Sense-Tech Kimax 1 Quick guide

Installation- and Instruction Manual

2

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Table of contents

How does it work? ......................................................................................................... 3

Air sensor installation..................................................................................................... 5

Hydraulic installation on a forklift .................................................................................... 8

Electrical installation ...................................................................................................... 9

Kimax 1 menu ............................................................................................................ 11

in menu ..................................................................................................................... 12

AdL menu................................................................................................................... 12

Adh menu................................................................................................................... 12

Calibration.................................................................................................................. 13

Alarms ....................................................................................................................... 14

Protecting your calibration ............................................................................................ 15

Daily use .................................................................................................................... 16

Serial output............................................................................................................... 17

Troubleshooting .......................................................................................................... 18

Dimensions and technical specifications.......................................................................... 19

Warranty

Kimax 1 cabin, trailer and hydraulic are all covered by Sense-Tech Weighing Systems ApS

guarantee. Electronic failure and broken components caused by normal use are repaired or

exchanged when necessary, when sent to the factory.

Damage to your vehicle caused by installation of Kimax instruments or loss of time caused by

recalibration or repairs of Kimax instruments are not covered by Sense-tech Weighing Systems

ApS in any case.

Basic safety rules:

Before you start the installation procedure, make sure that the instrument has not suffered

any damage during transport.

Note that the Kimax 1 instruments must be installed and connected in accordance

with the regulations valid for the vehicle and country in question.

The Kimax 1 instruments must be protected from gravel, water spray from wheels

and other factors that may damage the instruments.

We recommend mounting the instruments in a position where it is protected from

water jets and rinse water.

Once you have decided where the instrument is to be mounted in the cabin, you must consider

the cable routing.

Special attention should be given to potential damaging factors such as hinging points for

tilting the cab.

Once you have decided where the instrument is to be mounted on the chassis, you must

consider the cable routing. Special attention should be given to tensile forces, cuts and other

factors that may damage the cables and hoses.

3

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Connection of compressed air.

Before you carry out any installation work related to the air suspension, make sure

that the suspension has been brought to the lowest possible position.

Electrical connection

Always disconnect the battery before you perform any installation work on the

system of the vehicle.

How does it work?

The Kimax 1 on board scale is an axle pressure gauge that uses pressure gauging on the air

suspension to indicate the load, and to always keep you informed about the present load

situation.

A mechanical or electrical system on the vehicle maintains a fixed level of the chassis height

through a level valve which adds or subtracts compressed air to the bellows according to the

actual load on the vehicle.

The top of the bellow, shock absorber and the level valve are all fixed on the chassis of the

vehicle.

The pressure in the suspension system represents the weight of the axle/axle group.

The weight of the vehicle is a linear function of the pressure in the suspension system, see the

chart on page 12.

The Kimax 1 instrument is customized to your vehicle by means of giving in the actual

unloaded weight in tons when the truck is empty and giving in actual loaded weight in tons

when the truck is loaded.

Both values, one for an empty vehicle (Lo) and one for a loaded vehicle

(hi) MUST be entered into the Kimax unit when the pressure in the air

suspension is present!

The accuracy of the weighing system is affected by the mechanical condition of your vehicle,

e.g. the condition of the shock absorbers.

The Kimax instrument is not a verified weighing system.

To Kimax

From air tank

4

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Basic Kimax 1 installation

A Single air inlet channel is used on vehicles with

combined level control for one or more axles.

In case of uneven load from one side to the other

the pressure will slowly be equalized between the

bellows in each side.

The reading on the Kimax unit will be correct when

the pressure is equalized.

This application is used for measuring the axle load

of a rear axle.

A dual air inlet channel is used on vehicles with

split level control for one or more axles.

The Kimax unit calculates the weight using the

air pressure from each side. In case of uneven

load the Kimax will show the correct axle load

immediately after loading.

This application is ideal for measuring the axle

load of a rear axle.

A dual air inlet can be applied on vehicles with

one or more individual axles arranged in a

combined level control system.

Using a Kimax 1 on two or more individual axles

offers you a limited accuracy, because the

measuring of the load depends on the center of

gravity for the entire load - for better accuracy

we recommend our Kimax 2 product group.

