____________________________________________________________________________________________

State: 09/2010 Technical changes reserved! 4

Technical documentation and

instruction manual

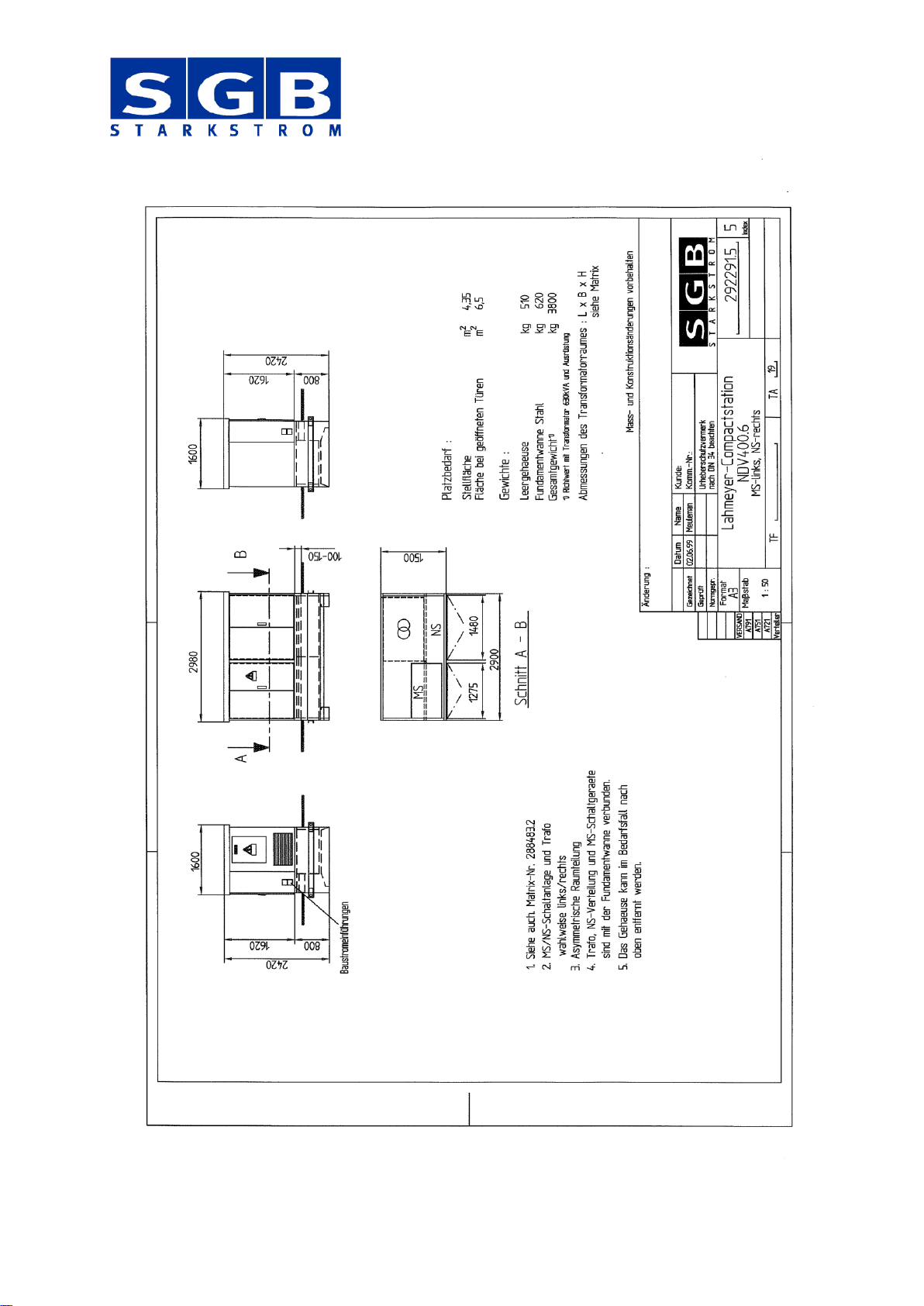

Lahmeyer-Compact-Station®

Type NDV400/401

Zeichnungs.-Nr.. 0152J77.0

2. Station housing

Temperature class = 15 K

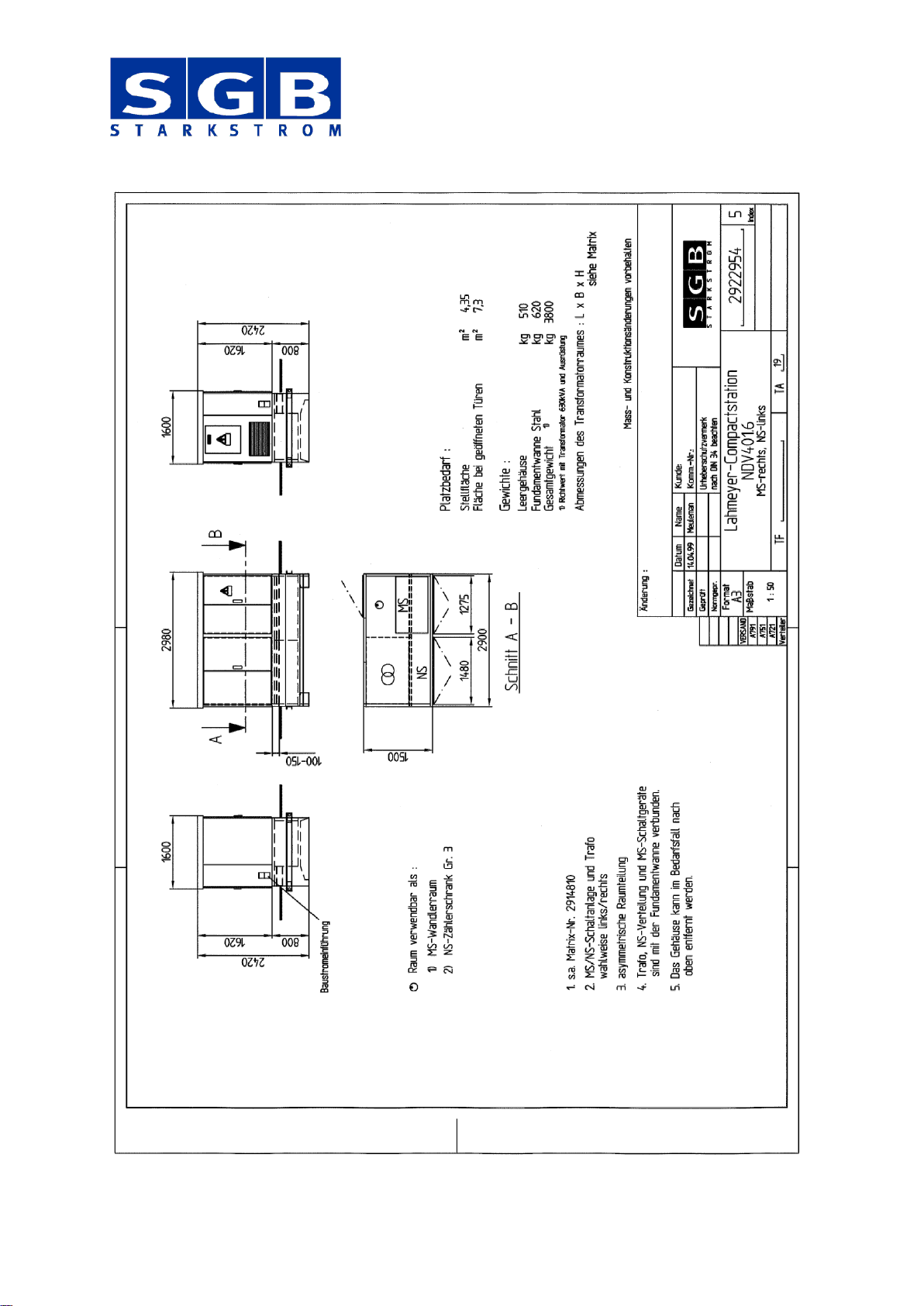

The substation, type NDV400/401 is, like all Lahmeyer-Compactstations®, a plant ready and

unit verified installation. It contains a medium voltage, a transformer and a low voltage room.

After connecting the MV and LV cables the substation is ready for operation.

2.1 The case of the substation, type NDV400/401, is a sheet-curved construction.

The sation consists of:

-the foundation with oil sump, oilproof welded, afterwards hot dip galvanized (zinc) and

double layer poudered (zinc pouder 70 m, top layer 70 m), with side parts formed like

skids which are the termination toward the earth and to the housing.

-two arbors curved of sheet iron to receive the MV and LV equipment, connected with the

foundation.

-simple movable roof ( the fixing screws are at the upper part of the door frame of the MV

and LV room and they are marked red)

-lockable plug diaphragm of the front side (access to the transformer).

-housing doors and cover diaphragms inclusive for the MV and LV room liftable in one unit.

