Sensor Partners LAM71 User manual

Sensor Partners

LAM71 Laser Distance Sensor

Manual

User advice

LAM71, Release 001_Revision 001

Dear User,

Please read this operating manual carefully before starting to operate the LAM71 laser distance

meter. This is the only way to make sure that you will be able to make full use of the capabilities of

your new laser distance meter, and to prevent any damage caused by operating errors.

Sensor Partners

Sensor Partners BV –Head Office

James Wattlaan 15

5151 DP Drunen

The Netherlands

Telephone: +31 416 378239

E-mail: [email protected]om

Internet: www.sensorpartners.com

Revision status:

Date

Release

Revision

Remarks/ Modifications

2018 March

001

000

Feasibility study version

2018 November

001

001

functional model

No part of this manual may be reproduced in any form (photograph, photocopy, microfilm or any

other procedure) without the prior written permission of Sensor Partners BV, nor may contents be

processed, reproduced or distributed using electronic systems . This operating manual was pro-

duced with the appropriate care. No liability will be accepted for damage resulting from the non-

observance of the information contained in this manual. We reserve the right to modify the docu-

ment following technical advancements without notice.

Table of contents

LAM71, Release 001_Revision 001

5

1 GENERAL INFORMATION ..................................................................................................... 7

1.1 Warning signs, symbols and references .............................................................................. 7

1.2 Intended use........................................................................................................................ 7

1.3 Integration of device in a system......................................................................................... 7

2 SAFETY ADVICE .................................................................................................................... 8

2.1 Laser class ............................................................................................................................ 8

2.2 Basic safety advice............................................................................................................... 8

2.3 Transport and storage ......................................................................................................... 9

2.4 Cleaning and maintenance .................................................................................................. 9

2.5 Service.................................................................................................................................. 9

3 INTENDED USE/ CONDITIONS............................................................................................ 10

3.1 Operating and storage conditions ..................................................................................... 10

3.2 Improper use and possible error sources.......................................................................... 10

3.3 Warning signs and type plates........................................................................................... 10

4 DEVICE DESCRIPTION......................................................................................................... 11

4.1 General information .......................................................................................................... 11

4.2 Scope of delivery................................................................................................................ 11

4.3 Laser beam image.............................................................................................................. 12

5 INSTALLATION AND START OF OPERATION....................................................................... 13

5.1 Preparatory work prior to installation............................................................................... 13

5.2 Mechanical installation...................................................................................................... 13

5.3 Connector pin assignment................................................................................................. 14

5.4 Serial interface RS232 / RS422........................................................................................... 15

6 PARAMETER SETUP AND MEASURING OPERATION .......................................................... 16

6.1 General information .......................................................................................................... 16

6.2 Measurement involving moving targets............................................................................ 17

6.3 Identification...................................................................................................................... 17

6.3.1 ID recognition.................................................................................................................... 17

6.3.2 ID? –Online help............................................................................................................... 17

6.4 Operation modes............................................................................................................... 18

6.4.1 DM –single distance measurement................................................................................. 18

6.4.2 DT –Continuous distance measurement (distance tracking)........................................... 18

6.5 Status ................................................................................................................................. 19

Table of contents

6

LAM71, Release 001_Revision 001

6.5.1 TP - Internal temperature ................................................................................................. 19

6.5.2 HW –hardware status ...................................................................................................... 19

6.5.3 PA –Display Parameter setting......................................................................................... 20

6.5.4 PR –Parameter reset ........................................................................................................ 21

6.6 Setup parameters .............................................................................................................. 22

6.6.1 AS –Autostart function..................................................................................................... 22

6.6.2 BR –Baud rate................................................................................................................... 22

6.6.3 DR –LAM71 restart (device reset) .................................................................................... 23

6.6.4 GN –Setup GAIN ............................................................................................................... 23

6.6.5 MF –Measurement frequency ......................................................................................... 24

6.6.6 MW –Measurement window ........................................................................................... 26