For more information please visit:

www.kimax.com

Air input

Air input

Air input

Air input rear

Air input front

5

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Air sensor installation

Connection of compressed air

Before you carry out any installation work related to the air suspension, make sure that the

suspension has been brought to the lowest possible position and all compressed air is released.

First step in the installation is to identify the hose supplying compressed air to the bellows.

This hose, typically 8 mm outer diameter, must be cut through and assembled once again with

the T-piece supplied with the Kimax instrument.

The 6 mm output port of the T-piece has to be connected to the Kimax instrument according to

the illustration on the next page.

It is important to install the hoses in such a way that they are not affected by other

components. The hoses must be fixed at suitable intervals

Route the hoses in such a way that they are not exposed to exhaust heat and other heating

sources that may lead to the permissible temperature being exceeded.

Avoid damage from gravel, friction and contact with sharp edges.

Avoid excessive tension of the hoses.

Make sure that the smallest bending radius is not exceeded.

Make sure there is no leakage at the fittings, it will affect the accuracy of the measurement.

Air pressure for Kimax

Storage

Tank

Shock absorber

Level valve

Maintain

level

Bellow

6

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

The Kimax instruments are equipped with push-in fittings.

You must make a clean perpendicular cut with a sharp knife or a hose cutter before you

connect a new air hose to a Kimax instrument.

You can release the locking mechanism in the fitting by pushing in the release ring.

(A 7 mm open-ended spanner is a suitable tool for pushing-in the release ring so you can pull

out the air hose).

Air inlet

Throttle

6 mm

Pressure towards Kimax 1

8 mm

Air pressure for the bellows

7

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Sensor layout on different vehicles

8

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

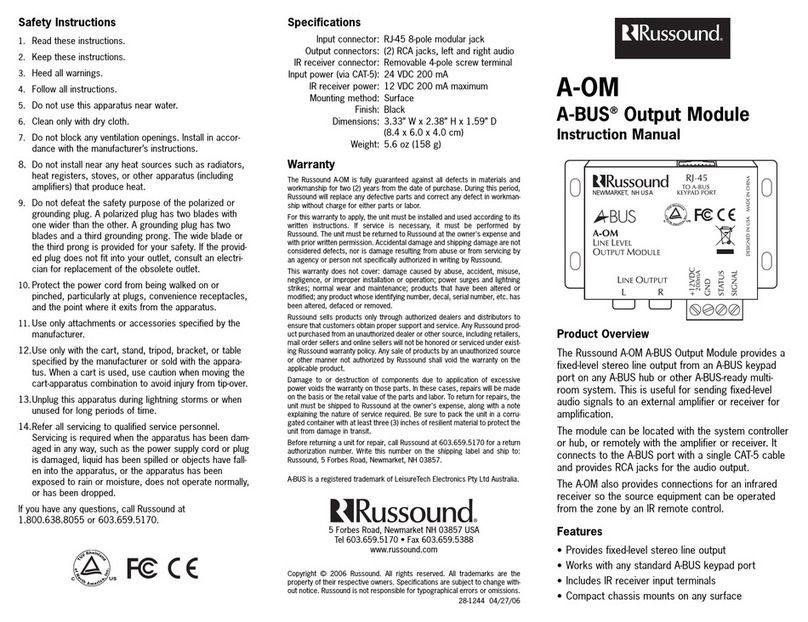

Hydraulic installation on a forklift

The hydraulic sensor is connected as indicated in

this illustration.

The hydraulic transmitter should be placed as close to the lifting cylinder as possible to obtain

the best measuring accuracy.

Setting the Lo calibration point (Kimax 1 Hydraulic)

Raise the forks approx. 20 cm from the ground and lower them again approx. 5 cm.

Enter the menu on the Kimax by pressing for approx. 4 secs (see page 11). Release the

button and the display reads in. Press twice and the display reads Lo.

Press again and the display reads the last saved value for Lo.

In case you want to skip/bypass the Lo calibration, press , now the display reads hi and the

previous value has not been modified.

To change the Lo calibration, you may change the value by pressing or until you have

the value that equals the readout you want when the pressure in the lift cylinder is like the

present pressure.

Example 0.00

You save the value by pressing . Press to continue to hi.

Setting the hi calibration point (Kimax 1 Hydraulic)

Raise the forks approx. 20 cm from the ground with a known weight (the best accuracy is

obtained if the weight is close to the maximum lift capacity) and lower approx. 5 cm again.

