SGK Pearl Joint KC Series User manual

1

Instruction Manual

No. : SE20019-0

Issued on : Mar. 16 2020

Pearl Rotary Joint

KC Series

This instruction manual applies to products with type designations

that begin with KC, or SKCL.

Pearl is a trade name of Showa Giken Industrial Co., Ltd.

This instruction manual describes important precautions for preventing

accidents and how to handle the product. To ensure safe use, be sure to

read this manual and fully understand its contents before using this product.

Store this manual carefully so that it can be referred to at any time.

2

Table of Contents

1. How to Read Nameplate (Nameplate Information) …………………………………………… P3

2. For Safety ……………………………………………………………………………………… P3

2‐1)Symbols …………………………………………………………………………………… P3

2‐2)For safe use ……………………………………………………………………………… P3

3. Product Overview ……………………………………………………………………………… P4

3‐1)Application ………………………………………………………………………………… P4

3‐2)Information indicated by model names …………………………………………………… P4

3‐3)Service conditions ………………………………………………………………………… P5

3‐4)Precautions for use ………………………………………………………………………… P5

3‐5)Product structures and materials ………………………………………………………… P6

3‐6)Product dimensions ………………………………………………………………………… P7

3‐7)Product masses …………………………………………………………………………… P7

3‐8)Accessories ………………………………………………………………………………… P8

4. Transport and Storage ………………………………………………………………………… P9

4‐1)Transport …………………………………………………………………………………… P9

4‐2)Storage ……………………………………………………………………………………… P9

5. Installation to Machinery ……………………………………………………………………… P9

5‐1)Internal pipe (for duplex only) ……………………………………………………………… P9

5‐2)Installing to a roll ………………………………………………………………………… P10

5‐3)Pipe laying ………………………………………………………………………………… P11

6. Removal from Machinery ……………………………………………………………………… P12

7. Operation ……………………………………………………………………………………… P13

7‐1)Operation …………………………………………………………………………………… P13

7‐2)Operation shutdown ……………………………………………………………………… P13

8. Inspection and Maintenance …………………………………………………………………… P14

8‐1)Daily inspection …………………………………………………………………………… P14

8‐2)Greasing …………………………………………………………………………………… P14

8‐3)Repair and replacement of consumables ………………………………………………… P15

9. Troubleshooting ………………………………………………………………………………… P16

10. Disposal ……………………………………………………………………………………… P17

11. Product Warranty …………………………………………………………………………… P17

A. Appendix - How to Repair or Replace Consumables ………………………………………… P19

A‐1)For simplex (KCL, KCLF, SKCL) …………………………………………………………… P1

A‐2)For duplex, stationary IP, thread connection (KC) ……………………………………… P20

A‐3)For duplex, rotational IP, flange connection (KCF) ……………………………………… P22

A‐4)For duplex, rotational IP (KCW, KCFW) ……………………………………………………… P24

P3

P3

P3

P3

P4

P4

P4

P6

P6

P7

P7

P7

P8

P9

P9

P9

P9

P9

P10

P11

P12

P13

P13

P13

P14

P14

P14

P14

P15

P16

P16

P19

P20

P22

P24

P26

3

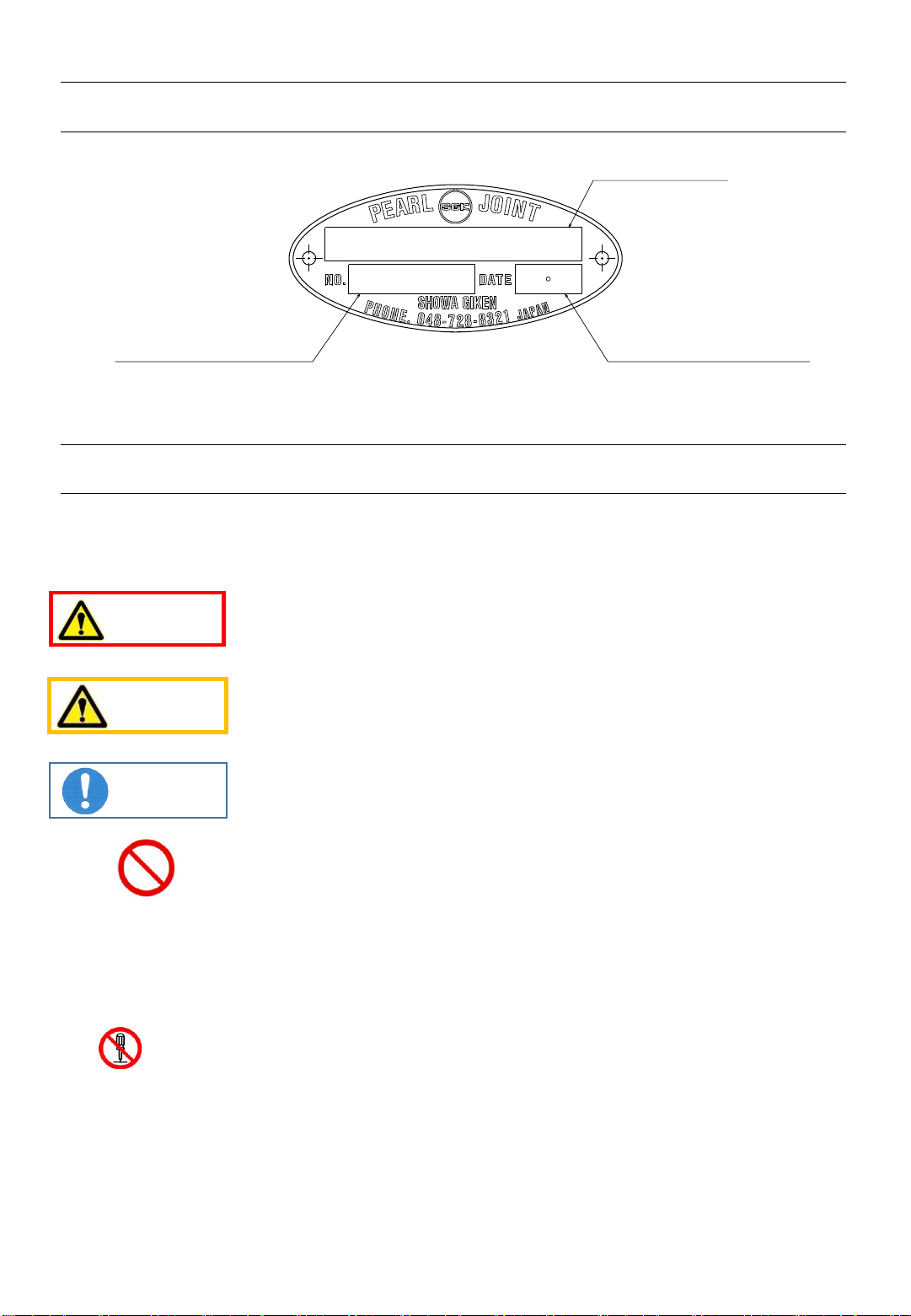

The nameplate attached to the product indicates the model name, manufacturing

number, and manufacturing date.

1. How to Read Nameplate (Nameplate Information)

2. For Safety

2‐1) Symbols

The symbols used in this instruction manual are described below.

Indicates that failure to follow the warning message may cause bodily

accidents that may result in serious or even fatal injury.

Indicates that failure to follow the caution message may cause

personal injury or damage to peripheral equipment.

Indicates that failure to follow the instruction message may cause

reduced product lifetime, product damage, or early leakage.

Indicates “prohibited actions”.

2‐2) For safe use

1. Transport, storage, installation, piping, operation, or maintenance of this product should be

carried out by an experienced expert.

2. Be sure to observe all warnings, cautions, and instructions described in each section.

3. Never disassemble or modify this product because doing so is dangerous. We shall assume

no responsibility for any malfunctions, accidents, or the results thereof involving a

reassembled product after disassembly or a modified product. Also, a reassembled product after

disassembly or a modified product shall not be covered by the product warranty even if the

warranty period is still valid. This also applies to repairs done by yourself.

