Sfere PD195Z-CD32F User manual

DIN-rail Mounted DC Energy Meter

User Manual

Applied to:

PD195Z-CD32F

JIANGSU SFERE ELECTRIC CO., LTD.

2

Safety instructions

Danger sign is used to warn operation personnel that

there is a danger. If this danger is neglected, injury or

death will occur to personnel, and equipment will be

damaged.

Warning sign is used to call operation personnel’s

attention to take appropriate care measures, otherwise

injury or death will occur to personnel.

CAUTION:

◆Make sure only the qualified technicians perform the installation and

maintenance;

◆Before performing wiring operation to the meter, make sure the input signal and

the power supply are switched off;

◆The proper voltage detecting device should be used to guarantee no voltage in

any part of the meter;

◆The electrical parameters supplied should be within the rated range;

The following situations may result in damages to the meter or cause mistakes in

the operation of the meter.

◆The voltage of the auxiliary power supply goes beyond the rated range.

◆The frequency of the power distribution system goes beyond the rated range.

◆The input polarity of the voltage or the current is incorrect.

◆Remove or connect the communication plugs without powering off.

◆Connect the terminal wires against the related instructions.

Please don’t touch the terminals when the meter is in

operation!

3

Content

Safety instructions ..................................................................................... 2

1. Product introduction ............................................................................. 1

1.1 Overview ......................................................................................1

1.2 Model selection ........................................................................... 1

2. Technical specifications .........................................................................1

3 Installation and Wiring ........................................................................... 3

3.1 Dimension ....................................................................................3

3.2 Wiring .......................................................................................... 3

4 Operation ................................................................................................4

4.1 Panel ............................................................................................ 5

4.2 Display ......................................................................................... 5

4.3 Basic electricity measurement .................................................... 5

4.4 Key icon and function description ...............................................6

4.5 Settings menu overview .............................................................. 7

5 Function ................................................................................................ 10

5.1 Energy pulse output .................................................................. 10

6.1 Physical layer ............................................................................. 11

6.2 Communication protocol ...........................................................11

6.3 Message command format ....................................................... 12

6.4 Data format ............................................................................... 15

Appendix MODBUS-RTU Communication Register Information Table .. 17

Operating data .................................................................................17

Parameter settings .......................................................................... 17

