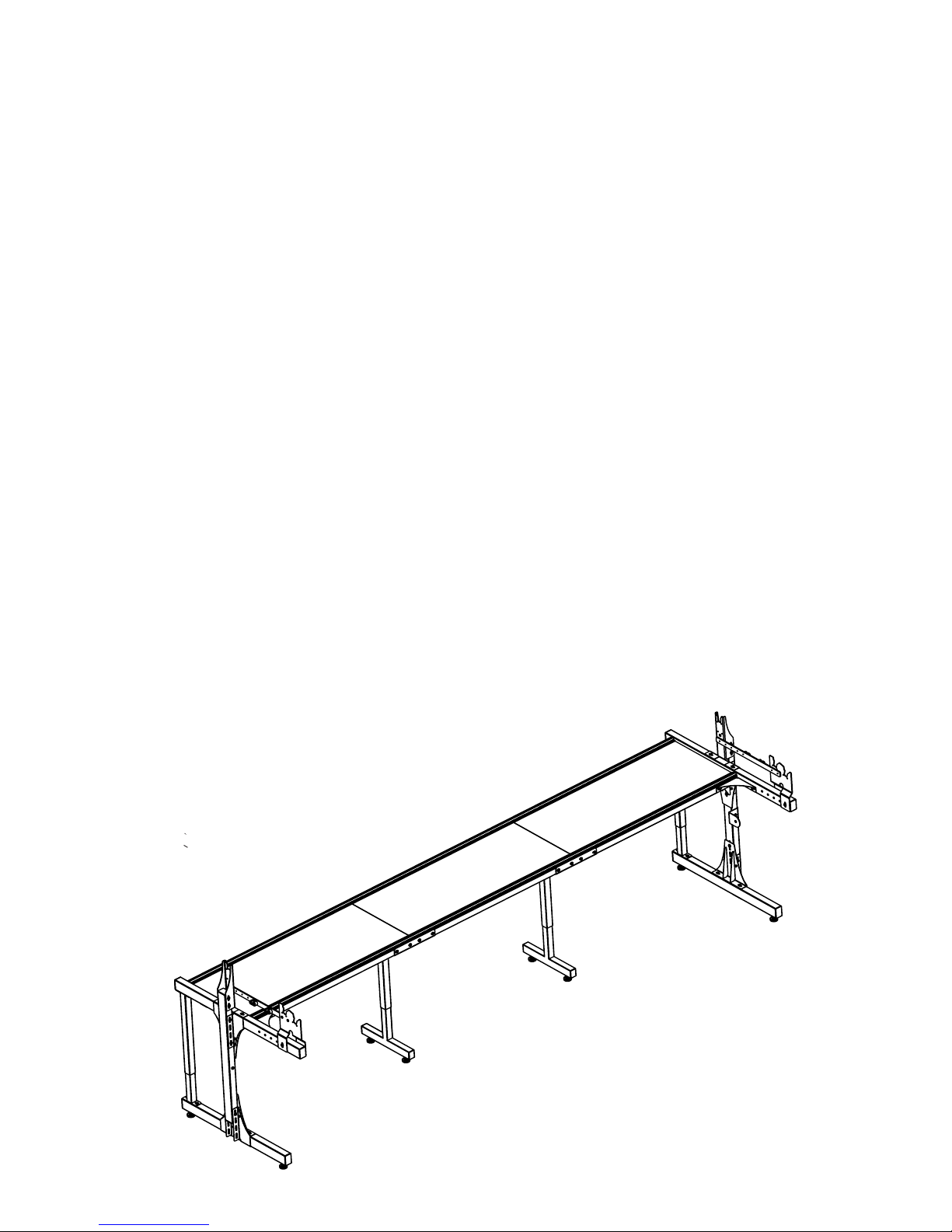

King Quilter Frame Assembly 1

King Quilter Frame

NOVEMBER 2018

Assembly Instructions

Table of Contents

Parts List ..........................................page 2

Preparation: Batting Bar Bracket Assembly, Do this First! ....page 7

Step 1: End Leg Assembly..............................page 8

Step 2: Table Assembly ...............................page 14

Step 3: Center Leg Assembly ...........................page 15

Step 4: End Leg to Table Assembly ......................page 17

Step 5: Precision-Glide Track Assembly .................. page 22

Step 6: Front Pole Carrier / Rear Pole Carrier Arm Assembly . page 25

Step 7: Bungee Cleat Assembly .........................page 26

Step 8: Leveling the Frame.............................page 27

Step 9: Pole Assembly ................................page 28

Step 10: Adding Pole Ends .............................page 29

Step 11: Pole to Frame Assembly ....................... page 31

Step 12: Rubber End Cap Assembly ......................page 32

Step 13: Bungee Clamp Assembly .......................page 33

Step 14: Hook and Loop Strips on Poles Assembly ..........page 34

Step 15: Attach Leaders ..............................page 35

#QF00007-12 and QF00007-10