8 | Install Slide Rail — Assembly | Flextrac Series

Install Slide Rail ASSEMBLY

Joining Slide Rail

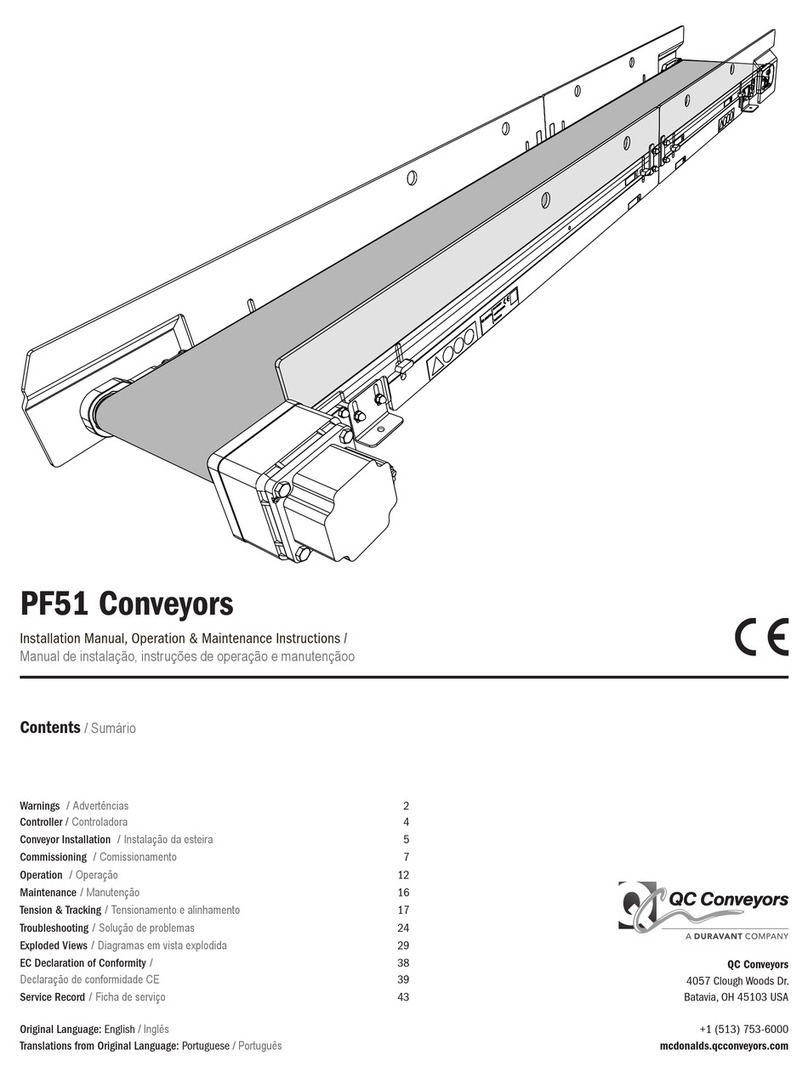

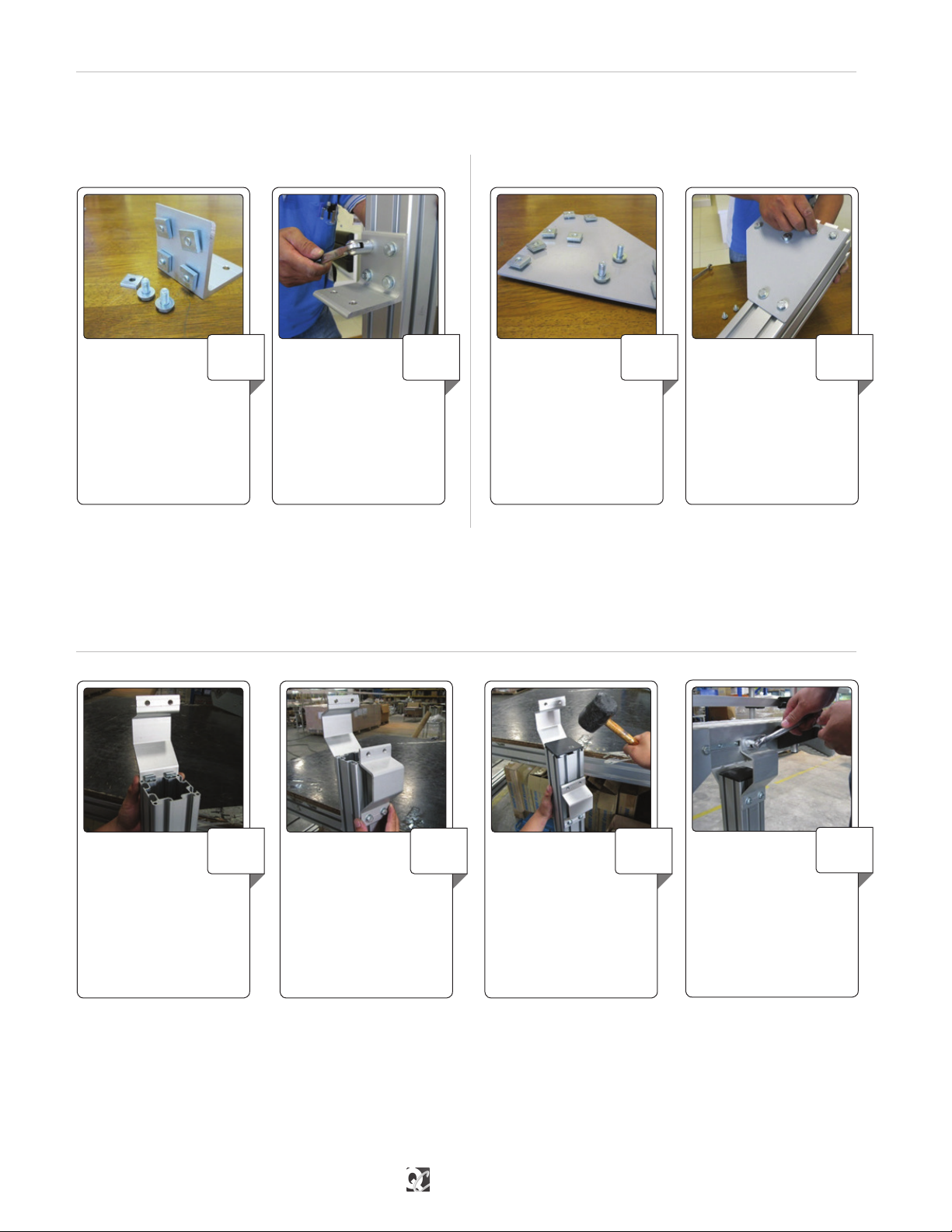

Start the slide rail assembly

at an idler end unit.

Separate the top and bottom

ange of the slide rail at the end of

the rail and press into place.

