SENTRONIC Mini-M Series User manual

MODEL: M2SES2

Super-mini Signal Conditioners Mini-M Series

HIGH/LOW SELECTOR

(with simple loop test output)

Functions & Features

• Monitors two DC input signals and transmitting an output

signal proportional to the higher or lower input

• Simple loop test output (0, 50, 100 %)

• High-density mounting

• CE marking

Typical Applications

• Selecting greater flow, pressure, etc. for control

• Heating control by multiple T/C’s on a furnace

Model

SPAN

ZERO

INP1

SPAN

ZERO

STAT2

STAT1

INP2

23 (.91)

76

(2.99)

mm (inch)

124

(4.88)

MODEL: M2SES2–[1][2]–[3][4]

ORDERING INFORMATION

• Code number: M2SES2-[1][2]-[3][4]

Specify a code from below for [1] and [4].

(e.g. M2SES2-AA-M2/CE/Q)

• Special output range (For codes Z & 0)

• Specify the specification for option code /Q

(e.g. /C01/S01)

[1] INPUT

Current

A: 4 – 20 mA DC (Input resistance 250 Ω)

B: 2 – 10 mA DC (Input resistance 500 Ω)

C: 1 – 5 mA DC (Input resistance 1000 Ω)

H: 10 – 50 mA DC (Input resistance 100 Ω)

Voltage

6: 1 – 5 V DC (Input resistance 1 MΩ min.)

[2] OUTPUT

Current

A: 4 – 20 mA DC (Load resistance 750 Ω max.)

B: 2 – 10 mA DC (Load resistance 1500 Ω max.)

C: 1 – 5 mA DC (Load resistance 3000 Ω max.)

D: 0 – 20 mA DC (Load resistance 750 Ω max.)

E: 0 – 16 mA DC (Load resistance 900 Ω max.)

F: 0 – 10 mA DC (Load resistance 1500 Ω max.)

G: 0 – 1 mA DC (Load resistance 15 kΩ max.)

Z: Specify current (See OUTPUT SPECIFICATIONS)

Voltage

1: 0 – 10 mV DC (Load resistance 10 kΩ min.)

2: 0 – 100 mV DC (Load resistance 100 kΩ min.)

3: 0 – 1 V DC (Load resistance 1000 Ω min.)

4: 0 – 10 V DC (Load resistance 10 kΩ min.)

5: 0 – 5 V DC (Load resistance 5000 Ω min.)

6: 1 – 5 V DC (Load resistance 5000 Ω min.)

4W: -10 – +10 V DC (Load resistance 10 kΩ min.)

5W: -5 – +5 V DC (Load resistance 5000 Ω min.)

0: Specify voltage (See OUTPUT SPECIFICATIONS)

[3] POWER INPUT

AC Power

M: 85 – 264 V AC (Operational voltage range 85 – 264 V,

47 – 66 Hz)

(Select ‘/N’ for ‘Standards & Approvals’ code.)

M2: 100 – 240 V AC (Operational voltage range 85 – 264 V,

47 – 66 Hz)

DC Power

R: 24 V DC

(Operational voltage range 24 V ±10 %, ripple 10 %p-p max.)

R2: 11 – 27 V DC

(Operational voltage range 11 – 27 V, ripple 10 %p-p max.)

(Select ‘/N’ for ‘Standards & Approvals’ code.)

P: 110 V DC

(Operational voltage range 85 – 150 V, ripple 10 %p-p max.)

[4] OPTIONS (multiple selections)

STANDARDS & APPROVALS (must be specified)

/N: Without CE or UL

/CE: CE marking

OTHER OPTIONS

blank: none

/Q: Option other than the above (specify the specification)

SPECIFICATIONS OF OPTION: Q (multiple selections)

COATING (For the detail, refer to M-System's web site.)

