Severn Trent Capital Controls CI1000B User manual

1

Capital Controls®

Cl1000B

Bufferless Residual Analyser

90-1024

Operation and Maintenance Manual

Part no: 04-1008-E

Issue: Aug 2004

210.6350.9

2

These instructions describe the installation, operation and maintenance of the subject equipment. Failure to strictly

follow these instructions can lead to an equipment rupture that may cause significant property damage, severe

personal injury and even death. If you do not understand these instructions, please call Severn Trent Water

Purification for clarification before commencing any work at 215-997-4000 and ask for a Field Service Manager.

Severn Trent Water Purification, Inc. reserves the rights to make engineering refinements that may not be described

herein. It is the responsibility of the installer to contact Severn Trent Water Purification, Inc. for information that

cannot be answered specifically by these instructions.

Any customer request to alter or reduce the design safeguards incorporated into Severn Trent Water

Purification equipment is conditioned on the customer absolving Severn Trent Water Purification from any

consequences of such a decision.

Severn Trent Water Purification has developed the recommended installation, operating and maintenance

procedures with careful attention to safety. In addition to instruction/operating manuals, all instructions given on

labels or attached tags should be followed. Regardless of these efforts, it is not possible to eliminate all hazards

from the equipment or foresee every possible hazard that may occur. It is the responsibility of the installer to ensure

that the recommended installation instructions are followed. It is the responsibility of the user to ensure that the

recommended operating and maintenance instructions are followed. Severn Trent Water Purification, Inc. cannot be

responsible deviations from the recommended instructions that may result in a hazardous or unsafe condition.

Severn Trent Water Purification, Inc. cannot be responsible for the overall system design of which our equipment

may be an integral part of or any unauthorized modifications to the equipment made by any party other that Severn

Trent Water Purification, Inc.

Severn Trent Water Purification, Inc. takes all reasonable precautions in packaging the equipment to prevent

shipping damage. Carefully inspect each item and report damages immediately to the shipping agent involved for

equipment shipped “F.O.B. Colmar” or to Severn Trent Water Purification for equipment shipped “F.O.B Jobsite”.

Do not install damaged equipment.

SEVERN TRENT SERVICES, COLMAR OPERATIONS

COLMAR, PENNSYLVANIA, USA

IS ISO 9001: 2000 CERTIFIED

Use only in accordance with Instruction Manual

PROTECTIVE GROUND (EARTH) TERMINAL

WARNING: HAZARDOUS VOLTAGES

WARNING: WARNING, AS USED IN THIS MANUAL, IS DEFINED AS A CONDITION OR

PRACTICE WHICH COULD RESULT IN PERSONAL INJURY OR LOSS OF LIFE.

CAUTION: CAUTION, AS USED IN THIS MANUAL, IS DEFINED AS A CONDITION OR

PRACTICE WHICH COULD RESULT IN DAMAGE TO OR DESTRUCTION OF THE EQUIPMENT

OR APPARATUS UNDER TEST.

3

Table of Contents

SAFETY...................................................................................................................................................4

1 INTRODUCTION......................................................................................................................................5

1.1 General Description..................................................................................................................5

1.2 Glossary....................................................................................................................................5

1.3 Definitions.................................................................................................................................5

1.4 Specifications ...........................................................................................................................6

1.5 Principle of Operation...............................................................................................................7

1.6 Chlorine Chemistry.................................................................................................................10

1.7 Galvanic Cell Theory..............................................................................................................11

2 INSTALLATION .....................................................................................................................................12

2.1 General...................................................................................................................................12

2.2 Mounting.................................................................................................................................13

2.3 Hydraulic Connections (Wall Panel Only) ..............................................................................13

2.4 Electrical.................................................................................................................................14

3 STARTUP...............................................................................................................................................17

3.1 Conditioning the Analyser.......................................................................................................17

3.2 Programming the Monitor.......................................................................................................17

3.3 Set-up.....................................................................................................................................18

3.4 Calibration...............................................................................................................................30

4 TEMPERATURE CALIBRATION ..........................................................................................................33

5 DIAGNOSTICS.......................................................................................................................................34

6 GRAPHICAL TRENDING CAPABILITIES ............................................................................................36

7 SERVICE................................................................................................................................................38

7.1 Overview.................................................................................................................................38

7.2 Cleaning..................................................................................................................................38

7.3 Equipment Service .................................................................................................................39

7.4 Recommended Preventive Maintenance Schedule ...............................................................43

8 TROUBLESHOOTING............................................................................................................................44

