SGB UVP 218 Operator's manual

Documentation

Overpressure/Vacuum pump ÜVP/VP 218

Read the instructions before starting any work

Issue: 01/2019

Art. no.: 605 642

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 2 -

1. General information................................................. 3

1.1 Marking

1.2 Unpacking

1.3 Erection

1.4 Disposal

2. Safety........................................................................ 4

2.1 Intended use

2.2 Responsibility

2.3 Motor protection

3. Use............................................................................ 5

3.1 Installation

3.2 Switching on

4. Maintenance............................................................. 6

5. Fault.......................................................................... 7

6. Figures...................................................................... 8

7. Declaration of conformity........................................ 10

Table of contents

22/01/2019 Overpressure/Vacuum pump ÜVP/VP 218

- 3 -

1. General information

1.1 Marking on the product

The overpressure/vacuum pump is marked with a CE sticker.

1.2 Unpacking

There may be pieces of metal on the packaging; always wear protective

gloves. Lift the overpressure/vacuum pump manually with the help of

another person and check whether the overpressure/vacuum pump is

complete and free of damage.

1.3 Erection

Always erect the pump with clearance of at least 50 cm to any obstruc-

tion which could obstruct the flow of air and thus hinder the cooling pro-

cess.

1.4 Disposal

Keep the packaging for a possible relocation for at least the duration of

the warranty period.

Both the packaging material and the overpressure/vacuum pump, includ-

ing all its parts, must only be disposed of at the designated centres.

General information

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 4 -

2. Safety

The overpressure/vacuum pump must only be used as a source for

generating negative pressure –any other used is prohibited. In case of

improper or incorrect use which does not correspond with the instruc-

tions for use, the manufacturer cannot be made liable for any damage.

2.1 Intended use

Find out how you stop the overpressure/vacuum pump and how you use

all the controllers.

Make absolutely sure that all parts have been re-installed correctly after

maintenance work.

Keep children and animals away from the operating area.

If you use the overpressure/vacuum pump for an extended period and

remain close to it in the process, it is advisable to use ear plugs.

2.2 Responsibility of the user

Do not touch the head, the cylinders, the cooling fins or the supply line.

During operation they can reach very high temperatures and may remain

hot for a certain amount of time even after switching off the device.

Do not place any combustible materials near to and/or on the overpres-

sure/vacuum pump.

Do not use the overpressure/vacuum pump if the mains cable is faulty or

if the power connection is not established correctly.

Do not allow anyone to use the overpressure/vacuum pump without hav-

ing received suitable training on use beforehand.

Do not strike the flywheel or the fans with blunt or metal objects. This

may cause them to break during operation.

Do not put the overpressure/vacuum pump into operation without the

condensate trap and liquids barrier.

When using the overpressure/vacuum pump, make sure that no inad-

missible pressure/vacuum is produced which might damage the tank/

pipe or their interstitial spaces.

The device must not be used in a potentially explosive atmosphere.

Potentially explosive vapour and air mixtures MUST NOT UNDER

ANY CIRCUMSTANCES be suctioned.

Do not use the overpressure/vacuum pump at temperatures lower than

0 °C. (Temperature range: +5 °C to +45 °C).

2.3 Motor protection The overpressure/vacuum pump is equipped with a motor circuit breaker

which breaks the power supply automatically in case of an overload. In

this case, switch off the power supply and wait for a few minutes before

you reset the motor protection switch (fig. 2) and re-start the device. If

the circuit breaker triggers again, disconnect the power supply and con-

tact an authorised customer service agent.

Safety

22/01/2019 Overpressure/Vacuum pump ÜVP/VP 218

- 5 -

3. Use of the overpressure/vacuum pump

3.1 Installation

Check whether the mains voltage matches the voltage specified on the

CE marking.

The overpressure/vacuum pump is equipped with a type CEE 7 plug

connector. If necessary, have it replaced by specialist staff.

