Sensata Crydom PMP Series User manual

Page 1

www.sensata.com

Copyright © 2019 Sensata Technologies, Inc.

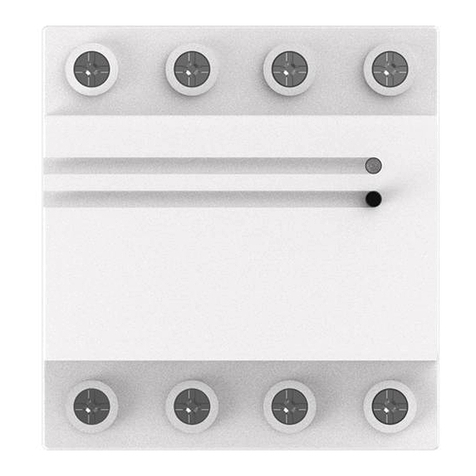

Terminals

Maximum recommended terminal screw torque

input terminal: 5 in-lb (0.5 Nm)

Maximum recommended terminal screw torque

load terminal: 18-20 lb-in (2.0-2.2 Nm)

Recommended wire sizes as shown in TABLE 1.

Important Considerations

Be sure to use input and output voltages within

operating ranges.

LED provides status operation of the SSR, as

shown in TABLE 3

|PMP SERIES

PANEL MOUNT PROPORTIONAL CONTROL SOLID STATE RELAYS

MOUNTING INSTRUCTIONS

ORDERING OPTIONS

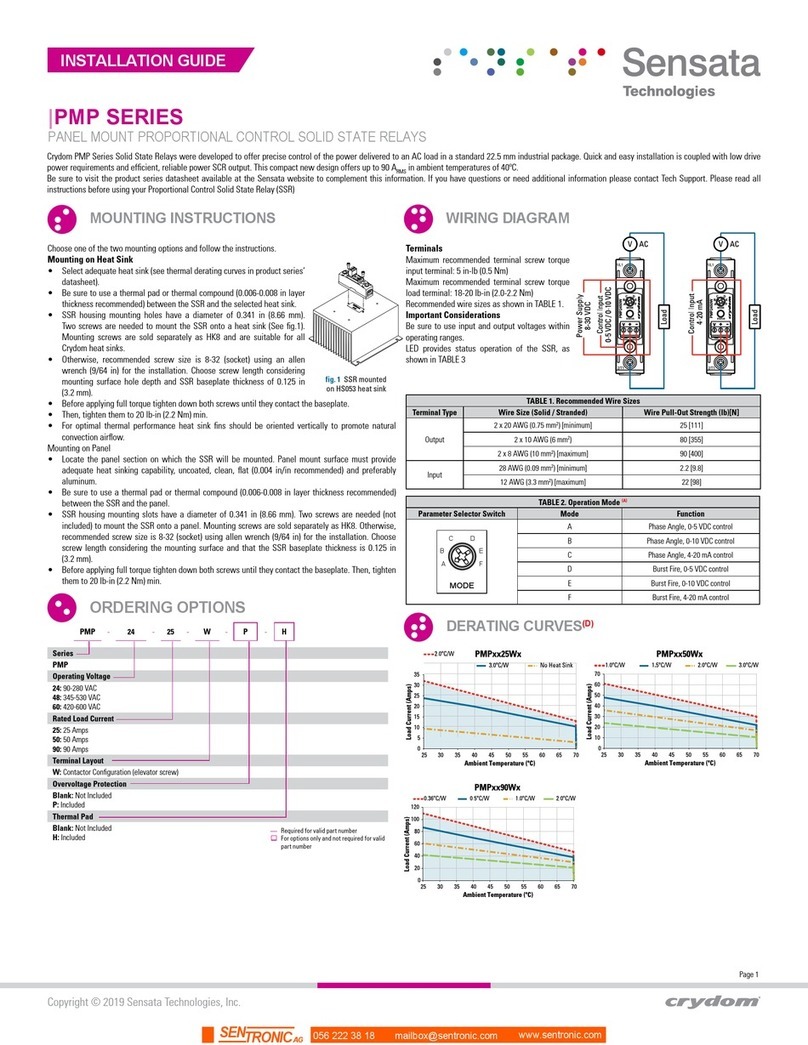

WIRING DIAGRAM

Crydom PMP Series Solid State Relays were developed to offer precise control of the power delivered to an AC load in a standard 22.5 mm industrial package. Quick and easy installation is coupled with low drive

power requirements and efficient, reliable power SCR output. This compact new design offers up to 90 ARMS in ambient temperatures of 40ºC.

