SERVE CANADA DS 50 USA Operating and installation instructions

DS 50 USA User/Install Manual

3/2019

USA

page 19

CONTENTS Page

WARNINGS 20

1. MACHINE INSTALLATION 22

1.1 Serial number data 22

INSTALLER SECTION

1.2 Receiving the machine 23

1.3 Storage 23

1.4 Prepare for installation 23

1.5 Water connections 23

1.6 Water supply characteristics 23

1.7 Positioning the machine 24

1.8 Electrical connection 24

1.9 Temperature adjustment 24

1.10 Rinse aid dispenser operation 25

2. DETERGENT DISPENSER INSTALLATION 26

2.1 Electrical connection 26

2.2 Water connection 26

2.3 Dispensing the detergent 26

3. TECHNICAL DATA AND USEFUL INFORMATION ON PUMPS 26

3.1 Emptying pump 26

USER SECTION

4. CONTROL PANEL AND RELATIVE SYMBOLS 27

5. OPERATION 27

5.1 Dishes and cutlery loading 27

WARNINGS 28

5.2 Detergent use 29

5.3 Rinse aid use 29

5.4 Compliance with hygiene regulations, H.A.C.C.P. and NSF 29

5.5 Discharge pump system 29

6. MAINTENANCE 30

6.1 Routine maintenance 30

6.2 Special Maintenance 30

7. ENVIRONMENTAL ASPECTS 30

7.1 Packing 30

7.2 Disposal 30

8. ECOLOGICAL ASPECTS 31

8.1 Recommendations for optimal use of energy, water and additives 31

9. TROUBLESHOOTING 32

TRANSLATION OF THE ORIGINAL INSTRUCTION

USA

page 20

WARNINGS

This instructions booklet must be kept with the machine for future

consultations. If the machine is sold or transferred to other users, make

sure the booklet always goes with the unit so that the new owner can

have all the necessary information on operations and all relevant instructions.

The dishwasher shall be installed in accordance with local codes, or in the absence

of local codes, installed in accordance with the applicable requirements in the

National Electrical Code, NFPA 70, Canadian Electrical Code (CEC), Part 1, CSA

C22.1, and Standard for Ventilation Control and Fire Protection of Commercial

Cooking Operations, NFPA 96.

These warnings are provided to safeguard the user in conformity with technical

standards UL 921 and NSF3.

The instructions booklet must be carefully read before installation and before

starting the machine.

The user must comply with the following rules:

• Adaptationoftheelectricalandwatersystemfordishwasherinstallationmustbe

carriedoutbyqualiedoperatorsonly.

• Theusershallnotcarryoutanyrepairand/ormaintenanceoperations.

• WhenthemainswitchisOFF,onlyqualiedpersonnelcanaccessthecontrolpanel.

• Servicingofthismachinemustbeperformedbyauthorizedpersonnelonly.

Note: Use genuine spare parts only. Non-genuine parts will void the warranty and

the manufacturer will take no responsibility for any damage.

• Donotuseoldhose,butonlynewones.

• Thisappliancecanbeusedbytrainedyouthagedfrom15yearsandabove.Itcannot

be used by persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge.

• Childrenshallkeepotheappliance.

• Cleaningandusermaintenanceshallnotbemadebychildrenwithoutsupervision.

• Thismachineisdesignedexclusivelyforwashingplates,glasses,trays,baskets

and various pots and pans with human food type of residue. DO NOT wash articles

dierentfromthosestatedaboveandfragileobjectsormaterialsnotresistantto

washing process.

• Asuitableomni-polarswitchshallbeinstalledandsizedaccordingtotheactual

absorption, in order to guarantee completely the disconnection, from the power

network. A fuse protection system with the characteristics shown on the data-plate

shall be installed (or equivalent system).

• Thisswitchshallbeincludedinthepowernetwork,besolelyandexclusivelyused

for this purpose and be installed in the immediate vicinity of the machine.

• Alwaysturnothemachinebythisswitch:onlythisswitchgivesafullwarranty

of a complete insulation from the electric network.

USA

page 21

• Makesuretheapplianceislinkedtoanecientgroundconnection.

• Donotopenthemachinedoorswhenoperating.Afterswitchingthemachineo,waitfor

at least 15 seconds after the motors stop.

• Beforeusingthemachine,thepersonnelshallknowthepositionoftheomni-polarswitch

that disconnected the machine from the electrical network, the position of the water

connectionshut-ovalveandtheprocedurestoswitchoandsecurethemachine.

• Followtheinstructionsgiveninthemanufacturer’sbookletforcleaningoperations(chap.

6).