Press and now the display reads the last saved value for hi.

In case you want to skip/bypass the hi calibration, press , now the display reads A1 and the

previous value has not been modified.

To change the hi calibration, you may change the value by pressing or until you reach

the value that equals the weight of the load.

You save the value by pressing . Press to continue to A1.

During calibration you can modify Lo and hi in a sequence as described above or you can

modify Lo or hi individually by bypassing the value you do not want to change by pressing

(see page 11).

Brown

Blue

Hydraulic transmitter

9

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Electrical installation

Electrical connection

Always disconnect the battery before you perform any installation work on the system of the

vehicle.

Do not route the cables next to ignition cables or other cables carrying large currents.

Make sure that the cables are not exposed to tensile or shearing forces.

Protect the cables with rubber grommets if you route the cables through holes.

For connecting cables use crimp connectors or another approved method.

Avoid short-circuiting the system by faulty connections or squeezed cables.

Fasten the cables at suitable intervals.

Make sure all Kimax 1 instruments are protected with fuses in the supply cables.

Pink RS232 TX Data for a printer

Green RS232 RX Data

Yellow RS232 TX Data

White Relay (A2)

Blue Relay (A2)

Grey Supply 10 - 30 V DC

Brown Ground

10

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Optional: Warning light (A2), Tracker and Kimax printer.

Unused wires must be separately isolated.