6.6.7 OF –Offset ........................................................................................................................ 27

6.6.8 QA –Analogue output....................................................................................................... 28

6.6.9 Q1/ Q2 –Switching output ............................................................................................... 30

6.6.10 SA –Mean value average.................................................................................................. 32

6.6.11 SO –Set offset................................................................................................................... 33

6.6.12 SD –Data format of serial interface output...................................................................... 33

6.6.13 SE –Error mode................................................................................................................. 36

6.6.14 ST –Select Target.............................................................................................................. 36

6.6.15 TC –Time Calibration ........................................................................................................ 37

6.6.16 TE –Terminator................................................................................................................. 38

6.6.17 TI + TO Trigger................................................................................................................... 39

6.6.18 UB –Unit for binary output............................................................................................... 43

7 SERIAL INTERFACE AND COMMUNICATION SOFTWARE................................................... 44

8 ERROR PROCESSING........................................................................................................... 45

9 TECHNICAL DATA ............................................................................................................... 46

LAM71, Release 001_Revision 001

7

1General information

1.1 Warning signs, symbols and references

The sign Caution warns against dangers to health which may occur if this advice is not observed

The sign Laser warns against emitting visible or invisible laser radiation.

The sign Electric shock warns against the danger of an electric shock.

The sign Attention warns against possible damage to the device

The sign Information points to important information.

This sign indicates that special environmental protection guidelines must be observed when dis-

posing of the device.

Note / important note

1.2 Intended use

The laser distance meter LAM71 is a custom built functional model. It is destined for

professionals to be used solely at research and development facilities. The customer and system integra-

tor is responsible for compliance with the relevant guidelines, laws and standards, in particular compli-

ance with the safety requirements.

1.3 Integration of device in a system

The combination or integration of the device, LAM71, with or into a system not provided and authorized

by Sensor Partners for the respective device may result in errors of the data transmission, including but

not limited to failures in the total measurement range, accuracy, repeatability, connectivity or transfer

speed of data. Sensor Partners assumes no liability for any damages, losses, expenses, costs, injuries,

claims or demands arising out of or in connection with the combination or integration of the device,

LAM71, with or into a system not provided and authorized by Sensor Partners for the respective device.

8

LAM71, Release 001_Revision 001

2Safety advice

2.1 Laser class

Based on the standard EN 60825-1:2014 the LAM71 is in correspondence with laser

class 1. The laser radiation of class 1 lasers is not dangerous to the human eye, thus,

any injury can be excluded.

2.2 Basic safety advice

Please read the safety and operating advice carefully, and observe the advice when operating the

LAM71 laser distance measurement device.

The LAM71 is equipped with a laser diode emitting in the infrared spectrum, which is not visible

to the human eye.

Ensure there is no voltage applied when establishing a connection to the device and while inte-

grating the device into the customer system. There is a potential risk of an electric shock to the

operator or of damage to the device.

Do not operate the device if there is any damage visible. Contact customer service for further as-

sistance.

The device may not be used in explosive environments; otherwise there is the danger of damage

to the LAM71 and the surrounding equipment, and of injuries of the user.

Observe the operating conditions for the LAM71. Adverse use can cause damage to the device

and will void the warranty.

Please consider the assembly advices when integrating the device in the system. By applying the

wrong voltage level and/or polarity to the LAM71 a permanent damage may be caused.

Avoid touching the optics and do not use the device if the optics are soiled or clouded.

Store the device in the delivered packaging.

Do not perform any modification to the device as this may cause potential harm to the operator

and the device. Any modification on the device will void the warranty.

LAM71, Release 001_Revision 001

9

2.3 Transport and storage

The laser distance meter LAM71 is delivered in standard packaging. All kinds of transport are permitted.

It is recommended to store the unit inside the transport packaging until it is used. Please observe the

storage conditions.

