PAGE 11

PAGE 10

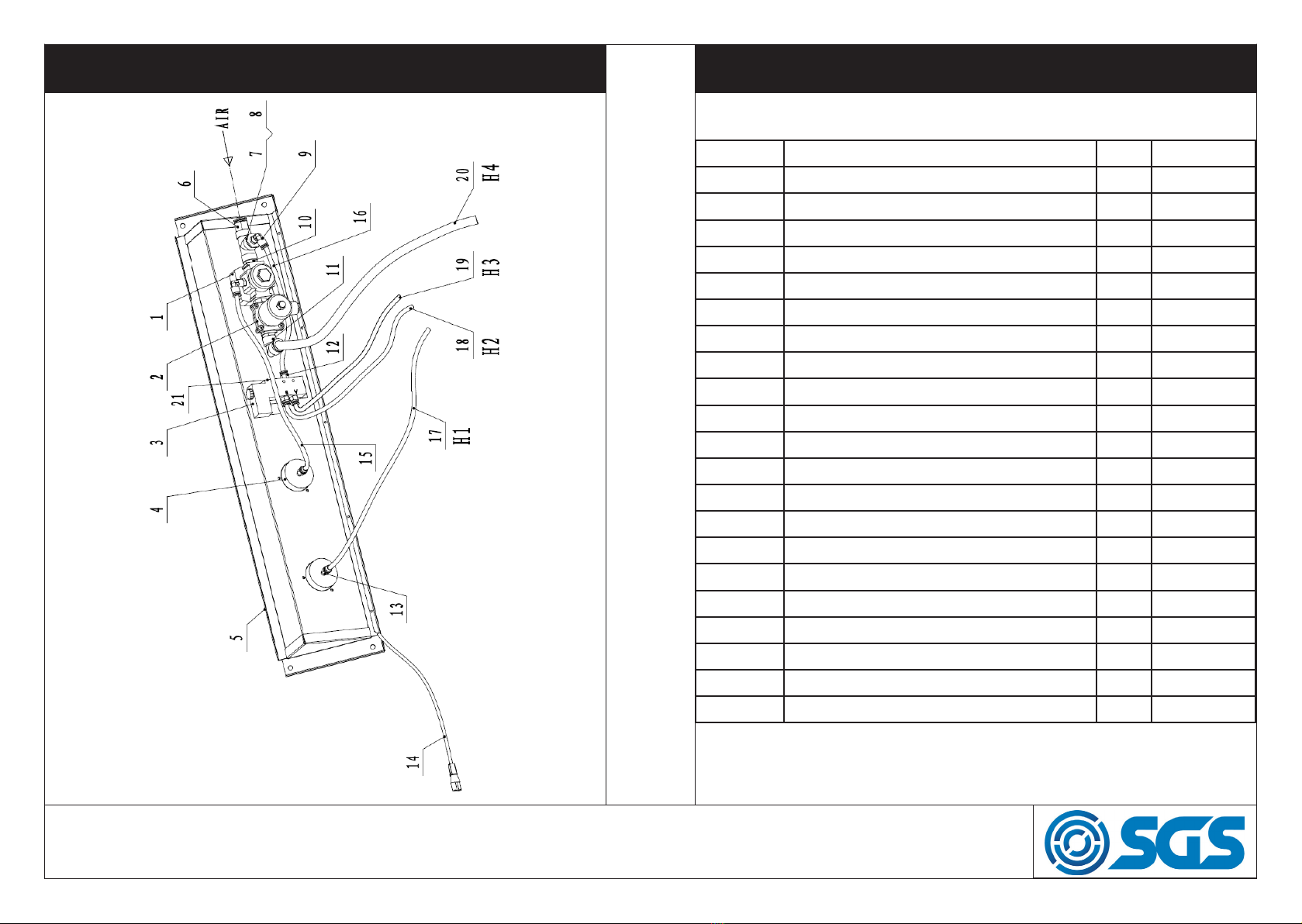

PARTS LIST EXPLODED VIEW OF LEFT BAR

Item No. Description Qty. Code

9-1 Left bar 1 905939

9-2 Straight Coupling 2 905992

9-3 Ball Valve 1 905993

9-4 Washer 2 905994

9-5 Moisture Separator 1 905995