Fuse

Battery

Switch

Key on

position

Tracker

Warning light

Green

Yellow

White

Grey

Blue

Pink

Brown

Imax 0,5 A

11

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

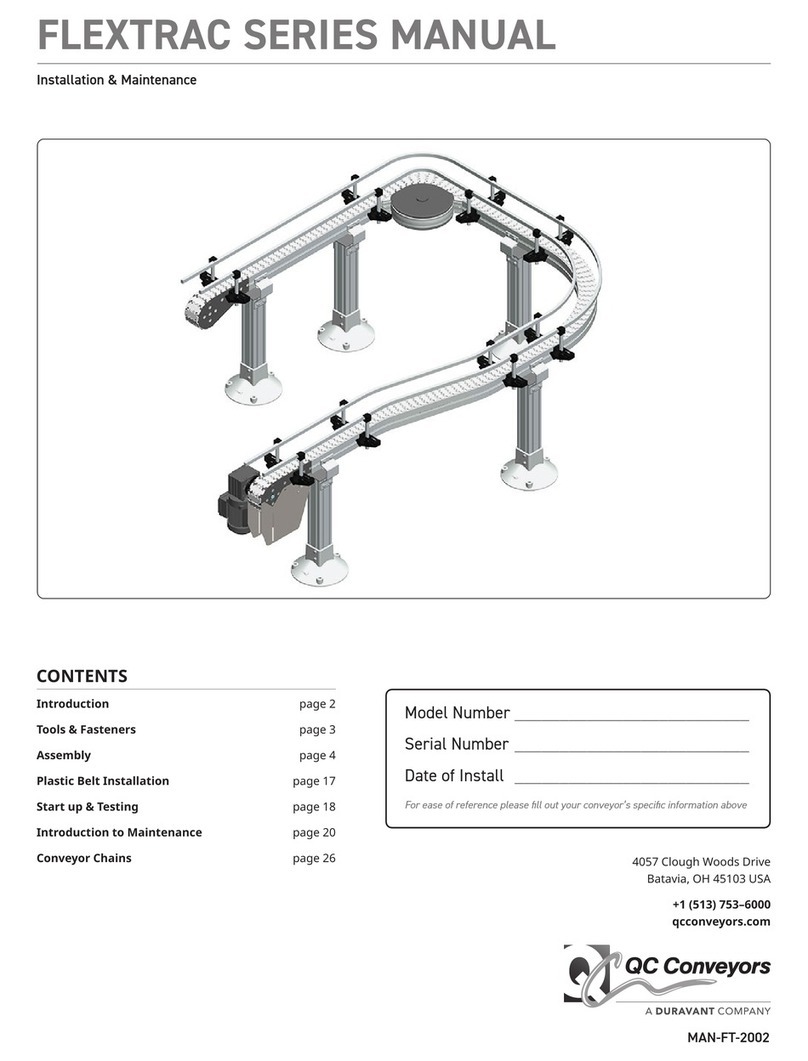

Kimax 1 menu

Press for

~4 secs

Value

Value

Value

Value

Value

Value

Value

Bypass

Bypass

Save value

Bypass

Save value

Bypass

Save value

Bypass

Save value

Bypass

Save value

Bypass

Save value

Adjust the value

Adjust the value

Adjust the value

Adjust the value

Adjust the value

Adjust the value

Back to weight

reading

12

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

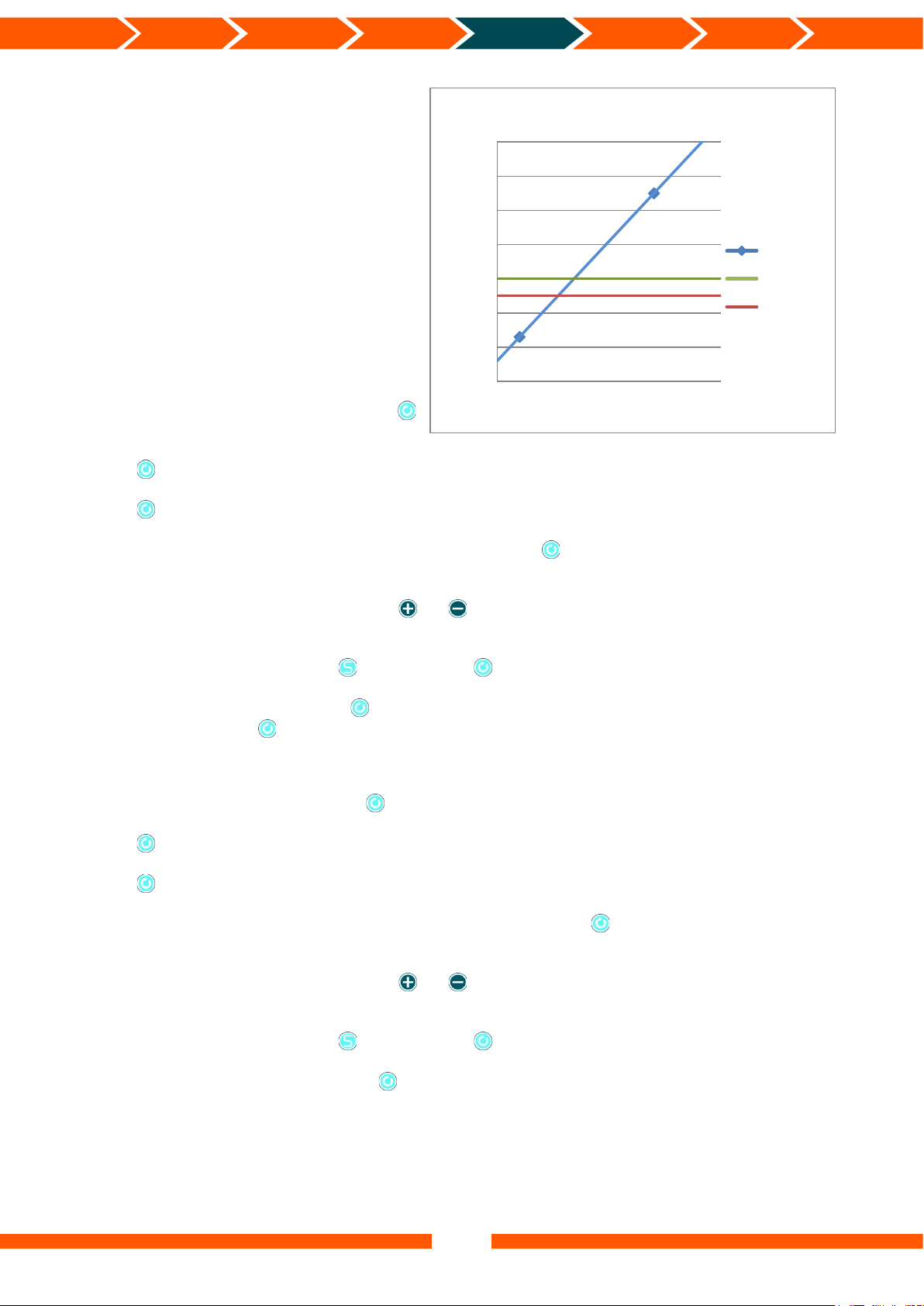

in menu

In the input menu it is possible to read the present signal from the sensor.

