Nordson EFD MicroCoat MC600 User manual

MicroCoat MC600 Pump System

Operating Manual

Electronic pdf files of Nordson EFD

manuals are also available at

www.nordsonefd.com

™

MicroCoat MC600 Pump System

2www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Contents

Contents..........................................................................................................................................................................2

Introduction .....................................................................................................................................................................3

Specifications..................................................................................................................................................................3

How the System Operates ..............................................................................................................................................4

Pump Tank Features .......................................................................................................................................................5

System Assembly............................................................................................................................................................6

System Diagram..............................................................................................................................................................7

System Setup..................................................................................................................................................................8

Preventive Maintenance ..................................................................................................................................................8

Accessories .....................................................................................................................................................................9

Replacement Parts..........................................................................................................................................................9

Troubleshooting ............................................................................................................................................................10

MicroCoat MC600 Pump System

3www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Introduction

The MC600M System is a gear-type pump that provides consistent fluid feed to the MC800 system.

Features include a 6 gallon capacity fluid tank, low fluid level detection switch, removable filter screen, lubrication

in-line filter, and fluid regulator. To obtain the maximum performance from your MC600M, please read through these

instructions carefully.

Our goal is to build not only the finest equipment but also to build a long-term customer relationship founded on

superb quality, service, value and trust.

Specifications

NOTE: Specifications and technical details are subject to change without prior notification.

Item Specification

Tank size 23.0Wx 26.9Hx 41.0Dcm (9.0Wx 10.6Hx 16.0D")

Weight 14.8 kg (32.6 lb)

Capacity 22.7 L (6 gal)

Construction Tank: 18 gauge steel

Gears: Hardened steel

Bearings: Bronze oilite

Level switch: Type 304 stainless steel

Motor Voltage: 90–125 VAC 50/60 Hz (MC600M-120)

208–230 VAC 50/60 Hz (MC600M-220)

HP: 1/8

Phase: Single

Amps: 2.4 maximum

Service factor: 1.0

Ratings: UL (E6312), CSA (LR37479), NEMA Class B

Operating pressure 2.07 bar (30 psi) maximum

Low level switch rating 20 VA, 50 W

RoHS标准相关声明标准相关声明 (China RoHS Hazardous Material Declaration)

产品名称

Part Name

有害物质及元素

Toxic or Hazardous Substances and Elements

铅

Lead

(Pb)

汞

Mercury

(Hg)

镉

Cadmium

(Cd)

六价铬

Hexavalent

Chromium

(Cr6)

多溴联苯

Polybrominated

Biphenyls

(PBB)

多溴联苯醚

Polybrominated

Diphenyl Ethers

(PBDE)

外部接口

External Electrical

Connectors

X00000

O: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准低于SJ/T11363-2006 限定要求。

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is below the

limit requirement in SJ/T11363-2006.

X: 表示该产品所含有的危险成分或有害物质含量依照EIP-A, EIP-B, EIP-C

的标准高于SJ/T11363-2006 限定要求.

Indicates that this toxic or hazardous substance contained in all the homogeneous materials for this part, according to EIP-A, EIP-B, EIP-C is above the

limit requirement in SJ/T11363-2006.