/C01: Silicone coating

/C02: Polyurethane coating

/C03: Rubber coating

TERMINAL SCREW MATERIAL

/S01: Stainless steel

GENERAL SPECIFICATIONS

Construction: Plug-in

Connection: M3 screw terminals (torque 0.8 N·m)

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2SES2

Housing material: Flame-resistant resin (black)

Isolation: Input to output to power

Overrange output: Approx. -10 to +120 % at 1 – 5 V

Input zero adjustments: -2 to +2 % (front)

Input span adjustments: 98 to 102 % (front)

DIP switch setting: Selecting output options

Status indicator LED 1: Green LED; indicates the

transmitter’s function mode (Refer to the instruction

manual.)

Status indicator LED 2: Orange LED; indicates the

transmitter’s function mode (Refer to the instruction

manual.)

INPUT SPECIFICATIONS

• DC Current: Input resistor incorporated

OUTPUT SPECIFICATIONS

• DC Current: 0 – 20 mA DC

Minimum span: 1 mA

Offset: Max. 1.5 times span

Load resistance: Output drive 15 V max.

• DC Voltage: -10 – +12 V DC

Minimum span: 5 mV

Offset: Max. 1.5 times span

Load resistance: Output drive 1 mA max.; at ≥ 0.5 V

INSTALLATION

Power Consumption

•AC Power input:

Approx. 3 VA at 100 V

Approx. 4 VA at 200 V

Approx. 5 VA at 264 V

•DC Power input: Approx. 3 W

Operating temperature: -5 to +55°C (23 to 131°F)

Operating humidity: 30 to 90 %RH (non-condensing)

Mounting: Surface or DIN rail

Weight: 150 g (0.33 lbs)

PERFORMANCE in percentage of span

Accuracy: ±0.2 %

Temp. coefficient: ±0.015 %/°C (±0.008 %/°F)

Response time: ≤ 0.5 sec. (0 – 90 %)

Line voltage effect: ±0.1 % over voltage range

Insulation resistance: ≥ 100 MΩ with 500 V DC

Dielectric strength: 2000 V AC @1 minute (input to output

to power to ground)

STANDARDS & APPROVALS

CE conformity:

EMC Directive (2004/108/EC)

EN 61000-6-4 (EMI)

EN 61000-6-2 (EMS)

Low Voltage Directive (2006/95/EC)