• Thismachinemustbedisconnectedfromthemainelectricalsupplyafteruseatthe

end of the day and for any service/maintenance operation following this procedure:

Switchthemachineofromthecontrolpanel.

Drainthetankbyremovingtheoverowpipe.

Disconnect the electrical supply by the omni-polar switch (main switch located on

the wall).

Shut the water supply valve(s).

Disregarding the aforesaid prescriptions is a serious misuse and can cause

damages and injures to property and people, and will relieve the manufacturer

from whatever liability.

• Donotusewatertoextinguishresonelectricalparts.

• Donotcovertheintakeordissipationgrids.

• Waterinfeedtothemachine60PSI(400kPa)maximum.

Note: The manufacturer declines any responsibility for accidents to people or any

damage deriving from failure to observe the above listed instructions.

WARNINGS: IT IS FORBIDDEN TO INSERT HANDS AND/OR TOUCH

INTERNAL PART WHEN THE MACHINE IS OPERATING AND/OR AT THE

END OF THE WASH CYCLE.

NOTICE: This machine must be operated with an automatic detergent

dosing pump including a visual means to verify that detergents are

delivered, or a visual or audible alarm to signal if detergents are not

available for delivery to the washing system. Please see instructions

for electrical and plumbing connections located in this manual and in

the feeder equipment manual.

USA

page 22

A Power source

B Total power installed

C Dynamic pressure

D Envelope protection degree

E Total electricity absorption

ATTENTION:

Attheendofinstallationmakesuretoremovethepartsofthisbookletrelevanttotheinstaller,forfutureconsultation.

1. MACHINE INSTALLATION

1.1 Serial number data

Code S/N

°

IPXX

RoHS

Maximum rating of supply circuit overcurrent

protective device XXXA xxxxxxxx

Valeur nominale maximale du dispositif de

protection contre le surintensités XXXA xxxxxxxx

S/N DW L 10XXXXX

ANNO

YEAR

ANNÉE

ANO

JAHR

NUMERO DI SERIE

SERIAL NUMBER

NUMÉRO DI SÉRIE

NUMERO DI SERIE

SERIENNUMMER

G=2012 - 2013

H=2013 - 2014

I=2014 - 2015

L=2015 - 2016

CODE DWXXXX

FAMIGLIA PRODOTTO

PRODUCT FAMILY

FAMILLE DU PRODUIT

FAMILIA PRODUCTO

FAMILIE DES PRODUKTES

CODE DWXXXX.YYYY

FAMIGLIA PRODOTTO

PRODUCT FAMILY

FAMILLE DU PRODUIT

FAMILIA PRODUCTO

FAMILIE DES PRODUKTES

CODICE MODELLO

MODEL CODE

CODE ARTICLE

CODIGO MODELO

KODE VON MODELL

Code S/N

°

IPXX

RoHS

Maximum rating of supply circuit overcurrent

protective device XXXA xxxxxxxx

Valeur nominale maximale du dispositif de

protection contre le surintensités XXXA xxxxxxxx

AD

B

C

E

USA

page 23

INSTALLER SECTION

1.2 Receiving the machine

Payspecialattentioninchoosingtheliftingpointsandthemachinebarycentreduringtheloadingand

unloading operations.

Beforeacceptingthemachine,verifythatallthedataonthedata-platecorrespondstotherequiredones

(asshownonpar.1.1) and to the ones of the available electrical supply.

Afterunpacking,makesurethemachinehasnotbeendamagedduringtransportation.Ifso,donotifythe

sellerimmediatelyabouttheproblem.Ifthedamagemightquestionthemachinesafety,donotinstallit.

Doublecheckthermtightnessofallhose-clampsonpiping,nuts,boltsandelectricalconnection

that might have come loose during transportation, to prevent water dripping leakages, or other damages, during

the machine operation.

Seechap.7 for disposing the packing material.

1.3 Storage

Storagetemperature:min.+40°F(+4°C)–max.+122°F(+50°C)-humidity<90%

The stored parts should be checked periodically to detect any sign of deterioration.

Donotstorethemachineexposingittoatmosphericagents(rain,sun,cold,etc.).Donotplacematerialonthepackedmachine.

1.4 Prepare for installation

Thisisjustaguide-lineforthemachineinstallation.Theinstallationmustbeperformedbyaqualiedengineer.

1.5 Water connections

Water connections must be carried out in compliance with current local standards.

TheWatersystemmusthavecharacteristicsbetweentheparametersspeciedintable1.

*Ifhigherthan60PSI(400Kpa),it is mandatory to install a pressure reducer.

To improve the machine performance keep the temperature intervals indicated.

Ithastobeinstalledawatersupplyshut-ovalveclosetothemachineinanaccessiblepoint.