Be sure to visit the product series datasheet available at the Sensata website to complement this information. If you have questions or need additional information please contact Tech Support. Please read all

instructions before using your Proportional Control Solid State Relay (SSR)

INSTALLATION GUIDE

Choose one of the two mounting options and follow the instructions.

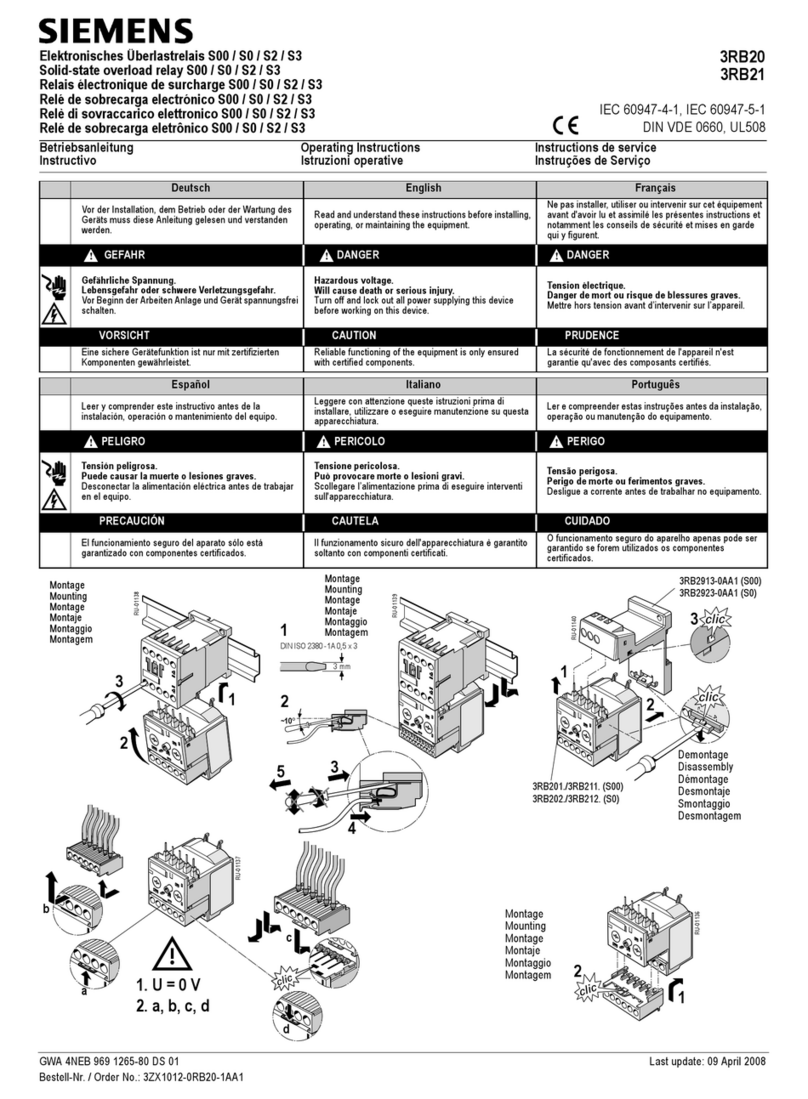

Mounting on Heat Sink

• Select adequate heat sink (see thermal derating curves in product series’

datasheet).

• Be sure to use a thermal pad or thermal compound (0.006-0.008 in layer

thickness recommended) between the SSR and the selected heat sink.

• SSR housing mounting holes have a diameter of 0.341 in (8.66 mm).

Two screws are needed to mount the SSR onto a heat sink (See fig.1).

Mounting screws are sold separately as HK8 and are suitable for all

Crydom heat sinks.

• Otherwise, recommended screw size is 8-32 (socket) using an allen

wrench (9/64 in) for the installation. Choose screw length considering

mounting surface hole depth and SSR baseplate thickness of 0.125 in

(3.2 mm).