FIGURES

1 Cl1000 Residual Analyser Components....................................................................................7

2 Flow Diagram.............................................................................................................................8

3 Sample Cell Assembly...............................................................................................................8

4 Flow Cell Assembly ...................................................................................................................9

5 Dissociation Curve...................................................................................................................10

6 Variation with pH .....................................................................................................................10

7 Galvanic Cell............................................................................................................................11

8 Dimensions..............................................................................................................................13

9 Sample Line Taps....................................................................................................................14

10 Four Residual Analyser Sample System Examples................................................................15

11 Wiring Diagram........................................................................................................................16

12 Main Screen.............................................................................................................................18

13 Trend Screen...........................................................................................................................36

14 X-Axis Screen..........................................................................................................................36

15 Analysis Screen.......................................................................................................................37

EC DECLARATION OF CONFORMITY…………………………………………………………………………45

AMMENDMENT RECORD SHEET……………………………………………………………………………....46

4

Safety

The recommended operating procedures have been designed with careful attention to safety. Severn

Trent Services has made formal safety reviews of the initial design and any subsequent changes. This

procedure is followed for all new products and covers areas in addition to those included in applicable

safety standards. Regardless of these efforts, it is not possible to eliminate all hazards from the test

equipment or to foresee every possible hazard that may occur. It is therefore essential that the user, in

addition to following the safety rules in this manual, also carefully consider all safety aspects of the test

before proceeding. Safety is the responsibility of the user.

This equipment has been designed in accordance with safety specifications IEC 1010-1 and ANSI/ISA

S82.01 and meets the requirements for Class I, Installation Category II equipment.

Observe the following safety precautions:

Observe all safety warnings marked on the equipment. These warnings identify areas of

immediate hazard, which could result in personal injury, or loss of life.

Do not use this equipment for any purpose other than described in this manual.

Disconnect power to the Cl1000B prior to making any terminal connections within the monitor

enclosure.

Do not operate the equipment with the electronics enclosure open for an extended period of time.

Operation without the protective instrument covers presents an electric shock hazard.

Use all practical safety precautions to prevent contact with energized parts of the equipment and

related circuits.

Use the recommended connection procedures described in Section 2 of this manual.

The Cl1000B Residual Analyser operates from a single-phase power source. A three-wire power cord is

required for power connection. The voltage to ground from either pole of the power source must not

exceed the maximum rated operating voltage, 240 VAC. Before making connection to the power source,

determine that the voltage of the power source is correct. The power source must have a fuse or circuit

breaker, recommended rating: 2 Amp anti surge MCB.

Severn Trent Services recommends that qualified personnel install and connect the instrument.

Component replacement and internal adjustments must be made by qualified service personnel only.

5

1 INTRODUCTION

1.1 General Description

The Capital Controls® Cl1000B Residual Analyser is an amperometric instrument designed to

continuously analyse residual levels of free chlorine or other oxidants in water, or aqueous liquids

without the use of a buffer reagent.

1.2 Glossary

1.2.1 Physical

mg/l Milligrams per liter

µg/l Micrograms per liter

ppm Parts per million (in water same as mg/l)

ppb Parts per billion (in water same as µg/l)

ml/min Milliliters per minute (as in sample flow)

1.2.2 Electronic

PC Personal computer

PSU Power Supply Unit

I/O Input and output

RS232 Standard form of serial communications, used in modems and faxes, etc.

RS485 Similar protocol to RS232 but uses different hardware to allow

communication over a long distance

PLC Programmable Logic Controller - a computer used for distributed control

RTD Resistive Temperature Detector

SCADA Supervisory Control And Data Acquisition - a plant control system

1.3 Definitions

Menu - The series of selections boxed and arranged vertically on the left side of the screen.

Return - The Return key will always return the user to the previous screen. When changing

values within a screen, pressing the Return key [ ]stores the new value.

Default - Pressing the Default key will restore factory settings.

Restore - Pressing the Restore key will restore the parameter to the previous setting or value.

Cold Start - A procedure for fully initialising the microprocessor.

Locked Up - A condition where the monitor appears to be completely frozen. This is usually a

microprocessor condition. This is rarely a permanent condition and can usually be cured with a

cold start.