EN 61010-1

Installation Category II

Pollution Degree 2

Max. operating voltage 300 V

Input or output to power: Reinforced insulation

Input to output: Basic insulation

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

MODEL: M2SES2

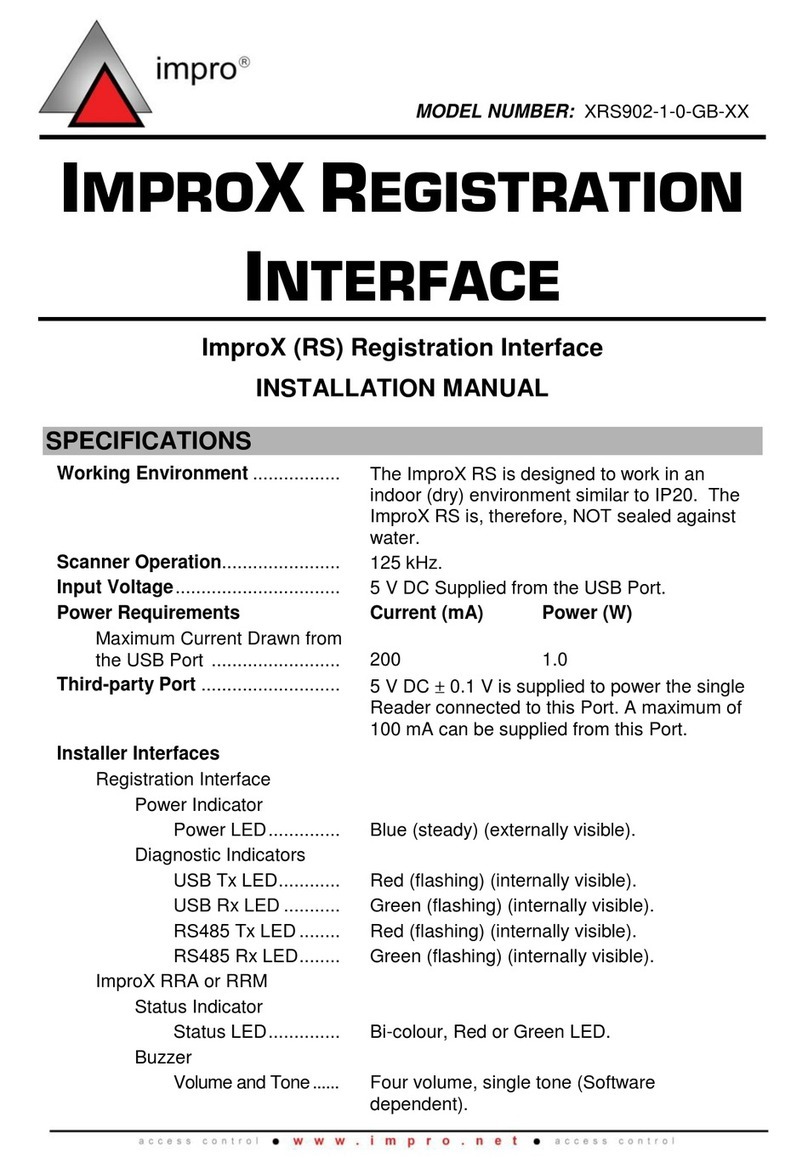

EXTERNAL VIEW

■FRONT VIEW ■SIDE VIEW

OFF

ON

1 2 3 4

SW1

Output Function

Setting

Zero Adj. (ZERO1)

Span Adj. (SPAN1)

Zero Adj. (ZERO2)

Status Indicator LED1

Status Indicator LED2

Span Adj. (SPAN2)

Input 2

Input 1

Refer to the instruction manual for detailed procedures.

