4 95-03034

Safety ................................................................... 3

Receiving and Warranty......... ......................... 5

Inspection

Loss or Damage

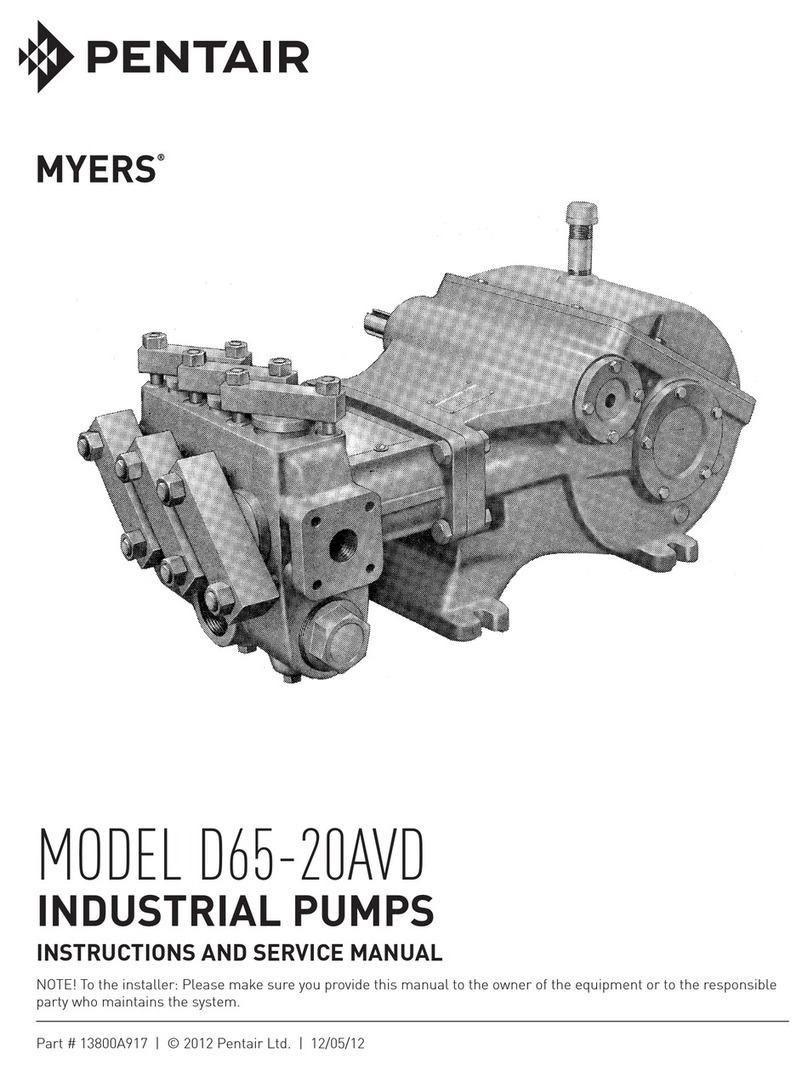

Introduction ........................................................ 6

Installation

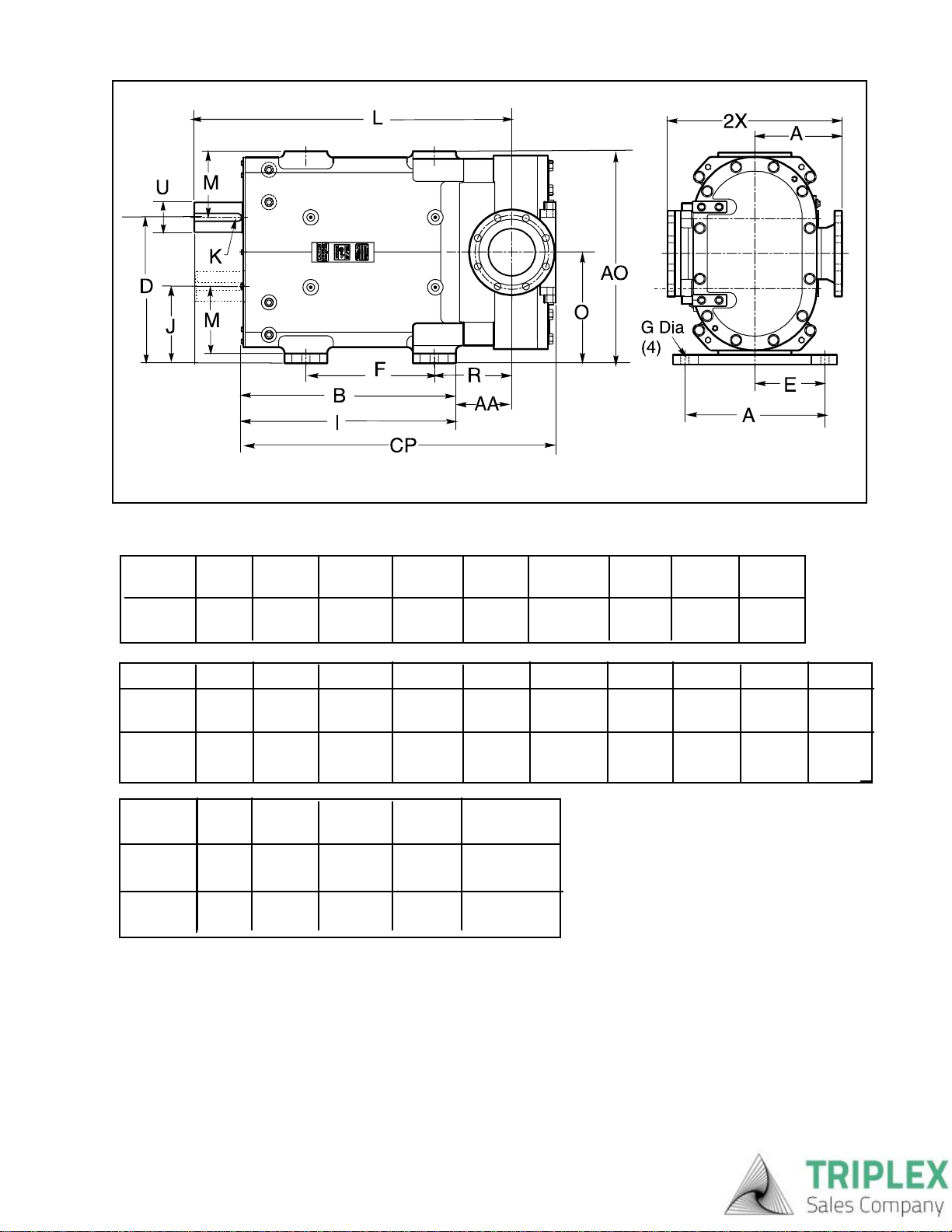

Basic Dimensions....................................... 7

Capacity ratings .......................................... 7

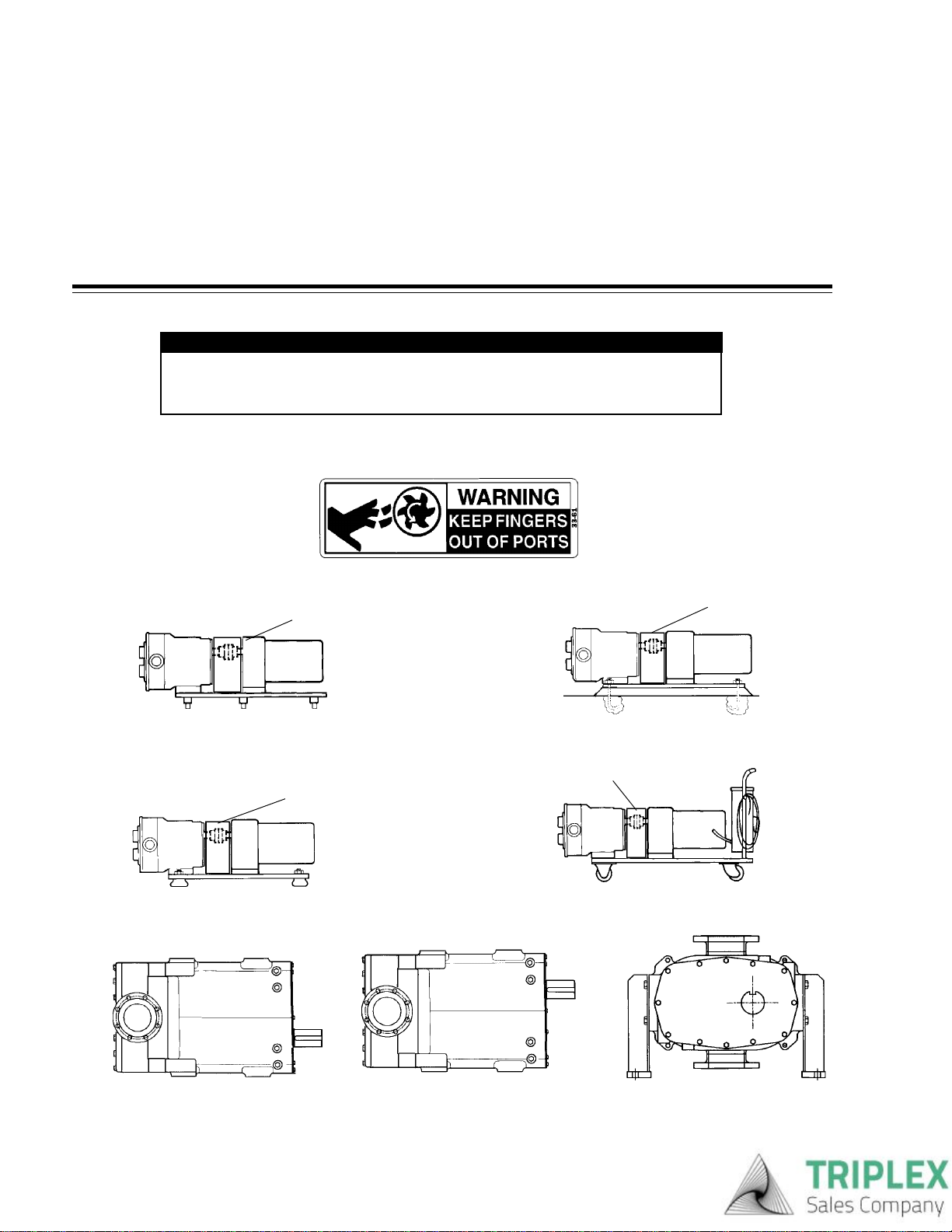

Pump and Drive Unit................................... 8

Piping Layout .............................................. 9

Valves ......................................................... 9

