Sensor Line SL MD-220 User manual

Optical Transmittance Analyzer

SL MD-220

USER'S MANUAL

Hardware Version 2.0 / Software Version 1.3

Sensor Line - Gesellschaft für

optoelektronische Sensoren mbH

Carl-Poellath-Str. 19

D-86259 Schrobenhausen

- Germany -

Tel.: +49 (0) 8252 / 8943-0

Fax.:+49 (0) 8252 / 8943-11

Email: [email protected]

www.sensorline.de

SL MD-220 User's Manual

- 2 -

Table of Contents

1. General..............................................................................................................................4

1.1 Introduction..................................................................................................................4

1.2 Principle of Operation..................................................................................................4

1.3 Technical Data ............................................................................................................6

2. Hardware Section.............................................................................................................7

2.1 Dimensional Drawing...................................................................................................7

2.2 Handling Precautions ..................................................................................................7

2.3 Installation ...................................................................................................................8

2.4 System Terminal..........................................................................................................8

2.4.1 Mechanical............................................................................................................8

2.4.2 Connections..........................................................................................................8

2.4.2.1 Power Supply Terminal......................................................................................8

2.4.2.2 Optocoupler Outputs..........................................................................................9

2.4.2.2.1 Internal Circuitry............................................................................................9

2.4.2.2.2 External Wiring.............................................................................................9

2.4.2.2.2.1Generating Voltage Output Signals ........................................................9

2.4.2.2.2.2Driving Loads........................................................................................10

2.5 RS-232 Interface .......................................................................................................11

2.5.1 Connector ...........................................................................................................11

2.5.2 Wiring..................................................................................................................11

2.6 Reset Switch..............................................................................................................12

2.7 8-Way SIL Switch......................................................................................................12

2.8 Jumpers.....................................................................................................................12

2.9 Status LEDs ..............................................................................................................13

2.10 Measuring Pins..........................................................................................................13

2.11 Fiber Optic Receptacles............................................................................................14

2.12 JTAG connector ........................................................................................................14

3. Software Section............................................................................................................15

3.1 General Description...................................................................................................15

3.2 Details .......................................................................................................................16

3.2.1 Startup Procedure...............................................................................................16

3.2.2 Timing.................................................................................................................17

3.2.2.1 Program cycle time..........................................................................................17

3.2.2.2 Watchdog Timer..............................................................................................17

SL MD-220 User's Manual

- 3 -

3.2.3 Triggering............................................................................................................17

3.2.3.1 Trigger Timing .................................................................................................17

3.2.3.2 Nominal Trigger Threshold..............................................................................17

3.2.3.3 Adaptive Trigger Threshold.............................................................................18

3.2.4 SIL Switch and Jumper Settings.........................................................................19

3.2.4.1 Switch Settings................................................................................................19

3.2.4.2 Jumper Settings...............................................................................................20

3.2.5 Status Outputs....................................................................................................20

3.2.5.1 Status LEDs.....................................................................................................20

3.2.5.2 System Terminal Block....................................................................................20

3.2.5.3 Status Table ....................................................................................................21

3.2.6 RS-232 Interface.................................................................................................22

3.2.6.1 General............................................................................................................22

3.2.6.2 Comm Parameters...........................................................................................22

3.2.6.3 Output Modes..................................................................................................22

3.2.6.3.1 Voltage Mode .............................................................................................22

3.2.6.3.2 Percent Mode .............................................................................................23

3.2.6.3.3 Transmittance Mode...................................................................................23

3.2.6.3.4 Status Mode ...............................................................................................24

3.2.6.3.5 Off Mode.....................................................................................................25

3.2.6.3.6 Software Version Query..............................................................................25

3.2.6.3.7 Fast Mode...................................................................................................25

3.2.6.3.8 Special Output Modes................................................................................25

3.2.6.4 Commands ......................................................................................................26

3.2.6.4.1 System Reset Command............................................................................26

3.2.6.4.2 Threshold Reset Commands......................................................................26

SL MD-220 User's Manual

- 4 -

1. General

1.1 Introduction

The SENSOR LINE MD-220 is a two-channel static opto-electronic interface for SENSOR

LINE’s SPZ/SPT fiber optic load sensors. This two-channel interface supplies light to two

fiber optic sensors, monitors the amount of light transmitted through the sensors and detects

small changes caused by loads applied to the sensors. With its advanced circuitry, the

interface can detect a load on a sensor for as long as it is applied to the sensor.

The MD-220 incorporates a TI MSP-430 embedded microcontroller, programmable via a

JTAG interface. It has a 10-wire screw-clip interface with power supply terminals and four

floating optocoupler outputs. It also has a RS-232 interface for input and output of data.

Direct external control is possible through the use of an 8-way SIL switch, two jumpers and a

reset switch. For quicker troubleshooting, six LED status displays show the function of the

interface and there are five easily accessible test points for analog measurements.

Power consumption has been minimized by circuitry that operates the transmitter diodes in

series while independently controlling the current through each diode. The MD-220 comes

with two different kinds of transmitter diodes, a near infrared diode giving each channel a

dynamic range of 30 dB and a more economic red diode for a dynamic range of 20 dB.

The hardware and software for the MD-220 come in different versions. This manual is

divided into a hardware and a software section.

Please ensure that you have the correct version of this manual.