4. Confirm specifications (dimensions, materials, masses) indicated on individual product drawings

before staring work. Contact our sales representative for requests for product drawings.

5. Always use the latest instruction manual. You can download the latest version from our website.

WARNING

CAUTION

Instruction

Manufacturing Date

Model Name

Manufacturing No.

4

●For installation with a taper thread or a flange

3. Product Overview

3‐1) Application

A rotary joint is used for supplying fluid to or draining it from a machine rotating part called a

roll, drum or cylinder, via fixed pipes.

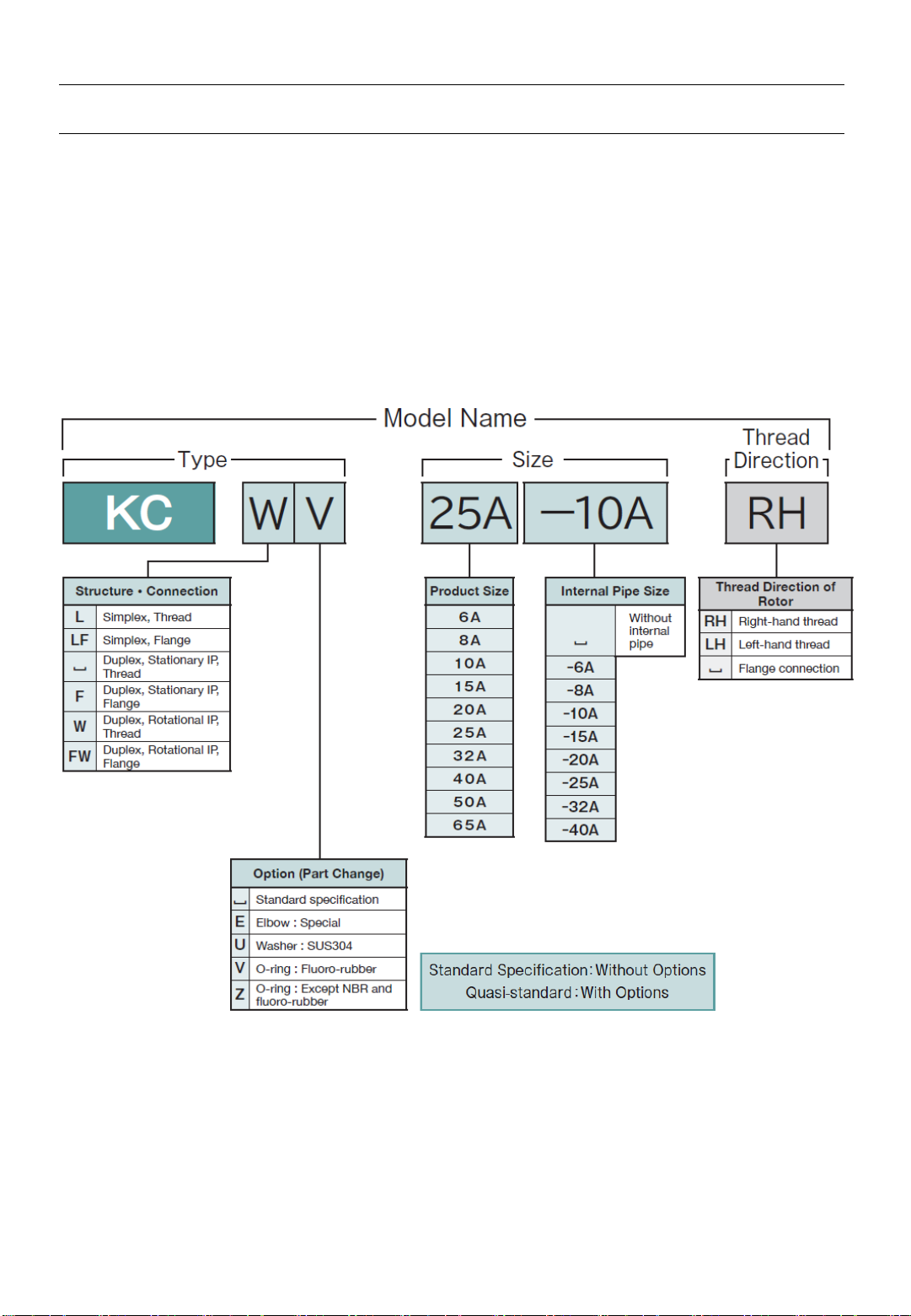

3‐2) Information indicated by model names

Information indicated by KC series model names is described below.

The product list is shown in our catalog or on our website.

Note 1) “␣” indicates a space. A model name is indicated without spaces.

2) If two or more option (part change) codes are selected, they are indicated in alphabetical

order.

3) The selection of two or more options resulting in a long model name is indicated as type

“OKC****” to denote a customized product for administrative reasons.

(The asterisks (****) indicate a four-digit number allocated to each model.)

If you have any questions, contact our sales representative.

5

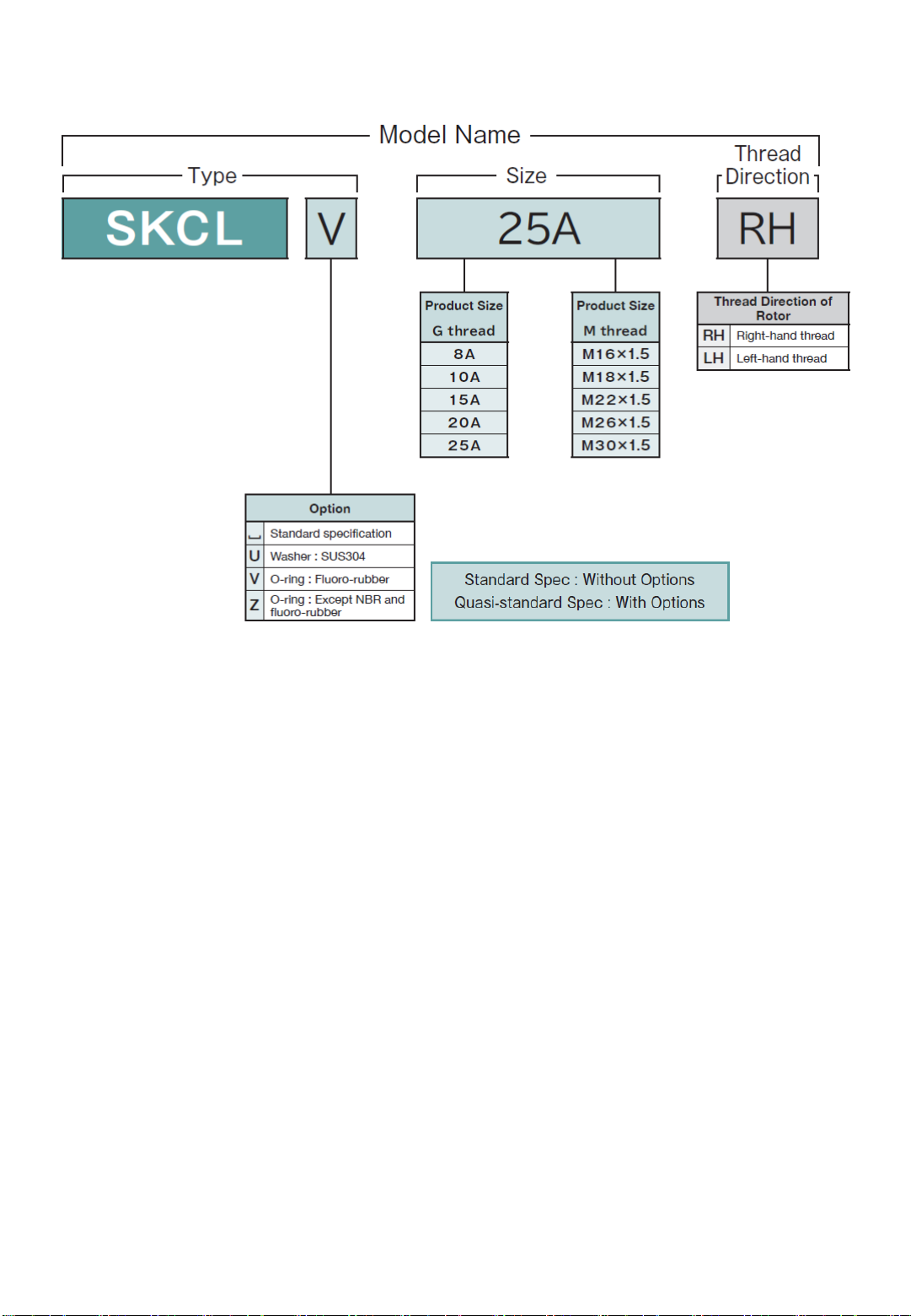

●For installation with a parallel thread (simplex only)

