PAGE 5

PAGE 4

• Always wear eye and ear protection when operating, servicing, or

performing maintenance on unit. Wearing eye pretection will help to

prevent rocks or debris from being blown or ricocheting into eyes

and face which can result in blindness and/or serious injury.

• Always wear foot protection. Do not go barefoot or wear sandals.

• Always wear a respirator face mask when working with in dusty

environments.

• Secure hair above shoulder length. Secure or remove jewelry, loose

clothing, or clothing with loosely hanging straps, ties, tassels, etc.

They can be caught in moving parts.

• Do not operate unit when you are tired, ill, or if you are under

the influence of alcohol, drugs, or medication.

• Eliminate all sources of sparks or flame (including smoking, open

flames, or work that can cause sparks) in the areas where fuel is

mixed, poured, or stored.

• Mix and pour fuel in an outdoor area; store fuel in a cool, dry, well

ventilated place; use an approved, marked container for all fuel

purposes.

• Do not smoke while handling fuel or while operating the unit.

• Make sure the unit is properly assembled and in good operating

condition.

• Do not fill fuel tank while engine is hot or running.

• Avoid spilling fuel or oil. Wipe up fuel spills before starting engine.

• Move at least 3 meters away from fuel and fueling site before starting

engine.

• Always store petrol in a container approved for flammable liquids.

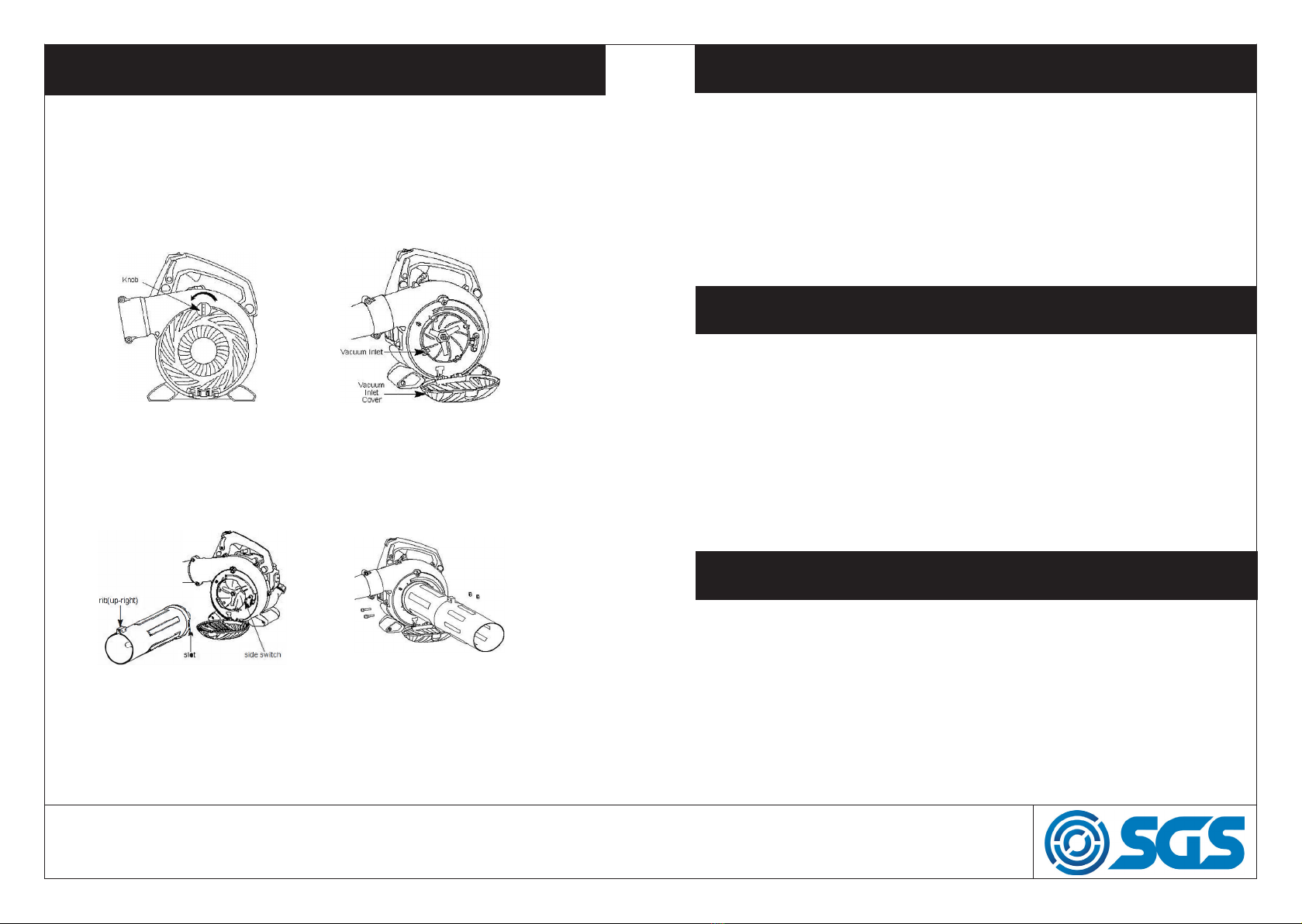

• Stop the engine before opening the vacuum inlet door. The engine

must be stopped and the impeller blades no longer turning to avoid

serious injury from the rotating blades.

• While vacuuming or blowing debris, hold the unit with the muffler

side facing away from your body and clothes.