6

1.4 Specifications

1.4.1 General

Quality Standards: Severn Trent Water Purification Ltd is ISO 9001:2000 Certified

Compliance: CE, UL (optional)

Residual Measured:

Free Chlorine

Bromine

Iodine

(Consult Factory for other oxidants)

Instrument Range: Automatic ranging from 0 - 60 (mg/l)

Display: 4" x 3", dot-matrix, graphical display

Data Logging: Up to 28 days; previous 7 days; previous 24 hours

Resolution: 0.001 mg/l for below 10 mg/l, 0.01 for 10 - 60 mg/l

Sensitivity: 0.001 mg/l or 1 ppb

Residual Units (Configurable): mg/l or ppm, µg/l or ppb

Analyser Location: As close as possible to sample point

Speed of Response: Twelve (12) seconds from sample entry to display indication. 90%

of full-scale response within 1½ to 2 minutes.

Ambient Temperature: 32°F-140°F (0°C-60°C)

Languages: English (for other languages, consult factory)

1.4.2 Electrical

Power Requirements: Automatic power recognition from 85-264 Vac, 47-63 Hz, single

phase; or 24 Vdc

Power Consumption: 50 Watts

Fuse: 2.5 amp, fast blow, 250 Vac, 5 mm x 20 mm

Output Signal: Dual 4-20 mAdc, 0-20 mAdc, 0 -10 mAdc, isolated into 1000 ohms max.

Relay Contacts: Six. Each relay is independently configurable to be high, low, attention,

or fail. The fail relay can be set by a hardware jumper to indicate a power failure. There

are also settings for hysteresis, delay and action. Alarm contacts 5A @ 240 Vac resistive.

1.4.3 Sample Data:

Sample Flow: 150 ml/min at 5 psig minimum (10 psig maximum)

Sample Temp: 32°F-120°F (0°-50°C)

Sample Supply: Continuous. Where sample interruption may be required, provision must

be made to keep electrodes wet.

Sample Limitations: Samples containing particles 100 microns (0.004 inches) in

diameter and larger may require pre-filtration. Samples containing high concentrations of

metal ions, oils, or certain corrosion inhibitors may effect analyser operation. Consult

factory for specific applications.

E.g. A hardness of 50ppm per 1ppm chlorine is required to supply sufficient proton

donors (eg 0.2ppm chlorine requires 10ppm hardness).

Accuracy: 1% of reading or ±0.002 mg/l, whichever is greater for residual levels below 20

mg/l; 5% of reading for residual levels 20-60 mg/l (see sample limitations).

7

1.4.4 Instrument Data:

Electronics Enclosure: NEMA 4X

Electrodes:

Cathode (measuring) - Gold

Anode (counter) - Copper

Reference - Ag/AgCl reference electrode

Shipping Weight: 22 lbs (10 kg)

Dimensions: 12.9" (w) x 12.9" (h) x 7.7" (d) (330 mm x 330 mm x 195 mm)

1.5 Principle of Operation

A sample of liquid is delivered to the sample inlet chamber at an approximate rate of 150

ml/minute. The excess overflows to drain. The flow to the analyser is monitored by a unique

infrared flow detection system (Reference Figure 2).

A 100 Ohm RTD is located in the inlet chamber, to allow for temperature compensations. The

sample then passes through an annular space between two electrodes in the sensing cell

assembly. (Reference Figure 3) As it passes, a small DC current is generated in direct linear

proportion to the amount of residual present in the sample. A third, reference electrode, located

upstream of the sensing cell, establishes a constant potential on the working electrode to provide

an accurate stable residual indication. The residual value is displayed on the dot-matrix display in

4 1/2-digit or graphical format. Residual units of ppb, µg/l, mg/l or ppm are user-selectable.

Figure 1 – Cl1000B Residual Analyser – Components

8

Figure 2 – Flow Diagram

Figure 3 – Analyser Cell Assembly

The surfaces of both electrodes in the sensing cell assembly are kept clean by the continuous

action of PVC spheres agitated by a motor-driven rotating striker assembly. This constant cleaning

minimizes signal drift and recalibration, and provides an accurate residual measurement. The

sensing cell assembly, including stepper motor, motor cable with quick-disconnect for connection

to electronics enclosure, cathode, anode, PVC spheres, and agitator assembly can be removed

from the wet-end of the analyser as a single assembly, for easy maintenance. A 100-ohm RTD

compensates for temperature variations.

9

Figure 4 – Flow Cell Assembly

The sample tap assembly (fig 4, 19) is an optional extra.

10

1.6 Chlorine Chemistry

As chlorine dissolves in water, hypochlorous acid (HOCl) and hydrochloric acid (HCl) are formed

according to the following equation:

Cl2+ H2O →HOCl + HCl

Hypochlorous acid may be formed with the addition of hypochlorite [e.g. sodium hypochlorite

(NaOCl) or calcium hypochlorite (Ca(OCl)2)] to water.