Useonlynewexiblepipesforthewaterconnections.

1.6 Water supply characteristics

The machine water supply must be potable.

The inlet water must also meet the parameters given in the table 2.

1Outofrangevaluesmightleadtocorrosionandjeopardizethelifeofthemachine.

2Shouldthewaterhardnessishigherit is compulsory to install a water softner and check periodically its operation.

3Outofrangevaluesmightleadscalingandsedimentswithaconsequentlowerperformance,functionality,andexpected

life of the machine.

4Desiredvalue:Outofrangevaluesmightleadstainlesssteelblackening/tarnishing.

Itisrecommendedawatertestonceayear.

Water supply characteristics Min Max

StaticPressure* 30PSI(~200Kpa) 60PSI(~400Kpa)

DynamicPressure 30PSI(~200Kpa) 50PSI(~350Kpa)

Cold water-supply temperature

(machinewithextrapower)

110°F(~43°C) 150°F(~65°C)

Hot water-supply temperature 140°F(~60°C) 150°F(~65°C)

Capacity 2,6gpm(~10l/min)

Table 1

Water parameters table Min Max

Chlorine 12mg/l

pH 6,518,5 3

Water hardness 8°f2-3

Iron30,2 mg/l

Manganese 40,05 mg/l

Table 2

USA

page24

INSTALLER SECTION

DO NOT USE POWER CORD OR GFI OUTLET

This unit MUST BE hard-wired to a dedicated appropriately size circuit breaker

1.7 Positioning the machine

Remove the packing with care.

Maintainaminimumdistanceofabout2inches(50mm)fromthewalls,sothatmotorsareventilated.

Check that the machine is properly levelled, by adjusting the legs.

Makesurethemachineisnotstandingonthepowercableoronthelling/drainhoses.Levelthemachineat,byadjusting

the support feet.

1.8 Electrical connection

Onlyqualiedandproperlytrainedpersonnelcanoperateontheelectricboardandconnections.

Before the installation:

Make sure that the voltage is the same as reported on the data-plate.

Makesurethelinevoltagematchesthemachinepowerandvoltageindicatedonthemachinedata-plate(asshownonpar.

1.1).

Electrical connection must be carried out in compliance with the current local standards.

Use the data reported on the data-plate to check dimensions and electrical connections.

The machine has a terminal on the back panel indicated by the symbol that is meant to link the metal structures of

dierentappliances,topreventelectro-staticshocks.

Note: Donotmodifytheprotectionsorremovethem.Onlyifthepowersupplyiscutofromthemainswitchonthewall.

Onlyifthepowersupplyiscutofromthemainswitchonthewallitispossibletoworkonthedishwasherelectriccircuits.

Lockthemainswitchonthewalltosignaltheworkinprogressonthedishwasher’selectriccircuits.DANGER!

WARNING:checkverycarefullyifthe“groundconnection”ofthemachine,isproperlysizedandfullyecient,

andthatnottoomanyunitsareconnectedonit.Anundersizedorpoor“groundconnection”mightleadto

corrosionand/orpittingeectonthestainlesssteelplates,eventoperforation.

A suitable omni-polar switch shall be installed and sized according to the actual absorption, in order

to guarantee completely the disconnection from the power network. A fuse protection system with

the characteristics shown on the data-plate shall be installed (or equivalent system).

Thisswitchshallbeincludedinthepowernetworksolelyandexclusivelyusedforthispurposeand

installed in the immediate vicinity of the machine.

This is the only model of switch that guarantees a total electrical power disconnection.

Makesurethatthefacilityisequippedwithecientgroundconnection.

1.9 Temperature adjustment

Theadjustmentsarealreadycarriedoutduringthefactorytesting.Ifnecessary,thewatertemperaturesofthewashand

rinsecyclescanbeadjustedbymeansofthene-tunescrewsontherespectivethermostats.

Thesettemperaturesare160°F(71°C)thewashcycle(tank)and185°F(85°C)fortherinsecycle(boiler).

USA

page 25

INSTALLER SECTION

1.10 Rinse aid dispenser operation

Operation:itutilizesthedierenceincombinedpressurecausedbyturningthewashingpumponando,andtherinse

pressure.

Water connection:

1) ConnectthedispensertubettingAtothepump,bymeansoftherubbertubeinstalledintheappliance(pumppressure).

2) ConnectthesmallblackrubbertubebythebrassdeliveryttingBtotheconnectionneartheboiler(injector).

3) MakesurethatthegreenproductsuctiontubeisinsertedonthespecialttingCandthatthesmalllterandtheballast

are inserted in the rinse aid tank.

