Sensocar SC-A1 User manual

SC-A1 Manual

User

SC-A1

Advanced weighing equipment with ABS or INOX finish, high contrast LED or acklit

LCD display and 5-key key oard.

2017-02-14

COMPLETE USER MANUAL

- 2 -

- 3 -

Features

Weight-Tare-Piece counter with possibility of options and add-ons.

Keys exclusively for the classic weighing system, similar to previous units, in the line of

SC1.

Clear, intelligible weighing symbols for improved, more convenient reading of the data

displayed.

Printing of weight on the platform with large, notable size.

Clock/Calendar fitted as standard.

Quicker weighing system optimised for greater fluidity, accuracy and exactness.

Intuitive menu system.

Enter menu with fully configurable, flexible scale, fraction and decimals.

Auto-calibration without having to re-adjust the weight when changing scales.

On/off by key.

Option to manually set the weight, for optimal, quick calibration.

Piece counter function with more than a million internal points.

Dedicated animal weighing function as standard.

Smart display-repeater function, with possibility of repeating most market protocols.

Extended accumulation: millions of accumulations with 64 bit totaliser.

Standard manual tare.

Accumulation and auto-accumulation of serial weighings.

Automatic totalling of serial weighings.

Accumulated Grand Total.

Configurable number of lines to finish ticket and delays per printed line.

Repeat ticket and optional ticket per weighing.

Dedicated selectable connection to the most used printers.

Label printing function (connection to Godex and Zebra labeller).

Possibility of serial communications up to 115200 baud rate, N81, E71 and O71.

Self-test of the default serial communication channels.

Continuous programmable send time.

Optional auto-zero in negative to prevent zero errors of the scales in hostile environments.

Energy-saving and optimisation measures: low consumption mode and programmable

power-off due to inactivity.

Transfer of external data and configuration from PC of the display parameters.

Battery status indicator (in versions with battery).

Possibility of independent auto-calibration of each display.

Multirange totally programmable, flexible twin scales.

Linearisation up to 16 points which can be easily defined by the user.

Large selection of compatible printers with optional auto-cutter.

Auto-calibration of analogue cell systems

Customer-programmable password.

6 languages: Spanish, Portuguese, French, Italian, English and German.

- 4 -

INDEX

1

DISPLAY AND KEYBOARD DESCRIPTION ........................................................................... - 5 -

2

FUNCTIONS MENU .......................................................................................................... - 7 -

3

INSTRUCTIONS AND GENERAL OPERATION MODE ........................................................... - 9 -

3.1

Ordi ary weighi g (Net/gross tare, tare lock) .................................................................... - 10 -

3.1.1

Quick zero: ......................................................................................................................... - 11 -

3.1.2

Stability .............................................................................................................................. - 11 -

3.1.3

Quick tare .......................................................................................................................... - 12 -

3.1.4

Gross weight/net weight: .................................................................................................. - 13 -

3.1.5

are lock ............................................................................................................................ - 13 -

3.2

Ma ual tare....................................................................................................................... - 14 -

3.3

Exte ded accumulatio a d totalisatio of weighi gs ........................................................ - 15 -

3.3.1

Manual accumulation ........................................................................................................ - 15 -

3.3.2

Automatic accumulation ................................................................................................... - 18 -

3.3.3

otalise .............................................................................................................................. - 18 -

3.4

Piece cou ter .................................................................................................................... - 19 -

3.4.1

Accumulation and totalisation .......................................................................................... - 22 -

3.5

U its with Battery ............................................................................................................. - 23 -

3.6

Equipme ts with DSD memory (Aliby) ............................................................................... - 23 -