NaOCl + H2O →HOCl + Na++ OH-

Ca(OCl)2+ 2H2O →2HOCl + Ca2+ + 2OH-

Hypochlorous acid is a weak acid, only partially dissociating into hydrogen and hypochlorite ions.

The sum of hypochlorous acid and hypochlorite ion in solution is called “free available chlorine".

HOCl →H++ OCl-

The degree of dissociation (or ionization) of hypochlorous acid is

affected by the availability of protons. Historically it was thought

that successful measurement of residual chlorine required a low

pH. In a zero hardness water with decreasing pH, the degree of

dissociation of hypochlorous acid decreases. Below

a pH of 5.0, the dissociation of hypochlorous acid is virtually zero,

regardless of temperature. As temperature increases or

decreases, the dissociation curve shifts along the pH axis. See

Figure 5.

This is only true if there is no other source of protons, except for

the low pH. For the electroreduction of chlorine there must be a

sufficient supply of protons, which can be provided by the natural

hardness in water. 50ppm of hardness (as CaCO3) is required per

1.0ppm of free chlorine to be measured.

As long as a sufficient supply of protons is available (hardness),

and with temperature compensation, the chlorine residual is

measurable at any pH below 9. See figure 6.

Figure 5 – Dissociation Curve

Figure 6 – Cl1000B Residual measurement on a sample with a constant residual, but varying pH

0

0.05

0.1

0.15

0.2

0.25

0.3

4.5 5.5 6.5 7.5 8.5 9.5

pH

Cl2 (mg/l)

11

SOLUTION

Cu° Cu + 2e

++ - HOCI + 2e

-

+ -

CI + OH

CATHODEANODE

1.7 Galvanic Cell Theory

Water, in pure form, is relatively nonconductive, but addition of an ionizing species (e.g. salt)

allows current to pass. The greater the concentration of ions in solution, the greater the

conductance of the solution.

If two electrodes are immersed in an ion containing solution, a chemical species capable of being

reduced (gaining electrons) can move toward the cathode where electrons are transferred from

the cathode to the reducible species, resulting in a cathodic current.

At the same time, an oxidation reaction (where an oxidizable species loses electrons) occurs at

the anode. Electrons are then transferred to the anode, producing an anodic current.

As the reaction occurs at the cathode, the

concentration of the reducible species at the

cathode drops. In response to the resultant concentration

gradient created, more of the reducible species moves

toward the cathode. This is referred to as diffusion. The

speed of movement of the reducible species toward the

cathode is called the rate of arrival.

The rate that the reducible species arrives at the cathode is

dependent on its concentration. As the concentration

increases the diffusion to the cathode increases, which

increases the current.

The current is also affected by temperature. With elevated

temperatures, diffusion increases. Most systems

compensate for temperature in some fashion.

Figure 7 – Galvanic Cell

If the electrodes are made of two (selected) dissimilar metals and the proper conditions exist with

regard to solution composition, current can be produced by simply connecting (shorting) the

electrodes. This type of cell is called a galvanic cell.

In a galvanic cell, a change in concentration is detected by measuring the change in current

flowing through the cell (Reference Figure 7). The cell current responds proportionally to changes

in concentration.

The cathode in the galvanic cell used in the Cl1000B Chlorine Analyser is gold. When

hypochlorous acid (or hypochlorite ion) is present in solution, electrons are exchanged at the

cathode surface and chloride ions are produced.

HOCl + 2e-→Cl-+ OH-

The anode is copper. As electrons are exchanged, an oxide product remains on the anode.

Because of this, an abrasion mechanism (constant stirring of cleaning spheres) is incorporated to

strip the oxide product off the metal surface. Since copper is consumed in the process, the term

sacrificial anode is applied to the copper electrode.

In addition to the gold cathode and copper anode, the Cl1000B includes a third, reference

electrode. The reference electrode fixes the potential across the cathode to provide an accurate,

stable residual indication.

Current flow in the amperometric cell may be affected by large changes in pH.

Temperature compensation circuitry is employed to counter the effects of diffusion and other

factors that are affected by temperature.

Copper Gold

12

2 INSTALLATION

2.1 General

The Capital Controls® Cl1000B Residual Analyser is designed for a multitude of applications. This

instrument will provide unparalleled accuracy for drinking water, cooling water, beverage,

industrial effluent, RO membrane, and process control applications or any application where

highly accurate chlorine detection and control are necessary. The tasks described in this section

require that individuals be technically knowledgeable and aware of proper safety procedures.