Priming: To prime the dispenser, turn on the appliance and carry out several complete wash cycles or press the adjustment

screw Dduring the wash cycle and open and close the door combined with pressing the pin D. This method speeds up the

rellprocess.

Adjustment:witheachrinsecycle,thedispenserdrawsanamountofrinseaid,adjustablefrom0to2cubicinches(from

0to4cc),equivalenttoalengthof0to11"(from0to30cm)drawnintothesuctiontube.

Inordertoregulatethedispensertotheminimumamount,turntheadjustmentscrewD(completelyclockwise.Forthe

maximum amount, turn the screw anticlockwise about 20 complete turns.

For the correct amount of rinse aid, see the paragraph Use of rinse aid(par.5.2).

N.B.:foreachturnofthescrewtheamountoftheproductdrawnintothetubevariesby5/8inches(1,6cm),equivalentto

13/16cubicinches/run(0,2cm³/turn)-(about1/8Dramme/run-0,21g/turn-withaconcentrationof0,60oz/cubicinches-

1,05g/cm³ofrinseaid).Therinseaidcannotfunctionproperlyifthedierenceinlevelbetweenthebottomofthemachine

andthecontainerexceeds31inches(80cm).

THE DISPENSERSARE PRE-SET TOA 2" (5 CM) INTAKE OF PRODUCT FOLLOWINGATEST PHASE SYSTEM

CHECK.THISMEASUREMENTSHOULDBEADJUSTEDACCORDINGTOTHETYPEOFRINSEAIDUSEDANDWATER

HARDNESS.

code 10799

C

D

B

A

10807

10806

10805

10805

10805

PROBLEMS CAUSES AND SOLUTIONS

Water exits from the rinse aid suction tube. The suction valves 10805 and delivery do not seal due to foreign

bodies in the closing seats.

Cleanthevalves10805,checkthattherinseaidsuctionlterispresent,

andlterthewaterenteringthedishwashwer.

The dispenser does not draw rinse aid. a) The delivery valve 10805 does not seal due to foreign bodies in

the closing seats.

Cleanthevalve10805,checkthattherinseaidsuctionlterispre-

sentandlterthewaterenteringthedishwasher.

b) Thepistonseal10806doesnotholdbecauseitisdamaged.

Replacetheseal10806withanoriginal.

c) Checkthediaphragm10807.

USA

page26

INSTALLER SECTION

2. DETERGENT DISPENSER INSTALLATION

2.1 Electrical connection

Follow the wiring diagram attached to the machine.

2.2 Water connection

a) Removethecapfromtheholeandtthedeliveryconnection.

b) Correctly mount the injector Cusingtheappropriatextures.

c) Connectthesuctiontubetothesuctionattachmentofthedispenser(seepict.2-pointA).

d) Connectthedeliverytubetotheotherattachmentofthedispenser,andthedeliverytting(seepict.2

point B).

e) Insertthesuctiontubewithlterinthedetergenttank.

f) Primethedetergentandproceedtodispense.

pict. 1

A

B

C

min1"1/4

(3cm)

PointB

CONNECTION DIAGRAM

pict. 2

2.3 Dispensing the detergent

The detergent dispenser capacity can be adjusted using a screwdriver

as shown in picture 1.

Every 13/16inches(2cm)ofproductdrawnintothetubecorresponds

to 1/64 cubic inches (0,25 cm³) equivalent to 0,01 once (0,3 g) with

a concentration of 1/16 once/cubic inches (1,2g/cm³). For proper

dispensing see paragraph 5.2.

3. TECHNICAL DATA AND USEFUL INFORMATION ON PUMPS

3.1 Emptying pump

Wheninstalling,payparticularattentiontothepositionoftheemptyingtube(seepict.3).

N.B.:Toemptythetub:turnotheappliancebymeansofthegreen0-1(seechap.4),pullouttheoverow

tube and leave the door open. Then keep button 5pressed until the tub is completely empty.

During the wash/rinse cycle, excess water will automatically be drained.

MAX 31” (0,8m)

pict. 3 CAUTION: INCORRECT

POSITIONING OF THE

TUBE.

CAUTION: CORRECT

POSITIONING OF THE

TUBE.

