill after it is felled.

Before felling is started, consider the natural

lean of the tree, the location of larger branches

and the wind direction to judge which way the

tree will fall. Remove dirt, stones, loose bark,

nails, staples and wire from the tree.

Make the notch 1/3 the diameter of the tree,

perpendicular to the direction of falls (Figure 2).

Figure 1 - Escape routes

Figure 2 - Notching undercut

This will help to avoid pinching either the saw

chain or the guide bar when the second notch

is being made.

Danger zone

Escape

route Escape

route

Felling direction

Danger zone

Direction of fall

Notch

50 mm Felling back cut

Hinge

50 mm

An escape path should be planned and

cleared as necessary before cuts are started.

The escape path should extend back and

diagonally to the rear of the expected line of fall

(Figure 1).

10 WWW.SENIXTOOLS.COM

Figure 3 - Tree limbing

Make the felling back cut at least 50 mm

higher than the horizontal notching cut (Figure

2). Keep the felling back cut parallel to the

horizontal notching cut. Make the felling back

cut so enough wood is left to act as a hinge.

The hinge wood keeps the tree from twisting

and falling in the wrong direction. Do not cut

through the hinge.

As the felling gets close to the hinge, the tree

should begin to fall. If there is any chance that

the tree may not fall in desired direction or it

may rock back and bind the saw chain, stop

cutting before the felling back cut is complete

and use wedges of wood, plastic or aluminium

to open the cut and drop the tree along the

desired line of fall.

When the tree begins to fall remove the chain

saw from the cut, stop the motor, put the chain

saw down, then use the retreat path planned.

Be alert for overhead limbs falling and watch

your footing.

Bucking is cutting a log into lengths. It is

your weight is evenly distributed on both feet.

When possible, the log should be raised and

supported by the use of limbs, logs or chocks.

Follow the simple directions for easy cutting.

When the log is supported along its entire

length, it is cut from the top (overbuck) (Figure

4).

Limbing is removing the branches from a fallen

tree. When limbing, leave larger lower limbs

to support the log off the ground. Remove the

small limbs in one cut (Figure 3).

Branches under tension should be cut from the

bottom up to avoid binding the chain saw.

Figure 4 - Log fully supported

Figure 5 - Log supported on one end

Figure 6 - Log supported on both ends

When the log is supported on one end, cut 1/3

the diameter from the underside (underbuck)

When the log is supported on both ends,

cut 1/3 the diameter from the top (overbuck)

When bucking on a slope always stand on the

uphill side of the log (Figure 7).

11

WWW.SENIXTOOLS.COM

Figure 7 - Stand uphill

To maintain complete control when cutting

through a log, release the cutting pressure near

the end of the cut without relaxing your grip

on the chain saw handles. Don’t let the chain

contact the ground. After completing the cut,

wait for the saw chain to stop before you move

the chain saw. Always stop the motor before

moving from tree to tree.

12 WWW.SENIXTOOLS.COM

1. Trigger

2. Safety Switch1

3. Battery2

4. Front handle

5. Hand guard/Chain break

6. Oil cap1

7. Guide bar

8. Chain

9. Side cover lock

10. Side cover

11. Battery release button

12. Chain tension wheel

1

2

3

5

56

7

8

9

10

11 4

12

13

WWW.SENIXTOOLS.COM

surface.

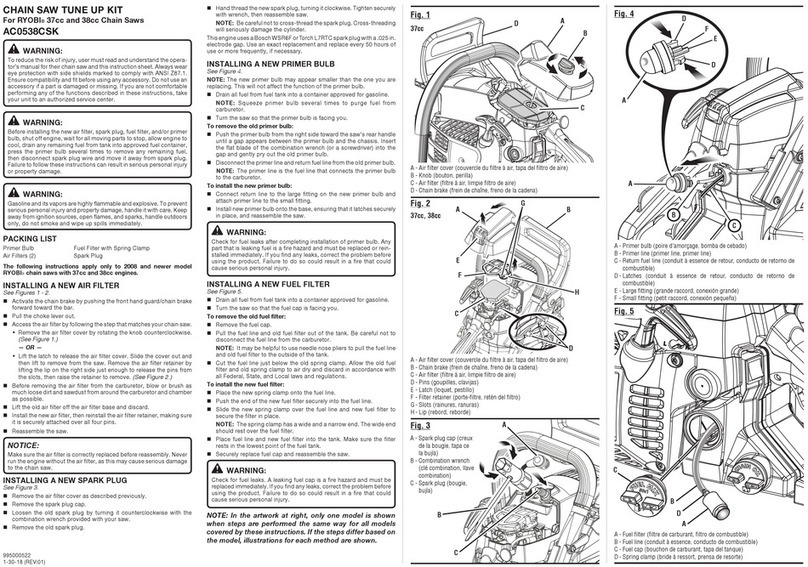

2. Rotate the side cover lock

counterclockwise to remove the cover from

the saw’s body (Figure 8).