2.4 Cleaning and maintenance

The LAM71 does not require any maintenance. Keep the optical glass surfaces (laser and receiver

lenses) free of deposits to ensure trouble-free measurements. Dust can be removed using an air brush.

In case of dirt which is hard to remove, please contact the manufacturer. Do not be clean the device by

using solvents or mechanical tools. Electrical, mechanical or optical modifications of the device are not

permitted!

2.5 Service

In case that repair work is necessary, please contact our After Sales and send the device to the address

below:

Sensor Partners

Sensor Partners BV –After Sales

James Wattlaan 15

5151 DP Drunen

The Netherlands

If you have any questions, please contact us via telephone or e-mail:

Telephone: +31 416 378239

E-mail: [email protected]om

10

LAM71, Release 001_Revision 001

3Intended use/ Conditions

3.1 Operating and storage conditions

Operating temperature

- 40 °C … + 60 °C

Storage temperature

- 40 °C … + 70 °C

Humidity

15% … 90%, non-condensing

3.2 Improper use and possible error sources

•The unit may be used only as described.

•Please do not remove any labels and type plates.

•Repair work must not be performed by the user. In case of questions or doubt, the

manufacturer is to be consulted. For contact data see section 2.5.

•In order to obtain correct measuring values the following advice is to be observed:

1. Measurements against the sun or onto surfaces with low reflectivity in very bright environ-

ments can result in faulty measurements.

2. Measurements through glass, optical filters, Plexiglas or other translucent materials can re-

sult in measurement errors.

3.3 Warning signs and type plates

Laser label

The LAM71 works with a class 1 laser.

Type plate

The type plate shown is an example. Serial number (SN) may

differ from this image.

LAM71, Release 001_Revision 001

11

4Device description

4.1 General information

The laser distance meter LAM71 is designed as a compact range finder dedicated for easy integration.

Interface solutions like RS232, RS422, analog output and switching outputs are integrated.

LAM71 is designed for an operating temperature (ambient temperature) of as low as -40°C up to +60°C.

The heating element ensures the operating temperature of the components and free optics (no con-

densation) of the LAM71.

Connecting cables are available, for order numbers please see chapter 4.2.

Devices with a cable length of up to 10 m are demonstrably EMC-safe.