MicroCoat MC600 Pump System

4www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

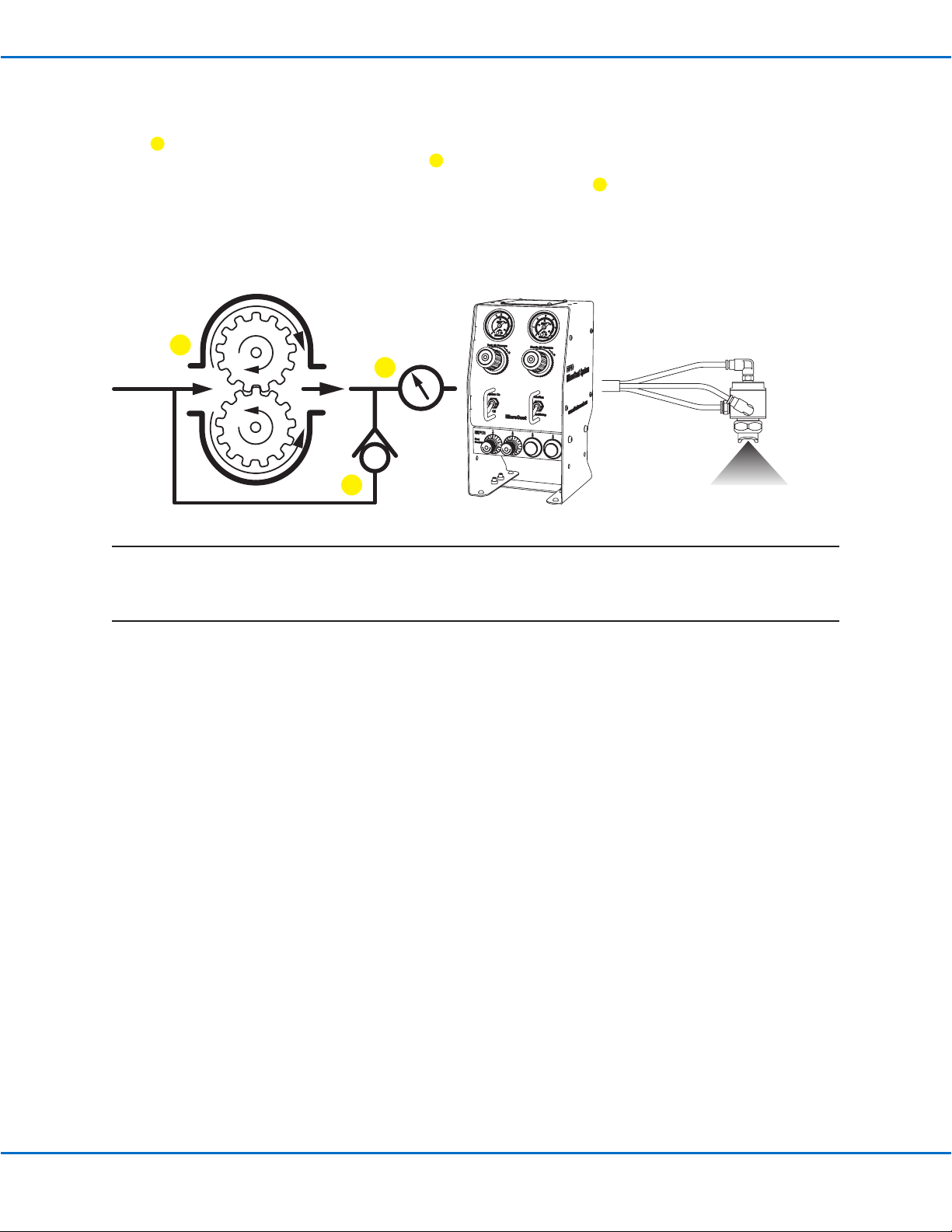

How the System Operates

The MC600M pump system is a low pressure gear-type pump. Lubricant is drawn in on one side of the

gears 1,carried around to the outside, and forced to the output. If the flow capacity of the pump is not used, the

excess lubricant will bypass an internal relief valve 2and recirculate back into the tank.

The 30 psi pump output is further reduced by a pilot-operated fluid regulator 3controlled by the tank pressure

regulator on the MC800 controller. The fluid regulator provides an operating range of 130. bar (15 psi) to 2.07 bar

(30psi).

IMPORTANT NOTICE: Caution should be used when selecting a lubricant to use with the MC600M system. Fluids

with a flash point lower than 38° C (100° F) are not recommended, as they could present a fire hazard. Examples of

products with low flash points are kerosene, acetone, general mineral spirits, naphtha, and other solvents. Please

check the product SDS carefully before using the intended product in this system.

