SENKO MGT User manual

MGT Docking Station

Version II

5

1

User’s Manual

Table Contents

Warning …………………………………………………..................…

Overview …………………………………………..................…

Specification

Button Function

LED Color

Main Operation Procedure

PC Program Configuration

Limited Warranty

…………………………………………………..................…

…………………………………………………..................…

…………………………………………………..................…

………………………………………..................…

……………………………………...................…

…………………………………………………..................…

3

4

5

6

7

8

9

11

Log Events Download …………………………………...................…10

MGT Docking Station version II

2

MGT Docking Station version II

WARNING

Any unauthorized attempt to repair or modify the product, or any

other cause of damage beyond the range of the intended use,

including damage by fire, lightening, or other hazard, voids liability

of the manufacturer.

Do not use if the device appears to be damaged.

Use the device in a clean environment, which has no hazardous

gases.

Do not use the expired gas cylinders.

Ensure to use the certified gas cylinders.

Ensure gas types and concentrations match with manuals and

devices.

Severe vibration or shock to the device may cause a sudden

reading change and cause the device malfunction.

Do not allow water and liquids to reach this device.

Read the operation manual before use

üBefore operation ,read the manual carefully and follow all the

instructions.

üIR link only works when it is placed at the bay 1on the docking

station.

üThe deice only operates when the power LED turns grean.

üBefore upgrading firmware, connect the plug to avoid any data

loss and malfunction by unexpected power off.And the file

name is fixed as below.

-Docking F/W File Name : DK_FW.bin,

-PM400 F/W Name : PM400_FW.bin

3

MGT Docking Station version II

1. Overview

Bump test and calibration are the key features to ensure the safety of devices and

users. The MGT Docking Station version II. MGT docking station version II

provides bump testing, event management and calibration from a simple to use

multi-unit station and gives fleet or safety managers the ability to update

configurations on large fleets. It also maintains the all important event logs that

demonstrate users are working within company requirements.

