OVA 7000 Routine Service Manual V1.2 8

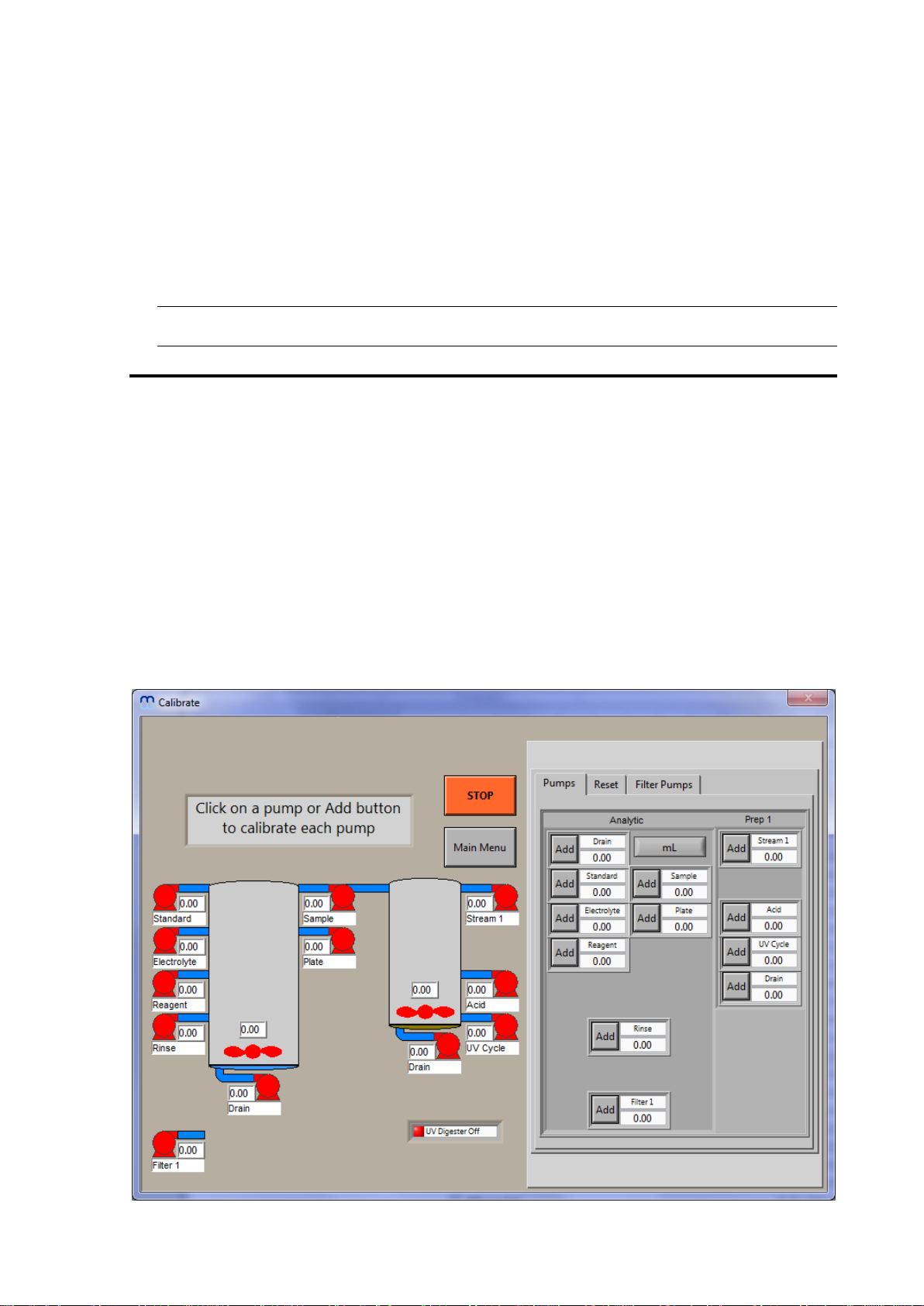

2.2 Priming Reagent Lines

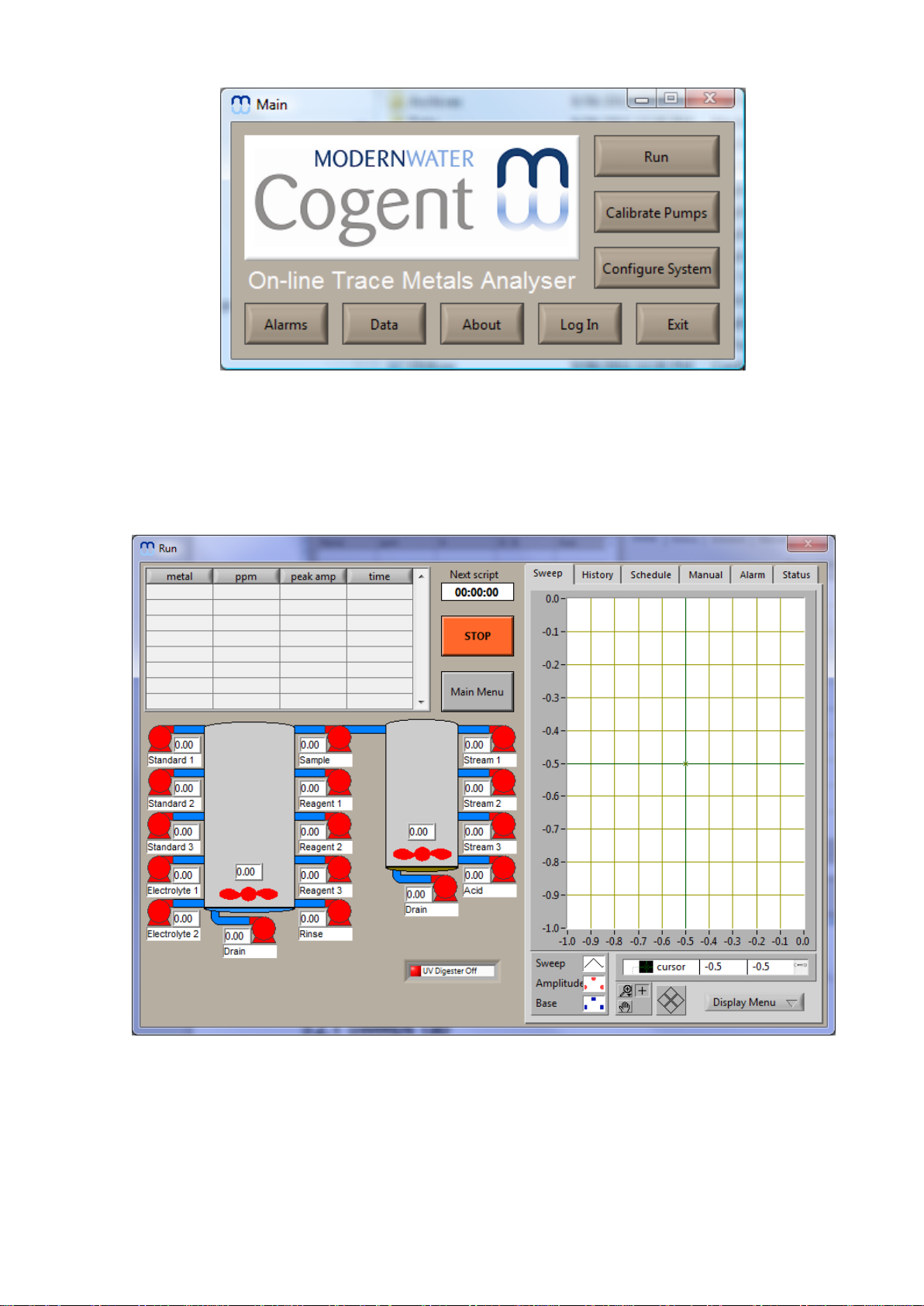

Before OVA 7000 operation, all tubing lines should be full of fresh reagent and free of air bubbles. To ensure

this, the lines need to be primed.

Prime reagent lines.

1. Ensure all reagent lines are sitting in full reagent containers, and the ends have tube weights.

2. Select the Manual tab on the Run screen.

3. Click on the pump icon for each pump to be primed. When on, the pump will turn and the pump icon

will change from red to green. All necessary pumps can be primed simultaneously if required. Also

select the drain pump for each cell to drain the cell and to prevent overflow.

4. When a line is full of reagent & free of air bubbles, click its icon again to turn the pump off.

2.3 Initiating OVA 7000 Operation

If the OVA 7000 has been inactive for a significant time, the weekly (see section 3) and or 3-monthly

maintenance procedures (see OVA 7000 Operation Manual) will need to be carried out before initiation.

Initiate OVA 7000 operation.

1. Select the Schedule tab in the Run screen.

2. Click on Run Schedule button to initiate automatic operation.

The OVA 7000 will now operate automatically in accordance with the method scripts activated by the

Scheduling feature of the OVA 7000 software. These are described in the OVA 7000 Operation Manual as they

are not routinely modified and should only be modified by suitably trained personnel.

2.4 Stopping OVA 7000 Operation

Stop OVA 7000 operation.

1. Click the Stop button in the Run screen.

2. If desired, both the Analytic and Prep cells can be drained by clicking the Drain all Cells button.

3. Exit the Run screen to the Main screen by clicking the Main Menu button.

2.5 Powering Down the OVA 7000

It is not normally necessary to power down the OVA 7000 for weekly maintenance. If it does become necessary

for any reason, follow the below procedure after stopping the OVA 7000 as described above.