Note 1) “␣” indicates a space. A model name is indicated without spaces.

2) If two or more option (part change) codes are selected, they are indicated in alphabetical

order.

3) The selection of two or more options resulting in a long model name is indicated as type

“OKC****” to denote a customized product for administrative reasons. (The asterisks

(****) indicate a four-digit number allocated to each model.))

If you have any questions, contact our sales representative.

6

3‐4)Precautions for use

Use this product by following the warnings and instructions described below.

Note ) The lowest pressure when used under a pressure lower than atmospheric pressure is 1.3 kPa abs (10 Torr).

3‐3) Service conditions

Service Conditions of KC Series

WARNING

1. If flammable fluids leak and ignite, bodily accidents including serious or

even fatal injury, or accidents that damage peripheral equipment may

occur due to explosion or fire. Depending on the type of fluid, this

product may subject to restrictions due to national laws or local

regulations.

2. This product cannot be used for food-processing machinery.

Doing so may lead to adverse health effects.

Instruction

1. Perform operation within the service conditions.

2. Do not operate under conditions where both pressure and rotation speed

are close to the max. values. Doing so significantly reduces product

lifetime.

3. This product cannot be used in temperature conditions where the

product ambient temperature exceeds the upper limit of the service

conditions.

4. The product cannot be used for liquid containing solid particles (slurry)

or pulverulent body. The product cannot be used for fluid that causes

corrosion on it.

5. This product cannot be used for operation with no rotation,

intermittent rotation, or low-rotation speed (a few rotations per minute).

Otherwise, fluid leakage may occur.

Pressure

Rotation speed Temperature

(MPa)

(min-1)(℃)

6A~25A 1,500

32A~65A 1,000

Max.

KC

Air / Gas / Water / Oil

0.98

100

Series

Fluid

Size

7

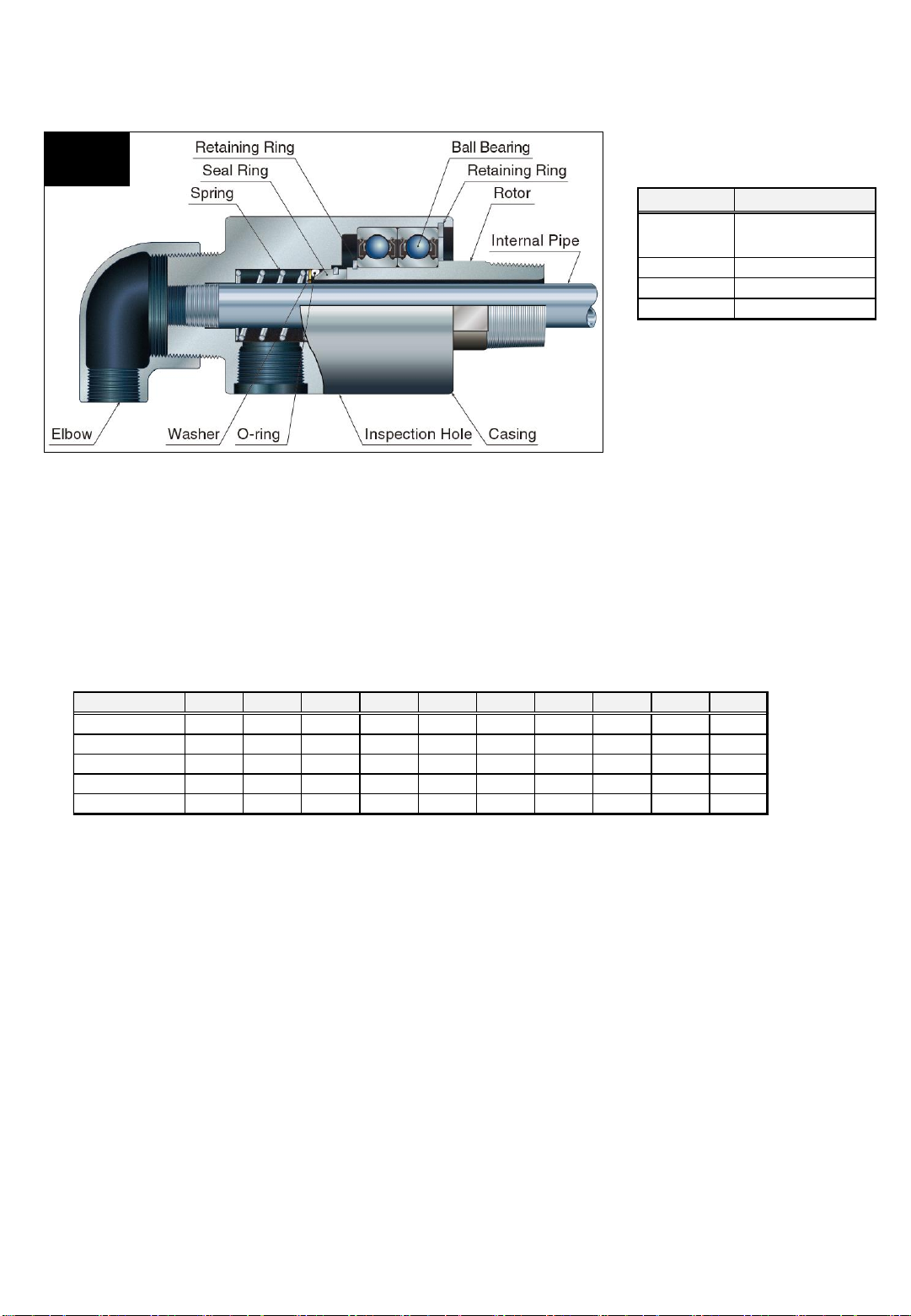

The casing is finished with alumite

treatment (anodizing).

KC

3‐5) Product structures and materials

Note ) Component materials are indicated on product drawings.

Contact our sales representative for requests for product drawings.

Materials of Main Components

(Standard Specification)

3‐6) Product dimensions

Product dimensions are shown on product drawings, in our catalog, or on our website.