1

3

2

Lubricant

MicroCoat MC600 Pump System

5www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

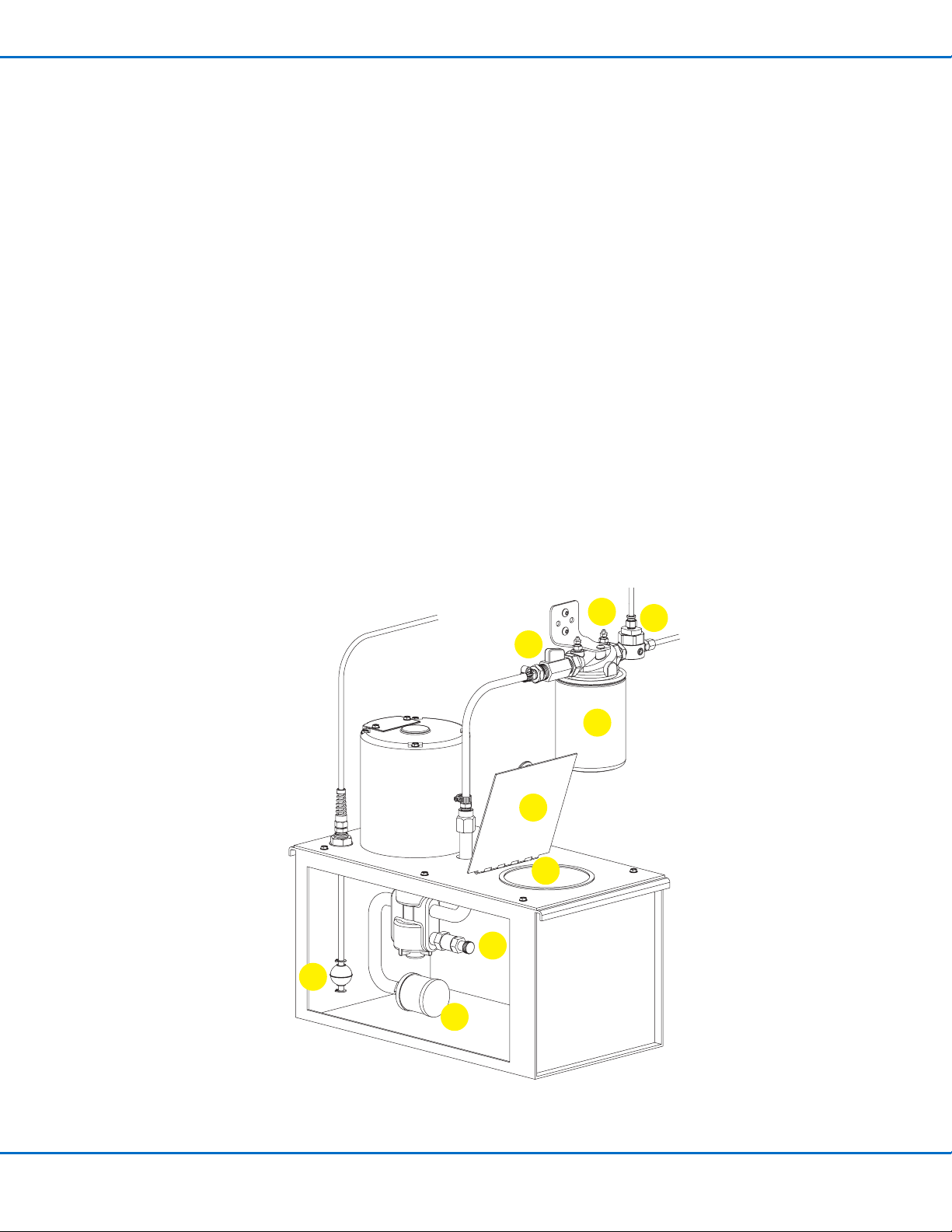

Pump Tank Features

1. Low Level Switch

Prevents the system from operating without

lubricant when connected to the emergency stop

circuit. Switch opens when the tank level is near

empty.

2. Fluid Bypass Valve

Automatically bypasses excess flow capacity of

the pump. Bypass lubricant recirculates into the

storage tank.

3. Inlet Filter Screen

Screens out contaminants that may enter the

inlet of the pump.

4. Fill Hole Cover

Prevents contaminants from entering the tank.

5. Removable Filter Screen

Screens out contaminants that may enter during

the tank filling process.

6. Shut-off Valve

Used to block fluid flow when servicing the filter.

7. Bleed Valve

Used to purge air when priming the system.

8. Fluid Regulator

Pilot-operated regulator provides control of fluid

pressure.

9. Lubricant Filter

Lubricant

filter

1

3

6

5

4

2

9

8

7

MicroCoat MC600 Pump System

6www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

System Assembly

First, place the MC600M system away from traffic areas and position the tank to allow for convenient refilling.

HIGH VOLTAGE! Pump must be wired, grounded and fused in accordance with local regulatory requirements.

DANGER

1. Before connecting the power, view the label located on the motor to ensure that the voltage matches your input

voltage. If not, see the diagram on page 7. Reconfigure the wiring inside of the motor terminal cover to

match the schematic on the side of the motor.

2. Connect the power.

3. Mount the filter and regulator assembly on the MicroCoat stand or other suitable mounting location. Ensure that

the filter hangs vertically as illustrated.

4. Connect the fluid feed line from the MC600M to the shut-off valve on the inlet side of the filter housing. Secure

with the clamps supplied.

5. Connect the black air line connection from the MC800 controller tank air outlet to the fluid regulator air inlet as

shown.

6. Connect the fluid feed line from the regulator output to the fluid inlet of the MC800 controller as shown.

7. Lubricate the oil filter gasket lightly and install the filter on the housing. Tighten the filter 3/4 turn by hand. Do

not overtighten.

8. Rotate the inlet shut-off valve to the “OFF” position.

9. Refer to the MicroCoat system operating manual for wiring the press emergency stop circuit and connecting the

low level switch cable to the controller.