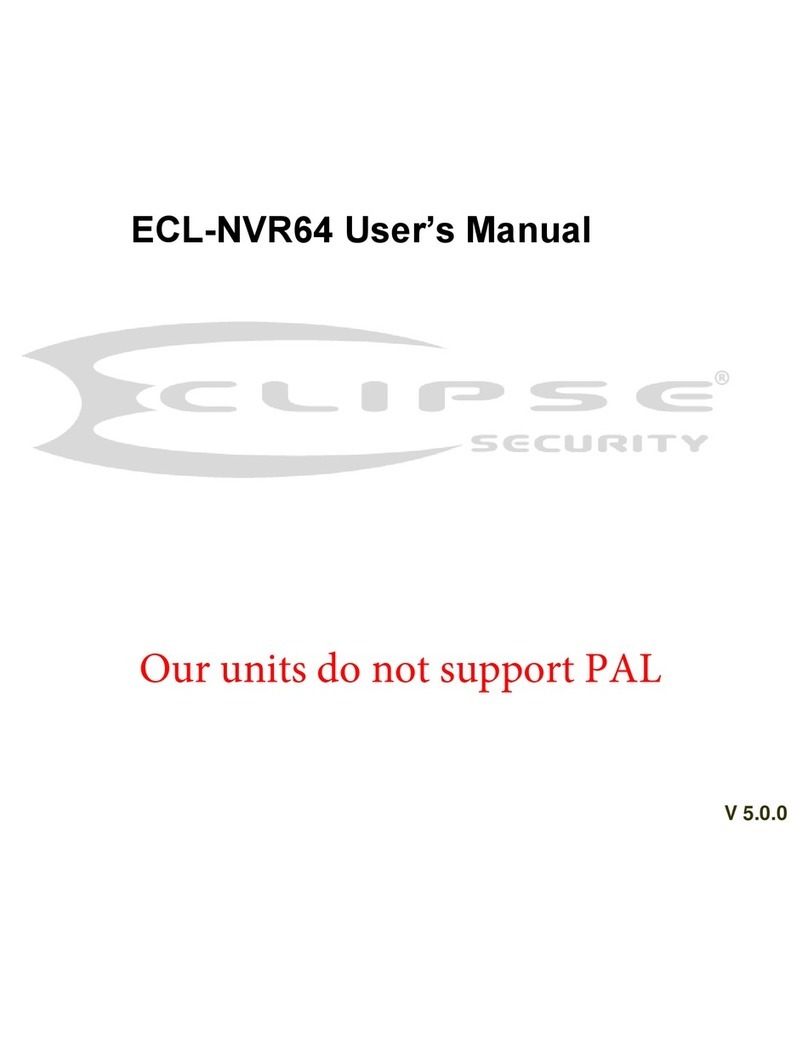

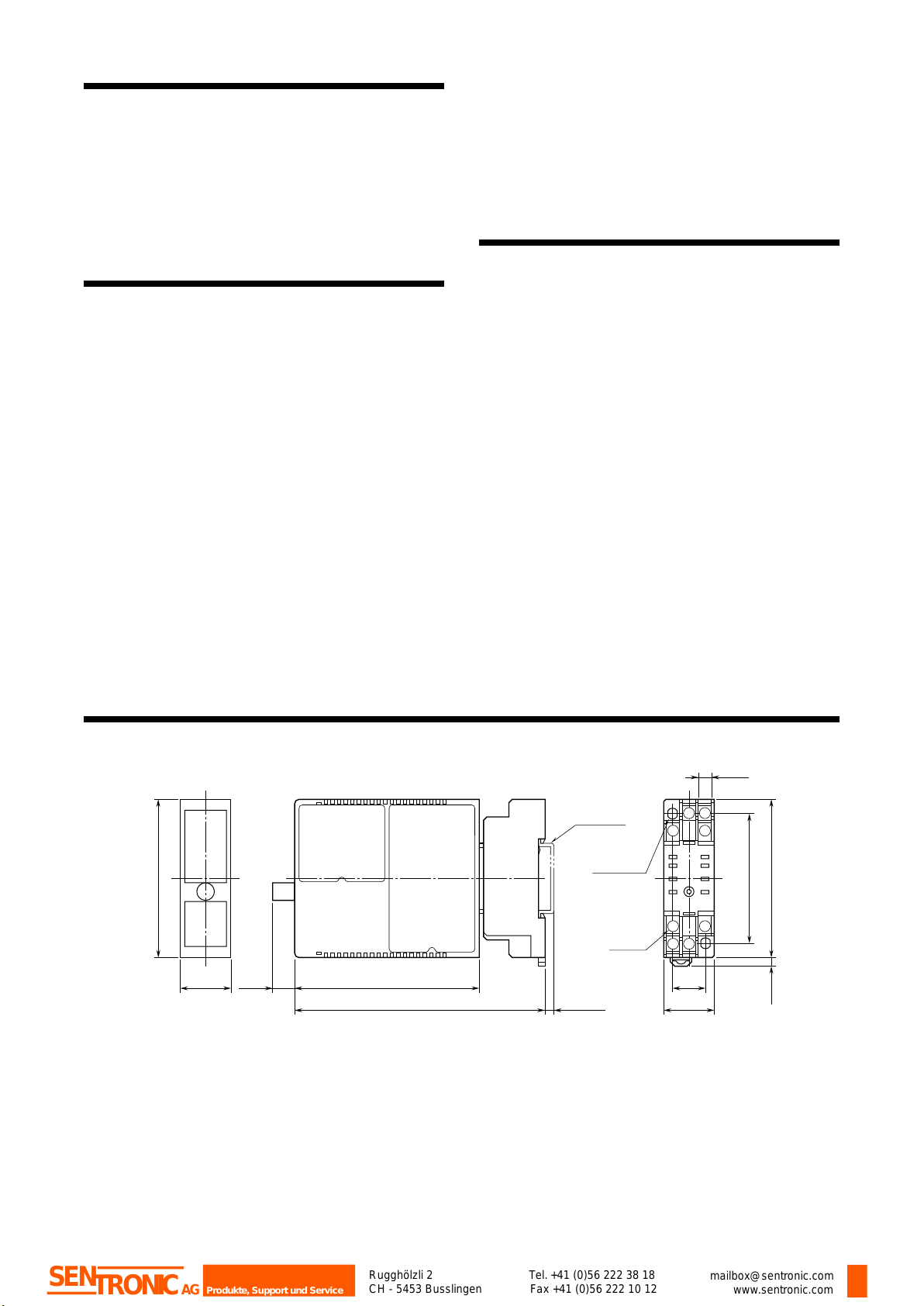

DIMENSIONS unit: mm (inch)

5

9

21.5 (.85)

70.5 (2.78)

84 (3.31)10 (.39) 15 (.59)

6 (.23)

59 (2.32)

DIN RAIL

35mm wide

[4 (.16)]

8–M3

SCREW

72 (2.83)

23 (.91)

2–4.2x5

(.17x.20)

MTG HOLE

