Copyright 2011 Robotzone, LLC.—All Rights Reserved

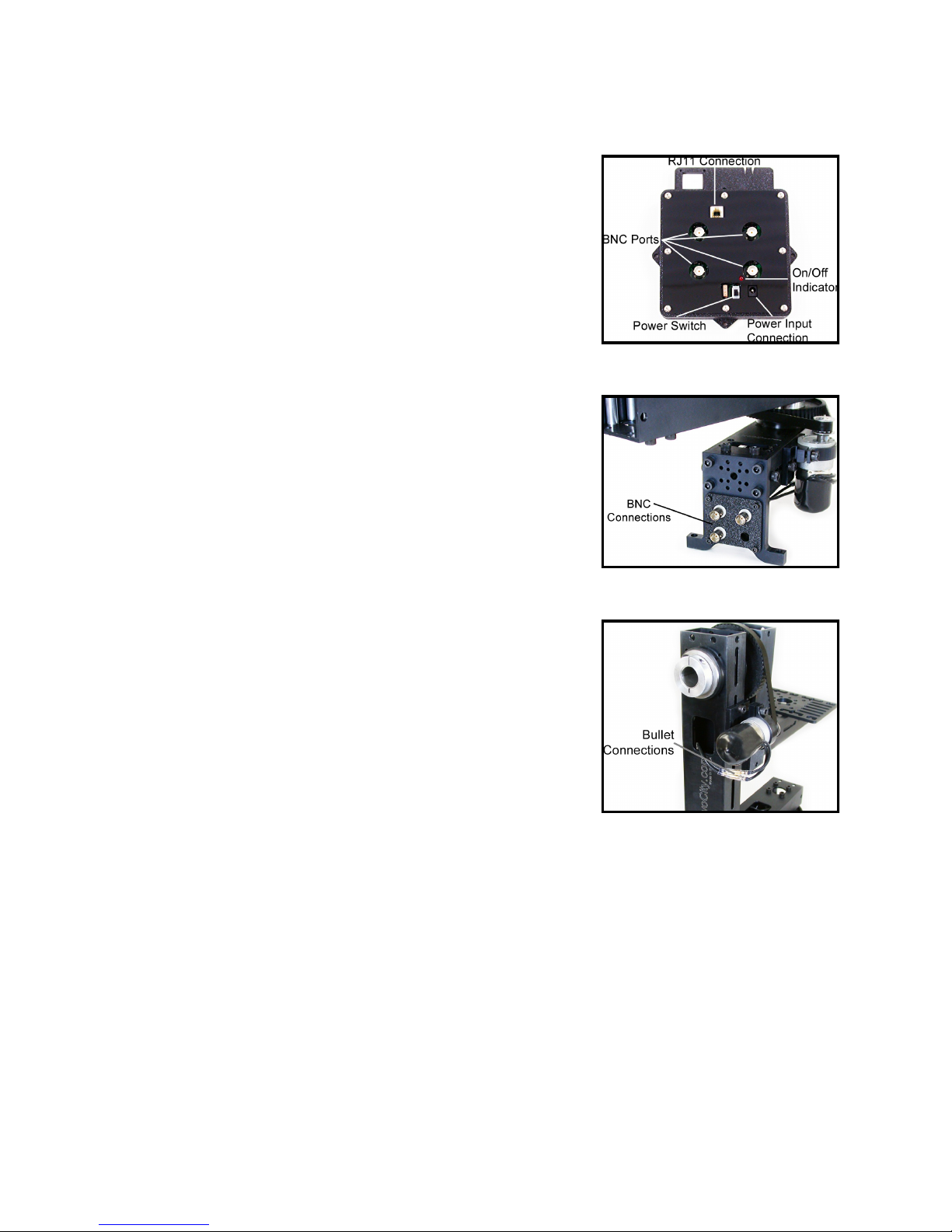

An extra BNC port has been provided on the base of the pan system for

the optional R-2200 roll attachment or any other future upgrades that

require an additional motor.

Initial Hook-up:

1. Uncoil the 7’ RJ11 cable and plug one end into the dual joystick control-

ler. Plug the other end into the 4-motor controller.

2. Uncoil the power supply and plug it into AC power. Plug the opposing

end into the 4-motor controller. Make sure the power switch is turned off at

this time (red LED is not illuminated).

3. Uncoil one 25’ BNC cable and plug it into the BNC port found on the leg

of the pan system that is wired to the pan motor. The BNC connection will

press on and twist 1/4 turn in the clockwise direction to lock in place. At-

tach the opposing end to a port on the 4-motor controller and lock in place.

4. You are now ready to run the pan motor with your dual joystick. Flip the

switch on your 4-motor controller; the red light will illuminate in the “ON”

position. Move the joysticks to determine which channel you have the pan

motor connected to. Move the BNC cable to the port on the 4-motor control-

ler that corresponds to the channel you wish to operate the pan system from.

5. Uncoil the second 25’ BNC cable and plug into the BNC port on the leg

of the pan system that is wired for the tilt motor. Plug the opposing end into

the 4-motor controller and determine which channel you wish to control the

tilt axis with in the same manner used to setup the pan axis.

6. It is advised at this time that you label the ports on the 4-motor controller

to make future set-ups simple.

7. If your pan or tilt motors operate in the opposite direction that you wish,

they can easily be reversed. Turn the power off and simply unplug the bullet

connectors found near the motors and switch them around. By reversing the

polarity of the motors they will respond to the joystick movements in the

opposite direction.

8. Your pan and tilt wiring is now complete and the PT-2100 pan and tilt

system is ready to operate.

Adjusting the belts:

The belts are adjusted from the factory, however, if you wish to change motors or pulleys the following steps will

make adjusting the belt alignment and tension very easy.

Belt Tension:

Belt tension can be adjusted by loosening the two bolts holding the motor mount. Slide the motor mount away

from the large pulley in order to increase belt tension; re-tighten bolts when desired tension is achieved.

Belt Alignment:

Belt alignment can be adjusted by loosening the clamping bolt on the motor mount. The motor can be raised and

lowered to achieve correct alignment. Re-tighten bolts when alignment is achieved. Re-check proper belt tension.

(Be sure the pinion pulley clears all rotating parts before operating)