• Before applying full torque tighten down both screws until they contact the baseplate.

• Then, tighten them to 20 lb-in (2.2 Nm) min.

• For optimal thermal performance heat sink fins should be oriented vertically to promote natural

convection airflow.

Mounting on Panel

• Locate the panel section on which the SSR will be mounted. Panel mount surface must provide

adequate heat sinking capability, uncoated, clean, flat (0.004 in/in recommended) and preferably

aluminum.

• Be sure to use a thermal pad or thermal compound (0.006-0.008 in layer thickness recommended)

between the SSR and the panel.

• SSR housing mounting slots have a diameter of 0.341 in (8.66 mm). Two screws are needed (not

included) to mount the SSR onto a panel. Mounting screws are sold separately as HK8. Otherwise,

recommended screw size is 8-32 (socket) using allen wrench (9/64 in) for the installation. Choose

screw length considering the mounting surface and that the SSR baseplate thickness is 0.125 in

(3.2 mm).

• Before applying full torque tighten down both screws until they contact the baseplate. Then, tighten

them to 20 lb-in (2.2 Nm) min.

Series

PMP

Operating Voltage

24: 90-280 VAC

48: 345-530 VAC

60: 420-600 VAC

Rated Load Current

25: 25 Amps

50: 50 Amps

90: 90 Amps

Terminal Layout

W: Contactor Configuration (elevator screw)

Overvoltage Protection

Blank: Not Included

P: Included

Thermal Pad

Blank: Not Included

H: Included

PMP -24 -25 -W-P-H

Required for valid part number

For options only and not required for valid

part number

TABLE 1. Recommended Wire Sizes

Terminal Type Wire Size (Solid / Stranded) Wire Pull-Out Strength (lb)[N]

Output

2 x 20 AWG (0.75 mm2) [minimum] 25 [111]

2 x 10 AWG (6 mm2) 80 [355]

2 x 8 AWG (10 mm2) [maximum] 90 [400]

Input 28 AWG (0.09 mm2) [minimum] 2.2 [9.8]

12 AWG (3.3 mm2) [maximum] 22 [98]

TABLE 2. Operation Mode (A)

Parameter Selector Switch Mode Function

MODE

D

E

F

C

B

A

A Phase Angle, 0-5 VDC control

B Phase Angle, 0-10 VDC control

C Phase Angle, 4-20 mA control

D Burst Fire, 0-5 VDC control

E Burst Fire, 0-10 VDC control

F Burst Fire, 4-20 mA control

DERATING CURVES(D)

fig. 1 SSR mounted

on HS053 heat sink

Specification No.: Rev. 11/12/18

Americas

+1 (877) 502 5500

Europe, Middle East & Africa

+44 (1202) 416170

Asia Pacific

China +86 (21) 2306 1500

Japan +81 (45) 277 7117

Korea +82 (31) 601 2004

India +91 (80) 67920890

Rest of Asia +886 (2) 27602006

ext 2808

Page 2

www.sensata.com

CONTACT US

Copyright © 2019 Sensata Technologies, Inc.

Sensata Technologies, Inc. (“Sensata”) data sheets are solely intended to assist designers (“Buyers”) who are developing systems that incorporate Sensata

products (also referred to herein as “components”). Buyer understands and agrees that Buyer remains responsible for using its independent analysis, evaluation

and judgment in designing Buyer’s systems and products. Sensata data sheets have been created using standard laboratory conditions and engineering

practices. Sensata has not conducted any testing other than that specifically described in the published documentation for a particular data sheet. Sensata may

make corrections, enhancements, improvements and other changes to its data sheets or components without notice.