Key Features

Advantages

üZero and Span Calibration, Bump Test Function

üIndicate the current status of operation by the Power LED and Unit LED color

üGas Ventilation system to remove a remained gas

üSave the log events after calibration and bump test

üEnable users to adjust the setting points of Docking station and MGT via IR

Link or USB

Gas usage controlled Lowers the cost of bump testing

Manages calibration Manages calibration and stores the records of log

events

All data is stored in a USB stick Simple to transfer the data

Rechargeable battery or power Ideal for in-vehicle or multi-site use

Holds up to 4 devices at once Faster testing of larger fleets

4

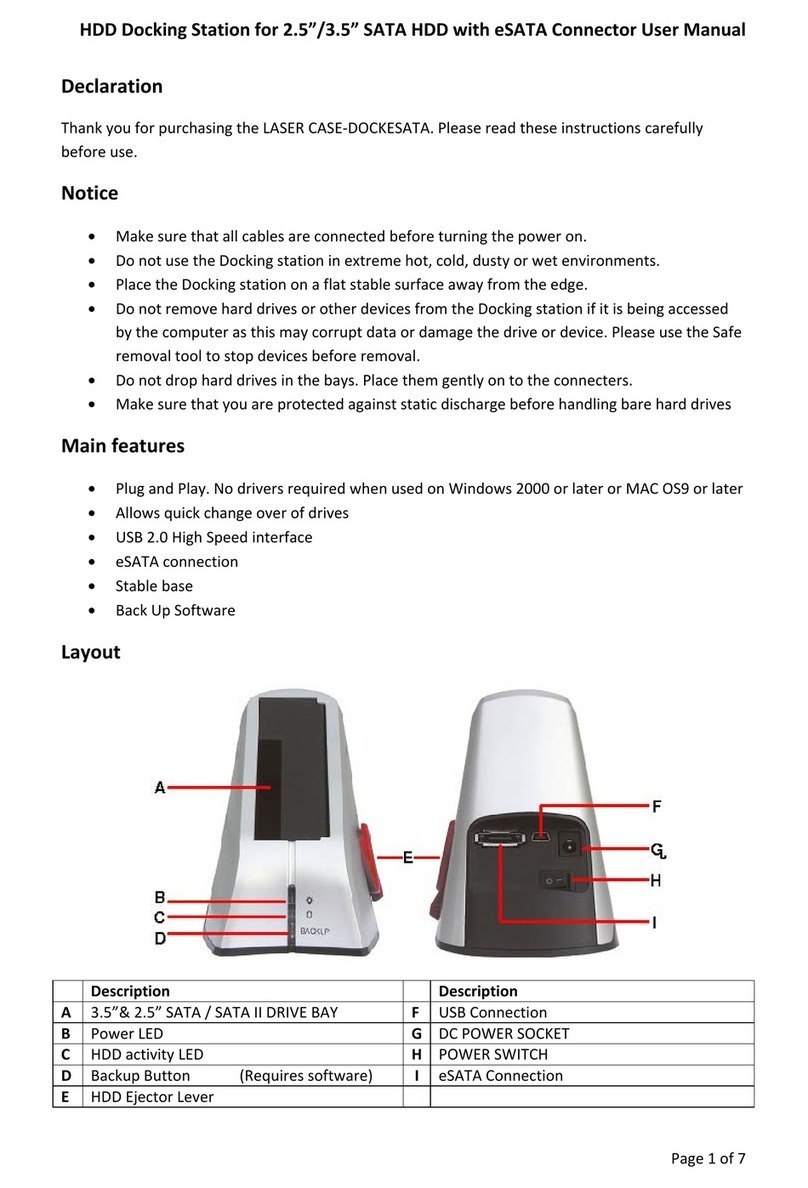