MicroCoat MC600 Pump System

7www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Connect to

emergency

stop circuit

5

4

3

2

7

1

6

8

9

Lubricant (clear hose)

Regulating pressure (black hose)

Fluid level switch (gray wire)

System Diagram

NOTE: Replace the filter element

(P/N 7017347) every 6 months or

1000 hours of operation.

MicroCoat MC600 Pump System

8www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

System Setup

Check All Connections

DO NOT RUN THE PUMP DRY.

CAUTION

1. Check that all connections are correct and secure.

2. Lift the cover of the MC600M and fill the tank with clean lubricant.

See the note on page 4 regarding the fluid flash point.

CAUTION

3. Close the cover.

4. Place the “System Pressure” on the MC800 controller in the “ON” position.

5. Set the MC800 tank pressure regulator to a minimum of 1.03 bar (15 psi).

6. Start the MC600M to begin lubricant flow to the filter assembly.

7. Slowly open the shut-off valve. Check for leaks.

8. Install the filter housing purge line into the bleed valves as shown in the system diagram. Open each bleed valve

and direct the purge flow into a container. Purge slowly until all air is eliminated. Do this for both bleed valves.

Preventive Maintenance

Before performing any maintenance, set the “System Pressure” to the “OFF” position and disconnect power.

WARNING

The MC600M is designed for long life with minimal maintenance. To ensure trouble-free performance, follow these

precautions and preventive maintenance steps.

• Always use clean lubricant.

• Check for residue at the bottom of the tank and clean if necessary. Keep cleaners away from the motor, lower

motor bearing and wiring.

• The electric motor requires no lubrication.

• Do not restrict the vents on the motor. Keep oil and debris from accumulating around the motor.

• To avoid pump damage, do not remove the filter screen from the pump intake.

• Replace the lubricant filter (P/N 7017347) every 6 months or 1000 hours of operation.

MicroCoat MC600 Pump System

9www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Accessories

Dual Float Switch

#7008012: For tank autofill applications. Mounts directly in the plugged hole

on the MC600M. Includes (1) dual float switch, (1) bulkhead union and (1)

cord strain relief.

Replacement Parts

Part # Description

7002004 6 mm OD urethane tubing, blue

7022195 Push-in fitting

7017038 3/8" OD x 1/4" ID tubing, polyethylene

7017421 Fluid regulator

7017449 Filter assembly gear pump intake

7016693 Oil resistant power cord

7017347 Lubricant filter element (4) per box

7020470 Float switch kit

7022156 MicroCoat filter assembly

MicroCoat MC600 Pump System

10 www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Troubleshooting

Problem Corrections

Lubrication flow reduced 1. Ensure that tank air pressure is set at a minimum of 1.03 bar (15 psi).

2. Replace the oil filter.

3. Ensure that the shut-off valve is fully open.

4. Check the fluid inlet screen to ensure that there is no debris blocking the

inlet.

5. Check the hoses to ensure there are no bends or restrictions.

6. Viscosity of the lubricant is too heavy (500 SUS maximum).

7. Check the voltage, cycle and phase to ensure that the pump is operating on

the right electrical current.

8. Ensure that the pump inlet is submersed.

9. Check the relief valve for dirt or chips lodging on the valve seat, preventing

the ball from closing and causing liquid to constantly bypass.

10. Check that motor rotation is free and does not bind. The motor and pump

may not be aligned. If there is binding, loosen the (2) nuts that hold the motor

to the pump casting, rotate the pump casting until it is aligned and the pump

runs freely. Retighten the nuts carefully.

MicroCoat MC600 Pump System

11www.nordsonefd.com [email protected] +1-401-431-7000 Sales and service of Nordson EFD dispensing systems are available worldwide.

Notes

For Nordson EFD sales and service in over

40 countries, contact Nordson EFD or go to

www.nordsonefd.com.

Global

800-556-3484; +1-401-431-7000

Europe

00800 7001 7001

Asia

The Wave Design is a trademark of Nordson Corporation.

©2021 Nordson Corporation 7023840 v012221

NORDSON EFD ONE YEAR LIMITED WARRANTY

This Nordson EFD product is warranted for one year from the date of purchase to be free

from defects in material and workmanship (but not against damage caused by misuse,

abrasion, corrosion, negligence, accident, faulty installation, or by dispensing material

incompatible with equipment) when the equipment is installed and operated in accordance

with factory recommendations and instructions.

