Servoflo mp6-QuadEVA User manual

(03.2018) rev.4

1

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

Operating Manual

for

mp6-QuadEVA board

(03.2018) rev.4

2

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

Content

1Introduction....................................................................................................................................................................... 3

2Proper use........................................................................................................................................................................... 3

2.1 Intended purpose.................................................................................................................................................... 3

2.2 Misuse........................................................................................................................................................................ 3

2.3 Staff selection and qualification ........................................................................................................................ 3

2.4 Safety notice............................................................................................................................................................ 4

3Overview ............................................................................................................................................................................. 5

4Interface and mode of operation ................................................................................................................................. 7

4.1 Push-button ............................................................................................................................................................. 7

4.2 Rotary knob: pump voltage.................................................................................................................................. 7

4.3 Rotary knob: pump frequency ............................................................................................................................. 8

4.4 Operation via USB port (after installation of the drivers)............................................................................ 8

4.5 Local control ............................................................................................................................................................ 9

4.6 Installation of the USB driver.............................................................................................................................. 9

4.6.1 For “Windows XP” and former Windows versions..................................................................................... 9

4.6.2 For “Windows 7”...............................................................................................................................................10

4.6.3 For "Windows 8"...............................................................................................................................................10

4.7 Software..................................................................................................................................................................11

5Maintenance....................................................................................................................................................................12

5.1 Cooling.....................................................................................................................................................................12

5.2 Exchanging the micropump ...............................................................................................................................12

6Dimensions.......................................................................................................................................................................13

7Technical data and Performance charts ...................................................................................................................14

8Serial solution..................................................................................................................................................................15

(03.2018) rev.4

3

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

1Introduction

The mp6-QuadEVA is an evaluation board that allows to control up to four mp6 micropumps

simultaneously with one setting and up to a frequency of 800 Hz.

It is possible to change pump voltage and pump frequency directly with the rotary control elements at the

board or via USB. Simple control software is provided with the board. Also any terminal software can be

used to remotely control frequency and amplitude or enable/disable each of the four pumps.

2Proper use

2.1 Intended purpose

The mp6-QuadEVA was designed to control up to four micropumps for gas pumping, i.e. four pieces of

mp6-AIR micropumps.

Nevertheless it is also possible to pump liquids, either with the mp6-AIR, mp6-pp or the standard mp6

pump; though the higher frequencies will not result in a performance boost.

If liquids should be pumped, please regard the following:

The micropump is intended for pumping liquids or gases with varying flow rates controlled by the

electronics. The mp6-QuadEVA controller is intended as a pump driver for mp6-AIR/mp6/mp6-pp.

Any other use of the micropump or controller unit is deemed improper.

Do not make any modifications or extensions to the pump or controller without the prior written consent of

the manufacturer. Such modifications may impair the safety of the unit and are prohibited! Bartels

Mikrotechnik GmbH rejects any responsibility for damage to the unit caused by unauthorized modifications

to the pump and risk and liability are automatically transferred to the operator.

2.2 Misuse

The use of gases or liquids which may alone or in combination create explosive or otherwise health-

endangering conditions (including vapors) is not permitted.

2.3 Staff selection and qualification

All work in connection with the installation, assembly, commissioning/decommissioning, disassembly,

operation, servicing, cleaning and repairing of the pump and the controller must be carried out by qualified,

(03.2018) rev.4

4

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

suitably trained and instructed personnel. Work on electrical components and assemblies must be carried

out by personnel with the necessary qualifications and skills.

2.4 Safety notice

The mp6-QuadEVA generates voltages of up to 260 Vpp. All parts of the evaluation board can carry

voltages in this range. Therefore, the board should only be used by qualified personnel. Although the output

power of the module is very low, proper insulation according to the application conditions needs to be

considered by the customer. This especially applies to the bottom side of the PCB. Contact with water or

other liquids needs to be prevented. The pump must not be unplugged while the board is active.

DANGER

THE EVALUATION BOARD CAN CARRY HIGH VOLTAGE!

BE CAREFUL, WHILE CONNECTING AND HANDLING THE BOARD!