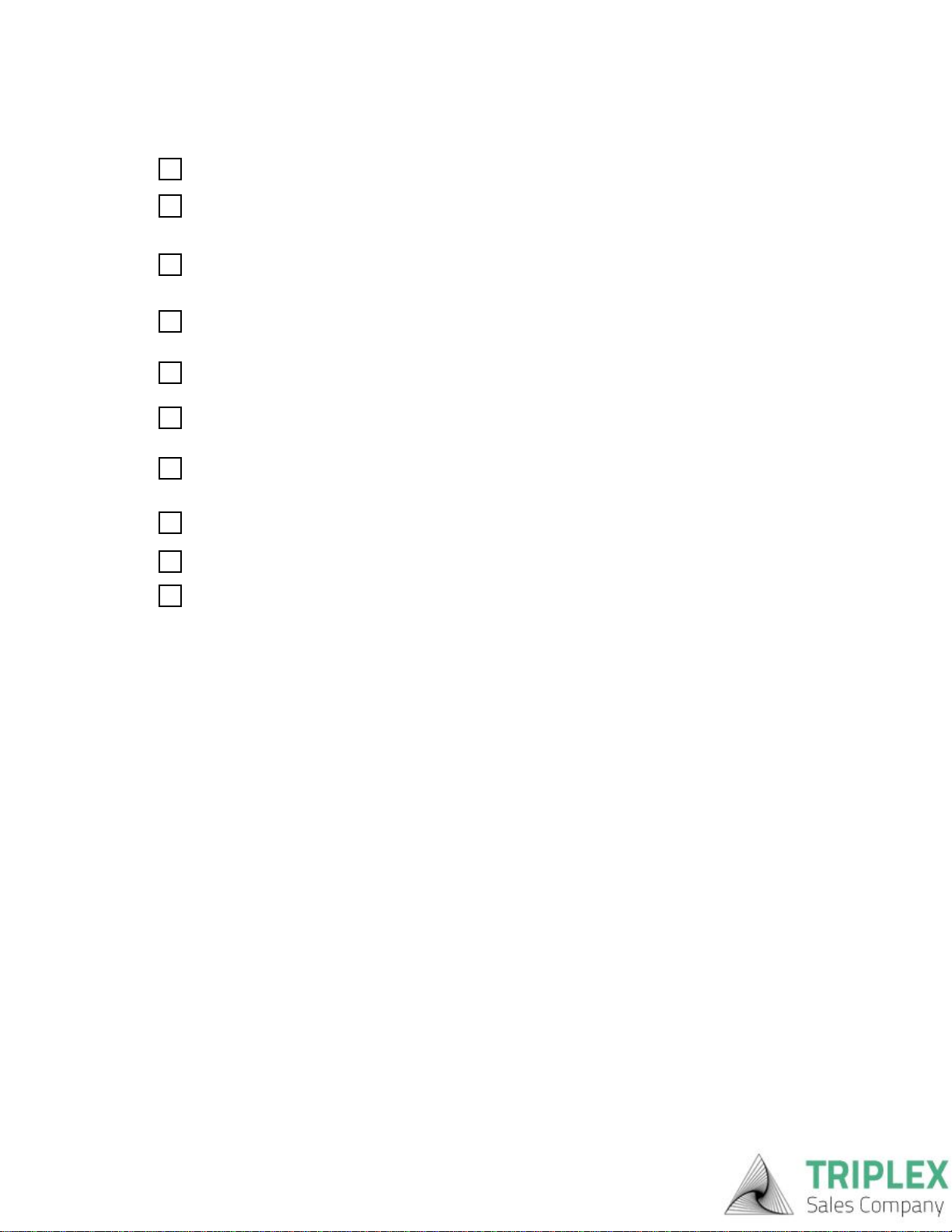

Strainers/Gages.......................................... 10

Alignment .................................................... 10-11

Pump Rotation ............................................ 11

Low Pressure Flush .................................... 12

High Pressure Flush ................................... 12

Start-up Check List ...................................... 13

Operation............................................................. 14

Lubrication.......................................................... 14

Cleaning .............................................................. 14