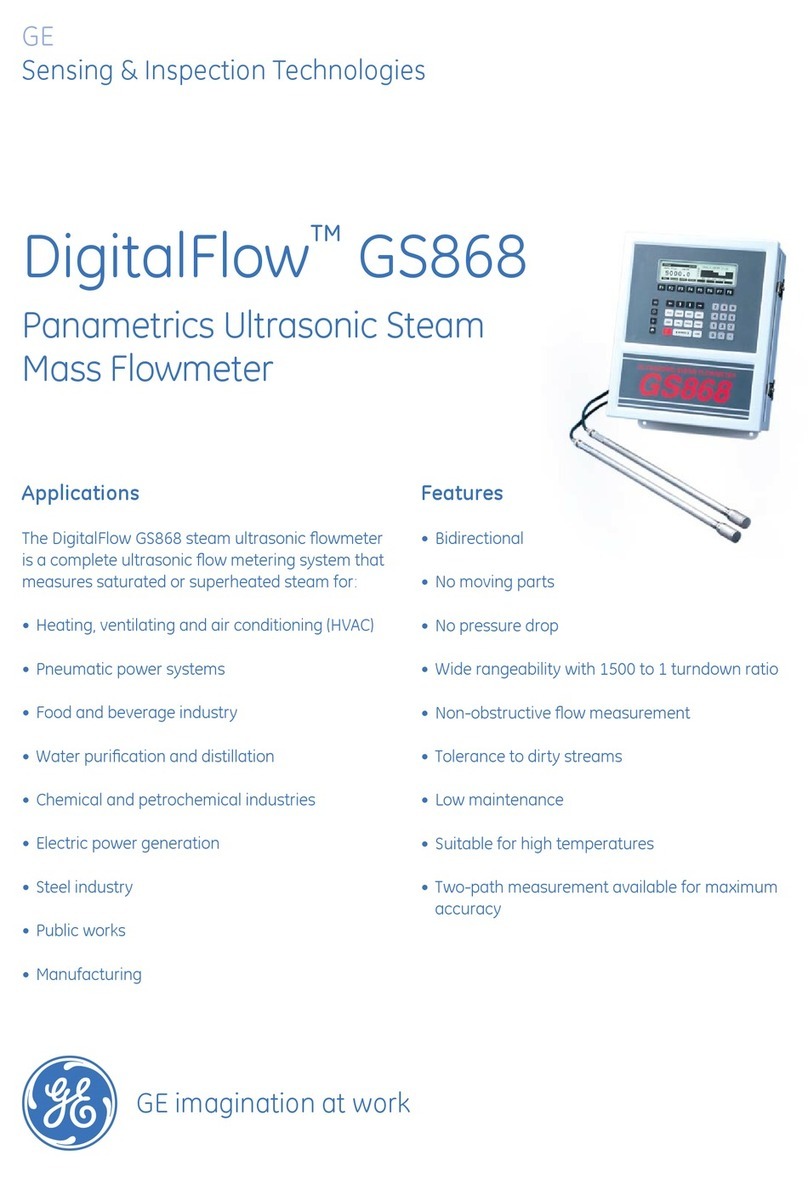

1. Product introduction

1.1 Overview

This DC watt hour meter is applicable to DC charging pile and can (support) measure

the voltage, current, power, electric energy and other parameters of two DC circuits.

It has RS485 communication interface to realize remote data transmission.

1.2 Model selection

Model

Measurements (2 channel)