- 5 -

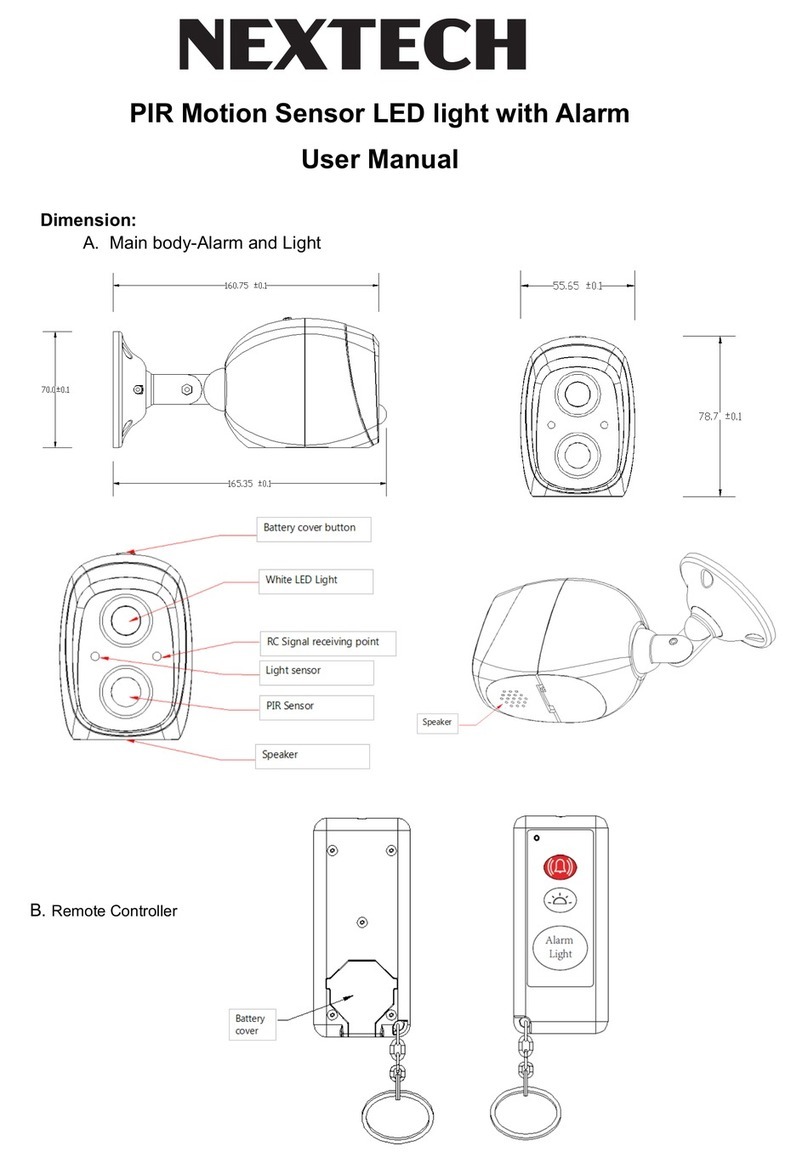

1DISPLAY AND KEYBOARD DESCRIPTION

Stability Zero Tare Tare lock Gross

Piece

counter/Non-

metrological

Lo

battery

ON / OFF:

On/Off (*)

T: Tare B: Zero/Gross FUN: Function

INTRO:

Enter/Print

- 6 -

Environment Key Descriptions (standard functions)

Always ON/OFF

With the equipment po er off, pressing the key turns the equipment on.

With the equipment po er on, long press the key (more than 2 seconds) turns the

equipment off.

Entering ata

of 3 figures

or less

T Increase. Keeping it pressed do n for a fe seconds increases 10 by 10

hen the lights

scroll is completed.

B Decrease. Keeping it pressed do n for a fe seconds ecreases 10 by 10 hen t

he lights

scroll is completed.

FUN Leave.

INTRO Save and exit.

Entering

ata

igit by

igit

T Increase digit.

B Change the digit to be modified (indicated by the corresponding decimal point).

FUN Leave.

INTRO Save and exit.

Weighing

T Carries out tare / tare lock / tare unlock.

B Zero is set. If there is a tare, the eight display mode is: net/gross.

FUN

Special key to combine ith any of the others:

-T: Enter manual tare / relays menu (if active)

-B: Functions menu

-ENT: Totalise

If the Piece Counter option is active, pressing uring scroll

ill s itch bet een

weight/pieces.