USA

page27

USER SECTION

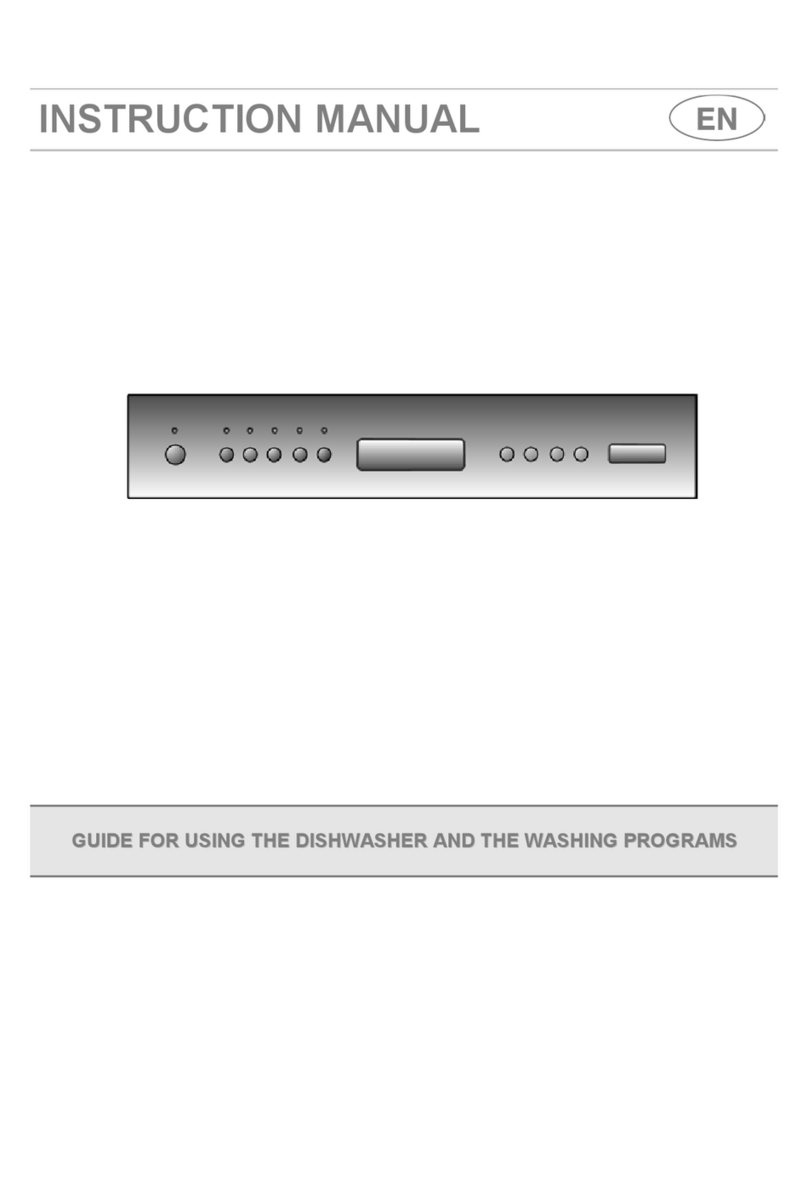

4. CONTROL PANEL AND RELATIVE SYMBOLS

5. OPERATION

• Inserttheoverowtubeinthespecialseatinsidethetub(pict.4)

• Checkthatthelteriscorrectlyttedinitsseat(pict.4).

Theltermustbecleanedafterevery20washcyclesandwhenevernecessary.

DONOTusetheappliancewithoutthelter.

• Closethedishwasherdoor.

• Insertthespecialrinseaiddispensertubeintheliquidcontainerandcheckthatthequantityof

additiveissucientfordailyuse(seeparagraphonrinse aid use).

• Turnonthewatertap.

• Turnswitch0-11(seechap.4)toposition1(pressed).

The operation is signalled by the switch indicator lighting up or by the indicator with the symbol a(seechap.4).

Themachinewillautomaticallyllthetubwithwater;thentheheatingphasebegins.

Indicatore(seechap.4) comes on when the water temperature is reached.

• Inserttheracklledwithdishestowash.

Theplatesmustbecorrectlyplacedintherack(seepar.5.1).

• Onmachineswithselector6(seechap.4)selectthewashcyclerequired.

• Tobeginthewashcycle,ifthereisnoautomaticoption,puttheliquiddetergentinthetubandpresstheSTART button

2(seechap.4). The button light or indicator c will come on, indicating that the cycle has started.

Attheendofthewashingcycle,ahotrinsecyclewilltakeplace.

The indicator light of the START button 2(seechap.4)willturnowhenthecyclehasnished.

Tocarryoutacoldrinse,onappliancesequippedwiththisoption,pressselector3(seechap.4) and hold it down for the

desired length of time after the indicator light c goeso.

• Theapplianceisnowreadyforanewwash.

• Attheendoftheday,cleanthemachine(seechap.6Maintenance).

• Turnothemachineandthewatertap.

5.1 Dishes and cutlery loading

Beforeloadingthedishesitisnecessarytocarryoutapropercleaningoofthefoodresiduals.