1

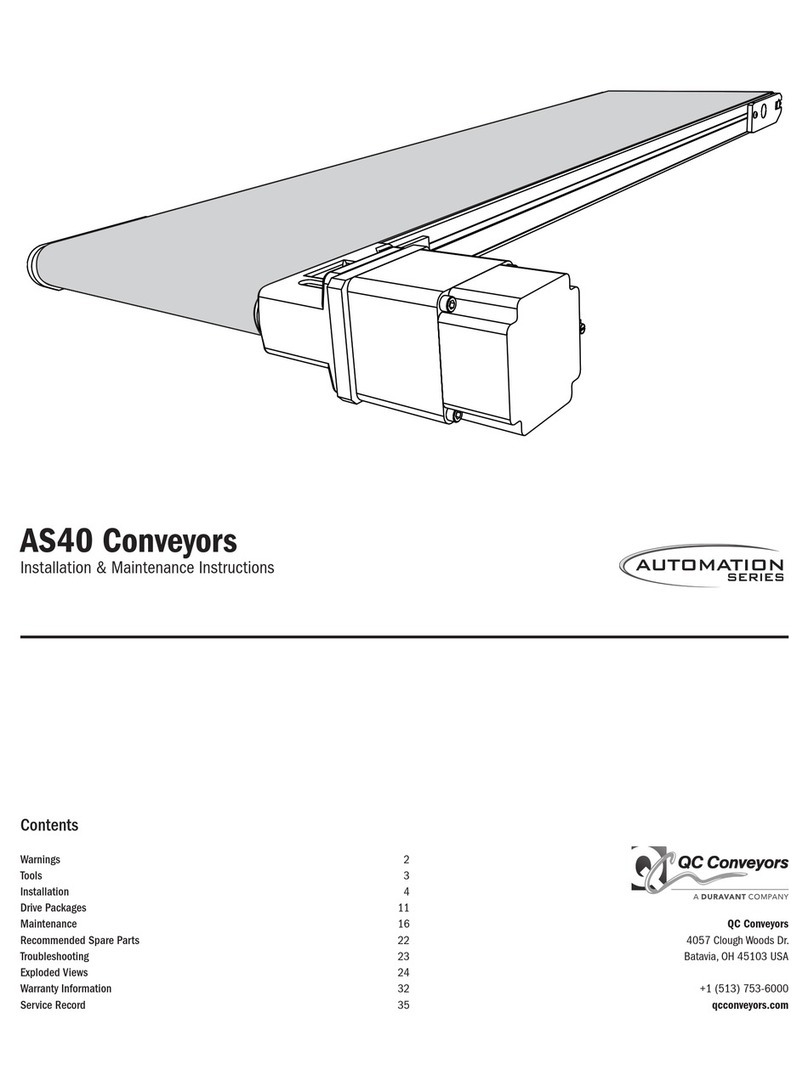

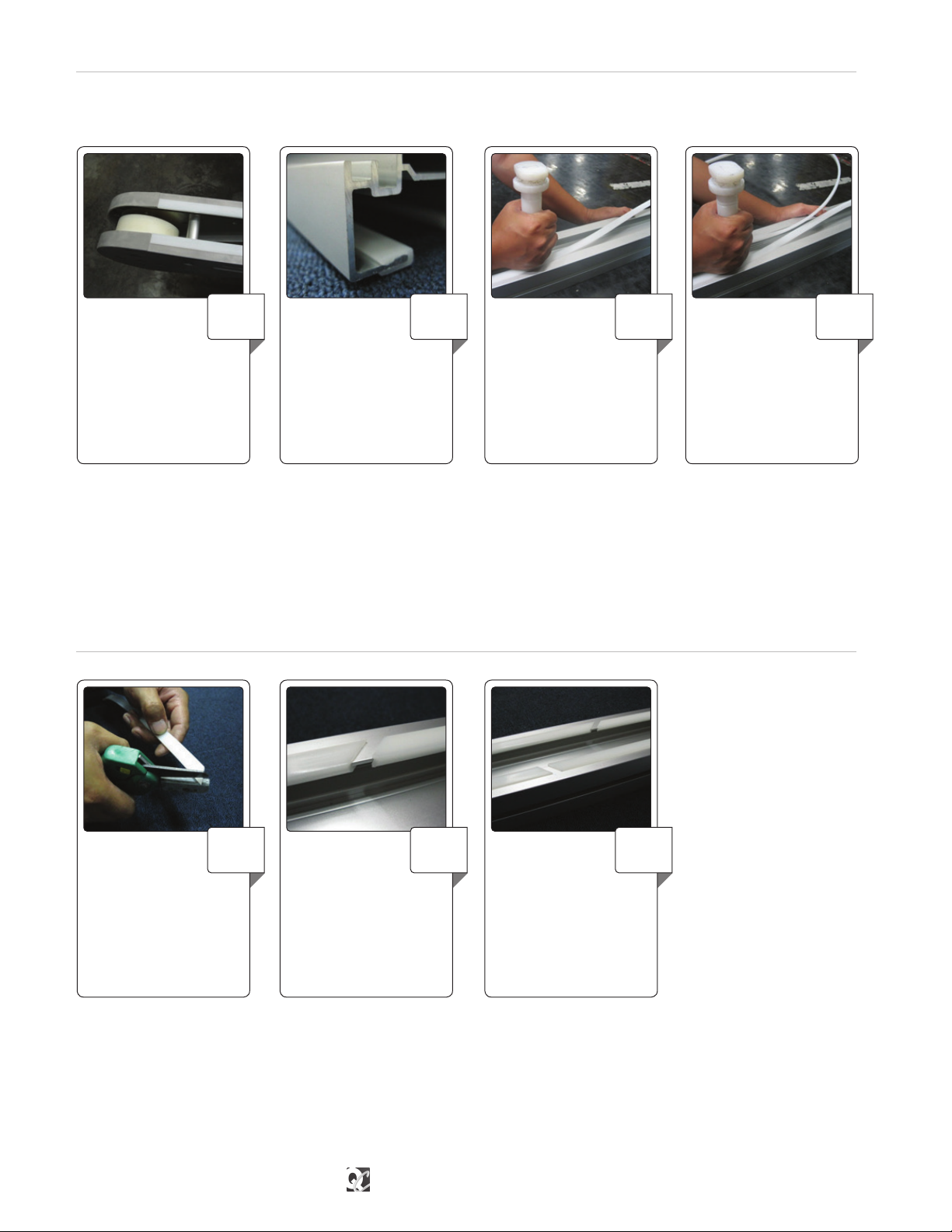

Cut both slide rail ends at

45° angle. The beginning

of the new slide rail section in the

direction of travel should receive

a second cut at a slightly steeper

angle.