A hydraulic transmitter input produces a value ranging from 0 - 100% (0 –22,9 mA).

An air input will give you a reading ranging from 0 - 10,0 bar.

AdL menu

In the AdLmenu it is possible to read the input value of the sensor input from when the Lo

calibration was performed (stored sensor value at empty calibration).

When a Lo calibration is performed the Kimax unit automatically saves the in value from the

sensor input as an AdL value.

Adh menu

In the Adhmenu it is possible to read the input value of the sensor input from when the hi

calibration was performed (stored sensor value at loaded calibration).

When a hi calibration is performed the Kimax unit automatically saves the in value from the

sensor input as an Adh value.

0

2

4

6

8

10

12

14

0 2 4 6 8 10

Tonne

Bar

Calibration Kimax 1 (example)

Calibration

Lo

hi

AdL

Adh

Adh

hi

Lo

AdL

13

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Calibration

Two reference values are needed to make a correct calibration, one value for an unloaded

vehicle (Lo), and one for a loaded vehicle (hi). By means of these two reference values the

Kimax 1 Axle Load Indicator will generate a complete pressure chart and display the current

axle load on the display.

Setting the Lo calibration point

Go to a weighing bridge with your empty

vehicle.

Enter the menu by pressing for approx. 4

secs (see page 11). The display reads in.

Press twice, now the display reads Lo.

Press again and the last saved value for Lo

will be displayed.

In case you want to skip/bypass the Lo

calibration, press , now the display reads hi

and the previous value has not been modified.

To change the Lo calibration press or ,

until you have the value that equals the readout

from the weighing bridge.

You save the value by pressing . Press to

continue to hi.

Setting the hi calibration point

Go to a weighing bridge with your loaded

vehicle.

Press , and the display reads the last saved

value for hi.

In case you want to skip/bypass the hi

calibration, press , now the display reads A1

and the previous value has not been modified.

To change the hi calibration press or

until you have the value that equals the readout

from the weighing bridge.

You save the value by pressing . Press to

continue to A1.

During calibration you can modify Lo and hi in a sequence as described above or you can

modify Lo or hi individually by bypassing the value you do not want to change by pressing

(see page 11).

0

2

4

6

8

10

12

0 5 10

Tonne

Bar

Lo calibration point

0

2

4

6

8

10

12

0 5 10

Tonne

Bar

hi calibration point

Weighing

bridge

Weighing

bridge

14

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Alarms

The Kimax 1 has two different alarm

functions.

When the weight reading exceeds the A1

alarm level, the three digits in the display

start flashing.

When the weight reading exceeds the A2

alarm level, an internal relay connects

the white and the blue wires in the supply

cable (see page 9-10).

Setting the A1 alarm level

Enter the Kimax menu by pressing

button for 4 sec. (see page 11).

Press button shortly several times until the display reads A1.

Press button once again, and the display reads the last saved A1 value.

In case you want to maintain the previous value, press and the display reads A2 without

saving any modified A1 value.

You can change the value by pressing or until you get a value equal to the alarm level

you want.

You save the value by pressing button, press and the display reads A2.

You leave the menu by pressing shortly several times until the display reads oFF and then

you press the button once more or restart the Kimax.

Setting the A2 alarm level

Enter the Kimax menu by pressing button for 4 sec. (see page 11).

Press button shortly several times until the display reads A2.

Press button once again shortly, and the display reads the last saved A2 value.

In the case you want to maintain the previous value, press and the display reads oFF

without saving any modified A2 value.

You can change the value by pressing or until you get a value equal to the alarm level

you want.

You save the value by pressing button, press and the display reads oFF.

You can leave the menu by pressing or restart the Kimax.

0

2

4

6

8

10

12

14

0 5 10

Tonne

Bar

Calibration Kimax 1 (example)

Calibration

Alarm 2

Alarm 1

15

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Protecting your calibration

Locking your Kimax 1

To lock your Kimax 1 and hereby prevent unintended changes to the calibration, activate

and at the same time for 5 seconds, while the Kimax is powered. When the display switches

off you may release the buttons. Now the display reads -L- and the Kimax is locked.