Itisnotnecessarytorinsethedisheswithwaterbeforetheloading.

Follow these tips:

• Crockeryandcutlerymustnotlieinsideoneanother,coveringeachother.

• Placethedishessothatallthesurfacescanbereachedbythewater;otherwisethedishescannotbewashedproperly.

• Makesurethatthedishesareplacedinastablepositionandthattheemptycontainers(cups,glasses,bowls,etc.)donot

turn upside down.

• Placealltheemptycontainerslikecups,glasses,etc.,upside down.

CONTROLS INDICATORS

a

b

c

d

e

2

3

1

pict. 4

WARNING:Donotwashitemscontaminatedbypetrol,paint,piecesofsteeloriron,ash,sand,wax,

lubricating grease. These substances damage the machine. Do not wash fragile items or made of

material that do not stand the washing process.

ON/OFF switch 0-1

CycleSTARTbutton

Supplementarycoldrinse

button

Manual empty button

(optional)

Wash type selector

(ifprovided)

Poweronindicator

Tub Temperature

Washing cycle

indicator

Water Pressure

BoilerTemperature

indicator

USA

page 28

USER SECTION

WARNINGS:

• Donotslamthedoorwhenopeningandclosing.

• Donotputmaterialorobjectsonthemachine.

• Thewaterusedforthewashingandtherinsingisnotpotablebecauseofthepresenceofchemicaladditives.In

case of contact with skin or eyes wash them immediately with plenty of water and check the safety instructions of

thedetergentmanufacturer.Ifnecessary,contactadoctor.

• Someimportantrulesmustbefollowedfortheuseofthisappliance:

1) Never touch the appliance with wet hands or feet

2) Never use the appliance when barefooted

3) Do not install the appliance in places exposed to water splashes.

• Thismachinemustbedisconnectedfromthemainelectricalsupplyafteruseattheendofthedayandfor

anyservice/maintenanceoperation.Switchothemainswitchlocatedonthewall,whichshallbeinstalled

by a professional installer. Shut the water supply valve(s).

WARNING: INTERNAL CLEANING OF THE MACHINE SHALL BE CARRIED OUT AT LEAST 10 MINUTES AFTER

IT HAS BEEN TURNED OFF.

WARNING: DO NOT INSERT HANDS AND/OR TOUCH THE PARTS LOCATED AT THE BOTTOM OF THE WASH

TANK AND/OR AT THE END OF THE WASH CYCLE.

• Placeintiltedpositionthedisheswithdeephollows,sothatthewatercandrain.

• Makesurethatthesmallerdishesdonotfallfromthebaskets.

• Checkallthewasharmsrunsfreelyandtheyarenotblockedbytootallortooprominent

crockery. Eventually, run a manual rotation of the arms to check it.

Somefoods, suchas carrots,tomatoes, and others, may contain some naturaldyes

substances, that in large amounts, can alter the crockery and plastic parts colors.

Anydiscolorationdoesnotmeanthattheplasticisnotheatresistant.

Crockery and cutlery not suitable for dishwasher

Not suitable for dishwasher:

• Woodencrockeryandcutleryorwithwoodenparts;waterathightemperaturecauses

deformationtowood.Alsotheadhesivesusedarenotsuitablefortreatmentinthedishwasher;

aconsequencecouldbethehandlesdetachment.

• Crafts,preciousvasesordecoratedglasses.

• Notheat-resistantplasticcrockery.

• Copper,brass,pewteroraluminumobjects:theymaybecomediscoloredoropaque.

• Thedecorationsonglass,afteracertainnumberofwashes,canlosegloss.

• Fragileglassesorcrystalitems,ifoftenwashed,canbecomeopaque.

We recommend to buy exclusively crockery and cutlery suitable for dishwashing.

Afterseveralwashes,theglasscanbecomeopaque.

It is mandatory to repeat the washing cycle if at the end of the cycle the crockery are

not well clean or if there are washing residues (glasses, cups, bowls, etc. with liquid

inside).

pict. 6

pict. 5

USA

page 29

USER SECTION

5.2 Detergent use

ONLYuseNONFOAMINGtypessuitableforindustrialglass-washersanddishwashers.

Itisadvisabletouseliquiddetergents.

The detergent must be put directly in the tub.

Thecorrectamount will besuggested by theproduct manufacturer accordingto the waterhardness. By

request,thedishwashercanbeequippedwithanautomaticdetergentdosingpump(alwaysrecommended).

3/8inches(1cm)oftheproductdrawnintothetubeisequaltoabout3/32Dr(0,15g).Acorrectamountof

detergent is very important for a successful wash.