1

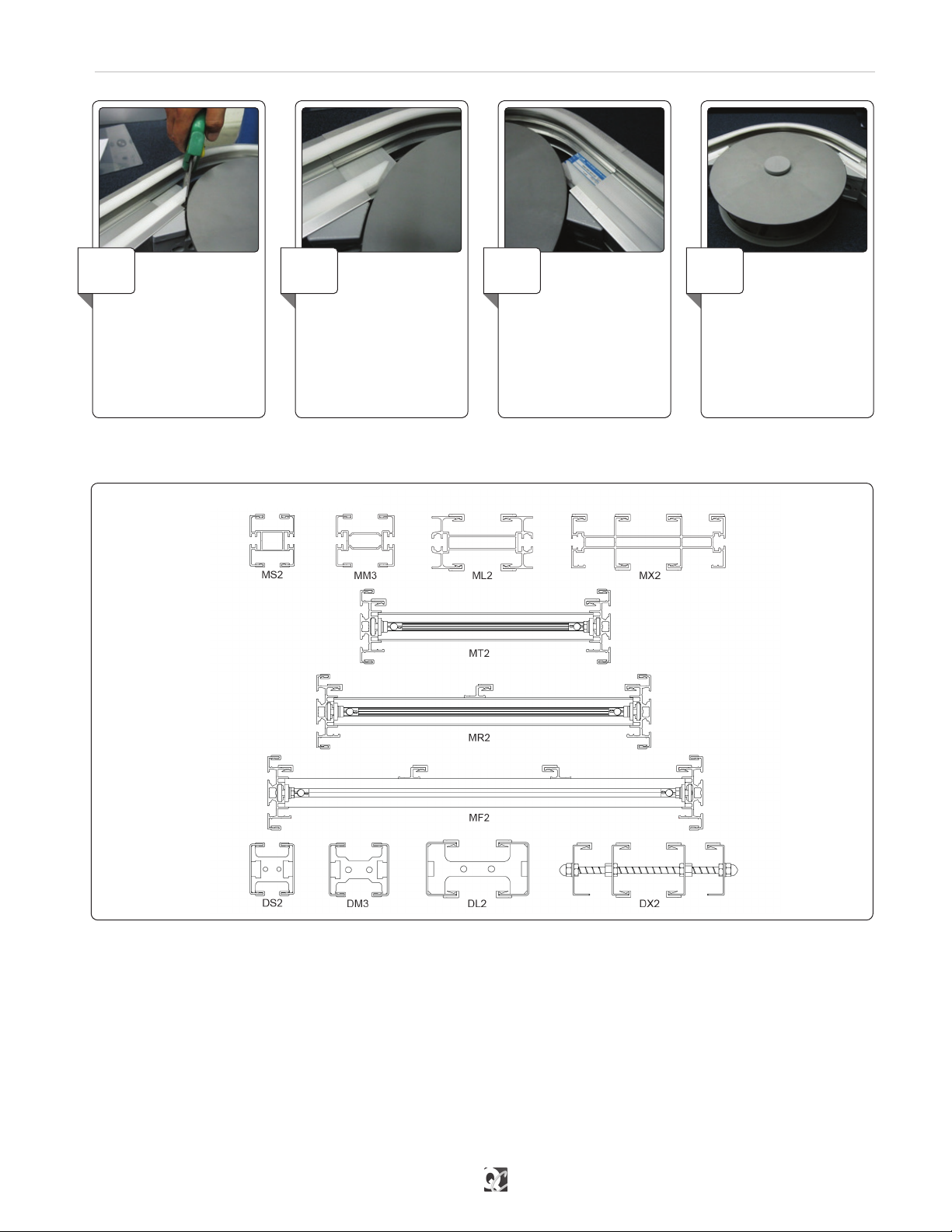

Ensure the slide rail is

properly mounted and

snaps onto the beam. The anged

edge of the siderail should snap

over the ange on the inner edge

of the beam.

2

Allow a space of

approximately 10mm

between two slide rail ends.