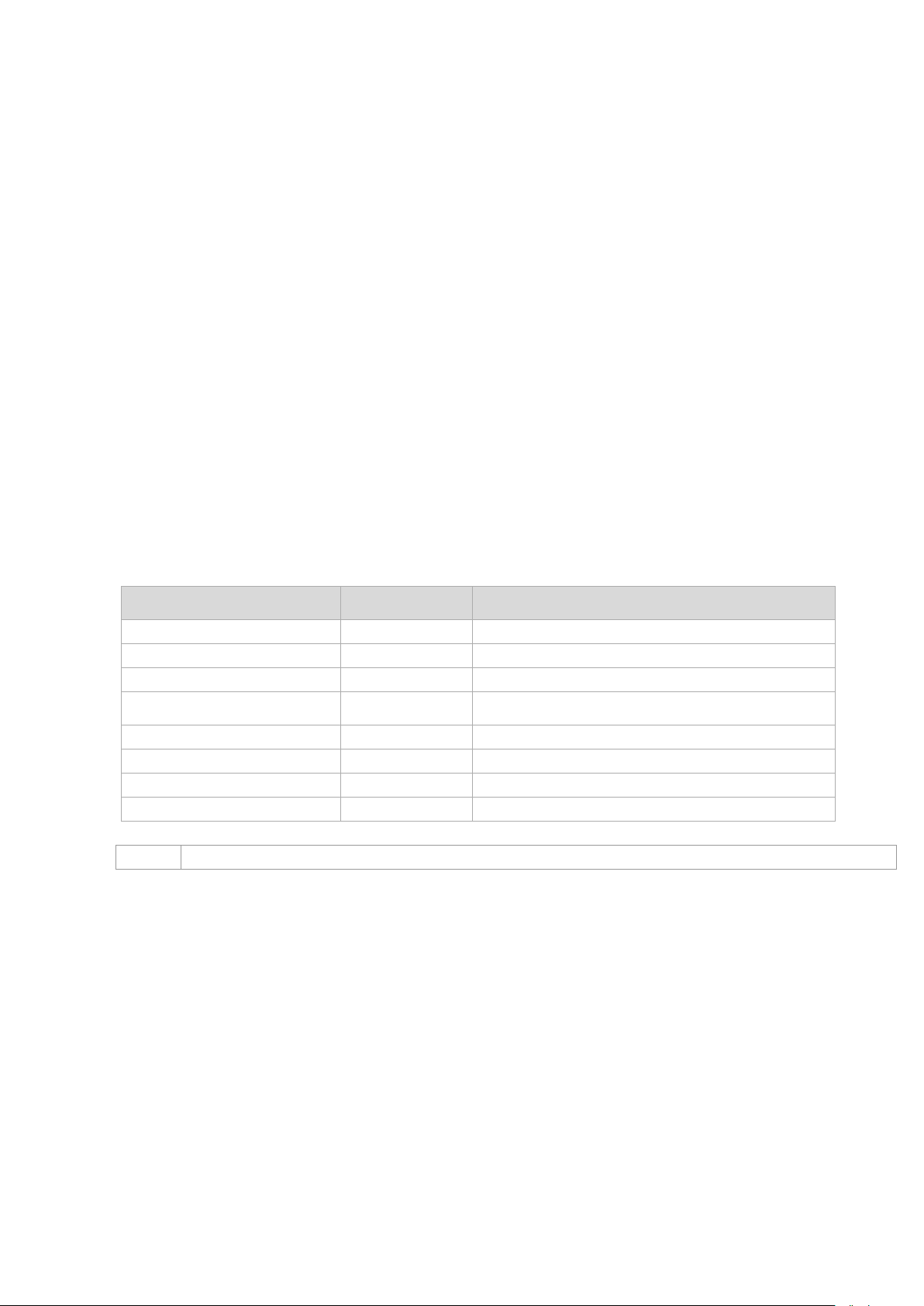

4.2 Scope of delivery

Designation

Part no.

Remarks

LAM71.101

225-0116

RS232 or RS42 (see connecting schema)

Accessories

Interface cable 3 m

18J25019

Interface cable 5 m

18J25020

Interface cable 10 m

18J25021

Light tube

18J25022

Device cables with angled plug-in connector are available upon request.

12

LAM71, Release 001_Revision 001

4.3 Laser beam image

Divergence of laser

Transmitter: 2 mrad x 0.4 mrad

Receiver: 5.8 mrad

The table below shows the size of the laser spot on the target in dependence on the distance.

Installation of LAM71

Lenses of LAM71 are vertical about each other.

Distance

Laser spot width

Laser spot height

Footprint laser spot

(not true to scale)

0.2 m

14 mm

9 mm

1 m

14 mm

10 mm

5 m

15 mm

19 mm

10 m

17 mm

30 mm

20 m

19 mm

51 mm

70 m

32 mm

157 mm

150 m

52 mm

327 mm

270 m

87 mm

625 mm

The above-mentioned laser spot holds approx. 50 % of the entire laser energy. An aura with less energy

forms around that spot.

LAM71, Release 001_Revision 001

13

5Installation and start of operation

5.1 Preparatory work prior to installation

•Remove the packaging of the LAM71 and accessories.

•Check the delivery for completeness.

•Examine the device and the accessories for damage.

5.2 Mechanical installation

The LAM71 can be screwed on 3 positions:

- front with 2 screws M3

- bottom side with 4 screws M3

- one small side with 3 screws M3

Length to be chosen depending on the counter piece.

Recommendation: Use screws with washer and ring washer

Screws are not included in the scope of delivery.

Exact positions are shown in the picture below.

The zero point for measurement is identical with the housing front face.