(03.2018) rev.4

5

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

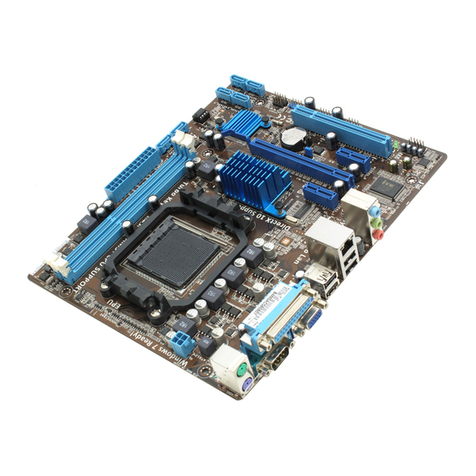

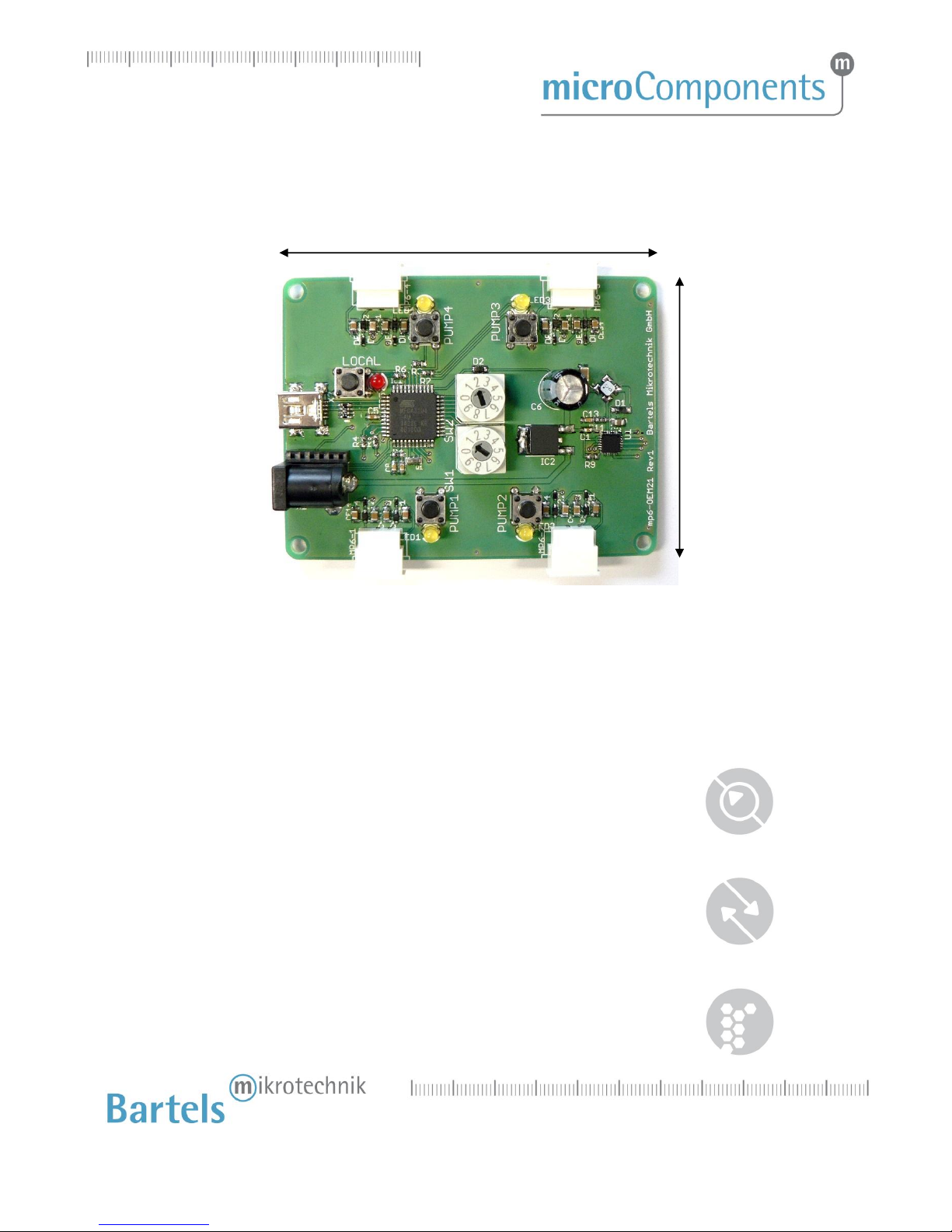

3Overview

The mp6-QuadEVA will only be available as a set of the following components:

mp6-QuadEVA Board

power supply 7.5 V; 1000 mA

Mini-USB cable

4x micropump mp6-AIR

software and driver CD (optional, software and driver will be send via Email)

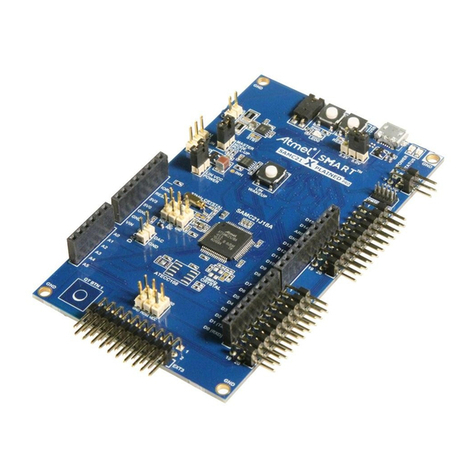

Figure 1 Overview of the mp6-QuadEVA board

In the figure above the parts are:

1. Molex connector for flexible wire of the mp6 (one per pump)

2. Push-button to switch back to local control

3. LED signaling USB driving mode

1

4

6

8

7

9

5

3

2

(03.2018) rev.4

6

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

4. Mini USB connector

5. DC connector

6. LED signaling activated pump (one per pump)

7. Rotary knob for pump voltage setting (SW1)

8. Rotary knob for pump frequency setting (SW2)

9. Push-button to turn the pump on/off (one per pump)

(03.2018) rev.4

7

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

4Interface and mode of operation

The board does not have any main switch. When connecting the power supply to the DC connector (5) the

board is ready for operation. Connecting to a PC is optional. The board can be operated without PC

connection. However, if connected to an USB-power supply or an USB-port the power connection via DC

connector is still necessary.

4.1 Push-button

The four push–buttons (9) allow turning the individual pumps on or off. If turned on the corresponding

LED (6) will be illuminated.

4.2 Rotary knob: pump voltage

Through rotation of the rotary knob “SW1” (7) the pump voltage of all pumps can be changed, please use a