2

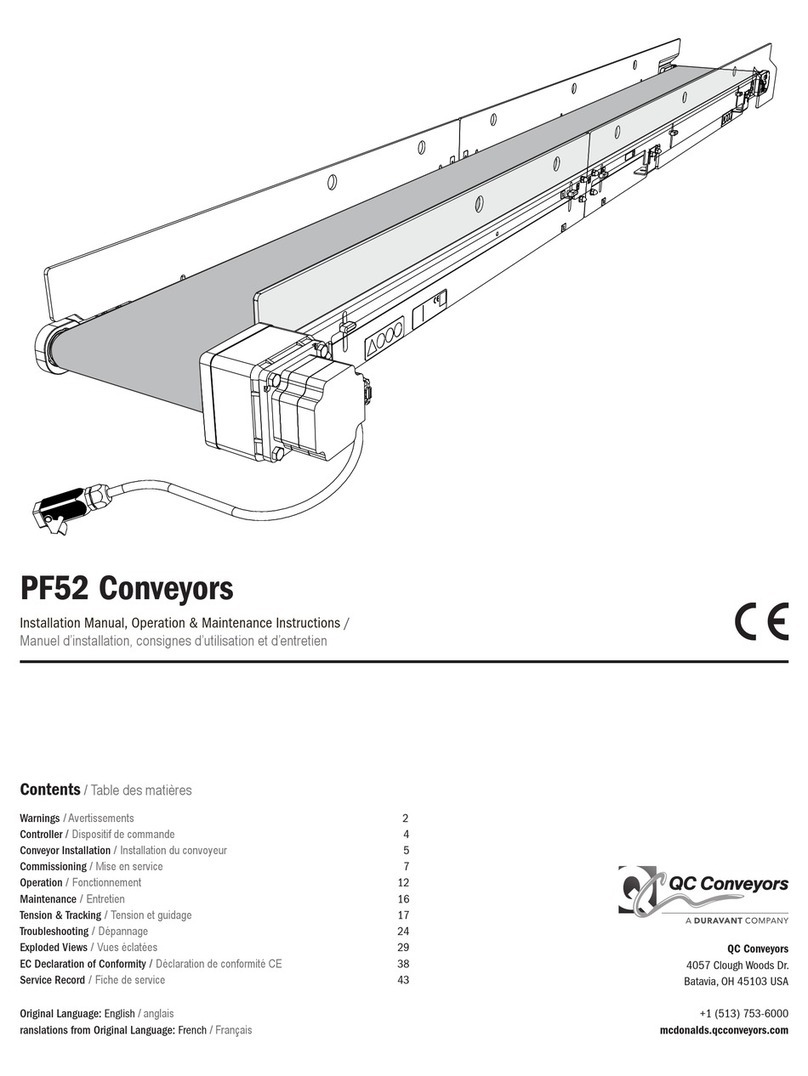

Use the slide rail assembly

tool to press the slide rail

into place. One end of the tool is

used when slide rail is mounted

onto rst side of the beam and the

other end is used when mounting

slide rail onto the second side.