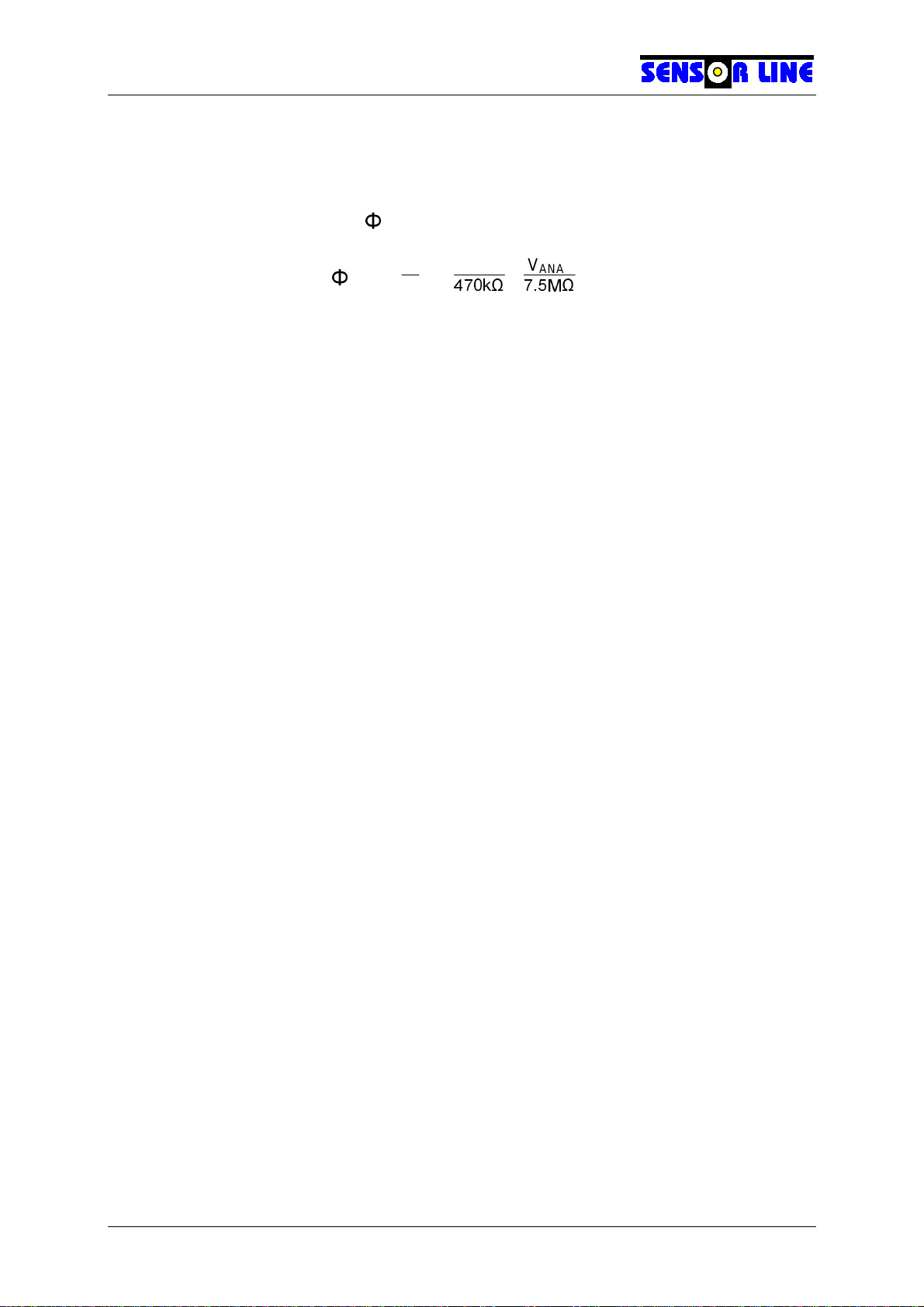

1.2 Principle of Operation

7.5M

470k

D

A

A

D

D

A

GNDGND

MONx

ANAx

I2 I1

The drawing above is a simple circuit diagram of one channel. When the photodiode is

illuminated with light from the sensor it proportionally sinks a current to the incoming light

power. This causes the output of the OP to go high so the current is supplied across the

7.5M resistor. When the light becomes too bright the OP output is clipped, and the controller

supplies additional current via the DAC and the 470k resistor until the OP output is

“unclipped.”

6PDOO FKDQJHV RI SKRWR FXUUHQW DUH DPSOLILHG E\ WKH 23 E\ D IDFWRU RI 0

9

$

The controller measures this voltage ("Analog Voltage" or VANAx) as well as the voltage

SL MD-220 User's Manual

- 5 -

produced by the DAC ("Monitor Voltage" or VMONx) with a resolution of 12 Bits. An additional

DAC controls the light power fed into the sensor.

Both voltages can be measured at test pins. Since the sensitivity of the photodiode is about

0.5 A/W the incoming light power

-

can at any time be calculated using the formula

-

= 2 W

A·

VMONx

N

+ VANAx

0

SL MD-220 User's Manual

- 6 -

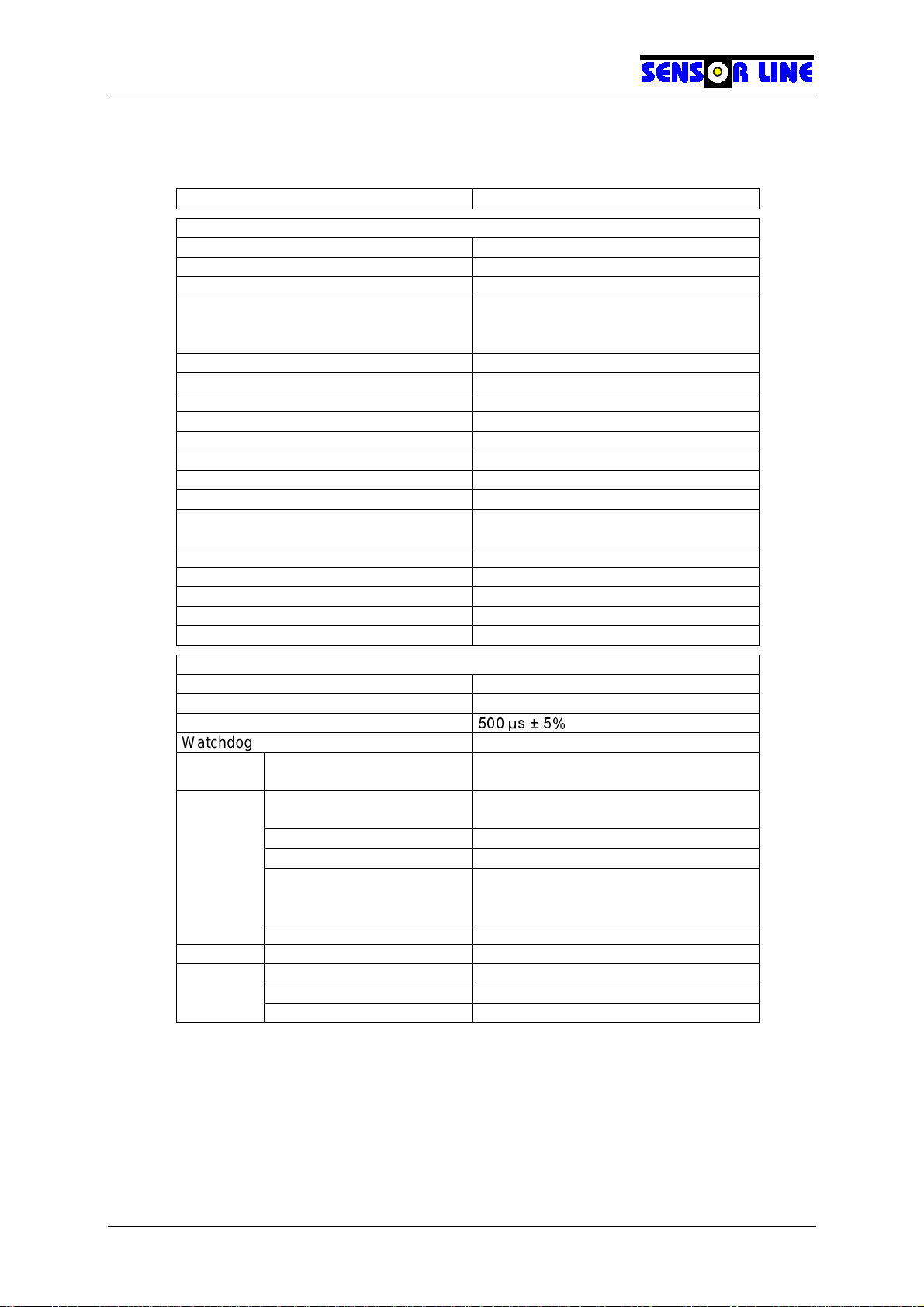

1.3 Technical Data

Device Type: MD-220

Hardware

Hardware Version: 2.0c STD-1

Number of Channels: 2

Size: 100x110x19 mm (3.54x4.33x.75 in)

Electrical Connections: 10-wire screw terminal block

RS-232, 3-wire**

5 test points

Optical connections: SMA 905

LED Peak Output Wavelength 850 nm (NIR) / 660 nm (VIS red)

Maximum Sensor Loss: 30 dB (NIR) / 20 dB (VIS)

Relative Humidity: 80% at 25°C (77°F)

Temperature Range: -40°C to 85°C (-40°F to 185°F)

Supply Voltage: +12 to +24 VDC

Supply Current: < 140 mA

Analog Output at Test Points: 0-10 V

Optocoupler Outputs max.: OFF: 50V/<1uA

ON: 5V/50 mA (250 mW @ 25°C)