3. Wearing protective gloves, wrap the saw

chain around the guide bar, making sure

that the teeth are aimed in the direction of

rotation (Figure 9). The chain should be

properly set in the slot running along the

entire outside edge of the guide bar.

4.Place the saw chain around the sprocket

while lining up the slot in the guide bar with

the internal bolt at the base of the saw and

the chain tensioning pin in the guide bar’s

pin hole (Figure 10). The chain tensioning

pin may need adjustment to properly align

with the hole in the guide bar. Use the

chain tensioning wheel to adjust its location

5.Turn the chain tensioning wheel to

preliminarily tighten the guide bar enough

that the chain stays in place (Figure 10).

While holding the bar still, reinstall the

cover. Make sure the tab properly line up

with the slot on the body of the saw (Figure

11). Reinstall the side cover lock and turn it

clockwise until it engages. Adjust the chain

tension.

1. Side cover lock

2. Cover

1— Sprocket

2— Internal bolt

3— Chain tensioning pin

4— Chain tensioning wheel

1

2

Figure 8 - Remove cover

Figure 9 - Correct teeth direction

Figure 10 - Install chain

Figure 11 - Reinstall cover

1

23

4

14 WWW.SENIXTOOLS.COM

Remove the battery before adjusting the

chain tension.

The chain tension is optimal if the saw chain

can be lifted 1/8 inch (3 mm) from the center

of the guide bar.

Because the saw chain heats up during

chain tension every 10 minutes of operation

and adjust as necessary, particularly for new

saw chains.

TIP: The saw chain shortens when cooling

down. Loosen the saw chain after work

is completed to elongate the chain’s life

and prevent possible damage.

1. Place the saw on a level surface. Clean

the area around the oil tank cap and then

open it.

2. Fill the oil tank with 4.06 oz. (120 ml) of

saw chain oil.

3. Close the oil tank cap.

1. Check the chain tension by pulling the saw

chain away from the guide bar. A properly

tensioned chain should have roughly 1/8

inch (3 mm) of distance between itself and

the bar guide (Figure 12).

2. If saw chain tension adjustment is needed,

loosen the side cover lock one full turn and

rotate the chain tensioning wheel (Figure

13). Rotating the wheel upwards increases

the tension. Rotating it downwards

decreases tension. A properly tensioned

chain should have no sag and should only

be able to be pulled 1/8 inch (3 mm) away

from the guide bar of the saw (Figure 14).

3. Once the chain is properly tensioned,

tighten the side cover lock.

Figure 13 - Adjust chain tension

Figure 14 - Correct chain tension

Figure 12 - Check chain tension

15

WWW.SENIXTOOLS.COM

Check the chain tension and

the condition of the blades.

The sharper the saw chain, the easier

and more manageable operations will be.

Wear appropriate

protective pants, gloves and safety shoes.

Wear a safety helmet with integrated hearing

protection and a face guard to provide

protection against falling and recoiling

branches.

To insert the battery, slide it into the back of

the unit until a “click” is heard. Make sure

the battery is fully inserted and latched into

position.

To remove the battery, press the release

button and slide the battery out.

Check the saw chain

tension every 10 minutes of operation to

maximize safety. New saw chains in particular

are subject to changes due to the heat

created by operation. Adjust as necessary to

maintain the correct chain tension.

Start the

machine; keep it running and check if the

chain oil is delivered as shown below.

Check the oil level while

for approximately 10 minutes of cutting

operation (depending the duration of pauses

and the density of the workpiece).

Before each use, check the following items to

ensure safe working conditions.

Inspect the chainsaw housing,

saw chain, and guide bar for damage. Do not

use the chainsaw if damage has occured. • In order to ensure safe work, do not operate

the saw above shoulder height.

• Never stand below a branch that is being

sawed.

• Exercise caution when sawing both

branches under tension or branches that

are splintering.

• Make sure to safe guard against the risk of

projectiles.

• If the machine is in operation, keep persons

and animals away from the danger area.

• The machine is not protected against

electric shock when coming into contact

with high-voltage lines. Maintain a minimum

clearance of 30 feet from current-carrying

power lines to avoid life-threatening electric

shock.

• Do not expose the unit to rain.

• When working on an incline, always stand

above or to the side of the branch being

sawed.

• Allow the chain to cut for you. Keep the saw

running at full speed for the entire duration

of the cut.