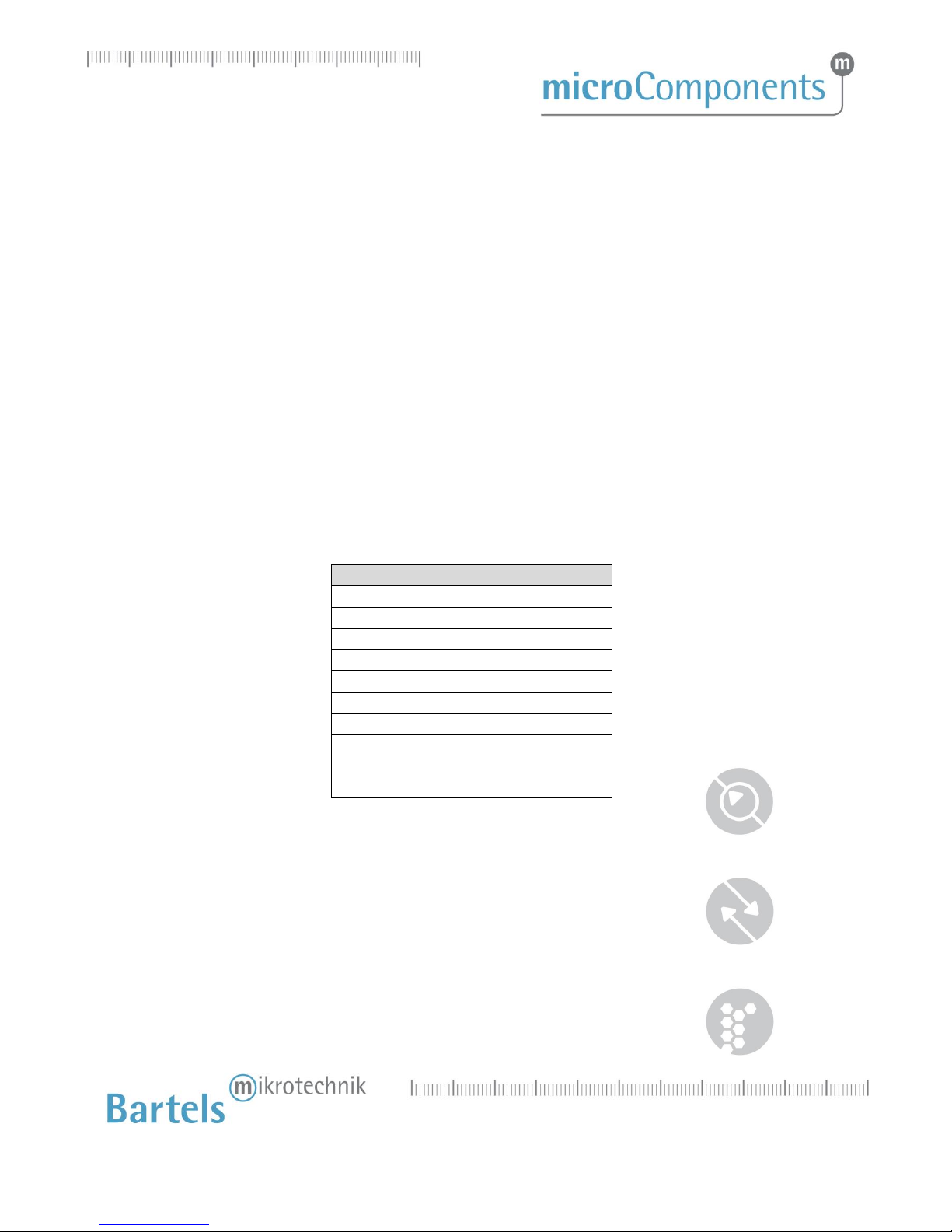

small flat blade screwdriver. The following table lists which voltage corresponds to the positions:

position SW1

pump voltage

0

0 Vpp

1

40 Vpp

2

80 Vpp

3

116 Vpp

4

150 Vpp

5

175 Vpp

6

200 Vpp

7

220 Vpp

8

240 Vpp

9

260 Vpp

Figure 2 Pump voltage at rotary knob SW1

(with four connected pumps and a frequency of 100 Hz)

The pump voltage may vary due to the number of connected pumps. With more pumps to operate the load

increases, hence the max voltage decreases. The pump voltage can also decrease a bit when operating with

higher frequencies.

(03.2018) rev.4

8

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

4.3 Rotary knob: pump frequency

With the rotary knob “SW2” (8) it is possible to change the frequency for all pumps, please use a small flat

blade screwdriver. The table below lists the possible frequencies:

position SW2

pump frequency

0

50 Hz

1

75 Hz

2

100 Hz

3

200 Hz

4

300 Hz

5

400 Hz

6

500 Hz

7

600 Hz

8

700 Hz

9

800 Hz

Figure 3 Pump frequency at rotary knob SW2

The control signal to the pumps is a pure sine signal. Therefore it is not the same as with the mp6-OEM.

4.4 Operation via USB port (after installation of the drivers)

The driving parameters can be set via your PC. For this purpose any terminal software can be used that is

capable of sending commands to serial COM-Ports. In the example below the Windows software

HyperTerminal is used. As the HyperTerminal is not available in Windows 7 anymore, we recommend

freeware terminal software like PuTTY (http://www.putty.org).

On the driver CD supplied in the set you will find simple control software that can be used for evaluation

(see chapter 4.7).