RS-232 connector 9-pin DSUB male

Velocity Range: 1 to 250 km/h (0.6 to 155 mph)

Feeder Length: up to 250 meters (820ft)

Comparative Laser Class: 3A (NIR, sensor disconnected)

EMV/EMI: Meets CE-requirements

Software

Program Name: MD220STD

Program Version: 1.3

Program cycle time:

V

Watchdog expiration time 4 ms

Triggering Thresholds 0.2%, 0.4%, 0.8%, 1.6%

change of light transmittance**

Adaptive Threshold 0%, 6.25%, 12.5%, 25%, 50%

of load signal**

Hysteresis: ± 2 digits

Minimum input ON time: 3 program cycles (1.5 ms)

Minimum output ON time: 3 program cycles (1.5 ms) /

40 program cycles (20 ms)*

80 program cycles (40 ms)*

Maximum output ON time: 30 s

RS-232 Baud Rate 9600 / 19200 / 115200 Bd**

Data Bits 8

Stop Bits 1

Parity N (no parity)

* selectable with jumper J1, ** selectable with SIL switch

SL MD-220 User's Manual

- 7 -

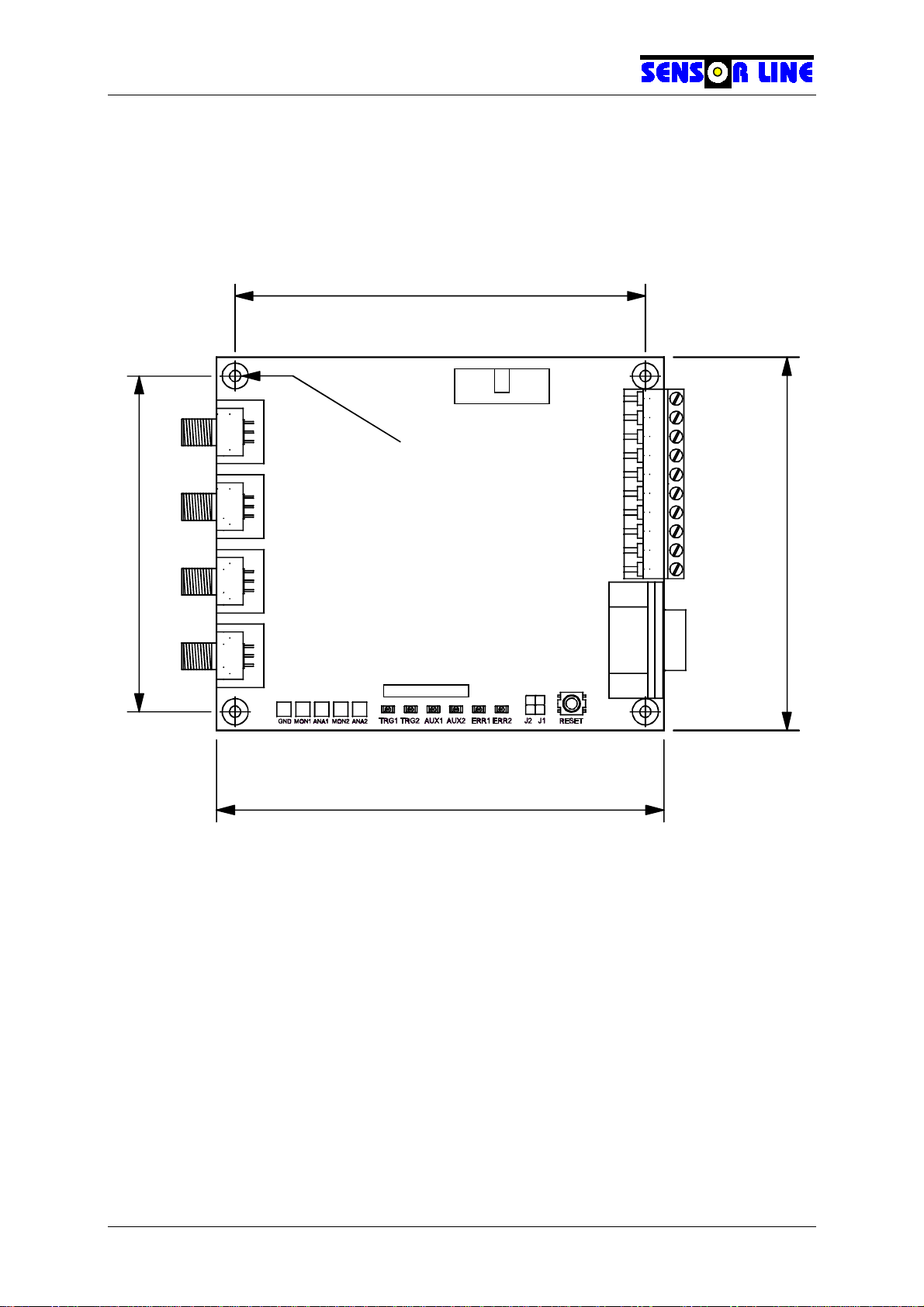

2. Hardware Section

The PCB version is found on the bottom layer of the PCB. This manual is for hardware

version 2.0.

2.1 Dimensional Drawing

.

Receiver 2

Transmitter 1

Receiver 1

Transmitter 2

100 (3.937)

120 (4.724)

110 (4.331)

90 (3.543)

JTAG

Connector

RS-232

Connector

Reset

Switch

Jumpers

System Terminal

Status LEDs

Test Points

Channel 1

Receiver

Channel 1

Transmitter

Channel 2

Transmitter

Channel 2

Receiver

+12..24VDC

GND

AUX2-

AUX2+

AUX1-

AUX1+

TRG2-

TRG2+

TRG1-

TRG1+

Through Holes Ø3.1 (.122)

Maximum Height 19 (.748) - Dimensions in mm (in)

Fiber Optic SMA 905 Receptacles

1

2

3

4

5

6

7

8

90

SIL-Switch

2.2 Handling Precautions

The MD-220 is delivered without a housing so handle it the same way as a PC card. Some

of the interface components are sensitive to electrostatic discharge (ESD). Leave the

interface inside its conductive bag until installation. Discharge yourself by touching a

grounded conductor before touching the interface. The receptacles are either non-

conductive or grounded and the system outputs have a special protective circuitry. It is

relatively safe to handle the interface by these parts. If conductive spacers are used, the

interface may be handled by these spaces because the rims of the through-holes are also

grounded. Before pressing the reset switch by hand first discharge yourself. The jumpers

and LEDs are connected directly to the controller and should never be touched. The test

points are connected to OP outputs, which are also sensitive to ESD. Discharge any

measuring clips on the GND pin before contacting one of the other test points.

SL MD-220 User's Manual

- 8 -

2.3 Installation

The MD-220 PCB has four Ø3.1mm (0.12”) through-holes, allowing it to be mounted on any

appropriate flat surface by means of M3 screws. At least 5mm (0.2”) spacers are

recommended to ensure a sufficient gap between the PCB and the mounting surface.

2.4 System Terminal

2.4.1 Mechanical

The system terminal is a 10-wire screw terminal block which accepts 0.14–1.5 mm2(26–16

AWG) wires. To fasten the screw clips a screwdriver with a blade up to 3.5 mm wide can be

used. The terminal block can either be a flat or angled design, the latter is used if several

interfaces are stacked.

