Serco S-420 User manual

S-420

RIGID DOCK SHELTER

W/ INTEGRATED

S-900DD DRYDOCK®

RAIN SEAL SYSTEM

SERCO STEELGALVANIZED STEEL FRAMING

Installation Instructions

FORM NO: 4F-420-DD-INT-9/16

PART NUMBER: T31645

Do not install this product unless you read and

understand the Warnings and Installation

Instructions contained in this manual. Failure to

do so could result in serious injury or death.

4Front Engineered Solutions, Inc.

W183 S8253 Racine Avenue

Muskego, WI 53150

Tel: (262) 679-6200

Fax: (262) 679-6210

WARNING

1. Mark centerline location of door opening width on dock floor. Take ½ of the truck shelter or wiper seal

head frame width and mark this distance on either side of door centerline.

NOTE:This will determine position of outside edges of foam side members.

Serco S-420 Rigid Dock Shelters with the integrated S-900DD® Rain Seal System are custom built for each

application. Installation procedures are the same for all S-420/ S-900DD Dock Shelters regardless of size.

Installation requires two people and a forklift truck or similar device to lift and position the shelter components.

Lifting equipment to be determined by installer.

Improper installation of anchoring devices or installation into aged or unsound concrete or other faulty or

inadequate building wall construction could result in serious injury or death, as well as premature product

wear, product failure or property damage.

Inadequate lifting equipment or unsafe lifting practices can cause a load to fall, tip or swing unexpectedly.

Make sure lifting devices are in good condition and have a rated capacity of at least 500 lbs. at the lifting angle

being used. Never allow anyone to stand on or near the dock shelter component when it is lifted or placed.

Failure to follow this warning could result in serious personal injury or death to bystanders if component

unexpectedly falls, tips or swings. If you have any questions contact your supervisor or your local Serco

distributor for assistance.

A

ssembly of components should be performed in such a way so as to maintain cleanliness of equipment before

final installation. Lifting equipment to be determined by installer (man lift and forklift or boom lift typical). Wear

safety glasses, gloves, hard hats, safety shoes and all necessary protective clothing.

WARNING

MANDATORY INSTALLATION NOTE:

To insure proper functioning of the S-900DD DryDock rain seal system, this rigid frame dock shelter must

be applied so that top of shelter is in a range of from 14’-10” to 15’-2 off grade. Installation of the top of

the shelter at less than 14’-10” off grade may result in damage to the DryDock. Installation of the top of

the shelter at greater than 15’-2” of grade will reduce or eliminate the DryDock’s rain sealing

effectiveness. Correctness of product sizing for various applications must be established at the time of

equipment order.

SERCO S-420 RIGID FRAME DOCK SHELTER W/ INTEGRATED

S-900DD DRYDOCK RAIN SEAL SYSTEM

2. Mount steel supports. Outside edge of steel support protector should be placed at mark on dock wall.

Top flat surface of steel support should be mounted level with dock floor or at the top of raised dock

bumpers. Use supports as either right or left.

3. Mount side frames to wall. Side frame is positioned on top of flat portion of steel support protector.

The outside edge of the side frame should be flush with outside edge of steel support protectors. Be sure

frames are plumb from top to bottom. Three (3) anchors are recommended for each side frame. Unscrew

and remove cross banding on side frames.

! IMPORTANT !

IF BUILDING WALL SURFACE IS IRREGULAR, DAMAGE TO SIDE AND HEAD FRAME COVER

MATERIAL CAN OCCUR AS ANCHORING FASTENERS ARE TIGHTENED. USE SHIMS AS

REQUIRED TO COMPENSATE FOR IRREGULARITIES. TIGHTEN FRAME TO WALL CAREFULLY.