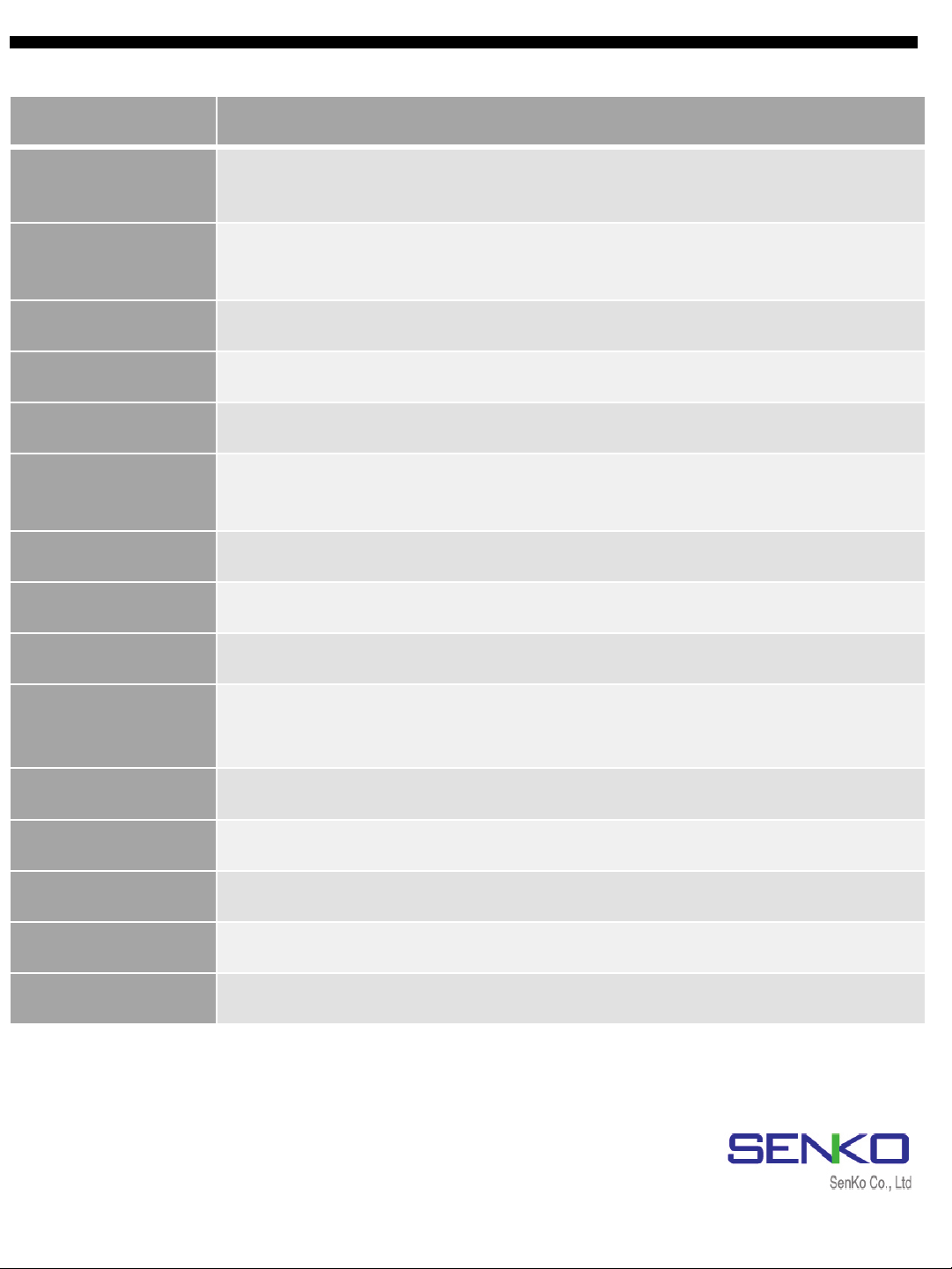

Size 52.5 x 43.7 x 21.3cm(20.66” x 17.20” x 8.40”)

Weight

(Without gas cylinder)

11.0kg

Operating

Temperature 41 to +104˚F (5 to +40˚C)

Warranty Full 2 years

Battery Type Rechargeable Lithium Ion

Battery Life 1,000 Bump Tests

LEDs 6 Blue LEDs for each unit(unit x 4) , 3-color LED for power ,

Switch Back Light LED(Yellow, Green)

Memory USB 8GB Standard

Log Capacity Approximately Up to 5 million tests(8GB, removable USB memory)

Tests Performed Bump Test and Calibration

Information

Stored Bump/Cal Logs, Individual Monitor Event Logs, Firmware and Unit Configurations

Gases Available LEL, CO, H2S and O2

Unit Compatibility Works with SP-MGT(N, P)