3‐7) Product masses

(kg)

Masses of KC Series

Type 6A 8A 10A 15A 20A 25A 32A 40A 50A 65A

KCL 0.15 0.25 0.37 0.60 0.85 1.2 2.3 2.6 5.3 9.6

KCLF - - 0.90 0.90 1.25 1.7 3.0 3.3 6.6 10.9

KC/KCW - - - 0.75 1.05 1.5 2.6 2.9 6.5 10.6

KCF/KCFW - - - 1.05 1.45 2.0 3.3 3.6 7.8 11.9

SKCL - 0.25 0.37 0.60 0.85 1.2 - - - -

Part Name Material

Rotor

Stainless Steel

Carbon Steel

Casing Aluminum Alloy

Seal Ring Carbon

O-ring NBR

8

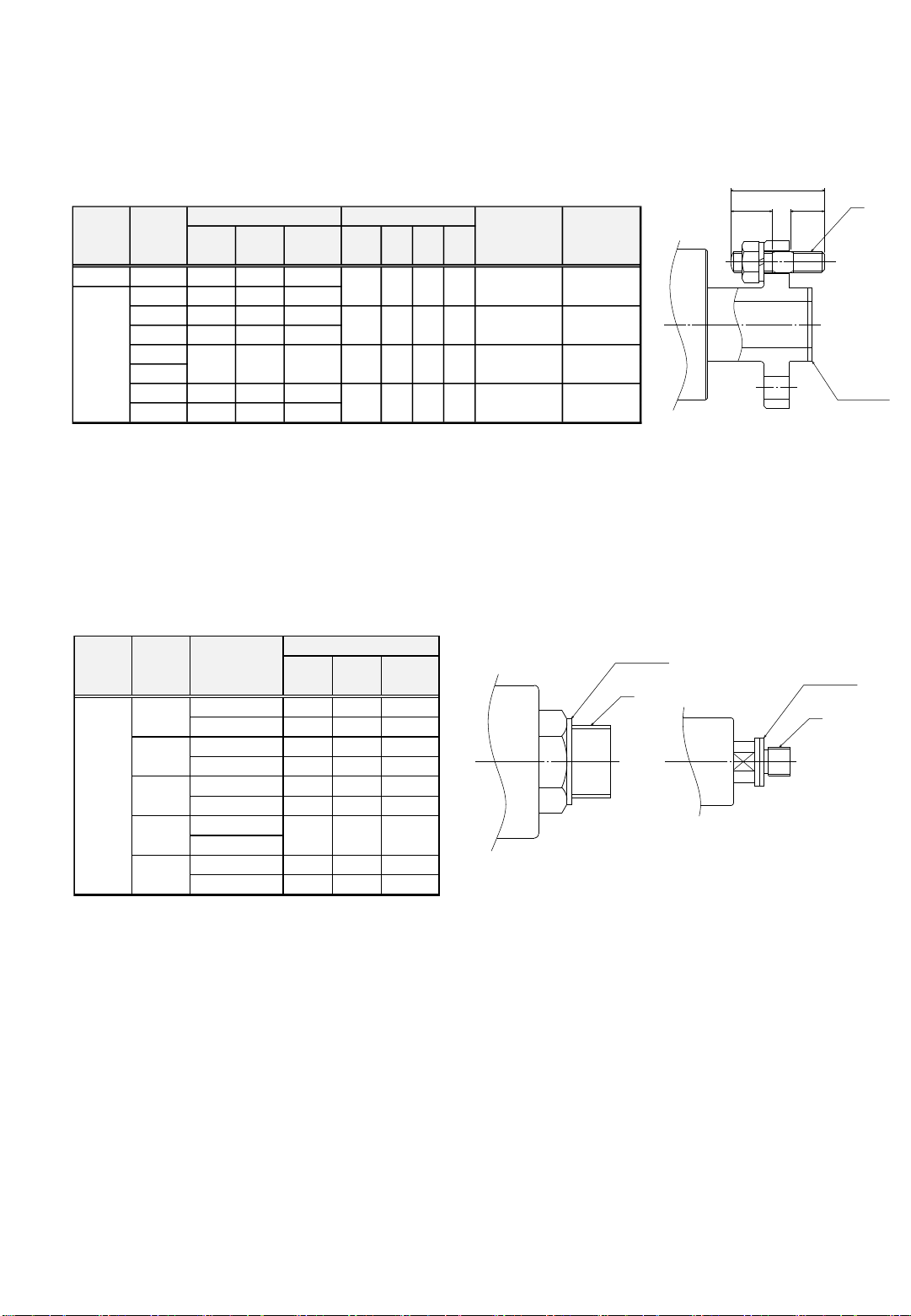

3‐8)Accessories

1. A product installed with a flange is supplied with a gasket (copper jacket) and four sets of a stud

bolt (SS400), a hex. nut (SS400), and a spring washer (SWRH).

2. A duplex, stationary IP, flange connection product (KCF) is supplied with a lock nut (right-hand

thread, SS400) used for securing the internal pipe.

3. A product installed with a parallel thread (SKCL) is supplied with a gasket (copper plate).

(mm)

(mm)

Accessories

(Installation with parallel thread)

Accessories(Flange Connection)

K

ab

L

Gasket

KCLF 10A 24 16 3.2

15A 24 16 3.2

20A 29 20 3.2

25A 34 26 3.2

32A

40A

50A 64 50 3.2

65A 79 62 3.2

KCLF

KCF

KCFW

M10

45

15

20

M12

58

18

27

49

37

3.2

M10

48

15

20

M12 type1

M12 No.2

M10 type1

Spring

Washer

M8 No.2

M10 type1

M10 No.2

M10 No.2

M8

36

11

18

M8 type1

Type

Size

Gasket

Stud Bolt

Hex. Nut

Outer

Dia.

Inner

Dia.

Thick-

ness

K

L

a

b

G1/4 22 13.5 2

M16×1.5 23 16.3 2

G3/8 26 17 2

M18×1.5 24 18.5 2

G1/2 30 21.3 2

M22×1.5 27.5 22.2 2

G3/4

M26×1.5

G1 39.5 33.5 2

M30×1.5 39 30.5 2

2

25A

Outer

Dia.

Inner

Dia.

Thick-

ness

Size

A

Gasket

35

26.8

SKCL

8A

10A

15A

20A

Type

A

A

8A10A~25A

Gasket

Gasket

9

●Duplex, stationary IP, thread connection (KC)

Screw the internal pipe taper thread into the head. For standard specification products, the

thread directions of the rotor and internal pipe are the same. Depending on the customer’s

request, the thread directions of the rotor and internal pipe may be different from each other.

Check the thread directions on the product drawings, etc. before installation.

●Duplex, stationary IP, flange connection (KCF)

Screw G thread (right-hand thread) of the internal pipe into the head, and then secure it with a

supplied lock nut.

Instruction

1. Do not subject the product to undue impact while it is being transported.

Falling down or impact causes product damage (seal ring, etc.) or early

leakage. If the product fell down or was damaged, contact us for maintenance.

2. When transporting a product with an internal pipe, do not secure the product

so that load is directly applied to the internal pipe. Doing so may bend the

internal pipe, hindering installation to a roll. Moreover, abnormal noise or early

leakage may result after installation.

4. Transport and Storage

4‐1) Transport

Transport this product by following the instructions described below.

4‐2) Storage

An improper storage method causes product damage or early leakage.

Store this product by following the instructions described below.

Instruction

1. Wrap the product before storing it to prevent the entry of foreign objects.

2. Store this product in a dry environment at 10℃ to 40℃.

3. The storage period should be within two years. If the storage period exceeds

two years, contact us for maintenance.

4. If the product is stored after use, clean and then store it under the above

conditions.

5. Installation to Machinery

5‐1) Internal pipe (for duplex only)

Install an internal pipe to the product according to the following instructions.

Product adjustment is not required before installation.

Instruction

1. When inserting an internal pipe into the product rotor, be careful so that the

pipe does not hit inner parts. Failure to do so could cause inner part damage,

resulting in fluid leakage.

2. When installing an internal pipe to the product, be careful not to bend the pipe.

If it is bent, product installation to a roll may be hindered. Also, vibration or

abnormal noise after installation, or early leakage may result.

10

5‐2) Installing to a roll

Install the product by following the cautions and instructions described below.

WARNING

Be sure to install the product so that an inspection hole faces downward.

Also, do not block the hole. This hole is used for detecting leakage at an

early stage. If this hole is directed toward other directions or is blocked,

leakage cannot be detected at an early stage. Moreover, leaked fluid may

accumulate in a casing and boll bearings may be damaged, causing serious

bodily accidents due to resulting rotation failure.