0 = zero point for measurement

tief = thread depth

Lasersender = laser transmitter

Figure 1 LAM71 dimensions

14

LAM71, Release 001_Revision 001

5.3 Connector pin assignment

Pin

Colour

Signal

Description

1

Brown

Q1

Switching output Q1

2

Blue

VDC-

GND of supply voltage

3

White

RS422 / RS232

Setting pin RS422 or RS232

4

Green

TX+

TXD

RS422 transmission data +

RS232 transmission data

5

Pink

RX-

RS422 receiving data -

6

Yellow

TX-

RS422 transmission data -

7

Black

Q2

Switching output Q2

8

Grey

RX+

RXD

RS422 receiving data +

RS232 receiving data

9

Red

VDC+

Supply voltage 10 … 30 V DC

10

Violet

TRIGIO

Trigger signal IN / OUT

11

Grey/ pink

QA

Analog output

12

Red/ blue

GND

Ground measurement

(for QA, RS232, RS422, Trigger)

Inverse polarity protection is provided.

Overvoltage protection is provided up to a maximum of 42 V DC.

The shield of the cable should be connected to the connector housing.

Open, unused cable wires must be insulated.

LAM71 connector: M12-A male panel mount connector 09 3491 970 12

Producer: Binder

Interface cable see chapter 4.2

LAM71, Release 001_Revision 001

15

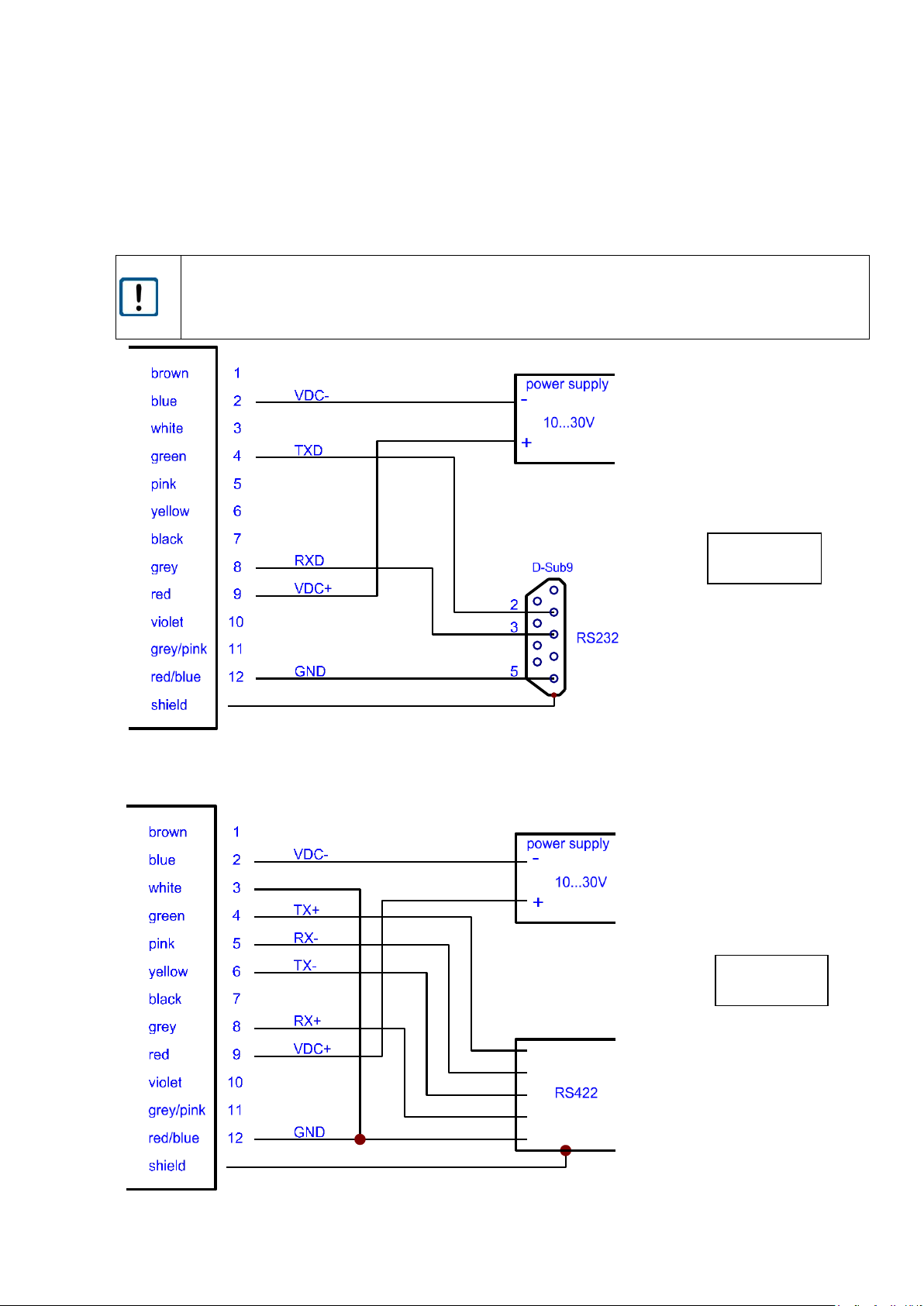

5.4 Serial interface RS232 / RS422

Before using the serial interface RS232 or RS422 the user has to check the connection of PIN 3 (white).

RS232 PIN 3 not connected

RS422 PIN 3 connected with PIN 12 (GND)

Figure 2 Wiring of serial interface RS232

Figure 3 Wiring of serial interface RS422

RS232

RS422

16

LAM71, Release 001_Revision 001

6Parameter setup and measuring operation

6.1 General information

The LAM71 is parameterized using the serial interface. Precondition for programming via UART is a con-

nection provided by a terminal program (e.g. HyperTerminal, Tera Term). The set parameters are stored