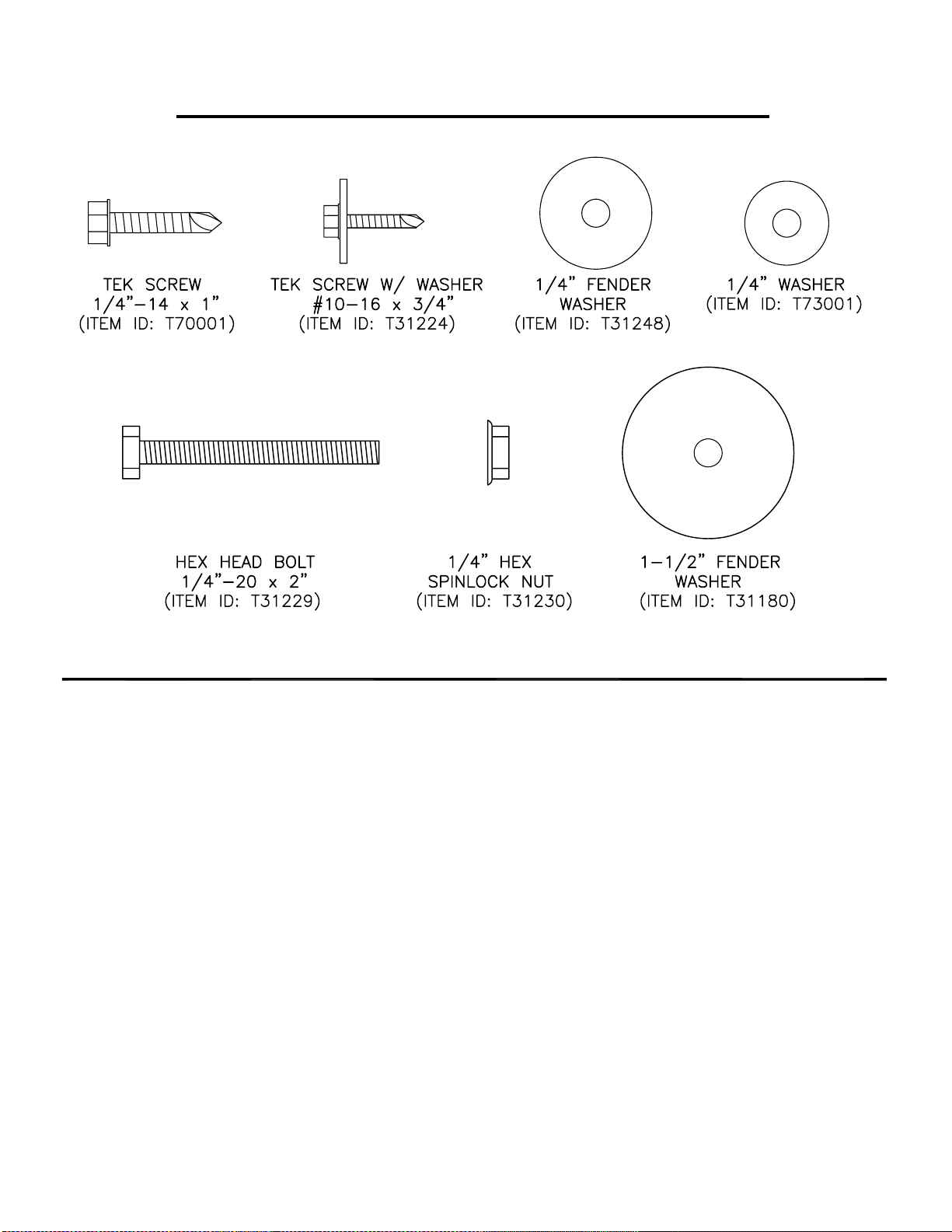

4. Attach side frames to steel supports using ¼” bolt, spinlock nut and 1-½” fender washers (provided)

through pre-punched hole in top of steel support. If pre-punched holes don’t align due to dock offset, drill

hole in side frame as required.

5. Assemble side curtains to side frames. Position side curtain on frame and push panel clip (pre-

inserted in side curtain) into pre-drilled hole in top front of side frame. Aluminum angle must be mounted

flush with bottom of side frame. Fasten aluminum angle to side frame with TEK screws (supplied) through

V-groove on angle and stays, and at 4” up from bottom of side frame.

7. Mount shelter head frame to wall. Center head frame on top of side frames, taking care to avoid damage to

fiberglass at top of side frame. It is necessary to anchor head frame to building in three (3) locations, one

on center and two approx. 12” from each end. For mounting on metal building walls, an a factory installed rear

brace on head frame is required. Three (3) anchors for this style of head frame are recommended (two anchors

evenly spaced is acceptable). Mounting anchors must support 1150 lbs in tension.

6. Attach wiper seal head frame mounting angles to truck shelter head frame. Position mounting angles as

shown with long leg of angle against ends of head frame. Fasten #10-16 x ¾” TEK screws through holes in long

leg of head frame bracket into side of head frame. These screws will be removed and re-installed through side

cover fabric later in the installation process. Note: Truck shelter head frame does not have stop plate on

front or head curtain mounting angle on bottom. These items are found on the wiper seal head frame.

8. Attach head frame to the side frames. Use 3” x 3” x 1” angle brackets with TEK screws to connect

bottom of head frame to top front inside edges of side frame. Removal of head frame banding is optional.

Fasten ¼”–14 x 1” TEK screws through top of side frame, head frame mounting angle, and bottom of head

frame in 3” from front and back of head frame.

9. Attach foam wiper pad to wiper seal head frame stop plate. Position back of wiper seal head frame on the

ground and secure from tipping over. Mark a reference line on the front of the stop plate that extends between

the top corners of head frame. Mount top of foam wiper even with this reference line.

NOTE: Clamp a temporary 1” to 2” spacer (by others) between back of foam wiper and front of top plate. This

provides the foam wiper with a forward bias after attachment.

Screw through galvanized steel strip (located inside pocket in top flap) and stop plate on 12” centers with self-

drilling TEK screws (provided). A portion of the top flap of the foam wiper will extend above the top of the stop

plate. Fold this fabric over the top of edge of the stop plate and cap with the plastic trim provided.