2.4.2 Connections

Pinning Sign Description

+12...24VDC Supply Voltage

GND Ground

AUX2–

AUX2+ }Auxiliary Optocoupler Output 2

(Low Resistance = Sensor Failure)

AUX1–

AUX1+ }Auxiliary Optocoupler Output 1

(Low Resistance = TRG1 AND TRG2)

TRG2–

TRG2+ }Trigger Channel 2 Optocoupler Output

(Low Resistance = Load Response)

TRG1–

TRG1+ }Trigger Channel 1 Optocoupler Output

(Low Resistance = Load Response)

2.4.2.1 Power Supply Terminal

Terminals 0 and 1 of the system terminal block are for connection of a 12-24 VDC power

supply. The MD-220 has built-in voltage regulators and is reverse voltage protected. The

interface draws a maximum of 140 mA. Connect the negative output to Terminal 1 and the

positive output to Terminal 0.

SL MD-220 User's Manual

- 9 -

2.4.2.2 Optocoupler Outputs

2.4.2.2.1 Internal Circuitry

68 V

0.25W

100 Ohms

Optocoupler

H11G1 + Terminal

–Terminal

The above schematic shows the internal circuitry of the TRG1 & 2 and AUX1 & 2

optocoupler outputs. When the phototransistor is illuminated by the LED (ON condition)

current flows into the + terminal and out of the - terminal. The resistor limits the maximum

allowable current to 50mA. Therefore, any DC voltage applied directly to the outputs must

not exceed 5V when the phototransistor is conductive because the maximum power the 100

Ohm resistor can dissipate is 250mW.

When the phototransistor is not conductive the maximum voltage is limited by the zener

diode to 68V. If a voltage above that value is applied (even with additional resistors), the

output might appear conductive but the phototransistor is not. To avoid any glitches caused

by voltage spikes or surges the optocoupler outputs should not be operated with voltages

above 50V.

2.4.2.2.2 External Wiring

The optocoupler outputs are not connected to any voltage source so there are many ways to

obtain various kinds of output signals. In all cases an external power supply must be added.

The outputs behave as switches with the restriction that current can only flow in one

direction. Below are examples of how the outputs may be wired.

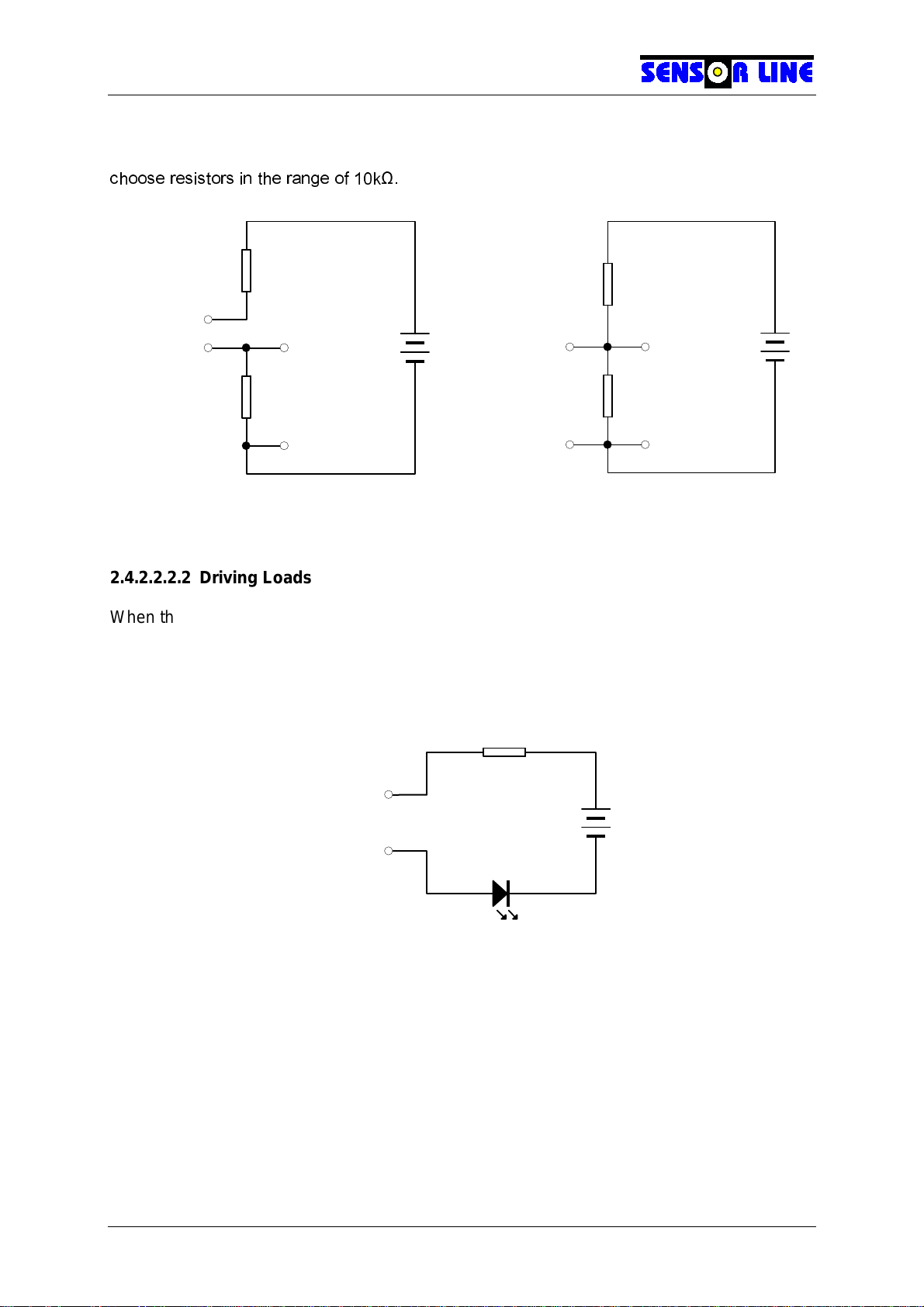

2.4.2.2.2.1 Generating Voltage Output Signals

Voltage output signals are required if high impedance inputs, like those on an oscilloscopes,

are connected. The wiring from the diagrams below can be used if the voltage from the

available source has the required value or is not critical.

10k

+ Terminal

–Terminal

+

–

+ Vout

–Vout

Positive output voltage going

LOW on ON condition

10k

+ Terminal

–Terminal +

–

+ Vout

–Vout

Zero output voltage going

HIGH on ON condition

SL MD-220 User's Manual

- 10 -

If the voltage available is too high for the intended inputs a second resistor must be added in

order to create a voltage divider as given in the schematics below. It is generally safe to

FKRRVH UHVLVWRUV LQ WKH UDQJH RI N

2.4.2.2.2.2 Driving Loads

When there are no high impedance inputs that inhibit the flow of current it is not necessary to

generate a voltage. In this case the optocoupler output can be used as a switch to turn

current on and off. The wiring below shows how to operate an LED or drive optocoupler

inputs or relays. The current must be limited to a maximum of 50mA with an appropriate

resistor.