in an EEPROM. The last entered data will be available upon restarting.

Retrieval of parameters

Input PARAMETER <ENTER> <ENTER> = CR = (0x0D)

Setting of parameters

Input PARAMETER VARIABLE <ENTER>

The variables are described with the individual parameters.

Several variables are separated by spaces (0x20).

Starting a measurement (operating modes)

Input COMMAND <ENTER> <ENTER> = CR = (0x0D)

Stopping a measurement

<ESC> <ESC> = (0x1B)

Distances are always entered in meter (m).

Examples: 631 cm →Input: 6.310

5.123 m →Input: 5.123

The output values shown in the manual are examples. They may vary depending on the settings and

environmental conditions.

Whenever an incorrect or incomplete command is entered, the following responses are shown:

? The input does not contain any parameter or command.

e.g.: HELLO<ENTER>

Parameter with current value Entry of a parameter with incorrect figure/ parameterization

e.g.:

Input: SAxxx<ENTER>

Output: SA 10 (where SA = 10 prior to input)

The LAM71 has a measurement control LED.

The LED is flashing green during measuring without a failure.

The LED is flashing red if a failure is happened.

LAM71, Release 001_Revision 001

17

6.2 Measurement involving moving targets

Where measurements involve a moving object or the LAM71 is moved during measuring, this will have

an impact on the accuracy of the measured value. This must be observed particularly when calculating

average values (parameter SA).

6.3 Identification

6.3.1 ID recognition

When entering the command ID, the LAM71 will respond by displaying the manufacturer’s data in the

following order: ID, serial number, firmware version.

Query: ID Response: ID SN 180004 V3.38R 630

6.3.2 ID? –Online help

By entering the command ID? the user will obtain an overview of all available operations and para-me-

ters described in the following sections.

Query:

ID?