HyperTerminal example:

Step 1: Connect the power supply to the board.

Step 2: Connect the board to your computer.

Step 3: Start Windows HyperTerminal. Every new session has to be titled.

Step 4: Choose the COM-port specified in the device manager.

Step 5: The connection-settings have to be:

Bits per second: 9600; Data bits: 8; Parity: none; Stop bits: 1; Flow control: none

(03.2018) rev.4

9

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

Possible commands (have to be acknowledged with the Enter-key):

P<X>ON

P1ON

turn on pump X

values for X: 1…4

P<X>OFF

P1OFF

turn off pump X

values for X: 1…4

F<X>

change frequency in Hz

values for X: 50…800

V<X>

change voltage in Vpp

values for X: 0…300

Figure 4 Commands via USB

As soon as the first command is transmitted via USB the evaluation board changes internally to USB driving

mode. In this mode of operation the red LED (3) is illuminated. Changes of pump voltage and frequency

overwrite the rotary knob settings. The appropriate driver for the board will be send via Email.

The mp6-QuadEVA can also be used via LabView, Matlab and the like. Using LabView, please ensure that

the “NI Serial” package is installed. This will be installed in regular cases together with LabView, but

sometimes this option is skipped during install.

It can be downloaded on the National Instruments website as the “NI-Serial” package:

http://joule.ni.com/nidu/cds/view/p/id/2316/lang/en

Afterwards it is possible to select the right COM-port in the VISA resource name.

4.5 Local control

The push-button (2) switches back to local control when the device is driven in USB driving mode. Pump

voltage and frequency will be reset to the rotary knob positions. The red LED (3) turns off.

4.6 Installation of the USB driver

4.6.1 For “Windows XP” and former Windows versions

Step 1: Connect the control unit with the USB port. A message appears that new hardware was found

and the hardware assistant starts automatically. Please click “Next” to continue.

Step 2: Choose “Find a suitable driver for the device” and click “Next” to continue.

Step 3: Place the CD into the disc drive.

Step 4: Choose “Search for the best driver in these locations” and tag “Include this location in the

search”. Then browse and select the CD.

Step 5: When the software has found the driver named "mp6-QuadEVA driver" select “Next”

(03.2018) rev.4

10

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

The installation will start now. If the message appears that the Windows Logo Test was not

successful, please select “Continue Anyway” as this has no relevance in this case. Click “Finish”

to complete the installation.

4.6.2 For “Windows 7”

Dependent on the individual system settings, different steps for installation might be necessary. The

procedure applies in general also for Windows Vista.

Step 1: Log in with administrator rights.

Step 2: Connect the control unit with the USB port. A message appears that new hardware was found.

Step 3: Open the device manager and double click the item "mp6-QuadEVA driver" filed under

"additional hardware" (or similar). In the pop up window click on "update driver" and select

the directory including the driver files (e.g. the cd rom drive). It needs to be confirmed that the

driver should really be installed as it has no digital signature.

Step 4: The device manager will show the number of the serial port (e.g. COM 4). Note this for further

use of the device with application programs.

4.6.3 For "Windows 8"

Step 1: Log in with administrator rights.

Step 2: From the Metro Start Screen, open Settings (move your mouse to the bottom-right-corner of

the screen and wait for the pop-out bar to appear, and then click the Gear icon).

Step 3: Click “More PC Settings”.

Step 4: Click “General”.

Step 5: Scroll down, and click ‘Restart now’ under “Advanced startup”.

Step 6: Click ”Troubleshoot”.

Step 7: Click “Advanced Options”.

Step 8: Click “Windows Startup Settings”.

Step 9: Click “Restart”.

Step 10: On the Startup Settings screen, tap the F7 or 7 key on your keyboard to select the “Disable

driver signature enforcement” option.

Wait until the system has restarted.

Step 11: Right-click on "mp6-QuadEVA driver", then click “Install”.

Wait until installation is finished.

Step 12: Now you can connect the board with any USB-port. If the board was already connected,

disconnect it and connect it again.