COMM

Energy

Pulse

U

I

P

E

PD195Z-CD32F

DC 1000V

DC 75mV

●

●

1 loop

2 loops

2. Technical specifications

Electrical character

Accuracy

Active energy Class 1

Data refresh frequency

1s

Measuring

Voltage

Input range

DC 1000V

Measurement

range

50V~1200V

Accuracy

0.2%

Characteristic

consumption<1W,

impedance >1MΩ

Current

Input

DC 75mV

Measurement

range

0.002In~1.2In

Accuracy

0.2%

Power

Accuracy:0.5%

Power supply

Working range

DC20V~36V

Power consumption

≤1W

Communication

RS485interface, Modbus-RTU

2

Baud rate 1200~38400bps

Mechanical character

Protection

IP20

Environmental characteristics

Working temperature

-25~70℃

Storage temperature

-30~70℃

Relative humidity

≤95%RH

Pollution degree

2

Altitude

2000m

Electromagnetic compatibility characteristics

Electrostatic discharge immunity

GB/T 17626.2 IV class

Radio frequency electromagnetic

field radiation immunity

GB/T 17626.3 IV class

Electrical fast transient burst

immunity

GB/T 17626.4 IV class

Surge (impact) immunity

GB/T 17626.5 IV class

Radio interference

GB 9254 B class

3

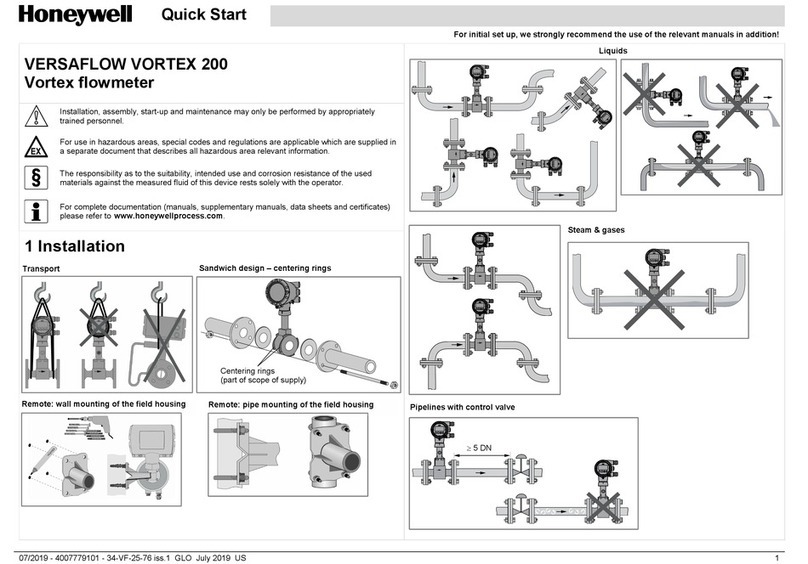

3 Installation and Wiring

3.1 Dimension

72

90

35

63.5

PD195Z-CD32F

11 12 4

1 2 5958 47 48

U1+ U1- I1+

BA +-

RS485

Power

+ -

49 50

+-

1 2

5

I1-

13 14 6

U2+ U2- I2+

7

I2-

Figure 3-2 PD195Z-CD32F Dimensions

3.2 Wiring

Figure 3-3 PD195Z-CD32F wiring

4

The terminals of the CD32F DC metering module are numbered uniformly, as

shown in the table below:

Power supply

1,2

Auxiliary working power supply

Current signal

4,5,6,7

75mV input

Voltage signal

11,12,13,14

DC voltage input

Energy pulse

47,48,49,50

47 and 49 are the positive terminal of

passive output, which is connected to the

positive terminal of the external power

supply.

RS485

58,59

A+, B-

Instructions:

(1) 1 and 2 are the auxiliary power supply of the instrument, please ensure that

the power supply is suitable for this series of products to prevent damage to the

product.

(2) For the use of the detailed wiring terminals, please connect according to

the wiring diagram on the specific product shell.

(3) The terminal of the current must not be suspended to prevent the wrong

value from being displayed.

(4) Connect the negative terminal of the voltage input to the negative terminal

of the corresponding current shunt.