R

+ Terminal

–Terminal

+

–

LED

Driving a LED

+ Terminal

–Terminal

+

–

+ Vout

–Vout

Zero output voltage going

HIGH on ON condition

+ Terminal

–Terminal

+

–

+ Vout

–Vout

Positive output voltage going

LOW on ON condition

SL MD-220 User's Manual

- 11 -

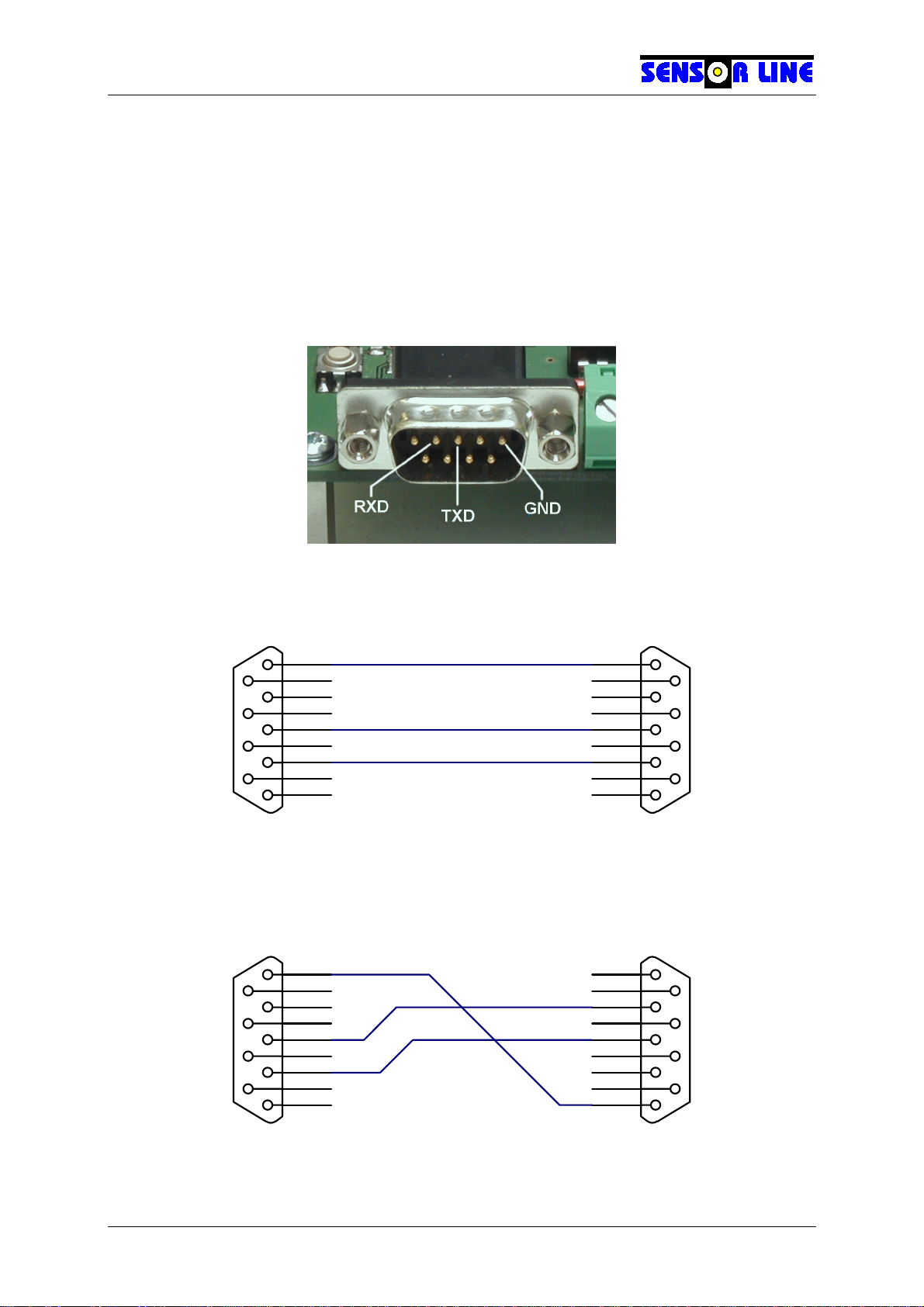

2.5 RS-232 Interface

The MD-220 has a three-wire RS-232 interface with a male 9-pin DSUB RS-232 connector. It

behaves like a PC, sending data on the TXD line (Pin 3) and receiving on the RXD line (Pin

2). It can be connected directly to a printer with a standard RS-232 cable. To connect it to a

PC a null-modem cable is required, similar to the connection between two PCs. Please refer

to the software section for communication parameters as baud rate, parity, etc.

2.5.1 Connector

2.5.2 Wiring

1

6

2

7

3

8

4

9

5

MD-220

Female Connector

1

6

2

7

3

8

4

9

5

RS-232 device

Male Connector

GND

TXD

RXD

Standard RS-232 Cable

1

6

2

7

3

8

4

9

5

PC

Female Connector

1

6

2

7

3

8

4

9

5

MD-220

Female Connector

GND

Null-Modem Cable

SL MD-220 User's Manual

- 12 -

2.6 Reset Switch

Pressing the reset switch causes a hardware reset of the microcontroller.

The two pads next to the right of the switch are connected in parallel and can accept a two-

pin header to allow for connection of an external switch.

2.7 8-Way SIL Switch

The SIL switch consists of eight individual switches which are connected to I/O pins of the

microcontroller. They are used to signal different conditions in order to modify the behavior

of the interface without re-programming it. Please refer to the software section of this manual

for the different switch settings.

2.8 Jumpers

The headers J1 and J2 can be used for the same purpose as the SIL switch (see above) by

installing jumpers or connecting external switches. They can also be used as I/O

connections for various purposes. Please refer to the software section of this manual for

more information.

SL MD-220 User's Manual

- 13 -

2.9 Status LEDs

There is a display of six LEDs controlled by the microcontroller. TRG1, TRG2, AUX1 and

AUX2 are yellow, and ERR1 and ERR2 are red. Please refer to the software section of this

manual for the meaning of the LED signals.

2.10 Measuring Pins

There are five test points with 1.3mm (0.05”) pins for measuring the analog voltages

evaluated by the microcontroller. The meaning of these voltages is thoroughly explained in

paragraph 1.2 on page 4.