10. Connect wiper seal head frame to truck shelter head frame. Remove banding from bottom of wiper seal

head frame. Loosen TEK screws closest to the ends of the head curtain mounting angle to provide clearance for

the wiper seal mounting angle. Slide wiper seal head frame onto mounting angles. Fasten to shelter head frame

using (6) TEK screws in a minimum of three (3) areas (center and approx. 12” from each end). Fasten TEK

screws through bottom of mounting angle into bottom wiper seal head frame. Re-tighten TEK screws in head

curtain mounting angles.

11. Mount side covers to combined head frame assembly. Remove and save TEK screws from shelter head

frame fiberglass along top end. Remove and save TEK screws (installed in Step 5) from head frame mounting

angle and end of head frame and save. Insert 1-½” flap at top of side covers between fiberglass and steel frame

and re-install TEK screws. Fasten side cover to ends of head frame through head curtain mounting angle holes,

in two locations on back edge and two locations on front edge of side frames.

12. Assemble head curtain to head frame. Center head curtain on head curtain mounting angle and

fasten with ¼” x 1” TEK screws through ¼” washers. All stays must be fastened to mounting angle.

Fasten curtain at each end and in two places evenly spaced over pleats.

13. Attach side curtain retention straps to head curtain mounting angle. Connect between grommet

tab on top inside edge of side curtain and holes in bottom leg of head curtain mounting angle. Crimp ends

of S-hooks.

14. Attach head curtain wind straps to side frames. Attach end of wind strap to head curtain grommet

tab. Extend strap to nearest curtain screw below the grommet tab, loosen screw and attach S-hook

behind aluminum angle and screw head. Crimp ends of S-hooks. Tighten curtain screw. (Wind straps

must not be pulled to a higher or lower curtain screw).

15. Attach draft pads. Bottom of pad should be level with dock floor. Attach to inside of side frame with

aluminum angle over fabric flap using TEK screws in two locations. Insure snug fit of draft pad to frame.

16. Caulk shelter head and side members at wall around the outside edges. Caulk between truck

shelter and wiper seal head frames and across front of wiper seal head frame behind stop plate. A

silicone caulk (supplied by others) is recommended.

IMPORTANT !

INSTALLATION OF HEAD CURTAIN WIND STRAPS OR SIDE CURTAIN RETENTION STRAPS

UNDER TENSION WILL RESULT IN SEVERE HEAD AND SIDE CURTAIN DAMAGE. UNDER NO

CIRCUMSTANCES SHOULD ANY WIND STRAP OR RETENTION STRAP IN THIS SYSTEM BE

STRETCHED BEFORE FINAL ATTACHMENT TO SHELTER.

S-420/ S-900DD DOCK SHELTER FASTENERS

WARRANTY

4Front Engineered Solutions, Inc. expressly warrants that this Dock Seal or Shelter will be free from defects in materials

and workmanship under normal use for a period of one (1) year from the earlier of 1) 60 days after date of shipment by

4Front Engineered Solutions, Inc. or 2) the date of installation of the Dock Seal or Shelter by the original purchaser,

provided the product is properly applied and installed. In the event this Dock Seal or Shelter proves defective in material

or workmanship, 4Front Engineered Solutions, Inc. will, at its option:

1. Replace the Dock Seal or Shelter or the defective portion thereof without charge to the purchaser; or

2. Alter or repair the Dock Seal or Shelter, on site or elsewhere, without charge to the purchaser.

The warranty stated in the preceding paragraph is the sole and exclusive warranty for this product AND IS IN LIEU OF

A

LL OTHER GUARANTEES AND WARRANTIES, EXPRESS OR IMPLIED. This warranty does not cover any failure

caused by improper installation or application, abuse, or negligence. Parts requiring replacement due to damage

resulting from vehicle impact, abuse or improper installation are not covered by this warranty. Seller assumes no

responsibility or liability for (1) consequential damages of any kind which result from the use or misuse of the Dock Seal

or Shelter, (2) damage or failure resulting from the use of unauthorized replacement parts or modification of the Dock

Seal or Shelter; (3) damage resulting from the misuse of the Dock Seal or Shelter. THERE ARE NO WARRANTIES,

EXPRESS OR IMPLIED, WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE HEREOF, AND THERE IS

NO WARRANTY OF MERCHANTABILITY OR OF FITNESS FOR A PARTICULAR PURPOSE.

DryDock, Serco, SnapBack, Ultra Dock Shelter, Ultra Seal, and WeatherAll are registered trademarks of 4Front Engineered Solutions, Inc.

Serco Steel is a trademark of 4Front Engineered Solutions, Inc. COVERED BY PATENT # 6,170,204, OTHER PATENTS PENDING

Table of contents

Popular Enclosure manuals by other brands

Pulsar

Pulsar 17/TRZ40/S-F Assembly instructions

Supermicro

Supermicro SC847E1C Series user manual

EndurEnergy Systems

EndurEnergy Systems ESP-5100 manual

Stahl

Stahl 8102 Series operating instructions

Extron electronics

Extron electronics HSA 822MS Installation and maintenance manual

Konig

Konig CMP-MOBPLAY40 manual