Calibration Gas Compatible with 58L & 116L cylinders

Interface Ethernet RJ-45(TCP/IP), 10Mb/s

Charging Adaptor DC12.0V, 3A/h

MGT Docking Station version II

2. Specification

5

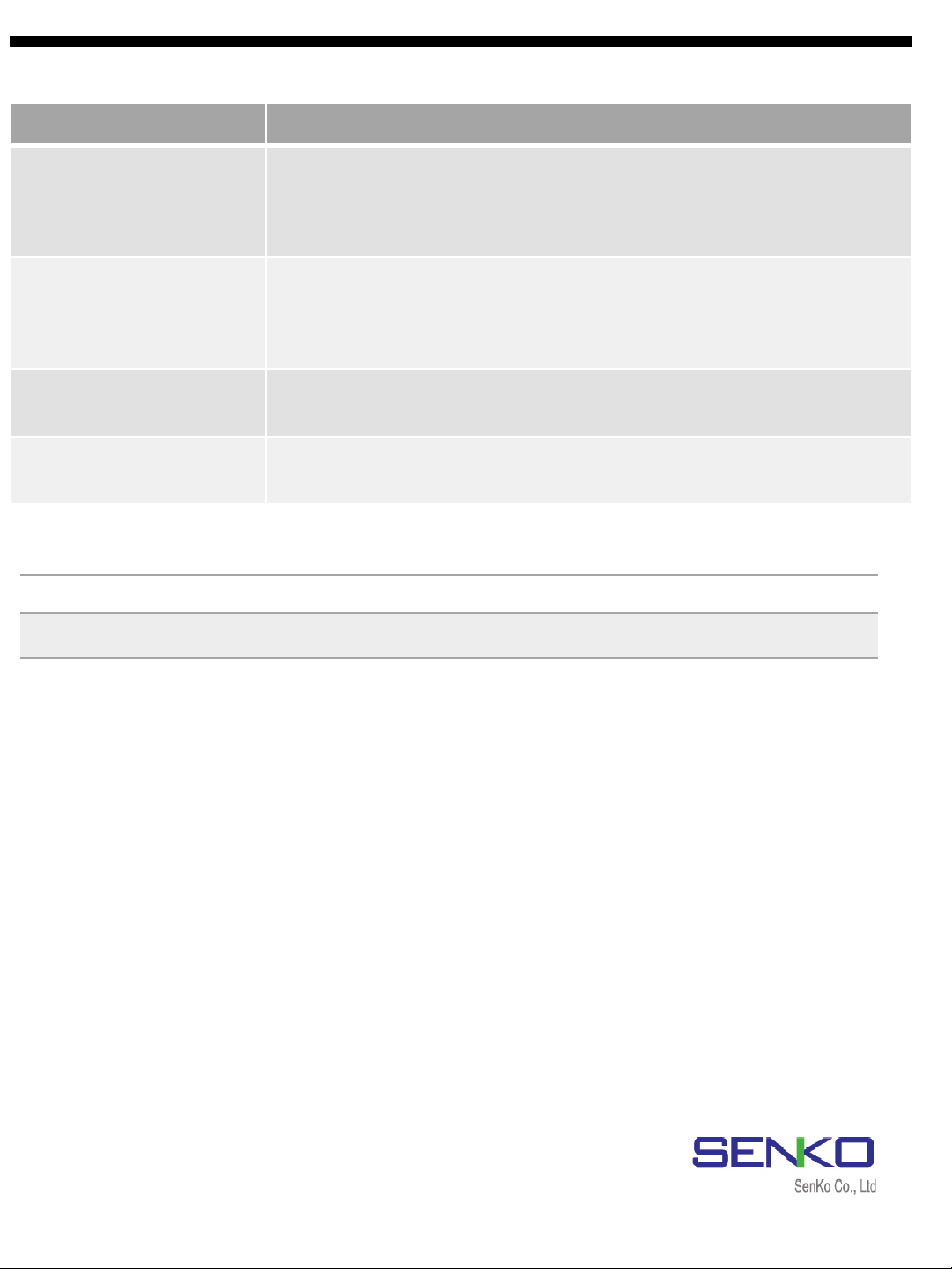

Button Instruction

Calibration or Bump

Test

•To turn on, press either calibration or bump test button for

1 second.

(Power Led: Orange -> Green

Calibration + Bump

Test

•To power off, press the calibration and bump test button

for three seconds.

Calibration •To activate the function, press the calibration button for

three seconds.

Bump Test •To activate the function, press the bump test button for

three seconds.

MGT Docking Station version II

3. Button Function

IR LINK only works when it is placed into the No.1 bay

The button only works when the power LED turns green

üNote

6

MGT Docking Station version II

4. LED Color

Status LED location Status Color

IDLE

(Ready to use)

Power LED Status Green

Unit LED Status -

Recharging Power LED Status -

Unit LED Status Blue (Cycling)

No USB inserted

Full USB Capacity

Power LED Status Orange (Blinking for 5 sec)

Unit LED Status -

Low Battery Power Power LED Status Red

Unit LED Status -

Test Progress Power LED Status -

Unit LED Status Blue Cycling

Test Result Power LED Status -

Unit LED Status Success: All LED on

Fail: Third unit LED will blink

FW Upgrading Power LED Status -

Unit LED Status No.6 Blue Color LED

Blinking

•During the recharging period, the unit LED(Blue

) will be cycling. The full charge takes about 4 hours and users can

use the bump test for 1,000 times. During recharging, users can use the device.