3

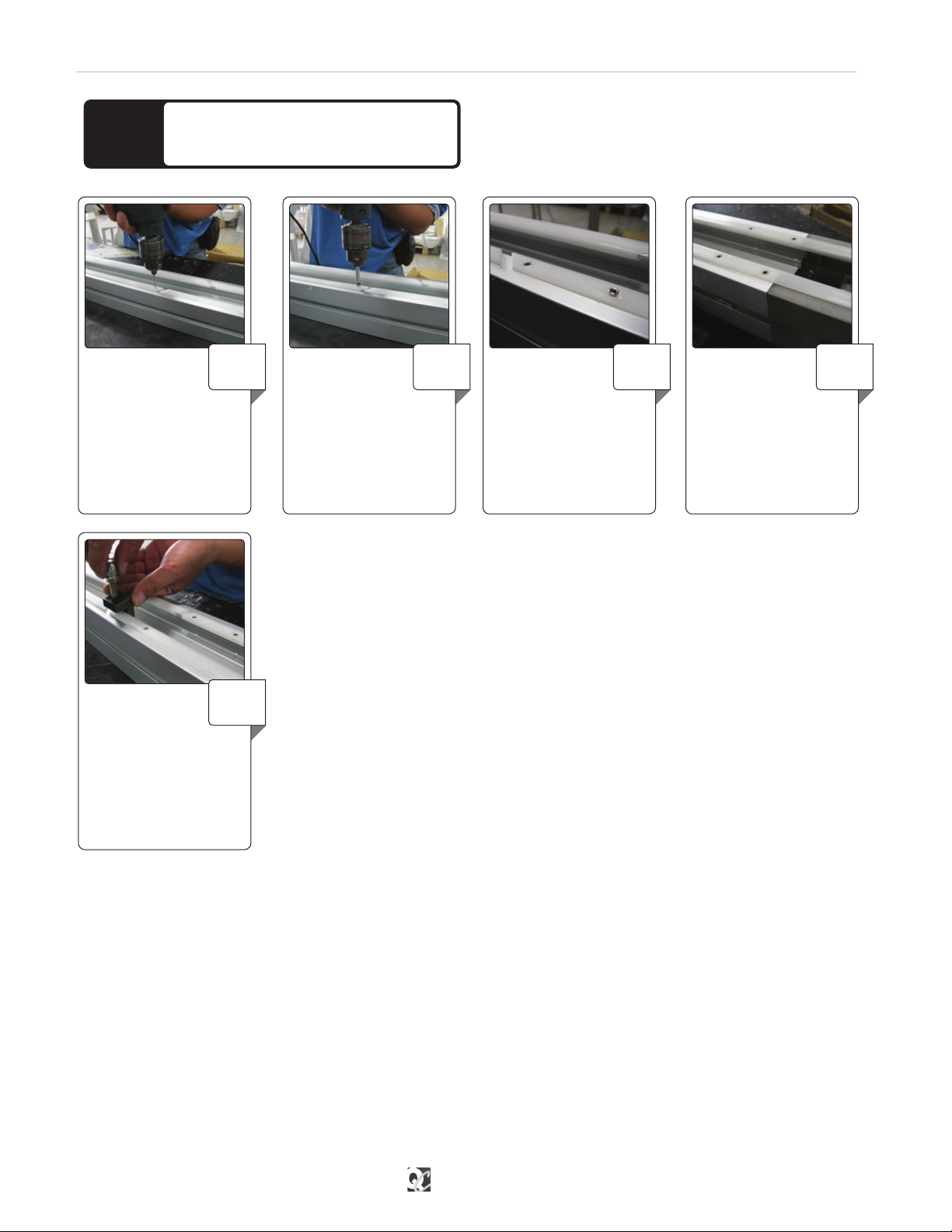

Do not place two slide rail

joints opposite each other.

Make sure there is a distance of

at least 100mm between them to

make sure the chain run smoothly

(this does not apply at idler end or

drive unit; these joints are always

parallel).