16 WWW.SENIXTOOLS.COM

To turn the tool ON: Push the safety button

(Figure 15) and then squeeze the trigger.

After the tool has started, you can release the

safety switch without turning the tool off.

To turn the tool OFF: Release the trigger

switch.

The chain brake is a safety mechanism

activated by the front hand guard. When

kickback occurs, the saw chain stops

immediately.

The following function check should be

carried out before each use. The purpose

of the chain brake testing is to reduce the

possibility of injury due to kickback:

1.Push front hand guard forward and try to

start the chain saw. The chain must not

start.

2.To deactivate the kickback brake, release

On/Off switch and pull hand guard

backwards.

1 — Safety button

2 — Trigger switch

Figure 15 - Safety and trigger switch

12

BRAKE ENGAGED

5

BRAKE OFF

17

WWW.SENIXTOOLS.COM

1. Rotate the side cover lock and remove the

cover of the saw’s body (Figure 8).

in the guide bar.

3. Place the new chain in this position,

making sure the teeth are facing the correct

into the slot around the guide bar (Figure 9).

4. Replace the cover and tighten the side

cover lock. Adjust tension before operating.

• Brush or blow dust and debris out of the air

vents using compressed air or a vacuum.

Keep the air vents free of obstructions,

sawdust, and wood chips. Do not spray,

wash, or immerse the air vents in water.

• Wipe off the housing and the plastic

components using a moist, soft cloth. Do

not use strong solvents or detergents on

the plastic housing or plastic components.

Certain household cleaners may cause

damage or cause a shock hazard.

• Routinely clean out the dust and debris

that gathers under the tension housing,

the oil outlet, and around the bar and the

chain sprocket. Otherwise it can jam up

the sprocket, the chain, and the lubrication

system.

356 mm (14 inch) 140SDEA041 91P052X Oregon Cutting System

18 WWW.SENIXTOOLS.COM

This chainsaw features an auto-oiling system

to keep the chain and guide bar properly

lubricated. The oil level

indicator shows the remaining oil in the

chainsaw. If the oil level decreases to below

bar and chain oil.

Operating the saw chain dry or with too little

shorten the product life span and cause rapid

wear to the saw chain and guide bar from

overheating!

bar discoloration! Adequate lubrication of

the saw chain during cutting operations is

essential to minimize friction with the guide

bar. Clean the sprocket wheel. Using a disposable

lube gun, insert the needle nose into the

lubrication hole and inject grease until it

appears at the outside edge of the sprocket.

Make sure that the chain brake is

disengaged. Rotate the saw chain by hand.

Repeat the lubrication procedure until the

entire sprocket has been greased.

1. Position the product in a way that the chain

oil tank cap faces upwards.

2. Open the cap and check the oil level. If the

oil level is more than 1-2 cm blow the screw

mm space between the top of the oil and

the inside edge of the tank to allow for

expansion.

5. Put the oil cap back on. Make sure to

check the oil level after every 10 minutes

of use.

If the bar wears unevenly, the rails widen,

which may cause the chain to clatter and

the product is operated with a saw chain

which is too tight, this will contribute to rapid

bar wear.

To help minimize bar wear, maintenance of

the guide bar as well as the saw chain is

recommended.

1. Disassemble the guide bar and saw chain

in reversed order from assembly.

2. Check the oiling port for clogging and clean

if necessary to ensure proper lubrication

of the guide bar and saw chain during

operation. Use a soft wire small enough to

insert into the oil discharge hole.

3. Check the drive sprocket. If it is worn or

damaged due to strain, have it replaced by

an authorized service center.

4. Clear residue from the rails on the guide

bar using a screwdriver, putty knife, wire

brush or other similar tool. This will keep

the oil passages open to provide proper

lubrication to the guide bar and saw chain.

5.Check the guide bar ‘rail’ for wear: Hold a

LUBE

19

WWW.SENIXTOOLS.COM

ruler (straight edge) against the side of the

guide bar and ‘cutter side plates’. If there is

a gap between the ruler and guide bar the

guide bar ‘rail’ is normal. If there is no gap

bar) the guide bar ‘rail’ is worn and needs

to be replaced with a new one of the same

type.

6. Turn the guide bar 180° to allow even wear,

thereby extending the life span of the guide

bar.

7. Check the saw chain for possible wear

and damages. Replace it with a new one

if required. Experienced user can sharpen

a dull saw chain (see section “Saw chain

sharpening” below).

8. Reassemble the saw chain and the guide

bar. See ASSEMBLY.

• Clean the unit before storing or transporting.

Be sure to secure the unit while

transporting.