•If USB is not connected and the USB memory is full, the power LED (orange)is blinking

•If the USB is not connected, users can still use the docking station, but log data will not be recorded.

•When the battery is drained, power LED(Red) will be on and the device is not working and it will enter the Idle

status.

•During the upgrading firmware, unit 6 LED(Blue) will be turned on and flashing for 2 minutes.

7

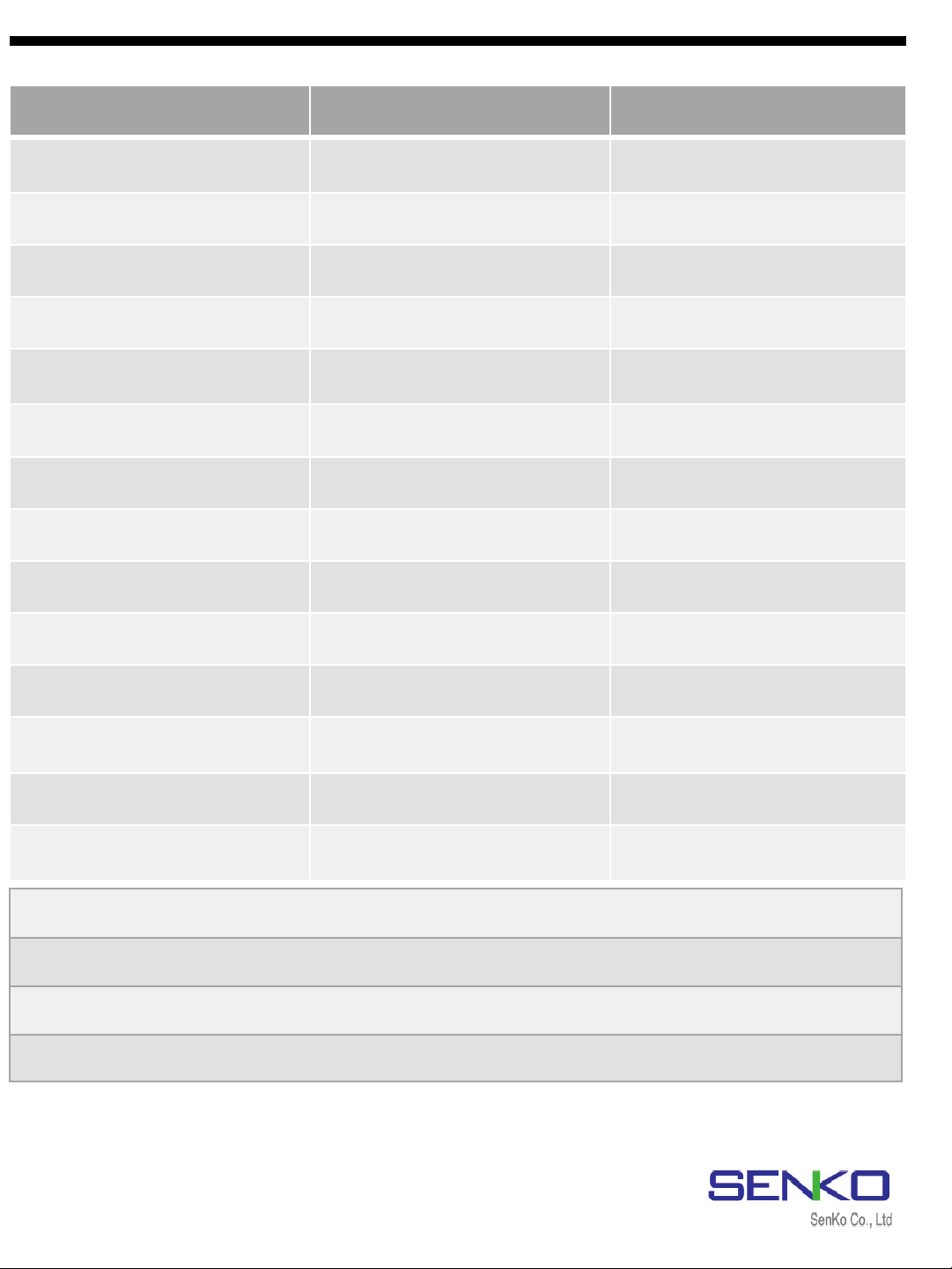

Initialize

System

ON Power

Status

USB

Status

Docking

Status

Status

MGT Docking Station version II

5. Main Operation Procedure

•

Docking Station On

When the device is on, the power LED will turn from orange to green.