This machine must be operated with an automatic detergent dosing pump. Verify the correct operation by checking the

detergentowinthetransparentsuctionhosefromthedetergentcanister.Makethecheckduringtankllingorrinsephase

5.3 Rinse aid use

Themachineisequippedwitharinseaiddispenser.

The machine automatically draws the product.

Therinse-aidchemical,shallbesuitableforprofessionalglassanddishwashers.Itisadvisabletorelyon

specializedretailersinthesector.

Theamountdispensedcanberegulatedbyoperatingthene-adjustmentscrewonthedispenser.

Reduce the amount by turning the screw clockwise, increase by turning it anticlockwise.

The recommended amount is 7/8- 1 15/16inches(2-5cm)ofproductmeasuredonthesuctiontube.

3/8inches(1cm)oftheproductdrawnintothetubeisequaltoabout1/16Dramme(0,13g).

Acorrectamountofrinseaidisveryimportantforaquickandcleandrying.

DETERGENT

RINSE AID

5.4 Compliance with hygiene regulations, H.A.C.C.P. and NSF

• Themachinesareequippedwithatemperatureindicator(chap.5) to indicate the boiler and tank temperature. Wait until

the set temperatures are fully reached.

• Thelightingofthelightpointsouttheattainmentofthetemperatureofthetank(160°F-71°C)andtherinsing(185°F-

85°C).

• Verifythatthepressureoftherinsingisbetween15and25Psi.

• Removesolidsformthecrockery,notcloglters,nozzlesandpipes.

• Drainthewashtanksandcleantheltersatleasttwiceaday.

• Checkthatdetergentandrinseaiddosingiscorrect(asrecommendedbythesupplier).Beforestartingthemachine

makesuretheamountofchemicalsinthetanksissucientforthedailyrequirement.

• Keepthetablessurfacesclean.

• Removethebasketfromthemachinewithcleanhandsorgloves,nottocontaminatethecutlery.

• Donotdryorpolishthecrockerywithunsterilecloths,brushesorrags.

5.5 Discharge pump system

Todrainthewash-tank:turnotheappliancebymeansofthebutton0-1(seechap.4),extracttheoverow

pipe and leave the door open. Then keep button 5pressed until the tank is completely empty.

During the wash/rinse cycle, excess water will automatically be drained.

USA

page 30

USER SECTION

6. MAINTENANCE

6.1 Routine maintenance

ATTENTION: The machine is not protected against pressurized water sprays. Do not use pressure

cleaning systems against the machine.

It is recommended to contact your chemicals distributor for proper cleaning instructions, in order

to have detailed indications on methods and products suitable for the correct periodical machine sanitation.

Do not use bleach or detergents containing chlorine.

Toensurethebestperformanceofthemachineaproperandsystematiccleaningisrequired.Thefollowingshallbecarried

out, at least once/day:

• TurnotheON/OFFswitch.

• Turnothewatervalve.

• Drainthewaterremovingtheoverowpipe.

Forappliancesprovidedwithemptyingpump,removetheoverowtube,turnotheON/OFFswitch(seechap.4), and

press button 5(seechap.4) until all the water has been completely emptied.

• Removethelterandcleanitwithabrushunderrunningwater.

• Removetherotorsbylooseningthexingscrews,andthoroughlycleanthenozzlesandcleaningandrinsingarmsunder

running water.

• Reassembleallpartsandrettherotorsintheirseats,xingthemwiththerelativescrews.

• Cleanthetubthoroughlyusingspecicproducts.

• Attheendoftheday,itisadvisabletoleavethedishwasherdooropen.

Note:Itisadvisabletoreplacethetubwaterbyrellingthetubatleastevery20washcycles,ortwicea

day. Do not use metal brushes or corrosive products which can damage the machine.

6.2 Special Maintenance

Onceortwiceayearhavethemachineinspectedbyaqualiedtechnician,inorderto:

1Cleantheinletlterofthesolenoid-valve

2 Remove incrustations from the heating elements

3 Check the status and the tightness of all gaskets

4Checkthewearingofeachcomponent

5Checktheeciencyofthedosingpumps.

7. ENVIRONMENTAL ASPECTS

7.1 Packing

The packing consists of the following:

• awoodpallet

• anylonbag(LDPE)

• multi-layeredcardboard

• polystyrenefoam(PS)

• polypropylenesupport(PP).

Please dispose of the materials listed above, according to the current regulations.

7.2 Disposal

Themachinemustbedisposedofaccordingtocurrentregulations:contacttheMunicipalizedFirmresponsible

for collection of urban solid waste.

Beforedisposingoftheappliance,disconnectallwaterandelectricalconnections.

Cut the electrical cable in such a way as to prevent further use.