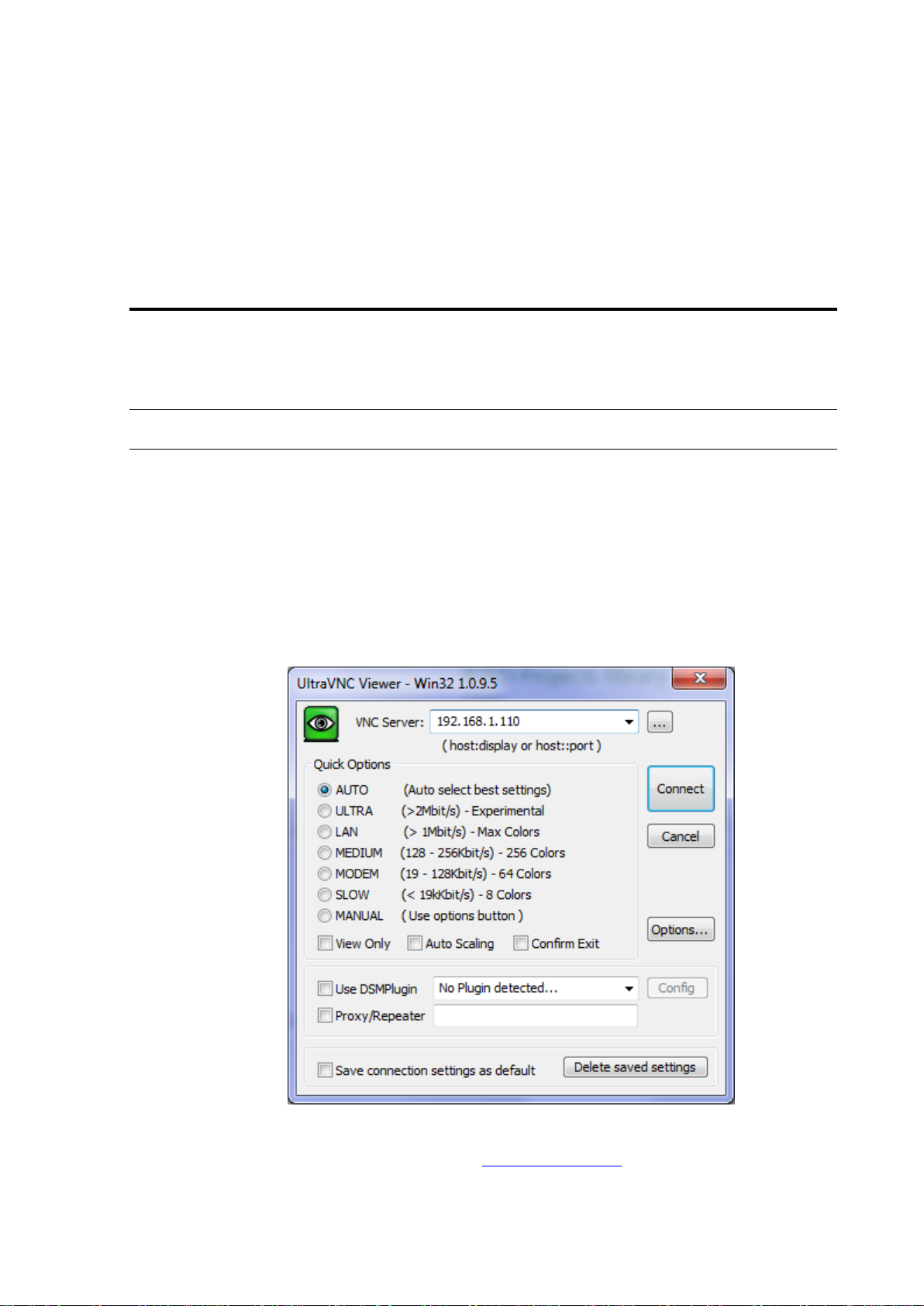

Caution: Selecting the “Shut down” option for the OVA 7000 via a remote desktop connection will result in the

OVA 7000 turning off, and an operator having to physically visit the OVA 7000 to turn it back on.

Selecting the “Restart” option will turn off and restart the OVA 7000 without a physical visit required.

Power down the OVA 7000.

1. Close the OVA 7000 software by clicking the Exit button from the Main page.

2. Shut down Windows from the Start menu in the bottom left hand corner of the screen. Select Shut Down

as with any other computer. This may take a minute to exit Windows.

3. After a minute the power to the OVA 7000 can be turn off at the supply point if desired.

Alternatively the user can restart Windows from the Start menu in the bottom left hand corner of the screen.

Select Restart as with any other computer. Power is maintained to the OVA 7000 throughout a restart

operation.