Troubleshooting a Pump System ... ............... 15-18

Maintenance

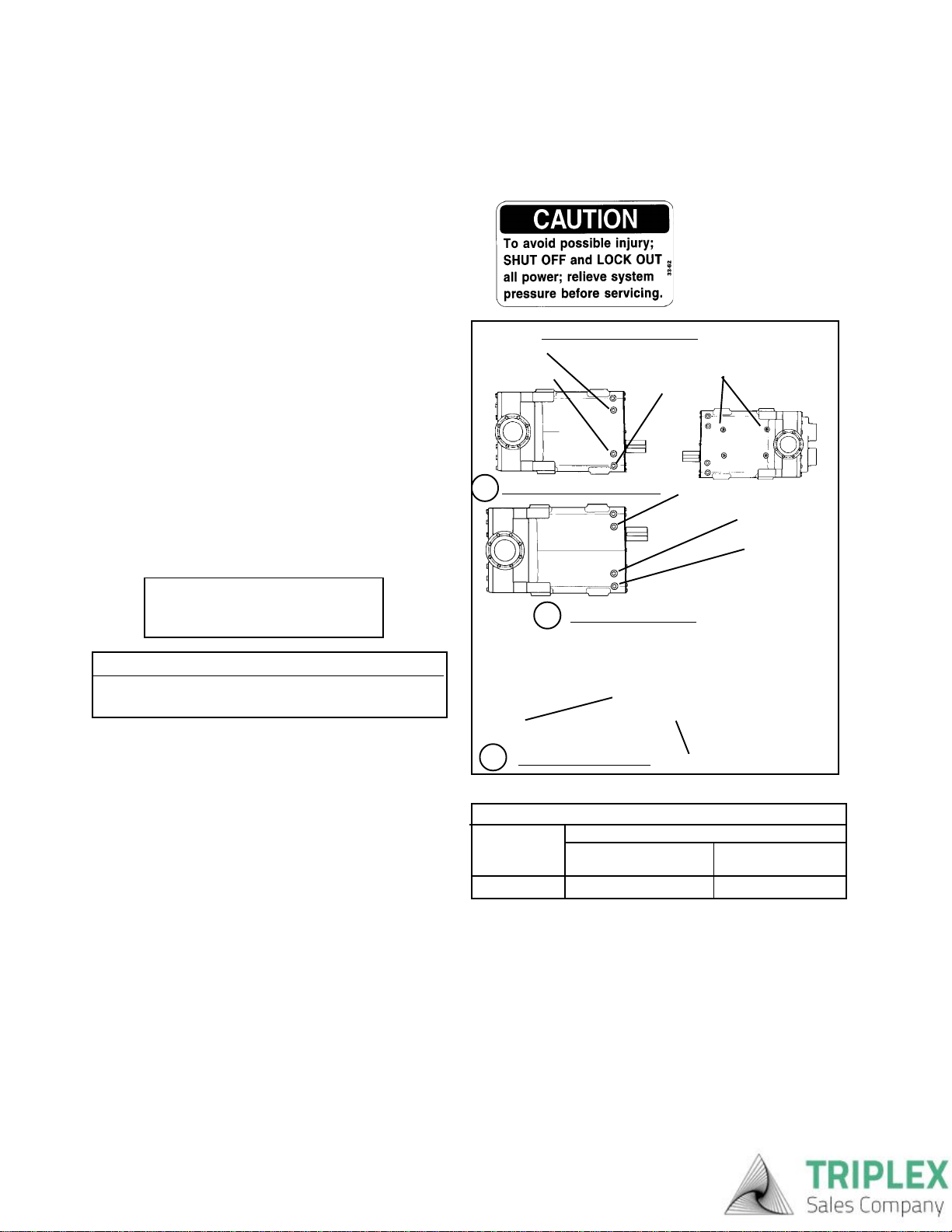

Safety Precautions ..................................... 19

Special Tools .............................................. 19

Disassembly Procedures

Fluid Head Removal ................................... 20

Cover Removal ........................................... 20

Rotor Removal ............................................ 21

Body Removal ............................................ 22

Mechanical Seal Removal ......................... 23

Gearcase Disassembly

... Timing Gears .......................................... 24

... Shaft and Bearing Removal................... 25

TABLE OF CONTENTS

Assembly Procedures

Shaft Sub Assembly..................................26

Bearings...................................................26

Shaft Installation in Gear Case Assembly 27-28

Timing Gear Installation..........................28

Adjusting Rotor to Body Backface .........29

Shims - All Models...............................................29

Fluid Head Assembly

Seal Assembly............................................30

Body Installation .................................................31

Rotor Installation.................................................31

Timing rotors ...............................................32

Cover Installation ................................................32

420/520 Gearcase Subassembly .......................33

Universal 420 Parts Listing................................34

Torque Specifications .......................34

Universal 520 Parts Listing................................35

Torque Specifications .......................35

SealsDouble Mechanical Seal.............................36

Single Inner Mechanical Seal.....................37

Single Outer Mechanical Seal....................38

Parts Ordering .....................................................39

Triplex Sales

1-847-839-8442

www.triplexsales.com