Asallmetalpartsarestainlesssteel,theyarethereforerecyclable.

Recyclableplasticpartsareidentiedbytheplasticsymbol.

USA

page 31

USER SECTION

8. ECOLOGICAL ASPECTS

8.1 Recommendations for optimal use of energy, water and additives

Use the machine fully loaded when possible

This shall prevent detergent, rinse aid, water and energy waste.

Detergent and rinse-aid

Use detergent and rinse-aid chemicals with high biodegradability, to respect the environment best. Verify the proper

dosageinrelationtowaterhardnessatleastonceayear.Excessofproductpollutesriversandseaswhileaninsucient

dosing will cause unsatisfactory dish washing and/or hygiene.

Tank and boiler temperatures

The tank and boiler temperatures are set by the manufacturer in order to obtain the best washing results with detergents on

themarket.Thesemaybere-setbytheinstalleraccordingtoyourdetergent(seeparagraph1.9).

Cleaningo

Carefullyremovesolidsothekitchenwareusingwateratroomtemperaturesoastomakeremovalofanimalfatseasier.

To remove encrusted matter, soaking in hot water is recommended.

Notes:

Washtheobjectsassoonaspossibleinordertopreventthedepositsfromdryingandjeopardizingtheeectivenessofthe

washing.Togetanecientwash,itisadvisabletoregularlycleanandmaintainthemachine(seechap.6).

Disregarding the points listed above and any information contained in this manual can cause energy, water and

detergent waste with a subsequent increase in running costs and/or performance reduction.

USA

page 32

USER SECTION

9. TROUBLESHOOTING

Type of problem Possible causes Cure

The machine does not

turn on

Main switch not ON. Turn switch ON.

The machine does not

load water.

Water valve shut. Open the hot and/or cold water valve.

The spray arm nozzles or the

solenoid lter are clogged and/or

caked with lime deposists

Cleantherinsingarmnozzles,thepipesandthelter.Check

thatthewaterhardnessis<10°f.Equipthemachinewith

an external water softener

Faulty pressure switch Replacethepressureswitch(calltheTechnicalAssistance

service)

Washing results are

unsatisfactory.

Thewashingnozzlesareobstructed

or the rack does not rotate.

Unscrewand clean the nozzles and the rotation shaft

carefully,retthemcorrectlyintheirseats

Filters are dirty. Removelters,cleanwithbrushunderajetofwaterand

replace in original position.

Presenceoffoam Use a non-foaming detergent or reduce the amount of that

used. Check the rinse aid dispenser

Fats or starches are not removed Detergent concentration too low

Check the tank temperature (it

mustbeabout160°F-71°C)

Adjustthe thermostat or checkcorrect heating element

operation

Lengthofwashingcycleinadequate

for type of grime build-up

Choose a longer cycle if possible, otherwise repeat wash

cycle

Wash water too dirty Emptywaterfromthetank,cleanlters;rellthetankand

correctlyretthelters

Glassesordishesarenot

completely dried

Insucientrinseaid Increasetheamountofrinseaidbyturningthescrewon

thedispenser(seeparagraphRinse aid use)

The rack is unsuitable for the

glasses and dishes

Use a suitable rack enabling the dishes to be tilted so water

canruno

The dishes have been too long in

the tank

Assoon as thewash cycle isnished, pull the rack out

immediately, allowing the air to dry the glasses and dishes

morequickly

Rinse water temperature is less

than185°F(85°C)

Check the temperature of the booster thermostat. Call the

TechnicalAssistanceservicetoadjust

Surfaceofdishesandglassestoo

rough or porous for material wear.

Replace type of dishes and glasses used

Streaks and spots on

glasses and dishes.

Too much rinse-aid chemical. Reduce the rinse aid amount by turning the micrometric

dispenserscrew(seeparRinse aid use)

Too hard water. Check the water quality. Water must not exceed 10°f in

hardness.Equipthemachinewithanexternalwatersoftener

The machine suddenly

stops during the cycle

The machine is connected to an

overloaded circuit

Connect the machine separately (call theTechnical

Assistanceservice)

Asafetydevicehasbeenactivated Checksafetydevices(calltheTechnicalAssistanceservice)

During wash cycle the

machine stops and draws

water

Water from the previous day has

not been replaced

Emptythetankandrellit

Faulty pressure switch HavetheTechnicalAssistanceservicecheckthethermostat

and the pressure switch

The overflow tube is incorrectly

positioned

Removetheoverowtubeandcorrectlyrepositionit

Note For any other problems, contact the Technical Assistance service.

The manufacturer reserves the right to alter the technical characteristics without prior notice.

Table of contents