•

Calibration or Bump Test

To initiate the calibration or bump test, press the button. And, the power LED will turn

orange

. The device will decide if the configuration will be loaded on the MGT based on if the

configuration check box is marked or not.

•

When the device enters the test procedure, the light will turn green and the unit LED will

turn blue as the following procedures.

-Unit 1 LED : Check if the device is connected

-Unit 2 LED : Initiate Air Pump

-Unit 3 LED : Initiate Bump or Calibration

- Unit 4 LED : Initiate Air Pump

-Unit 5 LED : Save Log events

•

To cancel the test, press the button one time.

•

When the test is completed successfully, the all unit LED will turn blue and

when the unit fails,

the third LED(blue) will flash.

•

To communicate with PC, connect IR link with the no.1 Bay.

8

MGT Docking Station version II

6. PC Program Configuration

Detector User ID

Calibration interval: 0~365 days

Low / High Alarm Setting

-H2S : 0 ~ 100.0

-CO : 0 ~ 300

-O2 : 0 ~ 30.0

-LEL : 0 ~ 100.0

Bump interval: 0~365 days

Choose the MGT firmware

STEL / TWA Alarm Setting

-H2S : 0 ~ 100.0

-CO : 0 ~ 300

TWA Method

-ACGIH : Accumulation Average

-OSHA : Movement Average Initiate the firmware upload.

TWA

-Default : 8 hours

average

STEL

-Default :15 minutes average

Safe Display : In the safe area, SAFE will displaced.

Dock Lock : Lock the bump / calibration

Maintenance Notification

Latching Alarms : Until the users push the button,

the alarm will be activated continuously.

Auto Zero : When the device is turned on, the

zero calibration will be activated.

Lel by volume : 100%LEL Standard

Off Lock : Prevent users from turning off the

device.