3

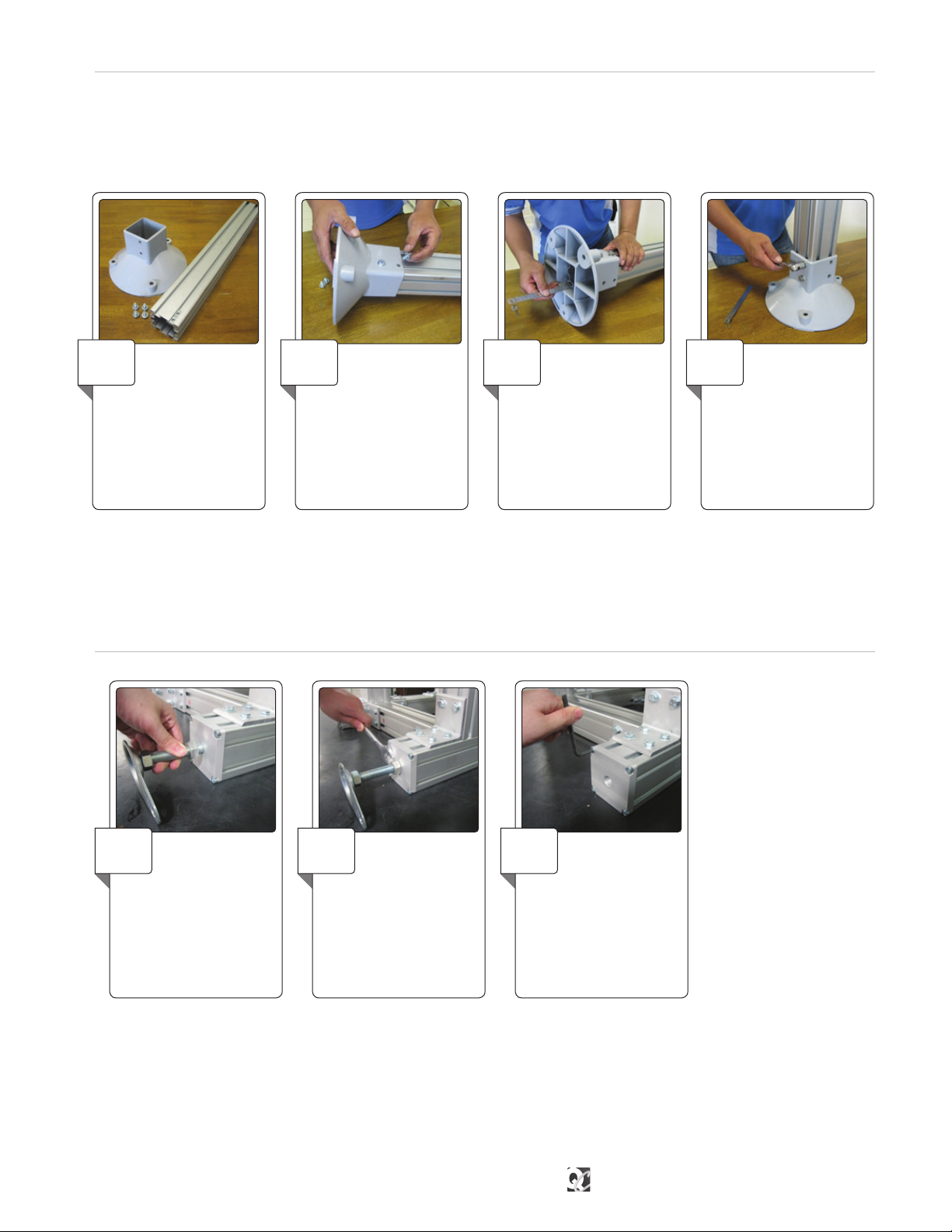

Slide rail should be

installed on both top

and bottom of beam (unless top

running chain only).

4

The slide rail is attached to the sides of the conveyor beam to reduce chain friction where the chain would otherwise be in direct

contact with the beam prole. It is very important that the slide rail is installed properly, so that the chain can run without disruption.