(03.2018) rev.4

11

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

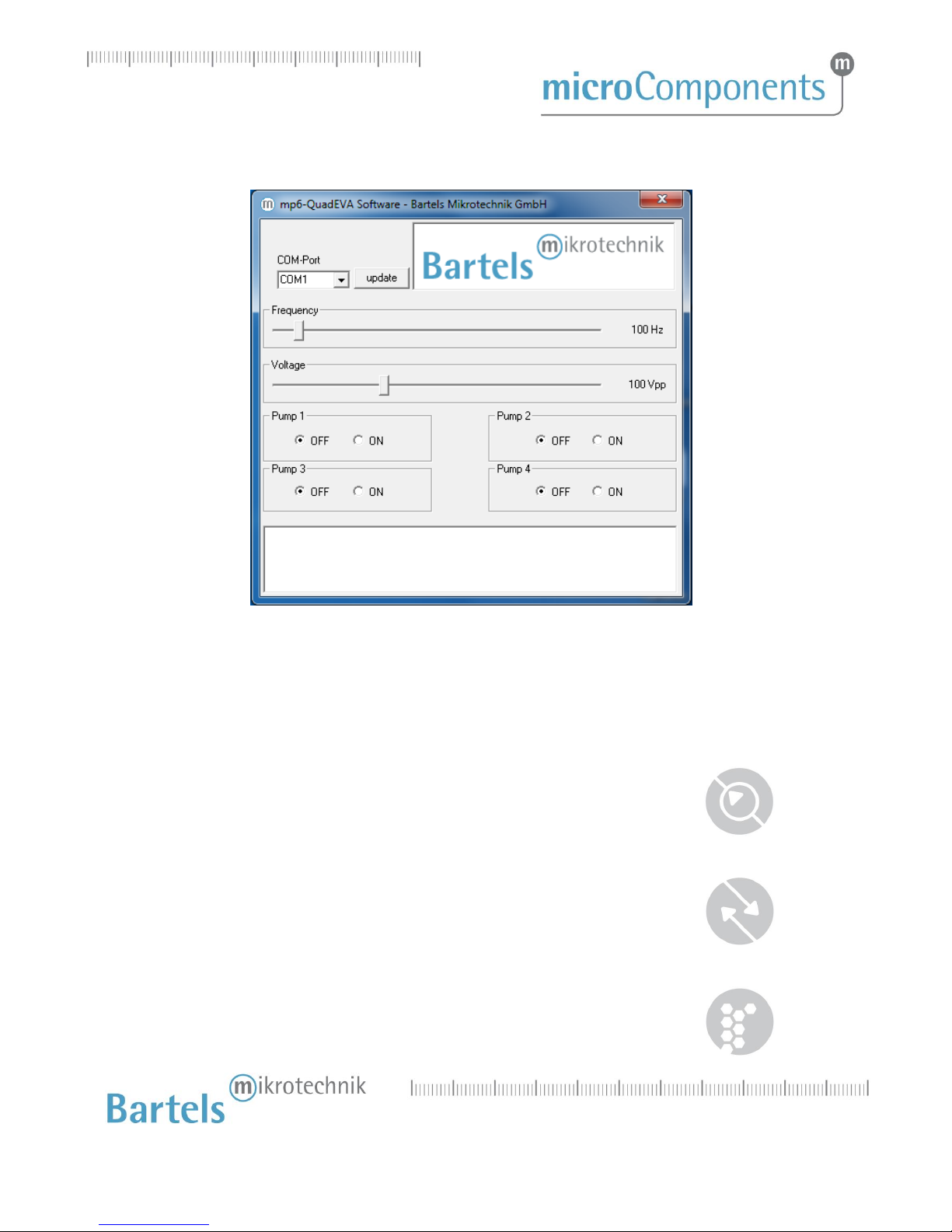

4.7 Software

Figure 5 Software window

Ensure that the board is connected to the PC and the driver is installed. After the software has started the

COM-port for the mp6-QuadEVA board has to be selected. If it is not present in the dropdown list please

verify that the board is correctly connected and press on “Update” to refresh the list.