6 (.24) deep

114 (4.49)

• When mounting, no extra space is needed between units.

4

8

12

14 13

1

4 (.16)

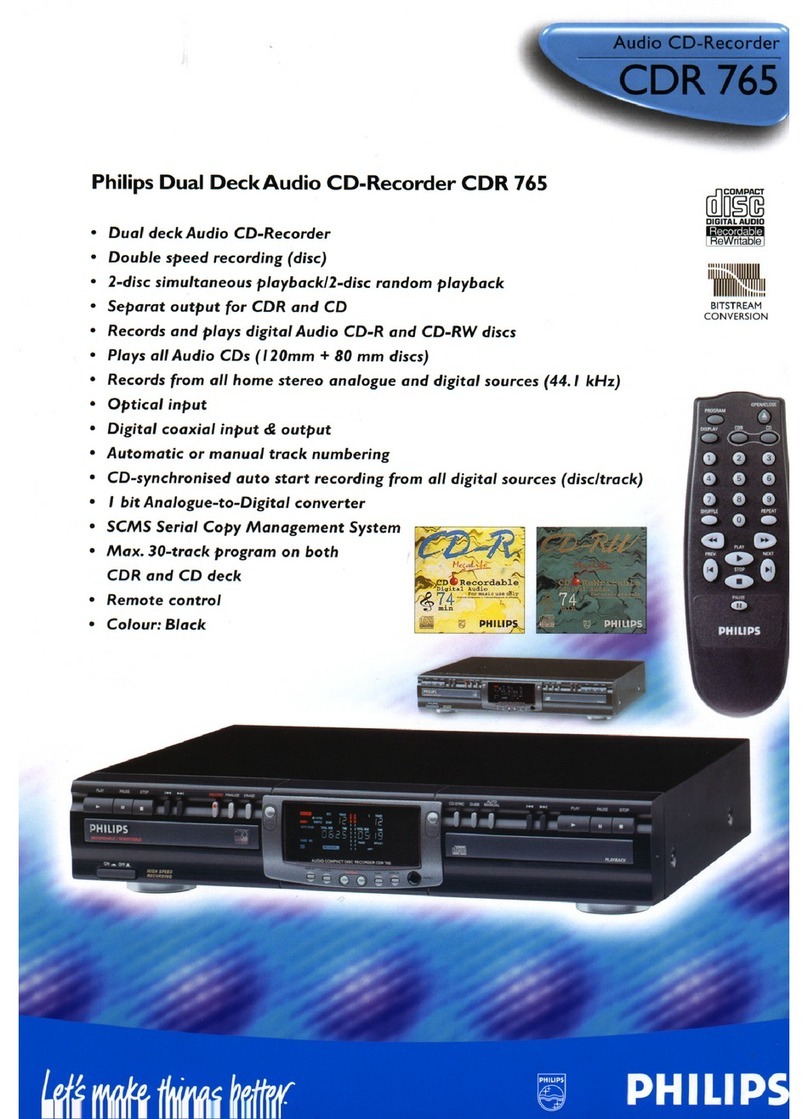

SCHEMATIC CIRCUITRY & CONNECTION DIAGRAM

+

–

Isolation

Base Socket

*Input shunt resistor incorporated for current inputs.