CAUTION In order to prevent injuries, take the product weight into consideration

before installing the product. Use equipment such as a crane as necessary.

This work should be performed by two or more persons.

Instruction

1. Remove any foreign objects in such flow passages as a pipe or a roll before

product installation. If the fluid contains foreign objects, install a strainer at

the flow passages. Foreign objects cause early leakage.

2. If the product is installed with its center misaligned or tilted, vibration or

abnormal noise may result. Moreover, the product or machine equipment may

be damaged due to vibration.

3. When tightening screws or nuts, properly torque-tighten them according to the

screw type or size.

4. To prevent uneven tightening, evenly tighten flange screws in a cross pattern.

5. Perform retightening after the start of use.

6. To prevent internal pipe damage, do not hook a sling wire rope to an

internal pipe. Hook a sling wire rope to a casing.

●Installation: taper thread

1. Wrap seal tape around the taper thread of the rotor.

2. Use the shank on the rotor to screw the product into a roll.

●Installation: parallel thread

1. Install the supplied gasket to the rotor.

2. Use the shank on the rotor to screw the product into a roll.

●Installation: flange

1. Install the supplied stud bolts to a roll.

2. Install the supplied gasket to a roll socket.

3. Insert the rotor spigot into the roll socket while checking that the stud bolts go through the rotor

flange holes.

4. Set spring washers on the stud bolts, and then secure the product with the supplied nuts.

11

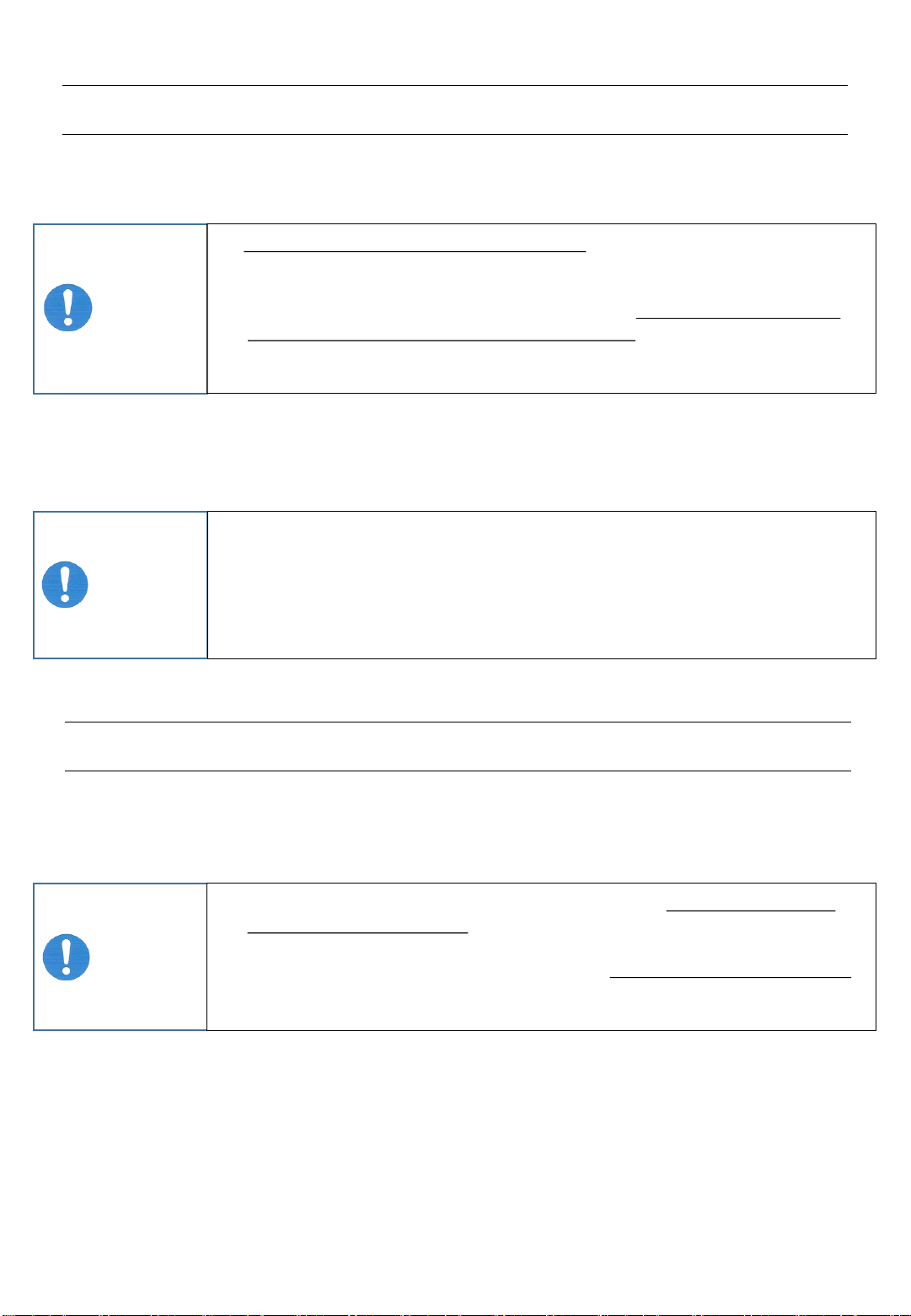

(mm)