The slider “Frequency” allows changing the pump frequency. The current frequency is displayed at the right

side.

The slider “Voltage” allows changing the pump voltage. The current voltage is displayed at the right side.

With the “OFF” and “ON” elements the individual pumps can be turned on and off.

All send commands and answers from the board are displayed in the text field at the bottom.

(03.2018) rev.4

12

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

5Maintenance

5.1 Cooling

The board may create some heat at the control chip when under continuous operation and at max

performance. It was successfully tested for the duration of one hour at 800 Hz, 250 V and four connected

pumps; no active cooling was applied.

However, it is recommended to take care of sufficient air flow to remove excess heat or consider installing

some active cooling on the board.

5.2 Exchanging the micropump

To connect the mp6/mp6-AIR/mp6-pp and Molex, refer to following three figures. Orientate both

components as indicated on the first picture, the mp6/mp6-pp facing downwards with its serial number

marking (!) and the Molex connector with the four small openings visible from above. Then insert the

mp6/mp6-pp flex into the Molex connector (Step1). Close the Molex connector to complete the

interconnection between both components (Step 2).

Step 1

Step 2

Step 3

Figure 6 Connecting and removing of micropumps from the connector

(03.2018) rev.4

13

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

6Dimensions

80 mm (3.15 in.)

Figure 7 Dimensions of the mp6-QuadEVA

Height over all:

16 mm (0.63 in.)

60 mm

(2.36 in.)