Always check whether the on/off switch is in the 0/OFF position before

you connect the plug connector (fig. 1).

3.2 Switching on

Plug in the plug connector and start the device with the on-off switch.

Always and exclusively use the switch (set to "OFF") to stop the over-

pressure/vacuum pump.

Use of the overpressure/vacuum pump

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 6 -

4. Maintenance

Before you perform any maintenance work, switch off the overpressure/

vacuum pump.

According to §15 BetrSichV a plant in need of monitoring is only to be

started after it has been subjected to a test before startup. Furthermore,

recurring inspections according to §16 BetrSichV have to be performed.

Such tests shall be carried out by an approved monitoring body or a

qualified person. For more details see BetrSichV.

Maintenance

22/01/2019 Overpressure/Vacuum pump ÜVP/VP 218

- 7 -

5. Troubleshooting

Fault

1. The overpressure/vacuum pump stops

and will not re-start.

2. The overpressure/vacuum pump heats up

excessively.

3. The overpressure/vacuum pump is very

loud and emits rhythmic, metallic blows.

4.The vacuum pump VP 218 does not build

up any negative pressure on the monitoring

chamber

5. The overpressure pump ÜVP 218 does

not build up any overpressure on the moni-

toring chamber

Remedy

1. Switch off the power and after a few

minutes press the switch for the motor circuit

breaker. If the motor circuit breaker triggers

again after restarting, contact the technical

customer service department.

1.1 The motor coil has burned through; con-

tact a customer service agent.

2. The cylinder head seal or valve is dam-

aged. Stop the overpressure/vacuum pump

immediately and contact the technical cus-

tomer service department.

3. The slide bush or the bearing bush has

seized up. Stop the overpressure/vacuum

pump immediately and contact the technical

customer service department.

4. Liquid is suctioned and the liquids barrier

has closed. Empty the condensate trap and

move the liquids barrier back into the initial

position (free passage)

4.1 Open the shut-off valve (fig. 1)

5. The liquid stop has blocked the suction

line. Bring the floater inside the liquid stop

back into normal position (free passage).

5.1 The pressure regulator at the pressure

line is completely closed. Open the pressure

regulator.

Troubleshooting

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 8 -

6. Figures

On/off switch Pressure gauge Shut-off valve

Figure 1 (refers to ÜVP 218 and VP 218)

Motor circuit breaker

Figure 2 (refers to ÜVP 218 and VP 218)

Figures

22/01/2019 Overpressure/Vacuum pump ÜVP/VP 218

- 9 -

Connections to overpressure pump ÜVP 218

Figure 3

Connections to vacuum pump VP 218

Condensate trap with

integrated liquid stop

Monitoring chamber

connection vacuum;

4 mm inner width for hose

Figure 4

Figures

Connection to interstitial space vacu-

um; for hose 4 mm inner width

Condensate trap with integrated liquid

stop

Connection to interstitial space;

overpressure; for hose 6 mm inner width

Pressure regulator overpressure

Pressure gauge

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 10 -

7. Declaration of conformity

We hereby declare,

SGB GmbH

Hofstraße 10

57076 Siegen, Germany

under sole responsibility, that the overpressure/vacuum pump

ÜVP/VP 218

complies with the basic requirements of the EC directives listed below.

This declaration will become null and void in case of any change to the device not approved

by us.

Directive

Meaning

98/37/EC (until 28.12.2009)

Machinery directive

2006/42/EC (from 29.12.2009)

Machinery directive

2000/14/EC

Noise emissions in the environment

2006/95/EC

Low voltage directive

2004/108/EC

EMC directive

EN1012-1

Compressors and vacuum pumps - Safety requirements - Part 1:

Air compressors; German version EN1012-1:2010

EN60204-1

Safety of machinery - Electrical equipment of

machines - Part 1: General requirements

EN60335-1

Household and similar appliances -

Safety - Part 1: General requirements

EN61000-6-3/4

EMC generic standard, EN61000-6-3 Emission standard for res-

idential, commercial and light-industrial environments, EN61000-

6-4 Emission standard for industrial environments

Compliance is declared by

Jost Berg

(Managing Director)