サイズ 6A~20A 25A 32A/40A 50A 65A

長さ 300~400 400~500 600~800 900~1000 1200~1300

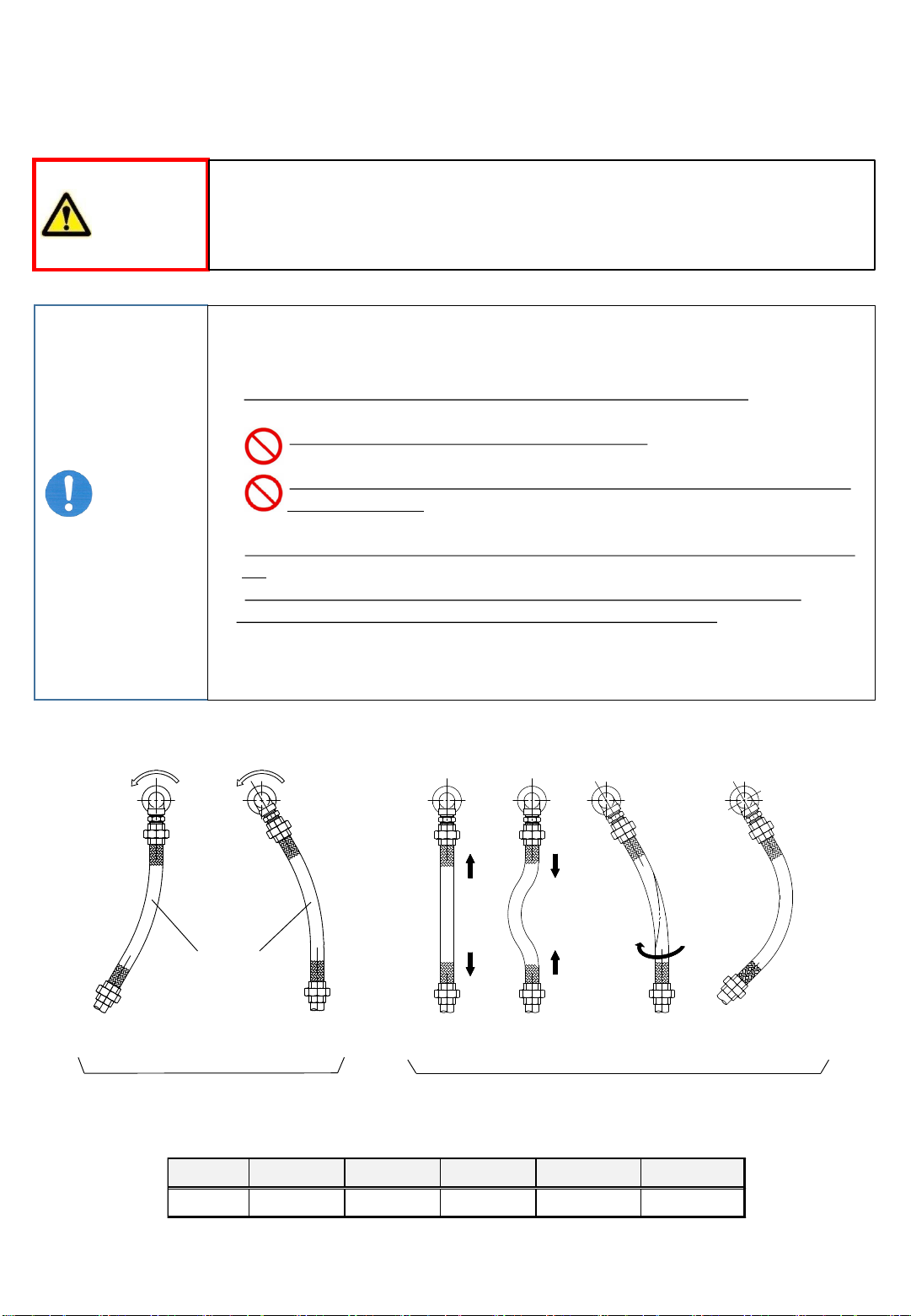

5‐3) Pipe laying

Perform pipe laying work by following the warnings and instructions described below.

WARNING

Use a hose for product connection suitable for characteristics of fluid used

and operating conditions (pressure, temperature). If an unsuitable hose is

used, it may be damaged, causing injury to workers or damage to peripheral

equipment.

Instruction

Observe the following instructions to prevent the generation of force applied to

the sides of the product, possibly causing product damage or early leakage.

1. Use a flexible metal tube or rubber hose with adequate flexibility.

2. Steel pipes should not be used for pipe laying.

3. Avoid such pipe laying where heavy items such as valves are suspended

from the product.

4. When installing a flexible metal tube, slightly bend it in the rotation direction of

roll. (See the bottom left figure.)

5. Carry out pipe laying work so that excessive “tension”, “compression”,

“torsion”, or “bending” is not applied to a flexible metal tube. In particular,

“torsion” may significantly reduce the lifetime of the flexible metal tube.

(See the bottom right figure.)

6. Use the following table as a guideline for the flexible metal tube length.

Flexible

Metal Tube

Rotation Direction of Rroll

Slightly bend the tube

in the rotation direction. Tension Torsion Bending

OK NG

Compression

Flexible Metal Tube Length (Guideline)

12

6. Removal from Machinery

Remove the product by following the warnings, cautions, and instructions described

below in reverse order of the installation.

WARNING In order to prevent bodily accidents due to residual fluid in the product or

pipes, remove the product after fluid has been completely drained from the

product or pipes and temperature has dropped to room temperature.

CAUTIION In order to prevent injuries, take the product weight into consideration

before removing the product. Use equipment such as a crane as necessary.

This work should be performed by two or more persons.

Instruction To prevent internal pipe damage, do not hook a sling wire rope to an internal

pipe. Hook a sling wire rope to a casing.

13

7. Operation

7‐1) Operation

Perform operation by following the warnings, cautions, and instructions described below.

7‐2) Operation shutdown

Follow the following instructions during operation shutdown.

WARNING Immediately stop operation if fluid leakage is detected during operation.

If operation is continued with fluid leakage not being repaired, serious

accidents including bodily accidents may result.

CAUTION During rotation or high-temperature/pressure fluid flow, keep well

away from the product to prevent injuries or burns. Do not directly

touch rotating or hot parts during operation.

Instruction

1. When starting operation, check for abnormal rotation (center runout, abnormal

noise, etc.) or fluid leakage from the product while gradually increasing fluid

pressure and roll rotational velocity.

2. If operation is continued under a center runout condition, product damage or

fluid leakage may result.

3. The occurrence of surging or water hammer can cause product damage or fluid

leakage. Avoid such occurrence.

4. Do not perform dry operation (operation without fluid flow) for a long time.

The product lifetime becomes shortened.

5. If the fluid is air, add oil mist to the air.

Instruction

1. If the product is left as is for a long time during operation shutdown, rust may

occur, causing fluid leakage after operation restart. Clean flow passages for the

product, pipes, and roll before restarting operation.

2. If water is used as the fluid, take a measure to prevent water from freezing in

the product. Freezing may cause product damage, resulting in fluid leakage after

operation restart.

3. Do not put your hand on or ride on the product during equipment

maintenance. Doing so may cause product damage or fluid leakage after

operation restart.

14

8‐2) Greasing

As grease-sealed ball bearings are used, greasing is not required.

8‐3) Repair and replacement of consumables

The ball bearings and the seal face of the seal ring become worn over the course of operation time.

O-rings also deteriorate. Moreover, if the internal pipe rotates in the product, bearings that support

the pipe also become worn. Then such malfunctions as fluid leakage may occur. However, the product

can be reused by repairing or replacing worn or deteriorated parts.

Contact us for repair or parts replacement. We carry it out according to our repair program.

Depending on the products, expenses for purchasing new products may be lower than repair expenses.

Consult with us when requesting repair or replacement.

< When carrying out repair or replacement of consumables by yourself >

・Repair or replacement should be carried out by an experienced expert.

・Perform work according to “A. Appendix - How to Repair or Replace Consumables".

・Use our genuine parts as replacement parts.

Contact our sales representative to request genuine parts.

・Properly dispose of waste resulting from work according to national laws or local government

regulations or ordinances.

(Attention)

If you carry out repair or replacement, we shall assume no responsibility for any product

malfunctions, equipment malfunctions or accidents resulting from such product or the results

thereof. Also, the product shall not be covered by the product warranty even if the warranty

period is still valid.

8. Inspection and Maintenance

8‐1) Daily inspection

Perform inspection according to the following instructions.

Instruction 1. Visually check pipe connections, product connections, and the product for fluid

leakage. If leakage is detected, repair the product or replace it with a new one.