Configuration

9

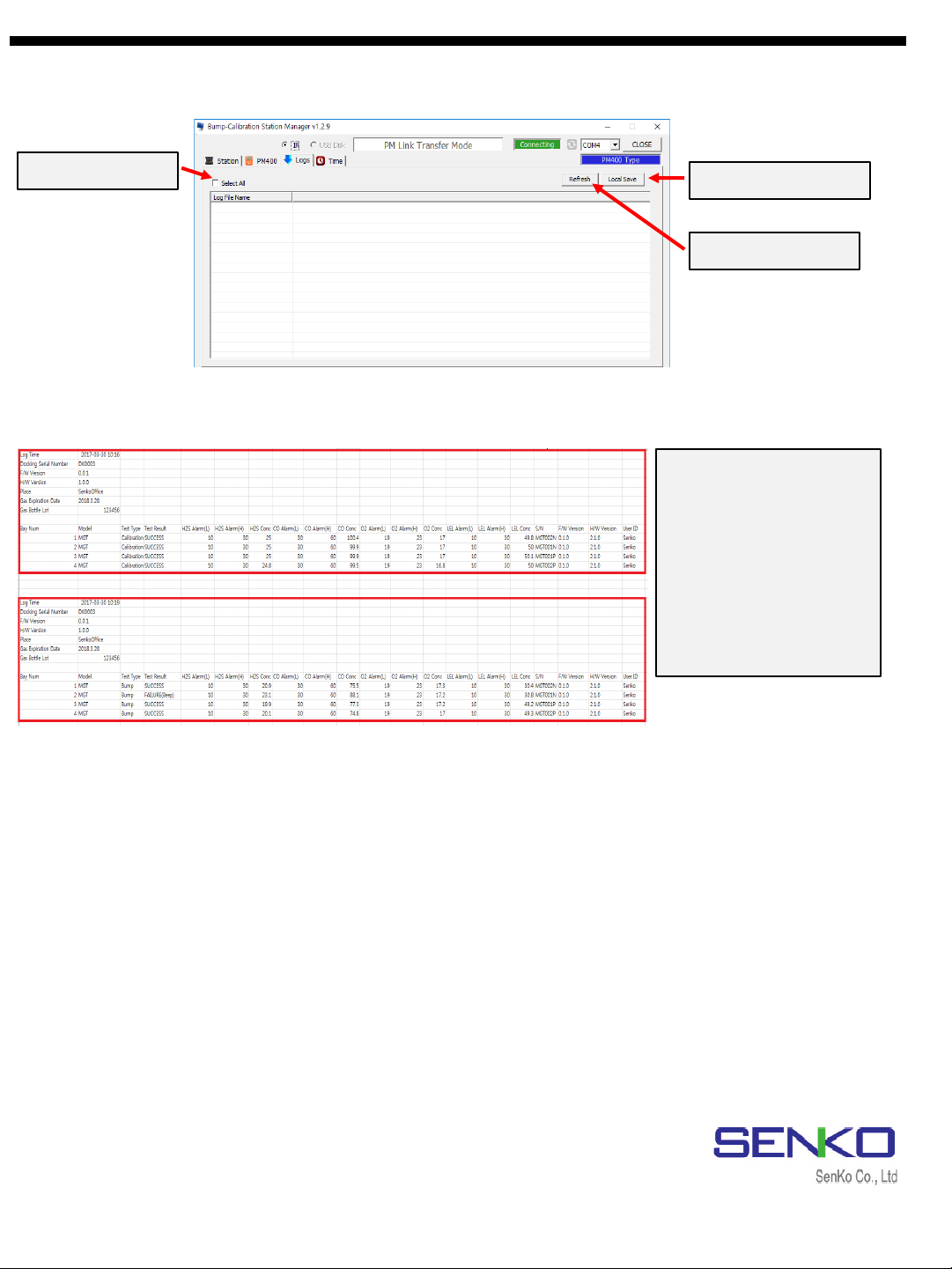

Refresh :Open the lists of log

events.

Local Save : Save the log events

in the PC.

Select All : All log events

stored in the docking station.

MGT Docking Station version II

7. Log Events Download

Docking for PM400 Log Data

Docking for PM400 Log

Format

Log Time : Total hours of log events

Docking Serial number : Docking S/N

F/W Version : Docking SW FW Version

H/W Version : Docking HW FW Version

Place : Docking Station Location

Gas Expiration Date : Expired Date

Gas Bottle Lot : Gas Cylinder Lot Info

10

MGT Docking Station version II

Limited Warranty

SENKO warrants this product to be free of defects in workmanship and materials-under normal use

and service for two years from the date of purchase from the manufacturer or from the product’s

authorized reseller.

The manufacturer is not liable (under this warranty) if its testing and examination disclose that the

alleged defect in the product does not exist or was caused by the purchaser’s (or any third party’s)

misuse, neglect, or improper installation, testing, or calibrations. Any unauthorized attempt to repair

or modify the product, or any other cause of damage beyond the range of the intended use,

including damage by fire, lightening, water damage or other hazard, voids liability of the

manufacturer.

In the event that a product should fail to perform up to manufacturer specifications during the

applicable warranty period, please contact the product’s authorized reseller or SENKO service

center at 82-31-492-0445 to repair/return information.

73, Oesammi-ro 15 beon-gil, Osan-si, Gyeonggi-do, 18111, South Korea

Tel : 82-31-492-0445 Fax : 82-31-492-0446

Email : [email protected] Web : www.senko.co.kr

11

Other manuals for MGT

1

Table of contents

Other SENKO Docking Station manuals