Unlocking your Kimax 1

To unlock the Kimax 1 you must activate and at the same time for 5 seconds, while the

Kimax is powered. When the display switches off you may release the buttons. Now the display

reads -u- and the Kimax is unlocked.

16

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Daily use

The Kimax 1 has four buttons and a display with three LED digits. The display is easy to read

in a dark cabin and outside in bright sunlight.

When the unit starts up it shows tot and after 1 sec. the display reads the value of the

currently measured weight of your vehicle/axle/axle group.

If you press the display reads PAY and after 1 sec. the display reads the value of the

payload of your vehicle/axle/axle group. Payload = tot value –Lo value

If you press the button again, the display switches off. Press the button again and you

are back to tot.

The Kimax instrument has a floating point. Values from 0.00 - 9.99 will be displayed with 2

digits after the decimal point. Values from 10.0 - 99.9 will be displayed with 1 digit after the

decimal point. Values from 100 - 999 will be displayed without digits after the decimal point.

Save

Plus

Scroll

Minus

After 1

sec.

After 1

sec.

Back to

tot reading

Power ON

17

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Serial output

OBC

The Kimax 1 instrument offers you a RS-232 serial output that broadcasts the measured value,

that you read on the display.

The string of data is broadcasted every 10th second and can be transmitted to a fleet

management vehicle tracker.

To test the serial output, you may set up a ”HyperTerminal” on your laptop with the

parameters below,

Bit pr sec

9.600

Data bit

8

Parity

N

Stopbit

1

Flowcontrol

N

Now you will be able to read the broadcasted value as numeric characters.

You need to set up your fleet management vehicle tracker for receiving data with the same

parameters.

The protocol looks like this:

A XX.X S

Send of message

XX.X actual value

Astart of message

Printer

The Kimax 1 instrument offers you a RS-232 serial output for a printer.

The string of data is broadcasted every time you activate the print function on the instrument,

by pressing for 3 seconds.

As a test, you can set up a ”HyperTerminal” on your laptop with

the parameters shown, and you may read the broadcasted data.

Bit pr sec

4.800

Data bit

8

Parity

N

Stopbit

1

Flowcontrol

N

You need to set up your printer to receive data with the

same parameters.

Most common printers with a serial input can be used

with a Kimax 1 unit.

18

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Troubleshooting

Problem

Possible solution

Display is flashing like this...

On

Off

On

Off

The value shown is below zero.

Display is flashing like this...

On

Off

On

Off

When the value on the display exceeds the value for A1

the display starts to flash.

For more information on this function see page 11.

Display is blank

Press the button to turn on the display.

For more information on this function see page 16.

or

Check the wiring see page 9 and 10.

The value shown oscillates..

Check the air hose for leakage.

Make sure the 0,4 mm hole in the throttle is not

blocked.

Check that the AdL and the Adh values are not equal

(see page 12).

Recalibrate the instrument.

The value shown is fixed

Check the air hose for leakage.

Make sure the 0,4 mm hole in the throttle is not

blocked.

Check that the Lo and the hi values are not equal (see

page 12).

Recalibrate the instrument.

Calibration is not possible, the

display shows -L-, when or is

pressed..

The unit is locked/protected from changes made in the

memory.

Check page 15 for unlocking the unit.

If you do not succeed in finding a solution to your issue, feel free to contact us.

19

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Dimensions and technical specifications

Kimax 1 cabin version

* Not present on single air inlet instruments

Supply cable

Air inlet

Air inlet*

20

Introduction

Sensor

installation

Electrical

installation

Setup

Calibration

Protection

Daily use

Additional

information

Kimax 1 Trailer version

*The Gore-Tex membrane is for venting the Kimax 1 housing, to avoid getting vacuum in the

housing during shifting ambient temperatures.

The Gore-Tex membrane is only present on the trailer versions of the Kimax 1 instruments.

If you paint the instrument, make sure the venting opening in the Gore-Tex membrane is not

blocked with paint, cover it with painter’s tape before painting.

** Not present on single air inlet instruments. On single air inlet instruments the Gore-Tex

membrane is placed here.

Air inlet

Air inlet**

Supply cable

Gore-Tex Membrane*

Table of contents