Response:

Operation Mode

DM[Enter]...................single distance

DT[Enter]...................continuous distance

Status

TP[Enter]...................internal temperature [°C]

HW[Enter]...................hardware status

PA[Enter]...................display parameter

Setup Parameter

PR[Enter]...................reset parameter

DR[Enter]...................reset device

AS[Enter]/ASs[Enter]........display/set autostart command

MF[Enter]/MFx[Enter]........display/set measure frequency

GN[Enter]/GNx[Enter]........display/set receiver gain

SA[Enter]/SAx[Enter]........display/set average value

MW[Enter]/MWx y z[Enter]....display/set measure window

OF[Enter]/OFx[Enter]........display/set distance offset

SO[Enter]...................set current distance to offset

SE[Enter]/SEx[Enter]........display/set error mode

Q1[Enter]/Q1w x y z[Enter]..display/set digital out Q1

Q2[Enter]/Q2w x y z[Enter]..display/set digital out Q2

QA[Enter]/QAx y[Enter]......display/set analog out QA

BR[Enter]/BRx[Enter]........display/set serial baud rate

SD[Enter]/SDx y[Enter]......display/set serial output format

UB[Enter]/UBx[Enter]........display/set unit for binary output

TE[Enter]/TEx[Enter]........display/set serial terminator

ST[Enter]/STx[Enter]........display/set first or last target for outout

TC[Enter]/TCx[Enter]........display/set DT recalibration timing x in sec (0 off)

TI[Enter]/TIx y[Enter]......display/setup input trigger

TO[Enter]/TOx[Enter]........display/setup output trigger

18

LAM71, Release 001_Revision 001

6.4 Operation modes

6.4.1 DM –single distance measurement

LAM71 performs one measurement and then waits for new commands.

The duration of the measurement depends on the number of preset measuring values SA and the pre-

set measuring frequency MF.

Input: DM

6.4.2 DT –Continuous distance measurement (distance tracking)

The LAM71 performs a continuous measurement.

The measurement can be interrupted by command:

ESC (Escape) = 0x1B

The measurement output frequency is determined by the number of preset measuring values SA, the

preset measuring frequency MF and the data format of serial output SD.

Parameter baud rate is important for the data transfer.

Input: DT

Example response (SD 0 3 setting):

D 0002.935 21.1 57.2

Output format = decimal (D)

Distance = 2.935 m

Signal quality = 21.1

Temperature = 57.2 °C

The output frequency of DT depends baud rate BR.

If the baud rate is to low not all measured values can be output / displayed.

LAM71, Release 001_Revision 001

19

6.5 Status

6.5.1 TP - Internal temperature

Output of the internal temperature of the device in °C

The internal temperature of the device is not the same as the operating temperature stated un-

der Technical Data (see chapter 9)! The internal Temperature will be approximately 25 Kelvin

higher as the ambient temperature.

Query:

TP

Example: TP 048.4

The user of the LAM71 must make sure that the stated ambient temperature (operating tempera-

ture) is adhered to. In case of deviations below or above the temperature range no measurement

is possible. The LAM71 will send an error message.

6.5.2 HW –hardware status

A device-specific list of parameters and measurements is shown.

All parameters are internal information regarding the hardware status, changes are not possible.

Query:

HW

Example:

Temp (Board) 45.0°C

Laser voltage 25485mV

Measure Result 0

20

LAM71, Release 001_Revision 001

Explanation of the hardware status items:

Error code

Fault indication

Temp (Board)

Temperature of the controller, internal

Laser-Voltage

Supply voltage Laser Diode Driver

Measure Result

Classification of measurement conditions, information to source of error message

0 –measurement o.k.