Individuals must adhere to all applicable electrical and plumbing codes.

2.1.1 Unpacking

Remove the instrument from its packing container and carefully inspect each item and

report damages immediately. Be sure that the following items were included in the carton:

Capital Controls® Cl1000B Residual Analyser

Electronics and Wet-End Mounted on a PVC panel

Reference electrode

Sample flowmeter

Sample Tubing

Drain Tubing

Sample Tubing Connectors (1/4" MNPT x hose)

Instruction Manual

2.1.2 Environmental Requirements

The instrument is designed for general duty indoor installation. Outdoor installation is

possible if the instrument is shielded from dripping water and not mounted in direct

sunlight. Ambient temperatures should range from 32°F to 140°F (0°C to 60°C) with

sample temperatures from 32°F to 120°F (0°C to 50°C).

2.1.3 Location

In order to obtain optimum performance from the Capital Controls® Cl1000B Residual

Analyser, selection of a good, representative sampling point is critical. If a sampling point

is too close to the chlorine feed, inadequate mixing, or incomplete chlorine/sample

reaction may occur. The sampling point should be where the sample and chlorine is

reacted and mixed thoroughly so the analyser is indicating the representative residual

chlorine being carried throughout the water system.

All residual analysers should be located as close to the sampling point as possible to

reduce sample lag time. Sampling lines should be run with small diameter tubing to

minimize the lag time.

The electronics enclosures of the Capital Controls® Cl1000B Residual Analysers are

rated NEMA 4X and are designed to protect the electronics from typical conditions in

water treatment plant or industrial facilities.

13

Figure 8 – Dimensions

2.2 Mounting

2.2.1 Wall Panel

Dimensional drawings are given to aid installation and to determine the position of

mounting holes. See Figure 8.

a. Position the analyser panel on a wall at eye level and as close as possible to the

sample source.

b. Secure with four (4) each x 6mm bolts, leveling the analyser before securing.

c. Use a spirit-level to level the instrument. This ensures that the sample liquid will

flow correctly through the instrument.

2.3 Hydraulic Connections (Wall Panel Only)

2.3.1 Procedure

a. Connect a length of 8mm (5/16”) drain hose to the drain outlet on the analyser.

Route the hose to maintain a gravity fed drain (downward slope).

NOTE: the drain connection is also the sample overflow connection and may be

recycled into the sample stream. Refer to Figure 1.

b. Connect a length of 5/16" sample supply tubing to the source using the 1/4" NPT

connector. Connect the other end of the sample supply tubing to the analyser

inlet. The maximum desired pressure for the flow is 10 psig (0.6 bar). The sample

tubing is rated to 55 psig (3.8 bar).

c. A sample tap assembly (figure 4, 18) attaching to the sample drain, is available as

an optional extra.