Nordson EFD will repair or replace free of charge any defective part upon authorized return

of the part prepaid to our factory during the warranty period. The only exceptions are those

parts which normally wear and must be replaced routinely, such as, but not limited to, valve

diaphragms, seals, valve heads, needles, and nozzles.

In no event shall any liability or obligation of Nordson EFD arising from this warranty exceed

the purchase price of the equipment.

Before operation, the user shall determine the suitability of this product for its intended use,

and the user assumes all risk and liability whatsoever in connection therewith. Nordson EFD

makes no warranty of merchantability or fitness for a particular purpose. In no event shall

Nordson EFD be liable for incidental or consequential damages.

This warranty is valid only when oil-free, clean, dry, filtered air is used, where applicable.

Table of contents

Popular Water Pump manuals by other brands

BUSCH

BUSCH R 5 instruction manual

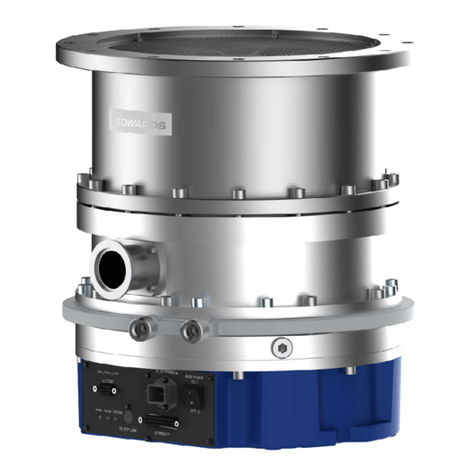

Pfeiffer Vacuum

Pfeiffer Vacuum HiPace 800 P operating instructions

Lafferty

Lafferty 920115 Installation & operation instructions

ASP

ASP FSPO Installation, operation and maintenance instructions

Franklin Electric

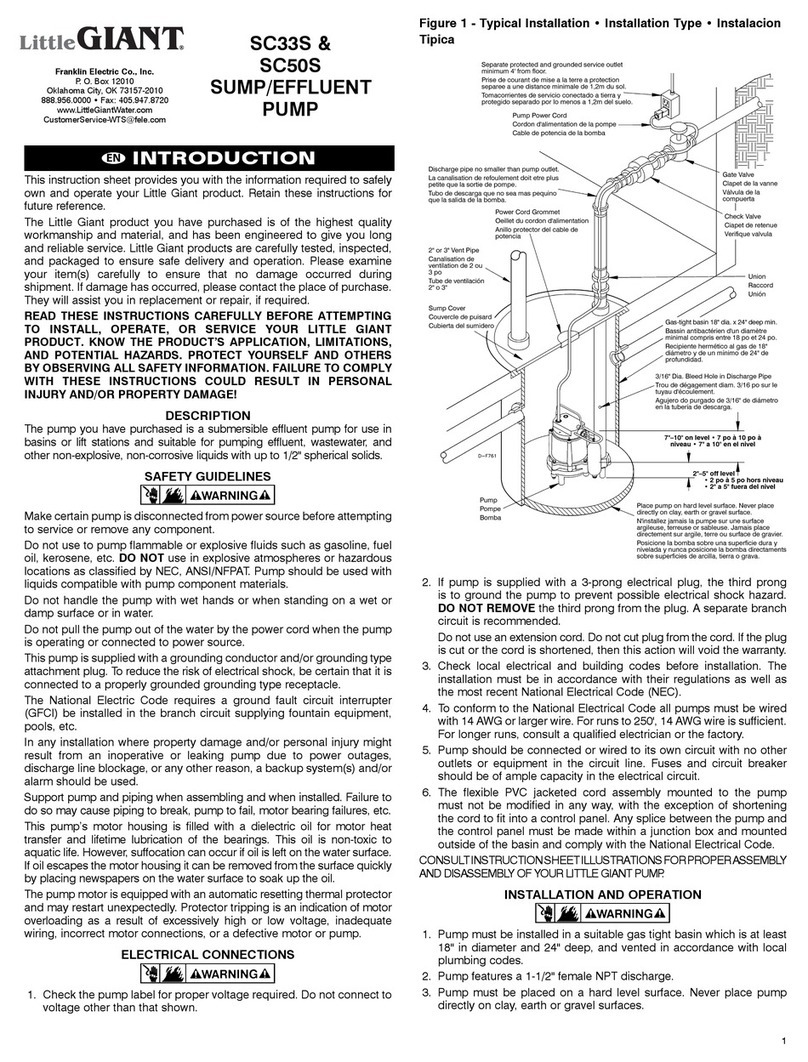

Franklin Electric LittleGIANT SC33S manual

Pentair

Pentair FP5112 Installation & operation manual