Selector Output

Driver OUTPUT

9

12

U(+)

V(–) POWER

1

+

–

INPUT 2 5

8

+

–

INPUT 1 4

13

14

*

*

DIP SWITCH

STATUS

SZSZ

Specifications are subject to change without notice.

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2SES2

P. 1 / 3EM-5098 Rev.1

HIGH/LOW SELECTOR MODEL M2SES2

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■ PACKAGE INCLUDES:

Signal conditioner (body + base socket) ...................... (1)

■ MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■ INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■ CONFORMITY WITH EC DIRECTIVES

• This equipment is suitable for use in a Pollution Degree

2 environment and in Installation Category II, with the

maximum operating voltage of 300V.

Basic insulation is maintained between signal input and

output. Prior to installation, check that the insulation

class of this unit satisfies the system requirements.

• Altitude up to 2000 meters

•The equipment must be mounted inside a panel.

• The equipment must be installed such that appropriate

clearance and creepage distances are maintained to con-

form to CE requirements. Failure to observe these re-

quirements may invalidate the CE conformance.

■ POWER INPUT RATING & OPERATIONAL RANGE

•Locate the power input rating marked on the product and

confirm its operational range as indicated below:

100 – 240V and 85 – 264V AC rating: 85 – 264V,

47 – 66 Hz, approx. 3 – 5VA

24V DC rating: 24V ±10%, approx. 3W

11 – 27V DC rating: 11 – 27V, approx. 3W

110V DC rating: 85 – 150V, approx. 3W

■ GENERAL PRECAUTIONS

• Before you remove the unit from its base socket or mount

it, turn off the power supply and input signal for safety.

■ ENVIRONMENT

• Indoor use

•When heavy dust or metal particles are present in the air,

install the unit inside proper housing with sufficient ven-

tilation.

• Do not install the unit where it is subjected to continuous

vibration. Do not subject the unit to physical impact.

• Environmental temperature must be within -5 to +55°C

(23 to 131°F) with relative humidity within 30 to 90% RH

in order to ensure adequate life span and operation.

• Be sure that the ventilation slits are not covered with ca-

bles, etc.

■ WIRING

• Do not install cables (power supply, input and output)

close to noise sources (relay drive cable, high frequency

line, etc.).

• Do not bind these cables together with those in which

noises are present. Do not install them in the same duct.

■ AND ....

• The unit is designed to function as soon as power is sup-

plied, however, a warm up for 10 minutes is required for

satisfying complete performance described in the data

sheet.

• With voltage output, do not leave the output terminals

shortcircuited for an extended time period. The unit is

designed to endure it without breakdown, however, it may

shorten appropriate life duration.