GENERAL SAFETY PRECAUTIONS GENERAL SAFETY PRECAUTIONS

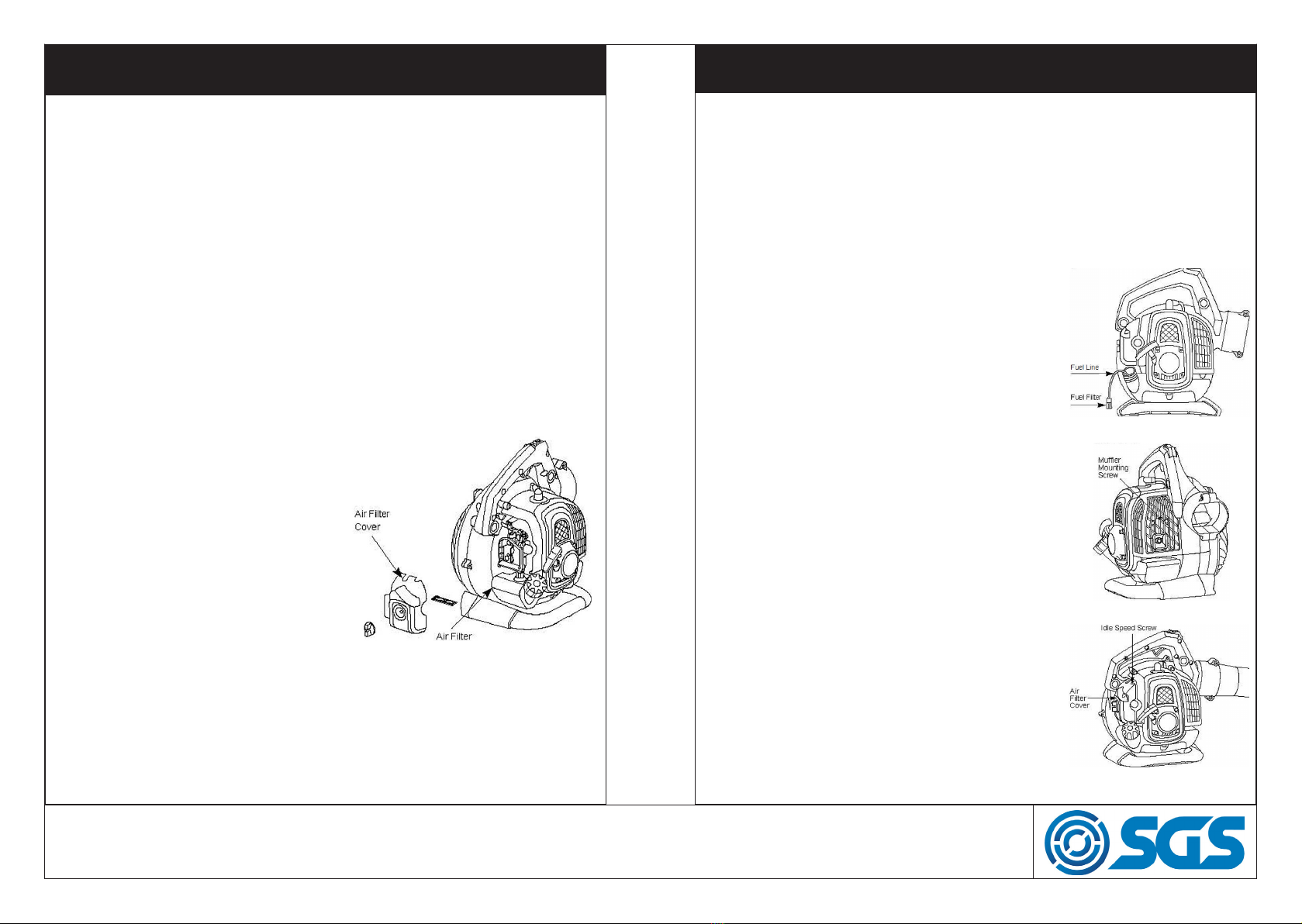

• Inspect unit before each use for worn, loose, missing, or damaged

parts. Do not use until unit is in proper working order.

• Keep outside surfaces free of oil and fuel.

• Never start or run engine inside a closed room cr building. Breathing

exhaust fumes can kill.

• Mufflers fitted with catalytic converters get very hot during use and

remain so for some time after stopping. This also applies at idle

speed. Contact can result in burns to the skin.

• To avoid a static electricity shock, do not wear rubber gloves or any

other insulated gloves while operating unit.

• Do not set unit on any surface except a clean, hard area while

engine is running. Debris such as gravel, sand , dust, grass, etc. could

be picked up by the air intake and thrown out through discharge

opening, damaging unit, property, or causing serious injury to by

standers or operator.

• Avoid dangerous environments. Do not use in unventilated areas or

where explosive vapors or carbon monoxide build up could be

present.

• Do not overreach or use from unstable surfaces such as ladders, trees,

steep slopes, rooftops, etc.

• Never place objects inside the blower tubes. The force of air can

cause rocks, dirt, or sticks to be thrown or to ricochet.

• Never run unit without the proper equipment attached.

• Check air intake opening, blower tubes, vacuum tubes, and elbow

tube frequently, always with engine stopped and spark plug discon

nected. Keep vents and discharge tubes free of debris which can

accumulate and restrict proper air flow.

• Never place any object in the air intake opening as this could restrict

proper air flow and cause damage to the unit.

• Never use for spreading chemicals, fertilizers, or ether substances

which may contain toxic materials.

WWW.SGS-ENGINEERING.COM