INTRO The eighing is accumulated and printe

. If there is an active dosing programme, the

START/STOP function is carried out.

- 7 -

2FUNCTIONS MENU

To enter: FUN+B

(The optional ones are shaded)

Option Description Actions

-

CODE

-

Code of weighing in progress. (6 alphanumeric characters).

N.LABEL.

(**)

Label number.

T

/

B

to modify (0. .255 different labels).

The 255 label is the total label.

(It appears only when a labelling machine has been

selected in the programming menu).

NOTE: See Programming Manual for more

information.

TICKET

(***)

Delivery ticket/note number. (6 decimal digits).

If 0, it will not appear in the ticket. Otherwise it will

increase automatically.

(It does not appear in the equipments with DSD option)

TIK.REP.

Repeat ticket (0. .15 automatic tickets).

Up to 255 weighings.

Each time a ticket is closed, proceed in accordance

with the values:

-0: Normal operation (it does not repeat ticket).

-1: You will be asked whether to repeat the ticket.

-2. .15: There will be as many tickets as the value.

SUBTOT

Shows the accumulated weight

subtotal so far.

INTRO

to show the total accumulated weights and the

total weight.

This will return to weighing state in a few seconds.

AUTOAC

Auto-accumulation when stability

is reached. Yes/No

AUT

.TAR

Auto Tare when stability is

reached after passing through

zero. Yes/No

NU.ACUM

(*)

Number of accumulations before

automatic totalling. (0. .255 accumulations).

W.UNIQ.

(*)

Single weighing mode selection.

Yes/No

There will be a complete ticket for each weighing (and

also when totalising weighing).

BIG.TOT

Grand Total.

Shows the accumulated weight

total since the last time its value

was reset.

INTRO

to show the accumulated grand total.

INTRO during scroll: Prints and deletes the

accumulated grand total.

INTRO kept pressed during the scroll: Prints and erase

the total accumulated.

F.WEIGHT

It displays the maximum weight.

When pushing

[INTRO]

the

memorized weight is erased and

recalculates a new maximum.

Yes/No

HI

-

RES

High resolution.

Shows the weight with another

precision digit (Weight x 10)

INTRO for high resolution weighing.

Bmakes a ZERO in the equipment.

PIECES

(*)

Advanced piece counter.

Selects Piece counter mode Yes/No

When activated:

-FUN during scroll: Change pieces/weight.

DISCHA. (*)

Accumulation in download.

Process (once in weight mode):

1- With full container press T.

2- Empty container and press

INTRO.

(repeat process until finishing with

FUN + INTRO)

Yes/No

GROSS

(*)

Select ticket printing type GROSS-

TARE-NET.

(There will be a tare automatically

after each accumulation)

Yes/No

P.ANIM. (

*)

Dynamic weighing for animals

INTRO

to access submenu.

FUN to exit submenu.

T/B to navigate submenu.

--

ON

--

Yes/No

Activate before editing the following values.

- 8 -

At high speed, it will be made an elevated number of

weight samples with which the weight is calculated and

the average is displayed at the end of the process.

LOW.BOW.

(6 digits).

Inferior limit of weight:

-Weight values below this value are rejected.

With AUTOMA=YES, waiting time T.INI is initiated

when the weight exceeds this value.

HIG.BOW

(6 digits).

Superior limit of weight:

- Weight values above this value are rejected.

INIT.T.

(0.. 25,5 seconds).

With AUTOMA=YES. Waiting time before initiating the

process of sample weight.

AWG.TIM

(0.. 25,5 seconds).

Waiting time of the process of sample weight

AUTOMA

Yes/No:

Yes -> Weight sample is automatically initiated once

INIT.T. time is passed after the weight value defined in

LOW.BOW is exceeded.

No -> The equipment waits for the pressing of

INTRO key to initiate the process of weight sample. (It

does not wait for INIT.T. even though the LOW.BOW is

exceeded).