14

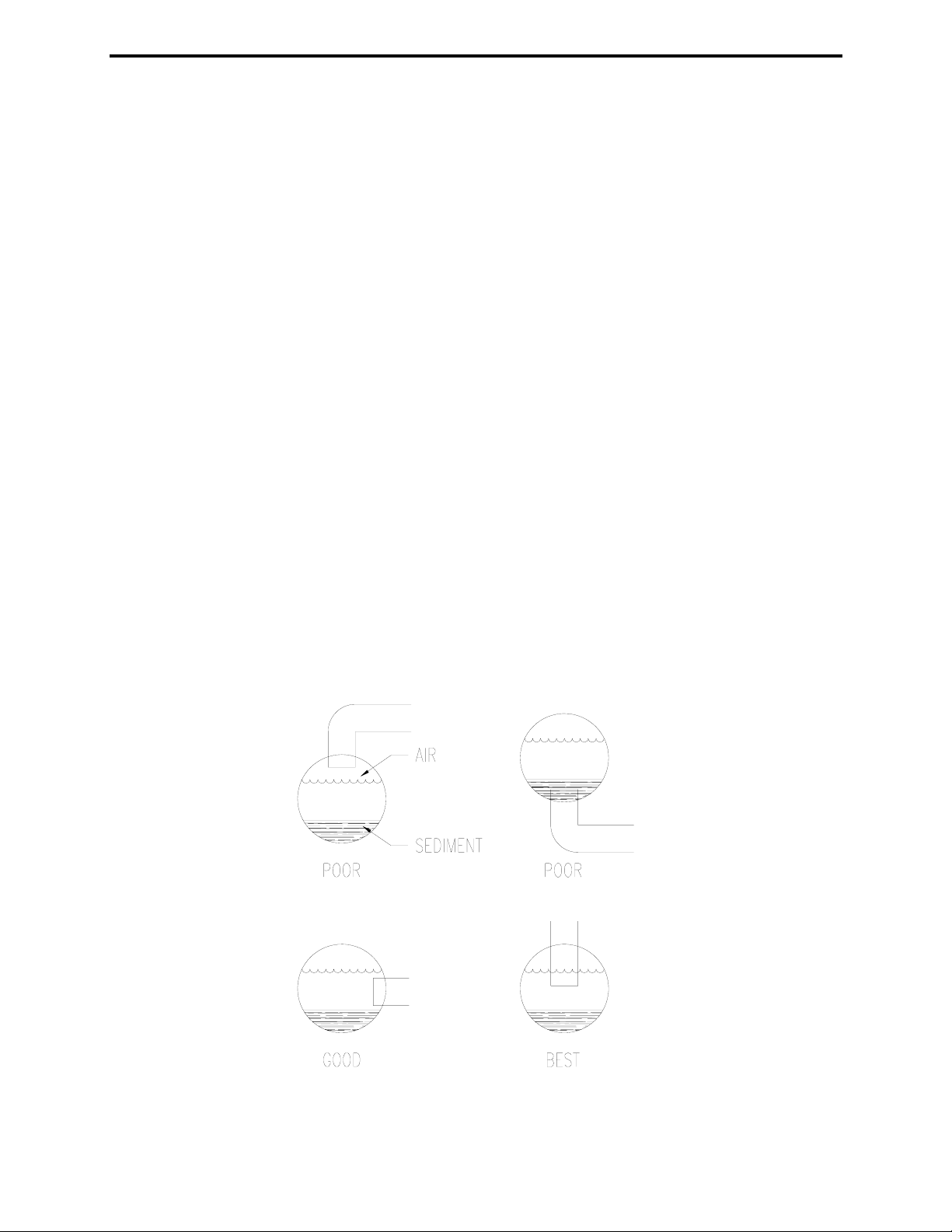

2.3.2 Sample Line Taps

Sample line taps into larger pipes should be installed to minimise the chances of air

bubbles or sediment entering the analyser. A tap should project into the centre of the line.

Refer to Figure 9.

2.3.3 Sample Flow

A typical installation may require a sample pump if the pressure is low and/or a Y-strainer

to remove any particulates. There may also be a need for a pressure reducing valve if

the sample pressure is too high or the sample pump needs to be regulated. Refer to

Figure 10.

2.4 Electrical

WARNING: FAILURE TO DISCONNECT POWER TO THE Cl1000 RESIDUAL ANALYSER

PRIOR TO ACCESSING THE INTERIOR OF THE ELECTRONICS ENCLOSURE MAY

RESULT IN SERIOUS PERSONAL HAZARD FROM EXPOSURE TO LETHAL VOLTAGES.

CAUTION: ALL WIRING MUST COMPLY WITH APPLICABLE LOCAL AND NATIONAL

ELECTRICAL CODES.

2.4.1 Wall Panel Mounted Conduit Connections - Refer to Figure 11

a. Remove four (4) screws securing the terminal cover located below the computer

screen.

WARNING: POWER FOR THE UNIT SHOULD BE SUPPLIED FROM FUSED

DISCONNECT (2 Amp anti surge MCB recommended). THIS DISCONNECT

SHOULD BE LOCATED IN CLOSE PROXIMITY TO THE UNIT AND SHOULD

BE LABELED AS THE DISCONNECT FOR THE UNIT. WIRING SHOULD

FOLLOW ALL APPLICABLE LOCAL ELECTRICAL CODES AND

REGULATIONS.

Figure 9 – Sample Line Taps

15

Figure 10 – Four (4) Residual Analyser Sample System Examples

b. Connect the power wiring to terminals labeled L1, N and ground.

d. Connect current output and alarm contacts.

NOTE: The green relay terminal strips ‘snap’ out to allow more room for cable

connection. Pull gently on the green terminal strip to remove, connect electrical

cables, and ‘snap’ terminal strip back in place on the terminal board.

CAUTION: DO NOT RUN LINE VOLTAGE AND LOW LEVEL SIGNAL

VOLTAGE IN THE SAME CONDUIT.

e. Replace terminal cover and secure with four (4) screws

16

Figure 11 – Wiring Diagram

17

3 STARTUP

3.1 Conditioning the Analyser

WARNING: FAILURE TO DISCONNECT POWER TO THE Cl1000 RESIDUAL ANALYSER

PRIOR TO ACCESSING THE INTERIOR OF THE ELECTRONICS ENCLOSURE MAY RESULT

IN SERIOUS PERSONAL HAZARD FROM EXPOSURE TO LETHAL VOLTAGES.