(03.2018) rev.4

14

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

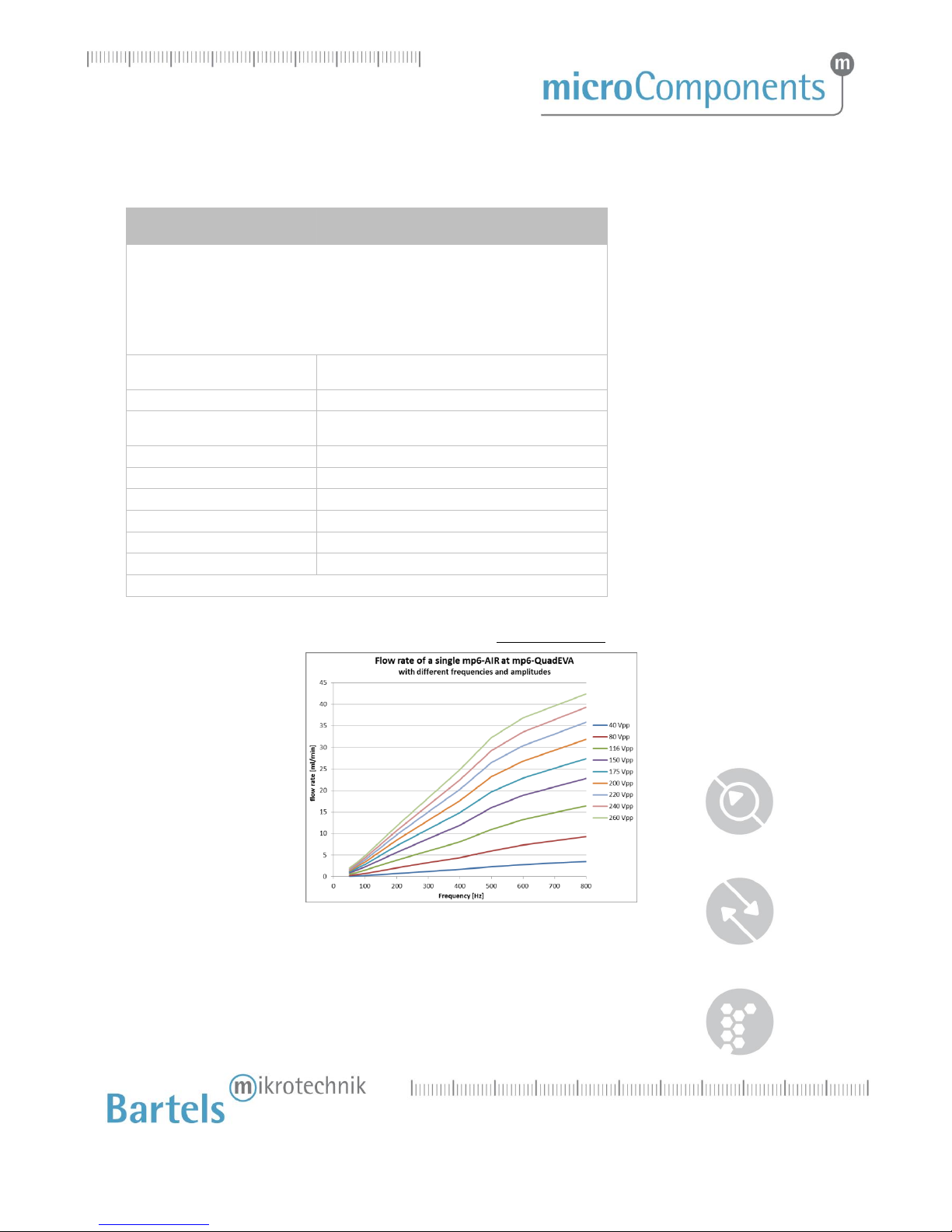

7Technical data and Performance charts

mp6-QuadEVA

evaluation board

Order code: mp6-QuadEVA

The mp6-QuadEVA is an evaluation board that allows controlling up to four mp6

micropumps simultaneously with one setting and up to a frequency of 800 Hz.

It is possible to change pump voltage and pump frequency directly with the rotary control

elements at the board or via USB. Simple control software is provided with the board. Also

any terminal software can be used to remotely control frequency and amplitude or

enable/disable each of the four pumps.

Dimensions

80 x 60 x 16 mm

3.15 x 2.36 x 0.63 in.

Pumping media

liquids, gases

Max. volume flow

(mp6-AIR, gas: air)

each single mp6-AIR:

~42 ml/min @ 260 V; 800 Hz

Adjustable parameters

amplitude, frequency

Amplitude range

0 –260 Vpp

Frequency range

50 –800 Hz

Signal form

sine

Power supply

7.5 V, 1000 mA

Current consumption

avg. 220 mA, peak 280 mA1

1four connected mp6-AIR @ 260 V and 800 Hz

For pumping air, the flow rate and pressure generation of a single mp6-AIR is displayed below.

Figure 8 Flow rate of a single mp6-AIR attached to the mp6-QuadEVA

(03.2018) rev.4

15

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

Figure 9 Forward and Suction pressure of a single mp6-AIR attached to the mp6-QuadEVA

The forward pressure of serial connected mp6-AIR pumps is presented below with the left diagram. An

amplitude drop occurs at higher frequencies and/or with the higher load, i.e. connected pumps. This

behavior of the mp6-QuadEVA can be seen below in the right diagram.

Figure 10 Left diagram: Forward pressure of serial connected mp6-AIR pumps.

Right diagram: Amplitude drop behavior of mp6-QuadEVA.

8Serial solution

The mp6-QuadEVA was designed as an evaluation board and does not represent the right solution for serial

products. However, the circuit can be adapted for various applications.

On request we offer such a development for your customized solution. Additionally it is possible to order

the schematics, part list and source code for a licensing fee.

(03.2018) rev.4

16

Bartels Mikrotechnik GmbH, Konrad-Adenauer-Allee 11, 44263 Dortmund, Germany

www.bartels-mikrotechnik.de, info@bartels-mikrotechnik.de

Tel: +49-231-47730-500, Fax: +49-231-47730-501

Bartels Mikrotechnik GmbH

Konrad-Adenauer-Allee 11

44263 Dortmund Germany

www.bartels-mikrotechnik.de

info@bartels-mikrotechnik.de

For tutorials and further information

Visit our BLOG:

http://blog.bartels-mikrotechnik.de

Or our YouTube channel:

https://www.youtube.com/user/BartelsMikrotechnik

You can also find us here:

Facebook

Twitter

Xinq

Instagram

LinkedIN

Tel: +49-231-47730-500

Fax: +49-231-47730-501

Table of contents