Label Signal Sign

GND Ground –

MON1 Monitor Voltage Channel 1 VMON1

ANA1 Analog Voltage Channel 1 VANA1

MON2 Monitor Voltage Channel 2 VMON2

ANA2 Analog Voltage Channel 2 VANA2

SL MD-220 User's Manual

- 14 -

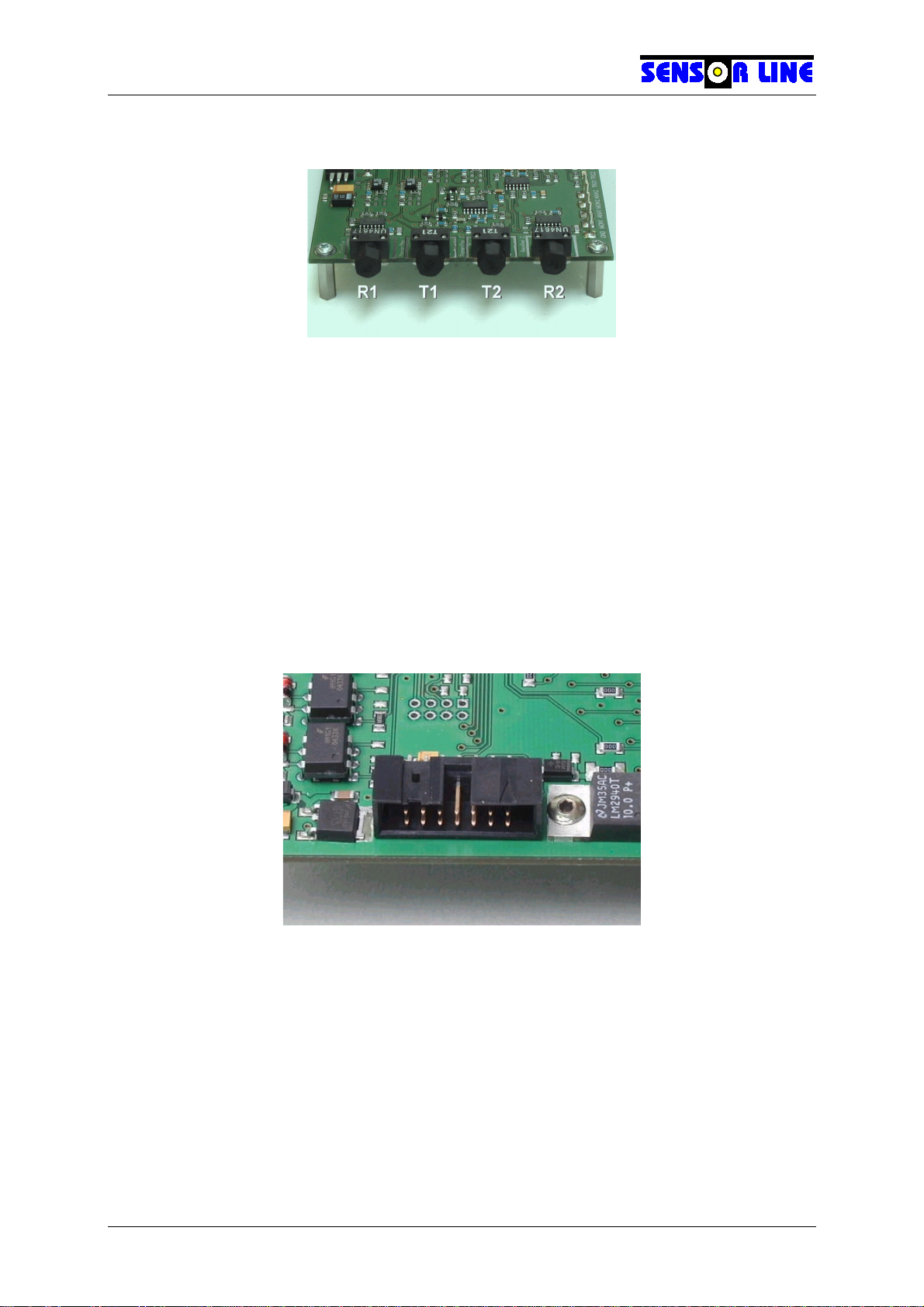

2.11 Fiber Optic Receptacles

Two fiber optic load sensors can be connected to the MD-220 via four SMA 905 fiber optic

receptacles. Viewed from the front the receptacles for Channel 1 are on the left hand side

and those for Channel 2 on the right hand side. The transmitters are the inner receptacles.

Do not stare into the transmitters when the interface is powered and there is no sensor

connected.

Fasten the sensor’s fiber connectors to the transmitter or receiver by screwing tightly on by

hand (the tighter, the smaller the attenuation). DO NOT USE PLIERS. The transmitter and

receiver connectors are interchangeable for each channel. The transmitter connectors are

not interchangeable i.e. a sensor connected for example to Transmitter 1 and Receiver 2 will

not work.

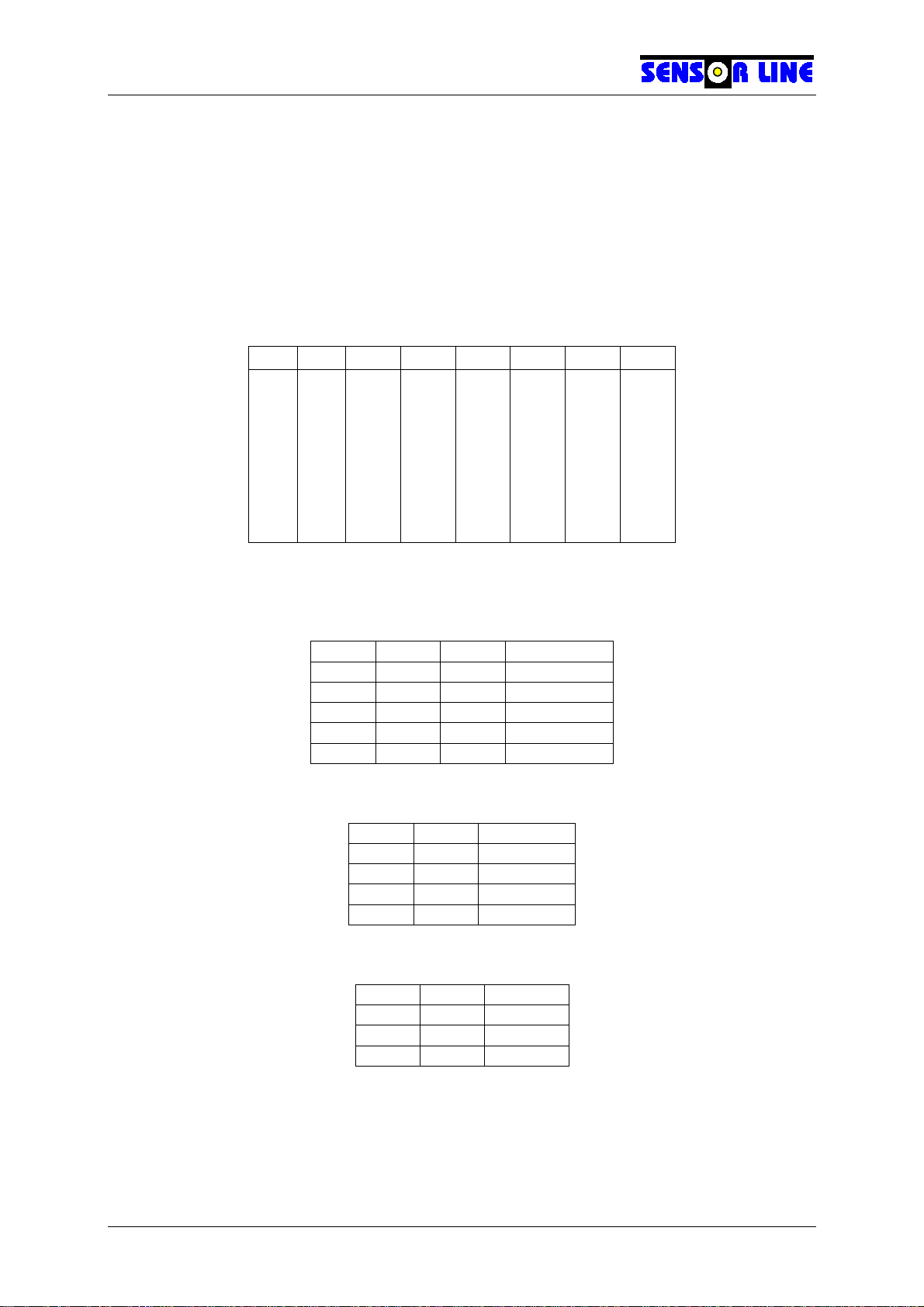

2.12 JTAG connector

The JTAG connector is used for programming the microcontroller at the factory. If you are

intending to re-program the device in the field please contact Sensor Line GmbH for further

information.

SL MD-220 User's Manual

- 15 -

3. Software Section

The following refers to the MD-220 program MD220STD version 1.3.

3.1 General Description

The program executed by the microcontroller controls all functions of the MD-220. Detecting

a load applied to the sensor is difficult because of the large variation in sensor transmittance

versus the small amount of transmittance change when load is applied. For example, if the

sensor transmittance could change by a factor of 100 (20 dB) and the transmittance change

caused by a load was 1% (=1/100) the complete light measuring range would have to be

resolved to 1/10000 of its value in order to detect the load. This is more than twice the

resolution of a 12-bit ADC.