1 –out of measurement window

2 –invalid pulse width

3 –small pulse width

4 –distance out of range

5 –noise pulses detected

6 –no pulses

6.5.3 PA –Display Parameter setting

Output of a parameter list with the current settings

Query:

PA

Response:

measure frequency[MF]............500(max 40000)Hz

average value[SA]................2

measure window[MW]...............-290.000 290.000 0

trigger in[TI]...................internal trigger

trigger out[TO]..................rising edge

distance offset[OF]..............0.000

error mode[SE]...................1

digital out[Q1]..................0.000 1.000 0.050 1

digital out[Q2]..................0.000 1.000 0.050 1

analog out[QA]...................0.000 1.000

receiver gain[GN]................0

serial baud rate[BR].............115200

serial output format[SD].........dec (0), value+amplitude (1)

unit for binary output[UB].......1000.000

serial output terminator[TE].....0Dh0Ah (0)

autostart command[AS]............DT

select target[ST]................0/first

recalibration timing[TC].........1 sec/enabled

LAM71, Release 001_Revision 001

21

6.5.4 PR –Parameter reset

All parameters are reset to the factory settings except baud rate (BR) and target selection (ST)

Query:

PR

Response:

reset parameter

measure frequency[MF]............10000(max 40000)Hz

average value[SA]................1000

measure window[MW]...............-290.000 290.000 0

trigger in[TI]...................internal trigger

trigger out[TO]..................rising edge

distance offset[OF]..............0.000

error mode[SE]...................1

digital out[Q1]..................0.000 1.000 0.050 1

digital out[Q2]..................0.000 1.000 0.050 1

analog out[QA]...................0.000 1.000

receiver gain[GN]................0

serial baud rate[BR].............115200

serial output format[SD].........dec (0), value (0)

unit for binary output[UB].......1000.000

serial output terminator[TE].....0Dh0Ah (0)

autostart command[AS]............DT

select target[ST]................0/first

recalibration timing[TC].........1 sec/enabled

22

LAM71, Release 001_Revision 001

6.6 Setup parameters

Transfer of the settings to the LAM71: Command + terminator 0x0D (ENTER). In case of commands with

one parameter, that parameter is entered directly or separated by a space (0x20). In case of commands

with several parameters, those are separated from each other by a space (0x20).

6.6.1 AS –Autostart function

The autostart function determines what the LAM71 does after a cold start.

Upon connection to the supply voltage and after the internal switch-on routine, the LAM71 carries out

the command automatically and sends the data to the available outputs.

Query:

AS

Set:

ASx

Value range

parameter x:

BR, DM, DT, HW, ID, ID?, MF, MW, OF, PA, PR, Q1, Q2, QA, SA,

SE, SD, TE, TP

Standard:

DT

The period of time between switching on the supply voltage and the output of the first measured value

is max. 750 ms (if SA=1).

6.6.2 BR –Baud rate

BR enables the adjustment of the serial baud rate x.

As soon as a new baud rate has been set, the device will immediately start to communicate based on

that new baud rate.

Query:

BR

Set:

BRx

Value range parameter x:

9600, 19200, 115200, 230400, 460800, 921600, 1843200, 2000000

Standard:

115200 bauds/ 8 data bits /1 stop bit / no parity

Setting a very high baud rate implies a risk. Some computers are unable to support a baud rate of

460 800, for example. If the baud rate is set via the command BR460800, communication will no

longer be possible without an interface converter, i.e. it will be impossible to reset the baud rate

to a lower value without any auxiliary means!

Example:

Input: BR 9600

Output: BR 9600

Table of contents

Popular Accessories manuals by other brands

Oregon Scientific

Oregon Scientific WS113 user manual

VARSITY Scoreboards

VARSITY Scoreboards VSBX-630LED Operation instructions

Keysight Technologies

Keysight Technologies U8480 Series Service guide

Cello

Cello 502432086 Mounting and user instructions

Meiko

Meiko TopClean M Instructions for use

Efficold

Efficold VRA user manual

Super Tramp

Super Tramp ESN NET user guide

LT

LT LTS-1-01 Series Translation of the original operating instructions

Viking Range

Viking Range LPKPDR installation guide

Celestron

Celestron CGE1100 supplementary guide

Siargo

Siargo AM1000 Series user manual

Nobile

Nobile Smartmatic Ambient Mounting Operation Instruction