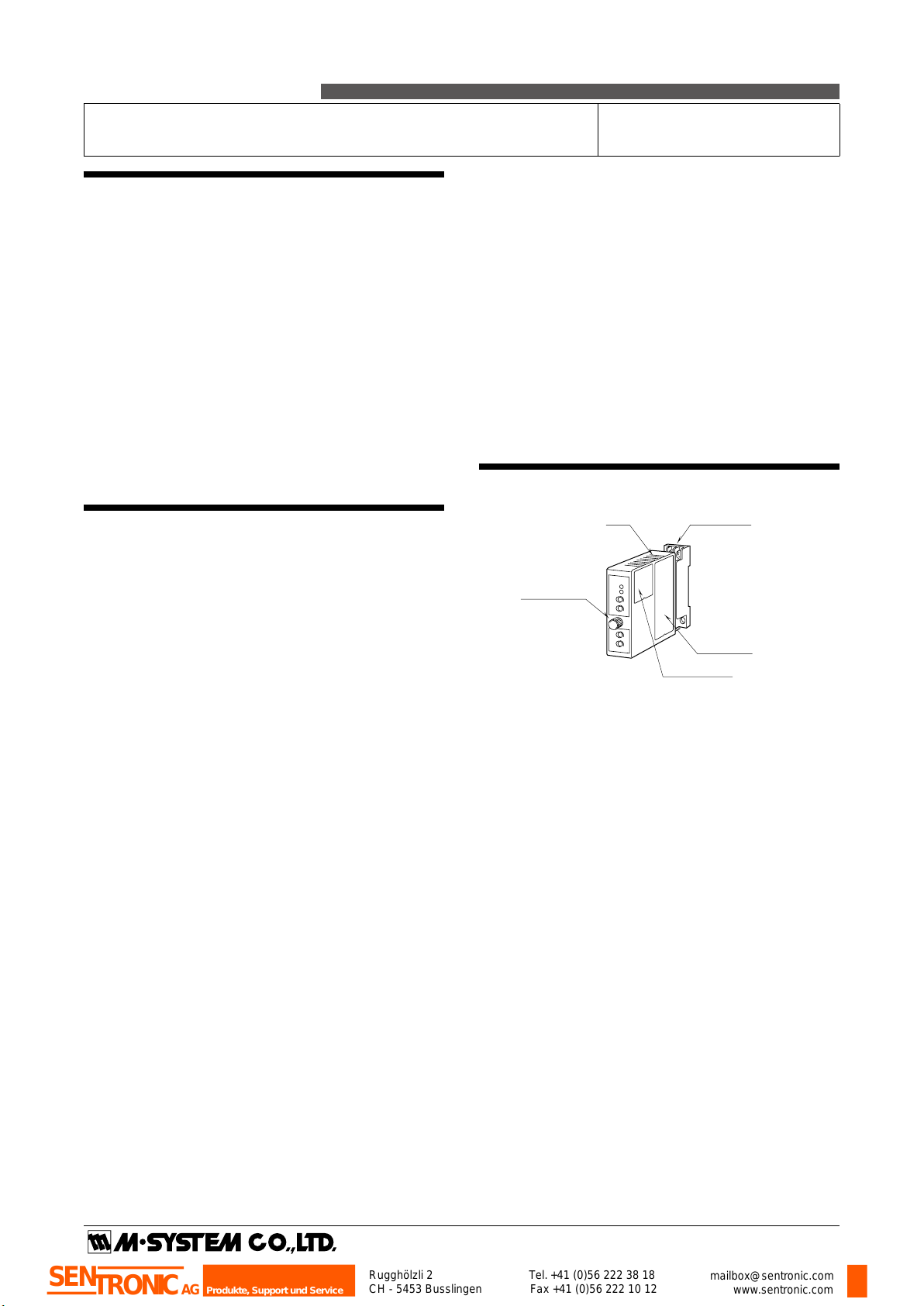

COMPONENT IDENTIFICATION

Model

SPAN

ZERO

INP1

SPAN

ZERO

STAT2

STAT1

INP2

Body Base Socket

Connection

Diagram

Specifications

Fixing Screw

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2SES2

P. 2 / 3EM-5098 Rev.1

INSTALLATION

Loosen the fixing screw at the front of the unit in order to

separate the body from the base socket.

■ DIN RAIL MOUNTING

Set the base socket so that

its DIN rail adaptor is at

the bottom. Position the

upper hook at the rear side

of base socket on the DIN

rail and push in the lower.

When removing the socket,

push down the DIN rail

adaptor utilizing a minus

screwdriver and pull.

■ WALL MOUNTING

Refer to the drawings be-

low.

+

–

1OUTPUT

4

9

12

U(+)

V(–) POWER

13

14

+

–

INPUT 1

5

8

+

–

INPUT 2

FRONT VIEW

■FRONT VIEW ■SIDE VIEW

OFF

ON

1234

SW1

Output Function

Setting

Zero Adj. (ZERO1)

Span Adj. (SPAN1)

Zero Adj. (ZERO2)

Status Indicator LED1

Status Indicator LED2

Span Adj. (SPAN2)

Input 2

Input 1

DIN Rail

35mm wide

Spring Loaded

DIN Rail Adaptor

TERMINAL CONNECTIONS

Connect the unit as in the diagram below or refer to the con-

nection diagram on the side of the unit.