Buyers are authorized to use Sensata data sheets with the Sensata component(s) identified in each particular data sheet. HOWEVER, NO OTHER LICENSE,

EXPRESS OR IMPLIED, BY ESTOPPEL OR OTHERWISE TO ANY OTHER SENSATA INTELLECTUAL PROPERTY RIGHT, AND

NO LICENSE TO ANY THIRD PARTY TECHNOLOGY OR INTELLECTUAL PROPERTY RIGHT, IS GRANTED HEREIN. SENSATA DATA SHEETS ARE PROVIDED “AS

IS”. SENSATA MAKES NO WARRANTIES OR REPRESENTATIONS WITH REGARD TO THE DATA SHEETS OR USE OF THE DATA SHEETS, EXPRESS, IMPLIED

OR STATUTORY, INCLUDING ACCURACY OR COMPLETENESS. SENSATA DISCLAIMS ANY WARRANTY OF TITLE AND ANY IMPLIED WARRANTIES OF

MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE, QUIET ENJOYMENT, QUIET POSSESSION, AND NON-INFRINGEMENT OF ANY THIRD PARTY

INTELLECTUAL PROPERTY RIGHTS WITH REGARD TO SENSATA DATA SHEETS OR USE THEREOF.

All products are sold subject to Sensata’s terms and conditions of sale supplied at www.sensata.com SENSATA ASSUMES NO LIABILITY FOR APPLICATIONS

ASSISTANCE OR THE DESIGN OF BUYERS’ PRODUCTS. BUYER ACKNOWLEDGES AND AGREES THAT IT IS SOLELY RESPONSIBLE FOR COMPLIANCE WITH

ALL LEGAL, REGULATORY AND SAFETY-RELATED REQUIREMENTS CONCERNING ITS PRODUCTS, AND ANY USE OF SENSATA COMPONENTS IN ITS

APPLICATIONS, NOTWITHSTANDING ANY APPLICATIONS-RELATED INFORMATION OR SUPPORT THAT MAY BE PROVIDED BY SENSATA.

Mailing Address: Sensata Technologies, Inc., 529 Pleasant Street, Attleboro, MA 02703, USA.

• The Elevator Screw option allows the screw and clamp

to be raised out of the mating threads completely. This

provides for the insertion and use of a ring or lug type

wire terminal.

• A #2 Phillips head driver should be used with the

Elevator Screws. If a powered driver is used, avoid

speeds above 500 RPM.

• Cutting threads in the cover plastic as the screw

elevates is key to the elevating feature. It has a finite

life and therefore not recommended to be used more

than 50 times during the product lifetime.

• Do not continue rotating the screw (in the elevating

direction) once it freely rotates at the top of the plastic surface. The Elevator screw is capable of

clearing 0.125 inches between the terminal and the bottom of the screw. Insertion of a terminal or

lug thicker than 0.125 in is not recommended.

• When inserting the terminal ensure that the terminal hole is in line with the screw.

• During tightening, be certain that the terminal is seated flat within the cavity, and that the clamping

washer is secure against the upper surface of the terminal.

• If fork terminations, spade lugs, or stranded wire are used, to prevent improper contact do not raise

the elevator screw out of the mating threads.

(A) The operation mode is detected during power up. Any changes done to the selector while the unit is

powered will be ignored until next power up

(B) UL approved rating is the one that intersects at 40°C.

TABLE 5. Recommended Accessories

Hardware Kit Thermal Pad Lug Terminal

Heat Sink

Part No.

Thermal

Resistance [ºC/W]

HK8 HS259DR

HS073

HS072

HS053

HS033

HS023

2.5

0.7

0.7

0.5

0.36

0.25

HSP-7 TRM0

TRM6

ACCESSORIES

ELEVATOR SCREW (”W” SUFFIX)

CONSIDERATIONS

GENERAL NOTES

Status LED Indicator

Flashes twice intermittently

Flashes three times intermittenl y

Flashes four times intermittenl y

Flashes five times intermittenl y

Varying brightness

Varying frequenc y

No Mains Voltage

Frequency Out of Range

Error on Selector

Overtemperature

Phase Control

Burst Control

SSR Output

OFF

OFF

OFF

OFF

ON

ON

Fork LugR ing Lug Copper Lug Copper Lug

Width [W] in (mm)

Terminals

Stud Size Dia [D] (in)

Wire Size AWG

Crydom Part No.

0.45 (11.4)

#8 (0.168)

0.45 (11.4)

#8 (0.168)

TRM0

6-0

TRM6

14-6

W D

W D

fig. 2 Elevator screw

TABLE 3. LED Status TABLE 4. Compatible Terminals

This manual suits for next models

3

Other Sensata Relay manuals