3.1.1 Remove the soaker teat from the measuring end of the electrode and place the reference

electrode in the reference electrode reservoir (See Figure 2).

Note: Retain the soaker teat for future use.

CAUTION: REFERENCE ELECTRODE MUST REMAIN IN REFERENCE ELECTRODE

RESERVOIR AT ALL TIMES DURING THE OPERATION OF THE Cl1000. REMOVAL

OF THE REFERENCE ELECTRODE FROM THE RESERVOIR DURING OPERATION

MAY CAUSE ERRONEOUS READING AND LEAD TO EQUIPMENT DAMAGE.

3.1.2 Start the sample water flow at approximately 150 ml/minute. If using the data from the

built in flow cell make sure the flow rate displayed in the diagnostics screens is at least

500mls/minute (the flow cell is used to detect flow/no flow and the actual flow rate

displayed tends to under read the actual real flow rate.

Water must be flowing over the overflow weir in the sample inlet chamber to drain.

3.1.3 If the system requires occasional cutoff, provisions must be made to keep the electrodes

wet.

3.1.4 Sampling from a pressurized source may require a pressure reducing valve to hold the

flow constant. Maximum desired pressure is 10 psig (0.6 bar).

3.1.5 If sampling from turbid water, a flushing Y-strainer is necessary to prevent clogging of the

sample line. Other types of filters are not recommended.

3.1.6 Connect power to the analyser terminals. (See Section 2.4)

3.1.7 Switch on the power to the analyser at the isolation point.

3.1.8 Turn ON the power switch on the analyser. To clear the analyser memory and return the

set up parameters to their factory defaults (perform a cold start), hold down the two left

keys on the keypad while you turn the analyser power switch ON.

NOTE: The analyser will take approximately 45 seconds to ‘boot up’.

3.1.9 Go to the analyser ‘Set Up’ to adjust any of the preconfigured screen settings on the

monitor. See Section 3.3.

3.1.10 For maximum accuracy the analyser requires a stabilisation time of up to 24 hours

however a result within ±10% is normally achieved within 1 hour. The analyser should be

run continuously, without interruption of power. Turning off the cell, even momentarily, will

require the appropriate stabilisation time upon restart. During operation, sample must be

feeding into the cell.

3.1.11 After stabilisation, calibration of the analyser may begin. See Section 3.4.

3.2 Programming the Monitor

All programmable options necessary for operation of the monitor are accessible through the four-

button keypad and display. To move from screen to screen, follow the instructions on the display.

From anywhere in the software, the [] key (far right key) will always return the monitor to the

18

previous screen. At factory default, the software is programmed to automatically return to the main

screen after 60 minutes without user interface.

3.2.1 Main Screen

The Main Screen is the default screen for viewing the residual value in digital format. The

residual value appears on the screen in four (4) x 1-inch high digits and a decimal; the

decimal place automatically shifts according to the residual value. The residual oxidant

and units (e.g. mg/l free Cl2) are displayed on this screen in smaller digits under the

residual value, and the current time and date are indicated at the top of the screen. The

software is programmed to automatically return to the main screen after 60 minutes

without user interface, unless the user is viewing the data in graphical format. From the

Main Screen, the user can initiate four selection options: Graphing, Calibration, Set Up, or

Diagnostics. If an error or alarm condition takes place, a warning message will appear

across the lower section of the screen, just above the user interface options.

Figure12 Main Screen

3.3 Set Up

The user set up screens are designed to allow for hardware and software adjustments to the

Cl1000 to configure the unit for site-specific operation. The following table summarises the user-

configurable options and the location of the screens for these adjustments:

Screen Name Screen Function Notes

Set Up Lists adjustable Set Up Parameters There are a total of 8 adjustable

parameters on the Set Up Screen (note

continuation arrows for additional options)

Buffer In the manual buffer adjustment mode,

this screen allows the user to adjust

the buffer feed rate.

No buffer used on Cl1000B

Therefore not used in Cl1000B

Buffer Setpoint Not used for Cl1000B

Setpoint Enter Not used for Cl1000B

Screen LCD settings, including screen

brightness, contrast and screen saver

are adjusted under this selection

Bright Allows user to adjust screen brightness

Contrast Allows user to adjust screen contrast

Lamp The lamp saver and timeout are

adjusted under this screen

Lamp Selection This screen allows the user to

configure the lamp to be always on, or

to go to low power after 10 minutes, 5

minutes, or 1 minute of inactivity. This

allows the user to adjust the life of the

lamp per operational requirements.