■ DIP SWITCH SETTING

Choose the output function: High/Low output, normal output proportional to the input 1, or loop test output of 0%, 50% and

100%.

Set the DIP switch to appropriate positions before turning on the power supply. No change in the switch positions is valid

while the power is supplied.

OUTPUT SW1-1 SW1-2 SW1-3 SW1-4 STAT1LED STAT2LED

High signal (*) OFF OFF OFF OFF ON OFF

Low signal ON OFF OFF OFF ON OFF

Input 1 *1 ON OFF OFF ON OFF

0% *1 *1 ON OFF OFF ON

50% *1 *1 OFF ON Blinking ON

100% *1 *1 ON ON ON ON

*1. ON/OFF position is irrelevant.

(*) Factory setting

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

M2SES2

CHECKING

1) Terminal wiring: Check that all cables are correctly con-

nected according to the connection diagram.

2) Power input voltage: Check voltage across the terminal

13 – 14 with a multimeter.

3) Input: Check that the input voltage is within 0 – 100% of

full-scale.

4) Output: Check that the load resistance meets the de-

scribed specifications.

ADJUSTMENT PROCEDURE

This unit is calibrated at the factory to meet the ordered

specifications, therefore you usually do not need any cali-

bration.

For matching the signal to a receiving instrument or in case

of regular calibration, adjust the output as explained in the

following.

■ HOW TO CALIBRATE THE OUTPUT SIGNAL

Use a signal source and measuring instruments of sufficient

accuracy level. Turn the power supply on and warm up for

more than 10 minutes. Be sure to start with the Input 1

adjustment.

1) Turn all DIP switches to OFF positions. (Selecting High

signal)

2) Set Input 2 lower than 0%.

3) Input 1 ZERO (ZERO1): Apply 0% input and adjust out-

put to 0%.

4) Input 1 SPAN (SPAN1): Apply 100% input and adjust

output to 100%.

5) Check Input 1 ZERO adjustment again with 0% input.

6) When ZERO value is changed, repeat the above proce-

dure 3) – 5).

5

9

21.5(.85)

70.5 (2.78)

84 (3.31)10 (.39) 15(.59)

6(.23)

59 (2.32)

DIN RAIL

35mm wide

[4 (.16)]

8–M3

SCREW

72 (2.83)

23 (.91)

2–4.2x5

(.17x.20)

MTG HOLE

6 (.24) deep

114 (4.49)

• When mounting, no extra space is needed between units.

4

8

12

14 13

1

4 (.16)

7) Set Input 1 lower than 0%.

8) Input 2 ZERO (ZERO2): Apply 0% input and adjust out-

put to 0%.

9) Input 2 SPAN (SPAN2): Apply 100% input and adjust

output to 100%.

10

)Check Input 2 ZERO adjustment again with 0% input.

11

)When ZERO value is changed, repeat the above proce-

dure 8) – 10).

MAINTENANCE

Regular calibration procedure is explained below:

■ CALIBRATION

Warm up the unit for at least 10 minutes. Apply 0%, 25%,

50%, 75% and 100% input signal. Check that the output

signal for the respective input signal remains within accu-

racy described in the data sheet. When the output is out of

tolerance, recalibrate the unit according to the “ADJUST-

MENT PROCEDURE” explained earlier.

EXTERNAL DIMENSIONS unit: mm (inch)

Rugghölzli 2

CH - 5453 Busslingen Tel.+41 (0)56 222 38 18

Fax +41 (0)56 222 10 12 mailbox@sentronic.com

www.sentronic.com

Produkte, Support und Service

SENTRONICAG

This manual suits for next models

1

Table of contents