2. When replacing, use the same type of product with the same size.

15

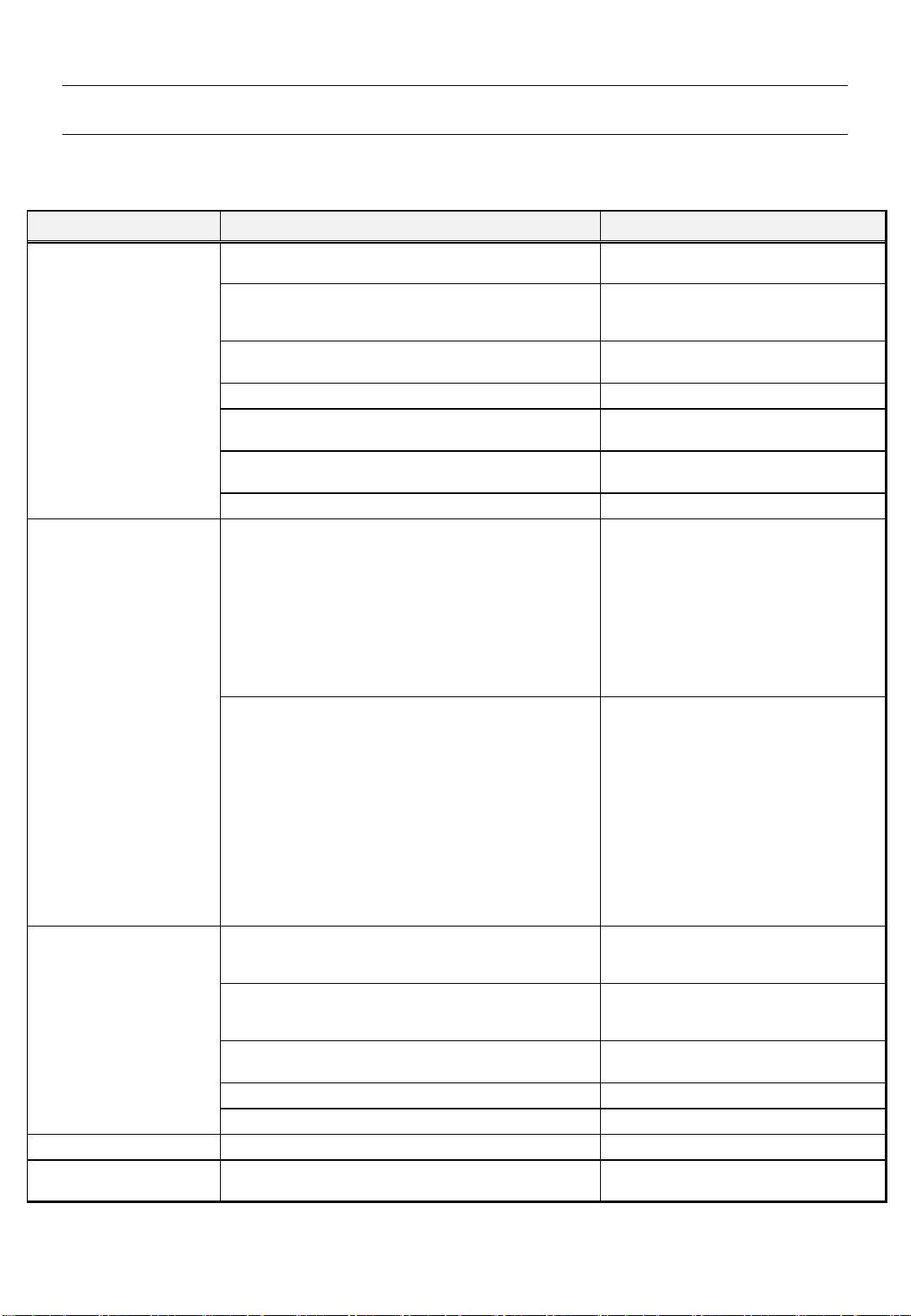

9. Troubleshooting

This section describes the possible causes of and countermeasures against malfunctions.

If a problem persists, contact our sales representative for assistance.

Malfunctions Causes Countermeasures

A load is applied to the product due to an improper

method of pipe laying.

Review the pipe laying method.

The seal ring is damaged.

The seal ring lifetime has been reached.

The rotor seal face is damaged.

Contact us for repair.

The fluid contains foreign objects.

Clean the inside of the product, pipes, and

roll. Install a strainer.

The O-ring adheres to the casing. Contact us for repair.

Operation is performed without rotation, or operation

occasionally ceases during the operation cycle.

Consult with us.

Operation is performed at low-rotation speed (a few

rotations per minute).

Consult with us.

Improper product selection. Consult with us.

The rotation axes of a roll and the product are

misaligned with each other.

-

<Flange connection type> <Flange connection type>

The shaft end socket of a roll is offset from the roll

rotation axis.

Repair the spigot /socket.

<Thread connection type> <Thread connection type>

The shaft end screw hole of a roll is offset from the roll

rotation axis.

Repair the screw hole.

The rotation axes of a roll and the product are inclined

from each other.

-

<Flange connection type> <Flange connection type>

The shaft end socket of a roll is offset from the roll

rotation axis.

Repair the installation face on the roll side

to which the product is installed.

Uneven tightening of fixing screws. Evenly tighten the fixing screws.

<Thread connection type> <Thread connection type>

The center lines of screw holes for fixing the product

are inclined from the roll rotation axis.

Repair the screw hole.

The product is screwed in diagonally. Reinstall the product.

The internal pipe bends and comes in contact with the

inner perimeter of the product rotor or that of the roll

shaft.

Straighten the bent internal pipe.

The internal pipe bent by its weight comes in contact

with the inner perimeter of the product rotor or that of

the roll shaft.

Consult with us.

A load is applied to the product due to an improper

method of pipe laying.

Review the pipe laying method.

Ball bearings are damaged. Contact us for repair.

A sliding sound is heard from the seal face. No fault is indicated.

The rotor does not rotate. A ball bearing does not rotate. Contact us for repair.

Oil is leaking from a ball

bearing.

Oil released from the grease seeps. No fault is indicated.

Noise occurs.

Fluid is leaking from the

inspection hole.

The product has center

runout. (It is vibrating.)

16

10. Disposal

When disposing of packaging materials or products, properly dispose of them according to

national laws or local government regulations or ordinances.

11. Product Warranty

If a malfunction occurs during the warranty period, contact us or the distributor and send the

product to us. Be sure to carefully pack the product for protection before sending it.

After receiving the product, we will confirm the malfunction. If the malfunction was clearly caused

by the materials of product components or the manufacturing method, we will repair the product

in question or replace it with a new one free of charge.

1. Warranty period

<New products>

One (1) year and six (6) months after shipment (from the manufacturing date) or one (1) year

after installation, whichever comes first.

<Repaired products>

Six (6) months after shipment (from the manufacturing date).

2. We charge a fee for repairs in any of the following cases.

①Failure after the warranty period has expired

②Failure caused by use of the product deviating from the service conditions

③Failure caused by misuse

(improper storage, installation, pipe laying, operation or maintenance, etc.)

④Failure caused by fluid contaminants or foreign objects in the fluid

⑤Failure caused by relocation, transport, or falling of the product after delivery

⑥Failure caused by disassembly, repair, or modification done by personnel other than our service

personnel

⑦Failure of the product attributed to using materials or according to standards specified by the

customer

⑧Failure of the product attributed to using materials provided by the customer

⑨Failure caused due to unavoidable acts of nature such as fires or other natural disasters

3. Scope of responsibility

Our responsibility shall be limited to repairs, replacements, or transport expenses covered by this

product warranty provision. Expenses or damages caused by said failures above shall not be

covered.

4. Applicable regions

This product warranty provision shall be applicable to products installed in Japan.

5. Another agreement

If another product warranty agreement is made separately with us and clearly states that said

agreement shall have priority over this product warranty provision, this provision shall not be

applicable.