4 Operation

5

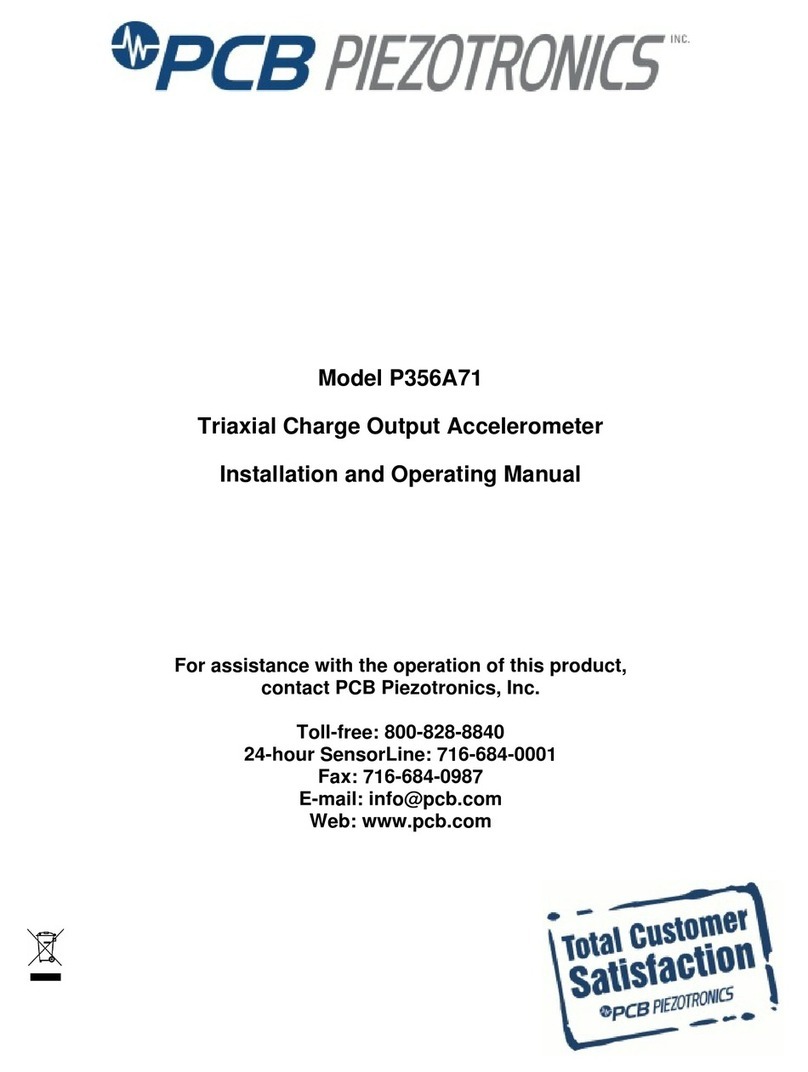

4.1 Panel

PD195Z-CD32F

Figure 4-1 PD195Z-CD32F panel diagram

4.2 Display

AB

C

A: Data (parameter) indication B: Data unit and order of magnitude

C: Data value

The meter uses segment code LCD to display meter information. Contains

information such as the unit, magnitude, type, phase, etc. of the data, as well as

communication instructions.

4.3 Basic electricity measurement

The meter measures electrical parameters such as voltage, current, power, and

electrical energy, which can be viewed on the meter screen, but some parameters

can only be read through communication.

The following table is an example of the display of basic electricity.

6

Voltage

U1=500.0V

Note: When the voltage value is greater

than 21.47MV, it is displayed as FFFF

Current

I1=100.0A

Power

P1=50kW

Positive energy

EP1=1000kwh

Negative energy

EN1=550kwh

4.4 Key icon and function description

The user can set the parameters of the instrument by pressing the keys.

Key icon

Key function description

Move options up / page forward / modify parameters / add

7

selected data bits

Move options down / page back / modify parameters

Return to the previous menu / show options to jump directly

Enter selected options

Value modification method

Press " " to move and modify the data bit, and press " " to increase the

current data bit cyclically.

Enter programming mode

In the measurement display interface, long press the " " key for more than

3 seconds, the meter will display " ", click the " " or " " key to select " ";

press the " " key to enter the password input interface, and enter the password

through the " " or " " key password (the default password is 0001), and then

press the " " key, if the password is correct, you can enter the setting interface.

Exit programming mode

After the data (or options) of the third-level menu is changed, press the " "

key to confirm the change, and press the " " key to exit the change. Press the

" " key to return to the first-level menu, and then press the " " key, the

meter will prompt "save--no", at this time, there are two options:

1) Do not save the setting parameters: press the " " key;

2) Save the setting parameters: press the " " or " " key to select "save--yes",

and then press the " " key;

3) Return to the programming menu: press the " " key

In setting operation: " " key is used for menu switch key and numerical value

left shift, " " key is used for menu switch key, numerical addition and subtraction

and movement of decimal point, " " key is used to return, " " key is used to

enter menu and confirmation after modifying the value.

4.5 Settings menu overview

8

For the detailed description of the setting menu, please refer to the following

description of the character code of the setting menu

First level

Second level

Third level

Code

Desc

riptio

n

Code

Description

Character code / value

Description

9

Syste

m

para

mete

rs

Password

~

Set user

password

Clean energy

Invalid

Valid

inpt

Input

setti

ngs

pt1-1

Circuit 1 primary

voltage

000001~999999

V

pt1-2

Circuit 1 secondary

voltage

000001~999999

V

ct1-1

Circuit 1 primary

current

000001~009999

A

pt2-1

Circuit 2 primary

voltage

000001~999999

V

pt2-2

Circuit 2 secondary

voltage

000001~999999

V

ct2-1

Circuit 2 primary

current

000001~009999

A

Com

muni

catio

n

Meter address

0001~0247

1~247

Baud rate

1200~38400

1200~

38400bps

Data format

N81

n.8.1

O81

o.8.1

E81

e.8.1

N82

n.8.2

Basic parameter settings

10

Example: Set the Modbus address to 12, modify the baud rate to 9600, and

modify the data parity format to even parity. The operations are as follows:

5 Function

5.1 Energy pulse output

The instrument provides 2-way energy pulse output to realize the verification

and remote transmission of power data. The pulse output is a collector-level

open-circuit optocoupler, and a remote computer terminal, PLC, and DI switch

acquisition module can be used to collect the total number of pulses of the

instrument to realize the cumulative measurement of electric energy. The output

11

method used is the method of accuracy inspection of electric energy (National

Metrology Regulations: Pulse Error Comparison Method of Standard Meter).

6 Communication

The instrument has one communication interface by default, and some instruments

can add one communication interface. The communication protocol is Modbus-RTU

6.1 Physical layer

1) RS485 communication interface, asynchronous half-duplex mode;

2) The communication speed can be set from 2400 to 38400 bps, and the factory

default is 9600 bps;

3) Byte transmission format (N81, E81, O81, N82): 1 start bit, 8 data bits, (1 parity

bit), 1/2 stop bit.

6.2 Communication protocol

The instrument supports the standard Modbus-RTU communication protocol.

Structure of the data frame: message format.

Address code

Function code

Data code

Check code

1 byte

1 byte

N bytes

2 bytes

Address code: Slave address, address range 1-247, other addresses are

reserved.

Function code: Indicates what function the addressed terminal performs. The

following table lists the function codes supported by the meter, as well as their

meanings and functions.

12

Code

(hexadecimal)

Significance

03/04

Read data register value

10

Write set register instruction

Data code: It contains the data required by the terminal to perform a specific

function or the data collected when the terminal responds to a query. The contents

of these data may be numerical values, reference addresses or setting values. For

example, the function code tells the terminal to read a register, the data field needs

to indicate which register to start from and how many data to read, and the

returned content of the slave data code includes the data length and corresponding

data.

Check code: The error check (CRC16) field occupies two bytes and contains a

16-bit binary value. The CRC value is calculated by the transmitting device, and then

appended to the data frame. The receiving device recalculates the CRC value when

receiving the data, and then compares it with the received CRC value. If the two

values are not equal, it indicates that an error occurred in the communication .

6.3 Message command format

(1) Read data register value (function code 0x03/0x04)

Request

Frame

structure

Address

code

Function

code

Data code

Check code

Start register

address

Number of

registers

Occupied

bytes

1 byte

1 byte

2 bytes

2 bytes

2 bytes

Data

range

1~247

0x03/0x04

0x0000~0xFFFF

Maximum 125

CRC16

Message

example

0x01

0x03

0x00 0x06

0x00 0x06

0x25C9

Response

13

Frame

structure

Address

code

Function

code

Data code

Check code

Register bytes

Register value

Occupied

bytes

1 byte

1 byte

1 byte

12 bytes

2 bytes

Message

example

0x01

0x03

0x0C

12 bytes of data

CRC16

Note

:

The starting register address requested by the host is the first data address of

the primary grid or secondary grid to be queried, and the number of registers is the

length of the query data. For example, the starting register address "0x00 0x06"

represents the three-phase phase voltage float type data address. The number of

registers "0x00 0x06" means the data length is 6 (3 float data occupies 6 registers).