To overcome this difficulty the microcontroller controls the photo currents detected by the

input amplifiers in two ways. First, it can vary the transmitter currents by a factor of ten.

Second, it can subtract an offset of up to 16 times the range of the amplifiers from their input

current. With growing sensor transmittance the light power fed into the sensors is reduced in

order to avoid clipping of the signal. When the minimum value is reached the controller

compensates for further increases in sensor transmittance by subtracting increasing portions

of the photo current before the remainder is fed into the amplifiers (see paragraph 1.2 on

page 4).

After startup the program uses these methods to adjust the amplifiers' output voltages (called

"analog voltages") to a value in the upper region of the ADCs' measuring range. Then it

establishes a threshold below that value corresponding to a constant fraction of the light

detected. After this initialization process the program enters its main loop. Here it monitors

the analog voltages and checks if they have dropped below the threshold values, thus

signaling load being applied to the sensors.

As long as there is no load detected the thresholds are carefully adapted to slow changes

(drifting) of the detected light and the analog voltages are adjusted,if necessary. However, if

there is load this process cannot be continued since it is impossible to determine whether a

change of the detected light is due to drifting or due to a change of the load. As equipment

does not stop drifting when there is load on the sensor the interface cannot be allowed to

detect load for infinite time. If during load detection the amount of light detected without any

load drifted below the stored threshold, the interface would no longer be able to notice the

load being removed; it would "hang".

For this reason there is a maximum detection time of 30 seconds. When this time has

elapsed, the interface performs an initialization process similar to the one at startup. The

interface is then ready to detect additional load being applied to the sensor. The original

load effect is regarded as intrinsic sensor attenuation. When the original load is removed the

threshold is adapted immediately.

When the sensor is broken (or disconnected) no light arrives at the receiver and the interface

is unable to detect any load. If the sensor fails during operation, the detected light falls

below the threshold and is reported as load being detected. Therefore, sensor failure during

operation is first reported as a load detected, and it changes to an error signal after 30

seconds.

SL MD-220 User's Manual

- 16 -

3.2 Details

3.2.1 Startup Procedure

After power-up or when a program reset is initiated the MD-220 first tries to adjust itself to the

particular sensors attached. This process takes about one second and is signaled by both

ERRx LEDs (see paragraph 3.2.5.1 on page 20) flashing at 8 Hz.

If insufficient light is detected, i.e. if there is no sensor connected to a channel or the

connected sensor is broken, the respective ERRx LED comes on continuously along with

the AUX2 LED. The AUX2 optocoupler output becomes conductive and the associated

TRGx LED flashes ten times at 2 Hz. The TRGx LED is then switched off.

In the case that there is too much light detected (which may happen when an interface with

infrared transmitters is used in conjunction with a low loss sensor) the ERRx and AUX2 LEDs

and the AUX2 optocoupler outputs behave the same way but the TRGx LED does not flash.

If the sensor loss is within a range where the interface can successfully adjust itself the

program waits for the transmitter to stabilize its output power. This is necessary because

during power-up the transmitter becomes warm, causing a slight decrease in its brightness

during the first few seconds.

Since it is not possible to derive a measure for the sensor loss from the analog voltages at

the test pins, the interface signals the virtual sensor loss during warmup time. It cannot

determine the real sensor loss. Rather, the sensor loss, in this, cases, defines a certain

value within an internal "theoretic" dynamic range of 30 dB. For a number of reasons this

range can not be fully utilized in practice but the interface "sees" the loss of the sensors vary

within it. In order to express this virtual sensor loss the internal dynamic range is divided into

ten intervals of 3 dB. While the transmitter is warming up the TRGx LED of each channel is

flashed from one to ten times. The number of times it flashes multiplied by 3dB is the virtual

sensor loss. If a sensor has high loss, the transmitter needs more time to warm up because

it is operated at high power.

The number of times the TRGx LEDs flash can not be directly translated into sensor loss

since it is given with respect to that particular channel's dynamic range. Dynamic range may

vary due to variations of the opto-electronic components. However, it shows how that

particular sensor is handled by that interface channel. If the TRGx LED flashes at least two

times and no more than nine times during the warmup time there is at least a 3 dB reserve

and operation can generally be considered to be safe, regardless of the exact sensor loss

and the particular interface used.

As long as the sensor loss is signaled by flashing TRGx LEDs, the ERRx LEDs continue

flashing at 8 Hz, showing the warmup time has not yet expired and the interface is not yet

operational. After the ERRx LEDs are switched off and the TRGx LEDs are continuously on

the startup process is complete.

SL MD-220 User's Manual

- 17 -

3.2.2 Timing

3.2.2.1 Program cycle time

The main loop of the program is executed during a constant time interval of approximately

V

. This time can vary about ± 5% due to the tolerance of the clock oscillator. All

quantities are updated at every cycle. The time resolution of the interface is therefore equal

to the program cycle time.

3.2.2.2 Watchdog Timer

The watchdog timer is serviced every time the main loop is executed. Its time interval is set

to 4 ms. If the program hangs for whatever reason and this time expires a program reset is

performed.

3.2.3 Triggering

3.2.3.1 Trigger Timing

The trigger function works with a threshold that has a hysteresis of only ± 2 digits. This is

just sufficient to prevent the interface from bouncing due to the sheer quantization error of

the ADC. Debouncing is done by requiring a valid load pulse to have at least 3 program

cycles (1.5 ms) of duration. This requires that the trigger delay also be 1.5 ms. The output

pulse duration is correct because switching off and on is subject to the same conditions.

Optionally the output pulse duration can be forced to a certain minimum value, regardless of

the input pulse duration. The output will then be on for at least that minimum time (20 ms or

40 ms in this program version). Otherwise the output pulse duration can become as short as

1.5 ms. Please refer to section 3.2.4 on how to define the minimum output pulse duration.

The maximum output pulse duration is 30 s. This is the maximum detection time explained

in paragraph 3.1. After 30s the interface is freshly adjusted and ready to detect a new load.

3.2.3.2 Nominal Trigger Threshold

Before introduction of hardware version 2.0 the trigger threshold was a fixed value and

adjustment required re-programming. MD220STD v1.3 allows to select threshold values of

0.2%, 0.4%, 0.8% and 1.6% change of light transmittance. Please refer to section 3.2.4 for

instructions.