6. This product warranty provision shall not restrict the customer's legal rights.

Product Warranty Provision

17

Blank Page

18

Export Department Phone : +81-3-3598-1400 Fax. : +81-3-3598-2700

Headquarters 7-24, Nishi-Kobari, Ina-Machi, Saitama, 362-0811 Japan

Phone : +81-48-728-9460 Fax. : +81-48-728-9461

Tokyo Sales Office 2-64-11, Akabane, Kita-ku, Tokyo, 115-0045 Japan

Phone : +81-3-3598-1400 Fax. : +81-3-3598-2700

Osaka Sales Office 2-9-7, Toyosaki, Kita-ku, Osaka, 531-0072 Japan

Phone : +81-6-6371-8341 Fax. +81-6-6371-6283

Nagoya Sales Office 1-107, Takaharidai, Meito-ku, Nagoya, 465-0054 Japan

Phone : +81-52-701-4068 Fax. : +81-52-704-4051

URL http://www.sgk-p.co.jp

19

A. Appendix - How to Repair or Replace Consumables

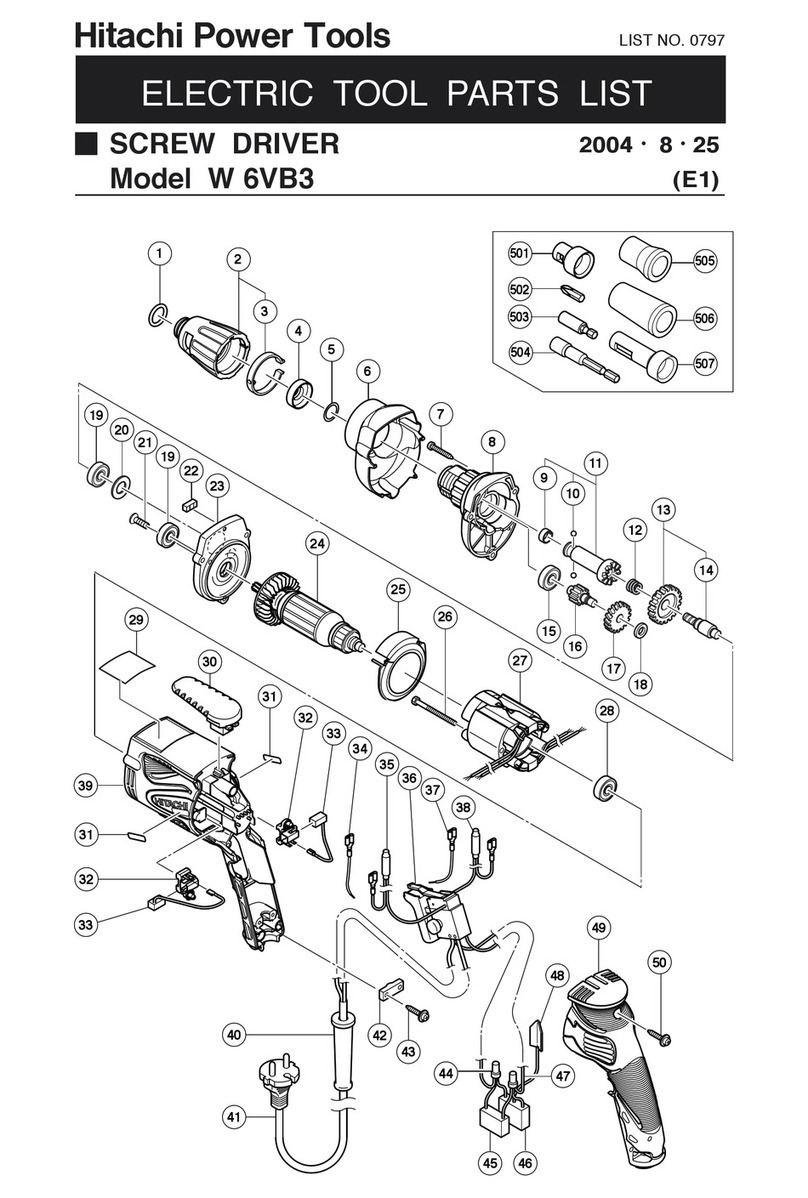

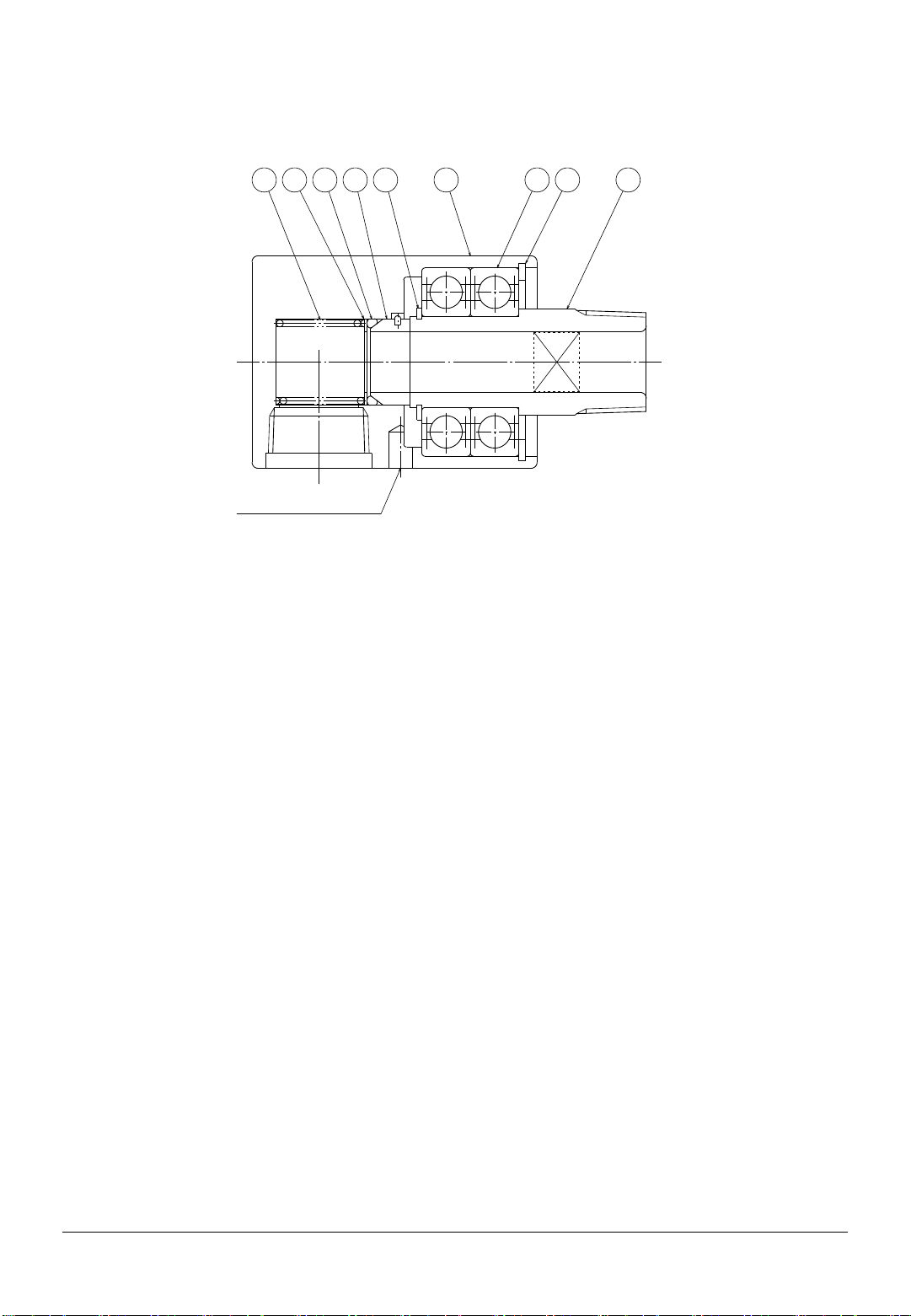

154263789

Inspection Hole

20

A‐1) For simplex (KCL, KCLF, SKCL)

An explanation is given below with reference to KCL (figure shown below).

The same workflow is applied to KCLF and SKCL.

①Rotor ②Casing ③Seal Ring ④Ball Bearing ⑤Retaining Ring

⑥Retaining Ring ⑦O-ring ⑧Washer ⑨Spring

< Disassembly >

Carefully disassemble the product so that each part is not damaged. In particular, be careful not to

damage the seal faces of rotor ①and seal ring ③.

1) Disconnect all pipes, etc. connected to the product.

2) Clamp casing ②with a vice, etc. so that rotor ①faces upward.

3) Remove retaining ring ⑤.

4) Pull out the assembly consisting of rotor ①, ball bearings ④, retaining ring ⑥(hereinafter called

the rotor assembly) from casing ②.

5) Remove seal ring ③, O-ring ⑦, washer ⑧, and spring ⑨from casing ②.

6) Remove retaining ring ⑥from rotor ①, and then pull out ball bearings ④.

7-24, Nishi-Kobari, Ina-Machi, Saitama, 362-0811 Japan

Phone : +81-48-728-9460 Fax. : +81-48-728-9461

SHOWA GIKEN INDUSTRIAL CO., LTD

http://www.sgk-p.co.jp

This manual suits for next models

7

Table of contents