14

(2) Write setting register instruction (function code 0x10)

Request

Frame

structure

Address

code

Function

code

Data code

Check

code

Register

start

address

Register

length

Register bytes

Write

value

Occupied

bytes

1 byte

1 byte

2 bytes

2 bytes

1 byte

2N

bytes

2 bytes

Data

range

1~247

0x10

0x080A

0x0001

N

CRC16

Message

example

0x01

0x10

0x08 0x0A

0x00 0x01

0x02

0x0064

0x2ED1

Response

Frame

structure

Address

code

Function

code

Data code

Check

code

Register start address

Register length

Occupied

bytes

1 byte

1 byte

2 bytes

2 bytes

2 bytes

Message

example

0x01

0x10

0x08 0x0A

0x00 0x01

0x23AB

Note

:

When writing the setting register, please strictly follow the meter setting

information address table in the meter appendix. Wrong writing to the setting

register may cause the instrument to work abnormally, please operate with caution.

15

6.4 Data format

Some measurement data of the meter provides primary data and secondary

data, such as voltage, current, power, electric energy, etc. There is a proportional

relationship between the two data. For example, the secondary data of voltage

multiplied by the ratio of the voltage transformer equals the primary data, the

secondary data of the current multiplied by the ratio of the current transformer

equals the primary data, and for the power and electric energy data, it needs to be

multiplied by The ratio of voltage and current transformers is equal to the primary

data.

(1) 32bit floating point format

32bit floating point format data follows the IEEE-754 format. The byte order of

the data adopts the big endian method, with the high byte first and the low byte

last.

(2) 16bit integer format

The 16bit integer format data adopts the complement storage method. The

byte order of the data adopts the big endian method, with the high byte first and

the low byte last.

(3) 32bit integer format

The 32bit integer format data adopts the complement storage method. The

Address (Hex)

Data (Hex)

Description

0000-0001

435C-8000

0x435C8000 = 220.5

0002-0003

4360-4CCD

0x43604CCD = 224.3

0004-0005

435E-B333

0x435EB333 = 222.7

Address (Hex)

Data (Hex)

Description

0000

0230

0x0230 = 560

0001

0172

0x0172 = 370

0002

0096

0x0096 = 150

16

byte order of the data adopts the big endian method, with the high byte first and

the low byte last.

Address (Hex)

Data (Hex)

Description

0000-0001

0007-A120

0x0007A120 = 500000

0002-0003

0000-07D0

0x000007D0 = 2000

0004-0005

FFFF-FDF0

0xFFFFFDF0 = -528

17

Appendix MODBUS-RTU Communication Register Information Table

Operating data

Address-HE

X

Address-

DEC

Form

at

Data description

Unit

R/W

0006-0007

6-7

Int32

Circuit 1 voltage

0.1V

R

0008-0009

8-9

Int32

Circuit 1 current

0.1A

R

000A-000B

10-11

Int32

Circuit 1 power

0.1kw

R

000C-000F

12-15

Int64

Circuit 1 positive energy

10wh

R

0010-0013

16-19

Int64

Circuit 1 negative energy

10wh

R

0014-0015

20-21

Int32

Circuit 2 voltage

0.1V

R

0016-0017

22-23

Int32

Circuit 2 current

0.1A

R

0018-0019

24-25

Int32

Circuit 2 power

0.1kw

R

001A-001D

26-29

Int64

Circuit 2 positive energy

10wh

R

001E-0021

30-33

Int64

Circuit 2 negative energy

10wh

R

Parameter settings

Address-HE

X

Address-DE

C

Form

at

Data content

Data description

R/W

0801

2049

Int16

Instrument setting

password

0000-9999

R/W

0804

2052

Int16

High byte: #1 meter

address

1-247

R/W

Low byte: #1 baud

rate

0:1200bps,

1:2400bps,

2:4800bps,

3:9600bps,

4:19200bps,

5:38400bps

0805

2053

Int16

High byte: #1 check

format

0:N,8,1,1:E,8,1

2:O,8,1,3:N,8,2

R/W

Table of contents

Other Sfere Measuring Instrument manuals