SL MD-220 User's Manual

- 18 -

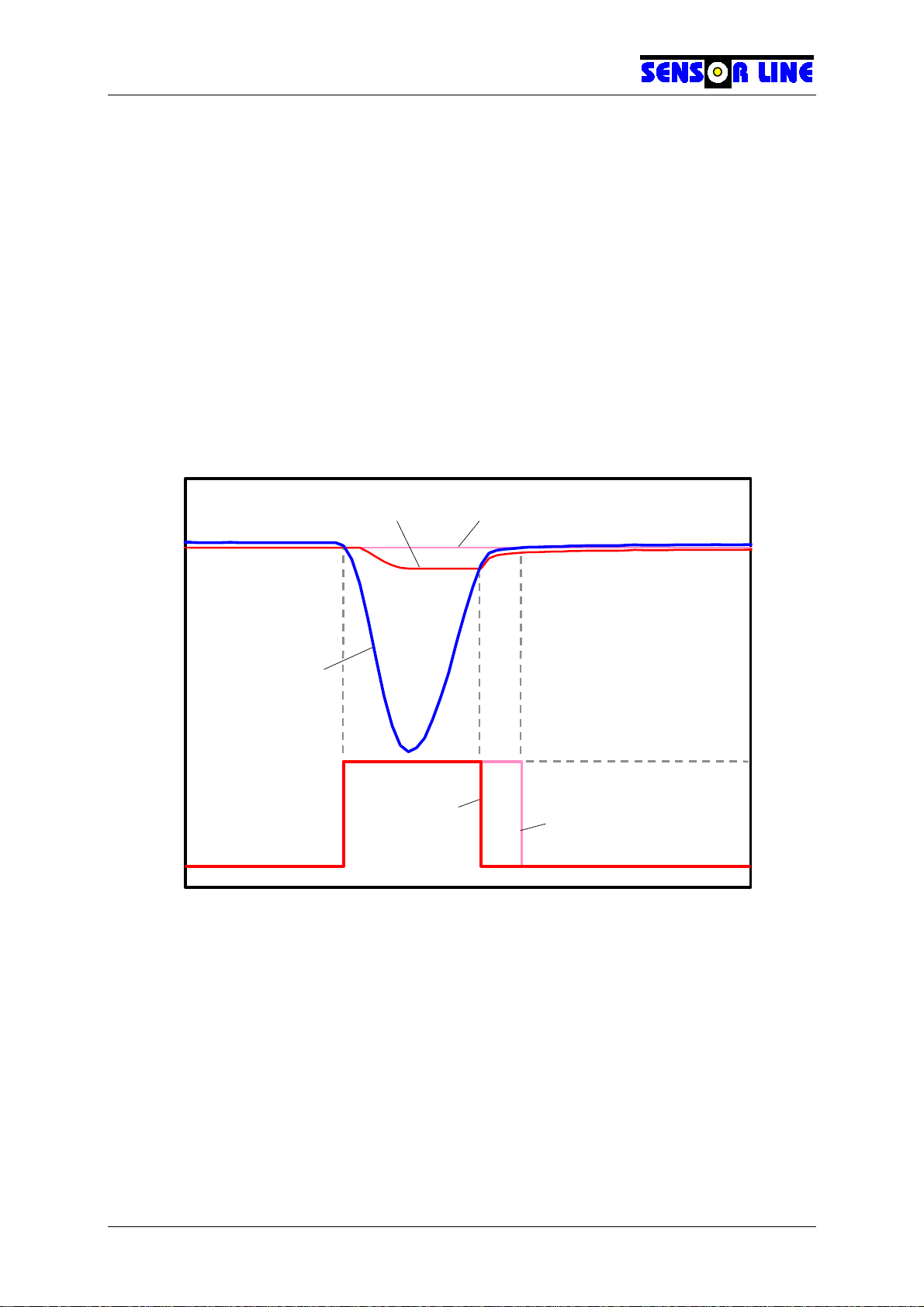

3.2.3.3 Adaptive Trigger Threshold

Adaptive threshold processing is a trigger algorithm introduced with Version 1.3 of

MD220STD. It is intended to be applied in cases where sensors show a noticeably delayed

relaxation process. Behaviour of this kind can encumber certain signal processing methods

for dual-tire detection or automatic vehicle classification which rely on correct registration of

the load pulse duration. In extreme cases it can even cause the trigger output to "hang" after

a tire has left the sensor.

This issue is overcome by the adaptive threshold algorithm: After the trigger event has

happened the trigger threshold follows the sensor signal with a certain fraction of its

amplitude as long as the amplitude is growing, i.e. the sensor transmittance is decreasing.

When the sensor transmittance rises the threshold is held constant until the trigger state has

switched to OFF again. After that the threshold is held at a level below the sensor signal

which complies to the nominal threshold value according to section 3.2.3.2 as long as the

sensor transmittance is not decreasing again.

Time

Sensor Transmittance

Trigger Output State

100%

ON

OFF

Sensor Signal

Fixed ThresholdAdaptive Threshold

Output Pulse

with Adaptive

Threshold

Output Pulse

with Fixed

Threshold

Adaptive threshold processing can be switched on and off. The ratio of signal amplitude to

which the trigger threshold adapts can be defined to values of 50%, 25%, 12.5% and 6.25%.

Please refer to section 3.2.4 for instructions.

SL MD-220 User's Manual

- 19 -

3.2.4 SIL Switch and Jumper Settings

3.2.4.1 Switch Settings

Both boards have an 8-way SIL switch immediately behind the display LEDs. The particular

switches are numbered from 1 to 8 where switch 1 is the leftmost one. They are in on-

position when swiveled towards the front edge of the board i.e. towards the LEDs. Factory

setting is all switches off.

Switch Functions:

12345678

Adaptive Threshold

Enable

Adaptive Threshold

HI

Adaptive Threshold

LO

Trigger Threshold

HI

Trigger Threshold

LO

Baudrate

Select

High Speed

Enable

Enforce Minimum

Pulse Duration

Switches 1-3 set the percentage to which the trigger off threshold follows an input pulse

(adaptive threshold, see section 3.2.3.3):

Way1 Way2 Way3 Percentage

off X X 0%

ON off off 6.25%

ON off ON 12.5%

ON ON off 25%

ON ON ON 50%

Switches 4 and 5 define the nominal trigger on threshold (see section 3.2.3.2):

Way4 Way5 Threshold

off off 0.8%

off ON 1.6%

ON off 0.2%

ON ON 0.4%

Switches 6 and 7 select the baud rate of the serial interface (see section 3.2.6.2):

Way6 Way7 Baud

off off 9600

ON off 19200

X ON 115200

When Switch 8 is in ON position the trigger output on time is forced to a minimum value

which depends from the setting of Jumper J1 (see below).

SL MD-220 User's Manual

- 20 -

3.2.4.2 Jumper Settings

When Jumper J1 is installed, the minimum trigger output on time is 40 ms, with J1 removed

it is 20 ms. This requires Switch 8 to be set to ON position (see above), otherwise the

configuration of J1 has no effect.

Jumper J2 is reserved for future use.

3.2.5 Status Outputs

The status outputs are the six status LEDs and four optocoupler outputs on the system

terminal block. In spite of the common labeling of some of them their behavior is not the

same. This might be confusing at first but provides maximum convenience during operation.

3.2.5.1 Status LEDs

There are three groups of status LEDs: TRGx, AUXx and ERRx. The TRGx LEDs show the

trigger status of both channels, the red ERRx LEDs report error conditions and the AUXx

show other conditions or events.

The TRGx LEDs correspond to one channel each. During initialization when the interface is

adjusting itself they are flashing up to ten times, giving a measure of the sensor loss (see

also paragraph 3.2.1 on page 16). They are on if the respective channel is ready to detect

load and go off when load a load is detected or when an error occurs.

The ERRx LEDs are also associated to one channel each. During initialization they are

flashing. If the controller cannot transmit enough light through a sensor the respective ERR

LED is switched on continuously.

The AUX1 LED is on when both channels are detecting load, otherwise it is off.

The AUX2 LED comes on when either of the channels has an error condition and its ERR

LED is on continuously. This might seem redundant, but the AUX2 LED is switched on and

off in accordance with the AUX2 optocoupler output which reports an error (see below). This

is convenient for troubleshooting purposes.

3.2.5.2 System Terminal Block

The system terminal block has four optocoupler outputs, divided into two groups: TRGx and

AUXx. The TRGx outputs become conductive (ON condition) when there is load detected by

the respective channel. This is inverse to the TRGx LEDs!

The AUXx optocoupler outputs follow the AUXx LEDs. The AUX1 output comes on when

both of the TRGx outputs are on and the AUX2 output comes on when there is an error

condition regardless at what channel.

Table of contents