• Remove the battery pack before storing.

Charge the battery completely before long-

term storage.

• When battery pack is not in use, keep it

away from other metal objects like paper

clips, coins, keys, nails, screws, or other

small metal objects that can make a

connection from one terminal to another.

• Store the tool out of reach for children

and other unauthorized persons in a well-

ventilated, dry and frost- free environment.

• Protect the machine against dusts and

moisture.

• Always protect the blades with a scabbard

(blade cover) when transporting or storing

the chain saw. Carefully handling the chain

saw greatly reduces the risk of accidentally

touching the sharp cutting blades.

Examine the unit thoroughly for worn, loose

or damaged parts. If you need to repair

or replace a part, contact Senix customer

service at 1-800-261-3981.

• Store the unit in a clean, dry place. Cover it

in order to provide added protection.

20 WWW.SENIXTOOLS.COM

1 199001000492 Blade Tension Cap Assembly 1

2 205001000031 Chain 1

3 205001000095 Guide Bar 1

4 202009000177 Sheath 1

5 207279900038 Oil Feed Seal 1

6 207310100046 Screw 22

7 207310100007 Screw 2

8 201999001224 Insulating Washer 1

9 202028000088 Tension Adjusting Knob 1

10 199117000032 Tension Ajustment Rod 1

36 202999001254 Rubber Washer 1

37 199123000422 Oil Cap Assembly 1

Other manuals for CSX5-M

1

This manual suits for next models

1

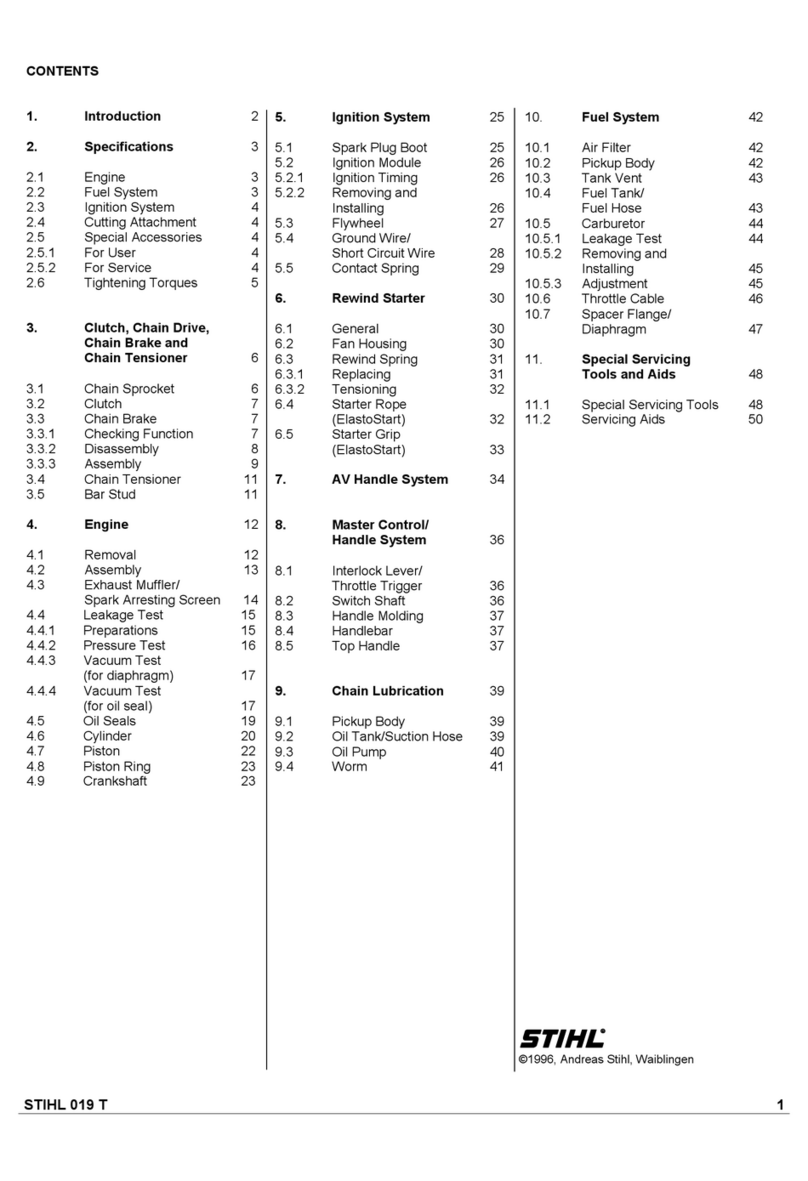

Table of contents

Languages:

Other Senix Chainsaw manuals