IND.BAT.

Battery status indicator.

(Only in units with battery)

INTRO

to see the battery status.

If there is no battery: NOBAT

If there is a battery: -OK-

If there is low battery: -BATB-

CLOCK

Shows/Sets the clock and

calendar. INTRO to access submenu.

TIME

Displays the current time. (HH: MM: SS)

INTRO to edit:

T/Bto modify (6 decimal digits).

INTRO to save.

FUN to leave.

DATE

Displays the current date. (DD. MM. YY)

INTRO to edit:

T/Bto modify (6 decimal digits).

INTRO to save.

FUN to leave.

-

CELLS

-

Display points and weight of each

load cell.

(Only in equipments with

communication cartridge for digital

load cells)

INTRO

to access submenu.

FUN to exit submenu

T/Bto increase/decrease the number of load cell.

INTRO to select load cell.

CEL. xx

(load cell selection with T/B)

INTRO

to commute between points and weight.

Tto select next load cell.

FUN to exit and come back to load cell selection menu.

-

DSD

-

(*)

Consult and print data saved in

DSD memory.

(Only in equipments with DSD)

INTRO

to enter the Ticket / Delivery Note selection

menu.

nnnnnn

Selection of ticket to consult

(by default, it displays the number

of the last ticket made)

T

/

B

to edit number of ticket (6 decimal digits).

INTRO to select and initiate the visualization of

number of weighings and the total accumulated weight

from the selected ticket, or display EMPTY if there is

no data.

(*) This option DOES NOT appear if there is an open ticket. (Close ticket by pressing FUN + Tin Weight mode)

(**) This option DOES NOT appear if any communication PORT of the equipment no has not been configured to connect

to the labelling machine. (See option -COM- from Programming menu).

(***) This option DOES NOT appear if the equipment has DSD. (With DSD option the equipment does not allow manual

modification of the number of Ticket / Delivery Note)

- 9 -

3INSTRUCTIONS AND GENERAL OPERATION MODE

When starting up the unit, the ON/OFF key can be pressed to carry out an initial test,

showing all the display's digits and pilots.

The equipment identifier is then displayed:

Then, if the equipment has dead weight (units with weight module or digital cell

communication), the counter value is shown the number of times the unit's metrological

(weight) parameters have been modified.

Finally a message (banner type) describing the different functions of the unit is displayed.

- 10 -

Once complete, the unit again shows the measured weight (weight mode).

3.1 Ordin ry weighing (Net/gross t re, t re lock)

By defect, the unit will start up showing the weight on the platform:

Both the text of the b nner displ yed when st

rting up the unit nd the

he ders nd footers of the tickets c n be defined by the user using the

SENSODATA progr m.

- 11 -

3.1.1 Quick zero:

Whenever, without any weight on the platform, the unit shows a weight value other than

zero.

The zero should be manually corrected by pressing the Bkey.

3.1.2 Stability

The display shows the measured weight variations. The speed with which the changes and

the degree of weight stability shown are displayed depend on the values set in the filter

parameters. (Options STAB.T, FILTER and FIL.DEP in the Programming Menu).

As soon as the weight stabilises, the display activates the stability pilot ( ) to indicate the

condition of stable weight.

The m chine c n utom tic lly reset t st rt

-

up

en bling

the

INIT.Z

option

in the WEI.OPT. progr mming submenu.

- 12 -

3.1.3 Quick tare

Pressing the Tkey when the unit shows stable weight other than zero causes the unit to

tare the weight on the platform, making the weight value displayed on screen pass to 0 and

activating the pilot NET.

As of this moment, the display shows the net weight whenever the platform weight changes.

Whenever the net weight displayed is not zero, pressing the Tkey again causes the unit to

carry out a new Tare.

The Quick T re function it’s only v il ble when the number of divisions of

gross weight is bigger th n the one defined in the minim weight option

(WEI.MIN) in the WE.CTR progr mming submenu.

Most of the ctions c rried out by the displ y (print ticket, st rt lo d or

disch rge, etc.) re ssoci ted with st ble pl tform condition.