Declaration of conformity

22/01/2019 Overpressure/Vacuum pump ÜVP/VP 218

- 11 -

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

______________________________________________________________________________________

Notes

Overpressure/Vacuum pump ÜVP/VP 218 22/01/2019

- 12 -

Text

Text

Imprint

SGB GmbH

Hofstr. 10

57076 Siegen

Germany

Phone +49 271 48964-0

Web www.sgb.de © SGB GmbH, 01/2019

This manual suits for next models

1

Table of contents

Popular Water Pump manuals by other brands

Homa

Homa C237 WF3 Original instruction manual

Davey

Davey AS Series Installation and operating instructions

Sam

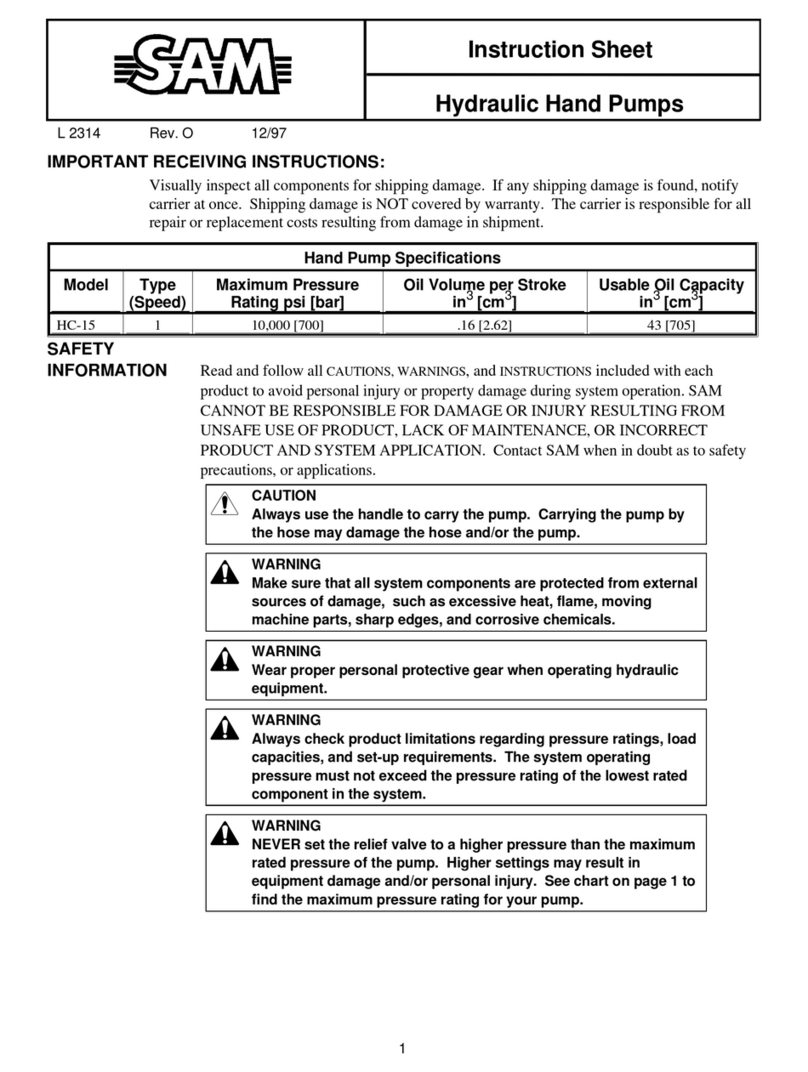

Sam HC-15 instruction sheet

Giant

Giant LP250 Operating instructions/ repair and service manual

TriboTec

TriboTec SAO 3P1 quick start guide

Triplex

Triplex SPX Universal Lobe 420/520UL Series instruction manual