If the lamp is configured to go to low power

after a time period, any button press will

return the screen to the normal brightness.

19

Screen Name Screen Function Notes

Screen Timeout The software for the Cl1000 is

designed to return to the digital display

on the main screen after a period of

inactivity when the user is in any of the

Calibration, Set Up, or Diagnostic

screens. This screen allows the user to

set this time period at 60 minutes, or to

turn the screen timeout off.

If amperometric titration is being used to

confirm calibration of the instrument, the

screen timeout should be set at 60 minutes

to allow time for the calibration results.

Date Settings The current date and time can be

adjusted under this screen, along with

the date format

Time The current time is adjusted from this

screen. The current time is indicated

on the top line of every screen.

Date The current date is adjusted from this

screen. The current date is indicated

on the top line of every screen.

Date Format The current date, which appears on

the top line of every screen, can be

configured to appear in

month/day/year, day/month/year, or

year/month/day format.

Outputs The user configures the two mA output

signals and the alarm relays under this

selection

mA Output A The function (or range) and high and

low set points for mA Output Signal A

are configured under this selection

1. Each mA output signal is independently

configurable.

2. The mA outputs and relays are

configured under the Output Set Up

screens. These outputs can be tested

under the Diagnostics screen.

mA Output A

Function The value of mA Output Signal A can

be configured for 4-20 mA, 0-20 mA, or

0-10 mA from this screen

mA Output A

Low

Setting

The residual value for the low mA set

point for Output A is configured from

this screen.

mA Output A

High

Setting

The residual value for the high mA

setpoint for Output A is configured

from this screen

mA Output B The function (or range) and high and

low set points for mA Output Signal B

are configured under this selection

20

Screen Name Screen Function Notes

mA Output B

Function The value of mA Output Signal B can

be configured for 4-20 mA, 0-20 mA, or

0-10 mA under this screen

mA Output B Low

Setting The residual value for the low mA

setpoint for Output B is configured from

this screen.

mA Output B

High Setting The residual value for the high mA

setpoint for Output B is configured from

this screen

Relay Assignments The status (off, high, low, attention or

fail) of the six alarm relays and the

residual value to activate the alarm

relays are configured under this screen

selection

1. The actuation value of each relay

cannot be adjusted until the status of

the relay is changed to ‘high’ or ‘low’

2. A status of ‘attention’ will provide

indication when any one of a series

of errors activates the relay. These

include sample flow failure,

temperature probe failure, calibration

error or activation of a concentration

alarm (if set).

3. A fail alarm is generated for a

general failure of the intsrument or

for a power failure (set by a

hardware jumper) see fig. 10.

4. There are a total of six alarm

relays, each independently

configurable (note the continuation

arrows for additional options)

Relay 1 Status Relay 1 can be configured for high, low,

attention or fail, or can be turned off

Relay 1 Value If Relay 1 is configured for a ‘high’ or

‘low’ alarm, the residual value to

activate the alarm indication is adjusted

from this screen

Relay 2 Status Relay 2 can be configured for high, low,

fail or attention, or can be turned off

Relay 2 Value If Relay 2 is configured for a ‘high’ or

‘low’ alarm, the residual value to

activate the alarm indication is adjusted

from this screen

Relay 3 Status Relay 3 can be configured for high, low,

attention or fail, or can be turned off

Relay 3 Value If Relay 3 is configured for a ‘high’ or

‘low’ alarm, the residual value to

activate the alarm indication is adjusted

from this screen.

Relay 4 Status Relay 4 can be configured for high, low,

attention or fail, or can be turned off

Relay 4 Value If Relay 4 is configured for a ‘high’ or

‘low’ alarm, the residual value to

activate the alarm indication is adjusted

from this screen

Relay 5 Status Relay 5 can be configured for high, low,

attention or fail, or can be turned off

Table of contents

Popular Measuring Instrument manuals by other brands

Powercor

Powercor Sprint 200 reference guide

MULTISPAN

MULTISPAN PI 38 manual

MESSKO

MESSKO MLog IM50 operating instructions

Watts

Watts HF Scientific AccUView LED Ex installation instructions

METREL

METREL EurotestIM instruction manual

PCB Piezotronics

PCB Piezotronics IMI Sensors 621C40 Installation and operating manual