Most of the ctions c rr

ied out by the displ y (t re, print ticket, st rt lo d

or disch rge of dose, etc.) re ssoci ted with st ble pl tform condition

(st ble weight).

- 13 -

3.1.4 Gross weight/ et weight:

With the unit tared, pressing the Bkey allows switching between net weight and gross

weight on the display.

To indicate that the weight shown on the display corresponds to gross, enable both the B

pilot and the NET pilot:

Tare is automatically disabled when all the weight is removed from the platform, deleting

and re-displaying the gross weight:

3.1.5 Tare lock

To prevent tare from being disabled when all the weight is removed from the platform, press

the Tkey a second time when the net weight shown is zero (pressing once tares the weight,

and pressing twice locks tare).

Locking the tare activates the unit's >T< pilot in order to indicate locked tare. As of this

moment, and always when the net weight shown is zero, the Tkey can switch between tare

and tare locked modes.

- 14 -

3.2 M nu l t re

The unit allows a tare value to be defined manually (*). To do this, press the FUN and T

keys at the same time without leaving weight mode. The unit will enter manual tare edit

mode, with the rightmost digit flashing to indicate the tare at this moment. To change the

tare value displayed, use the Tkey to increase the flashing digit value, the Bkey to change

digit, the FUN key to cancel and leave without validating, and the ENTER key to validate the

tare value entered, taring the unit whilst locking the Tare.

When a manual tare is active, printing the tare on a ticket will be accompanied by the

symbol "*", indicating that weighing was carried out with a manual tare.

(*)

The m nu l t re function is NOT v il ble if the limit, tr ffic light or

ny

dose option is en bled (options v il ble through the APPLIC progr mming

submenu).

========================================

N.WEIGH. CODE TARE kg NET kg

========================================

1 100350 * 21.57 0.216

T

The t re lock function is on

ly v il ble if initi l zero option (

INIT.Z

) h s

been en bled in the WE.CTR progr mming submenu.

- 15 -

3.3 Extended ccumul tion nd tot lis tion of weighings

The unit can account for weight (accumulate weighings), using the data to print a ticket per

printer and/or label and/or send the weighing data through the serial communication ports

(PORTS).

The unit allows individual weighings (printing a ticket for each weighing) or multiple

weighings (with several weighings in the same ticket and finalised with a total) to be done

automatically (when detecting stable weight on the platform) or manually (by pressing the

INTRO key when the unit displays stable weight).

Three conditions must be met in order for the unit to account for a weight (carry out

weighing): there must be stable weight, which exceeds the value defined as minimum

weighing (*), with the weight dropping below the minimum weight necessary to carry out

weighing at some point since last weighing (i.e. the last weighing has been discharged).

Pressing the key

3.3.1 Ma ual accumulatio

In order to carry out manual accumulation, press the ENT key when the unit shows a stable

weight value above the value defined as minimum weighing.

The following example assumes a stable weight of 1,754 kg, which we have previously

tared manually at 1,538 kg. (1754-1538 = 0.216).

Single weighing is selected using the

W

.

UNIQ.

option in the Functions

menu.

Autom tic weighing mode is selected using the AUTOAC option in the

Functions menu.

(*) The minimum weight v lue for weighing is determined using the

WEI.MIN option in the unit's Progr mming menu.

- 16 -

Start manual weighing by pressing the ENT key to display the message:

The unit then briefly displays the number of weighings accumulated so far (in our case, the

first):

And the accumulated weight subtotal (which, in our case, since it is the first weighing,

coincides with the weighing made)

- 17 -

Once weighing is complete, the unit returns to weight mode and displays the weight on the

platform.

If the unit is connected to a printer, and, for example, the code "100350" has been entered

(using the -CODE- option in the functions menu), the following ticket will have been printed:

At the same time, if a PC connection has been configured in any of the serial

communication PORTS with MANUAL send, pressing the Tkey causes a frame to be sent

with the weight on the platform at this moment.