2.2 Material and surface treatment

Material (underground):Oil sump: sheet iron 4 mm, hot dip galvanizes (zinc) (>750g/m²) and

double layer pouder coating (zincpuder 70 m, top layer 70 m), to pick

up the transformer

Skids made of sheet iron, 2 mm, hot dip galvanizes (zinc) (>225 g/m²)

double pouder coating 100 % without pores

(zinc pouder, top layer)

Optional : floor sump made of waterproof reinforced concrete using the exposure

calsses XC4;XF1;XA1 for exterior parts and XC1 for interior parts. The

armour of the floor sump consists of ribbled reinforcing concrete B 500

according to DIN EN 10080 and it is completely welded. The minimal

concrete covering is according to DIN 1048 part 1 bigger than the

possible water penetration detph.

Material (overground): sheet iron, 2 mm, strip galvanized (zinc) (> 225 g/m2)

Surface treatment: With IT-based pouder coating gear and 5-zones pretreatment layer

thicknesses equal > 70 µm. The used pouder varnishes are without

heavy metals and non toxic.

Zinc and pouder varnishes = highest corrosion protection.

Standard color: pebble grey (RAL 6003-S)

Remark:

The lodged pouder coeating can be recoated with liquid varnish into

another color by the user if he wants to. The former corrosion

protection remains existing!

2.3 All connecting elements of the housing are rust-proof (rustless steel).