In order to carry out a new weighing and continue accumulating, remove the weight from the

platform and place the new weight to accumulate on it; wait for the weight to be stable and

then press the ENT key again.

========================================

N.WEIGH. CODE TARE kg NET kg

========================================

1 100350 * 1.538 0.216

If the code

introduced

is 0 (def ult v lue when st rting up the unit

), nothing

ppe rs in the CODE field of the ticket.

All the unit's seri l communic tion

PORTS c n be configured (from the

-COM-progr mming submenu) to connect to printer, l beller, repe ter

or PC in order to send weights.

- 18 -

3.3.2 Automatic accumulatio

Automatic accumulations do not require the INTRO key to be pressed for weighing; the unit

simply has to detect a stable weight value greater than the value defined as minimum

weighing (*) after the last weighing has been discharged.

3.3.3 Totalise

To complete and totalise all weighings in progress, keep the FUN and ENT keys pressed

down at the same time. When doing this, the screen display switches between the total

number of weighings made and the total weight accumulated, returning to weight mode by

pressing any key.

For example, if 4 weighings are carried out with a total weight of 0.632 kg, the unit switches

between the number of weighings

and the total accumulated weight

until any key is pressed and the unit returns to weight mode.

Autom tic weighing mode is selected using the AUTOAC option in the

Functions menu.

(*) The minimum weight v lue for weighing is determined using the

WEI.MIN option in the unit's WE.CTR. progr mming submenu.

- 19 -

If the unit is connected to a printer, the ticket will finish, as in the following example:

In this example, the following operations have been carried out in the ticket:

-Code 100350 has been entered.

-A container of 1.538 kg has been tared.

-A weight of 0.216 kg has been entered and accumulated.

- The weight and the container have been removed.

-A weight of 0.252 kg has been entered and accumulated.

-A weight of 0.083 kg has been entered and accumulated.

-A container of 0.252 kg has been tared.

-A weight of 0.081 kg has been entered and accumulated.

-Totalised by pressing FUN+ENT.

3.4 Piece counter

In piece counter mode the unit calculates and displays at all times the number of pieces

resulting from dividing the measured weight and the weight of each piece.

Piece counter mode is enabled by entering the PIECES option in the unit's functions menu.

The unit can carry out and memorise up to

255

eighings before totalising, and

can accumulate a eight total of over 18 trillion eight units (g, kg, tn, lb) and a

Grand Total of over 60,000 eighings.

========================================

N.WEIGH. CODE TARE kg NET kg

========================================

1 100350 1.538 0.216

2 100350 0.000 0.252

3 100350 0.000 0.083

4 100350 0.252 0.081

========================================

TOTAL WEIGHINGS TOTAL WEIGHT kg

========================================

4 0.632

========================================

- 20 -

When leaving the functions menu, the unit returns to weight mode, displaying the measured

weight.

From this moment on, the unit can switch between weight and piece counter modes by

pressing the FUN key.

The unit enables the pilot to indicate that the value shown on screen corresponds

to a number of pieces and not to a weight value.

A sample of the pieces to count is weighed in order for the unit to determine the unit weight

value of each piece;

FUN

Table of contents

Popular Accessories manuals by other brands

SUP’AIR

SUP’AIR SHAMANE user manual

Multitech

Multitech MultiConnect Conduit Series manual

Silvercrest

Silvercrest SLS 2200 B2 User manual and service information

Baby Jogger

Baby Jogger Glider Board Assembly instructions

Pauli + Sohn

Pauli + Sohn Sword Assembly instructions

Soft Heat

Soft Heat WrapAround manual

Multitech

Multitech Conduit IP67 200 Series Hardware guide

Digistar

Digistar GT560 AUTOLOG Operator's manual

Digistar

Digistar SCALE LINK SL2 Technical manual

Silvercrest

Silvercrest Smart Home HmIP-SWDM-B2 Operating instructions and safety instructions

Black Box

Black Box AC044A-R2 Specifications

BJ Live

BJ Live BJ-234 user guide