9-6 Right-angle Quick Coupling 1 905996

9-7 Air Hose 1 905997

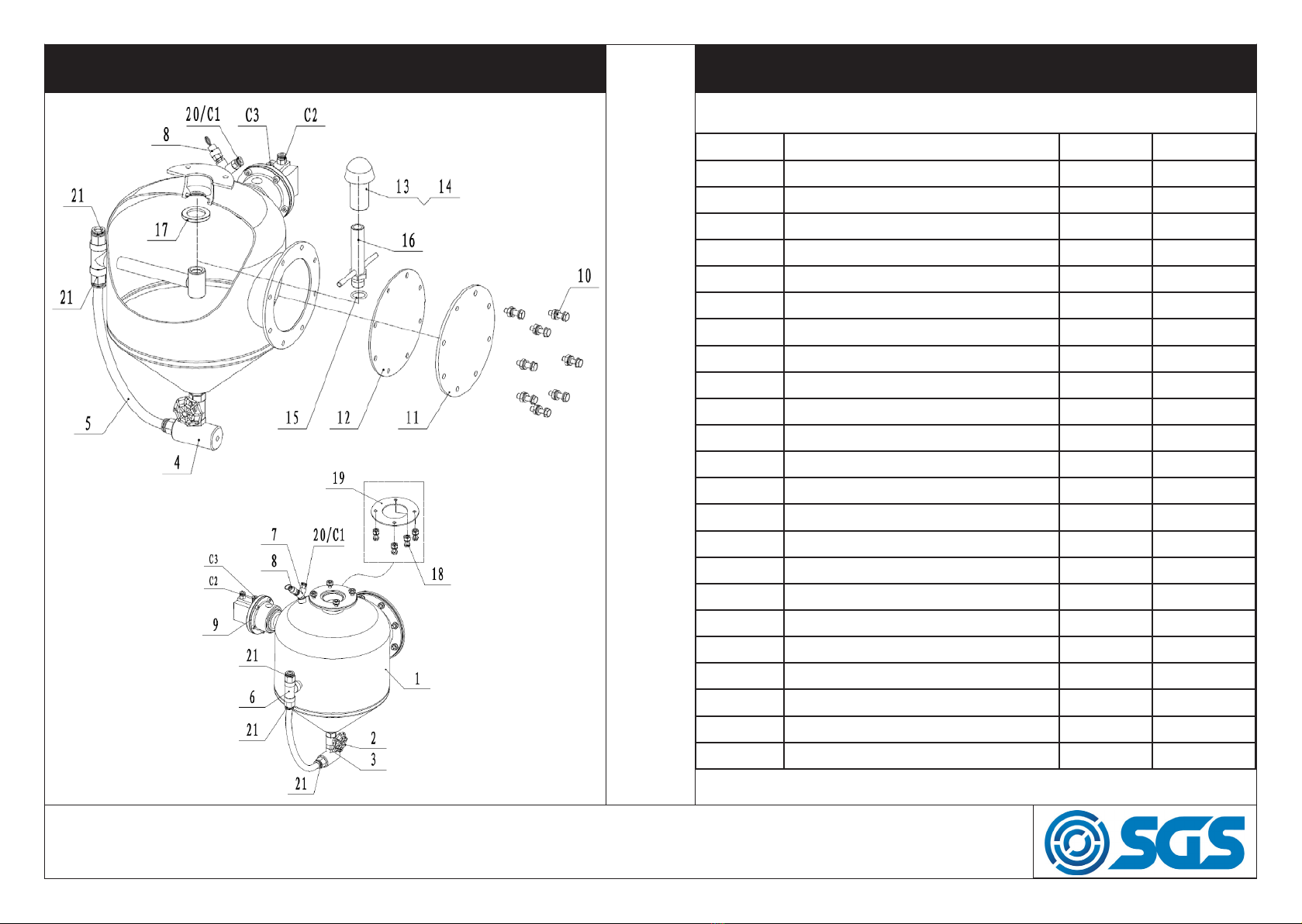

No Description Qty Code No Description Qty Code

1 Cabinet Assembly 1 905931 36 Air Spring Support Rod 2 905966

2 Grid 2 905932 37 Plastic Slot 1 905967

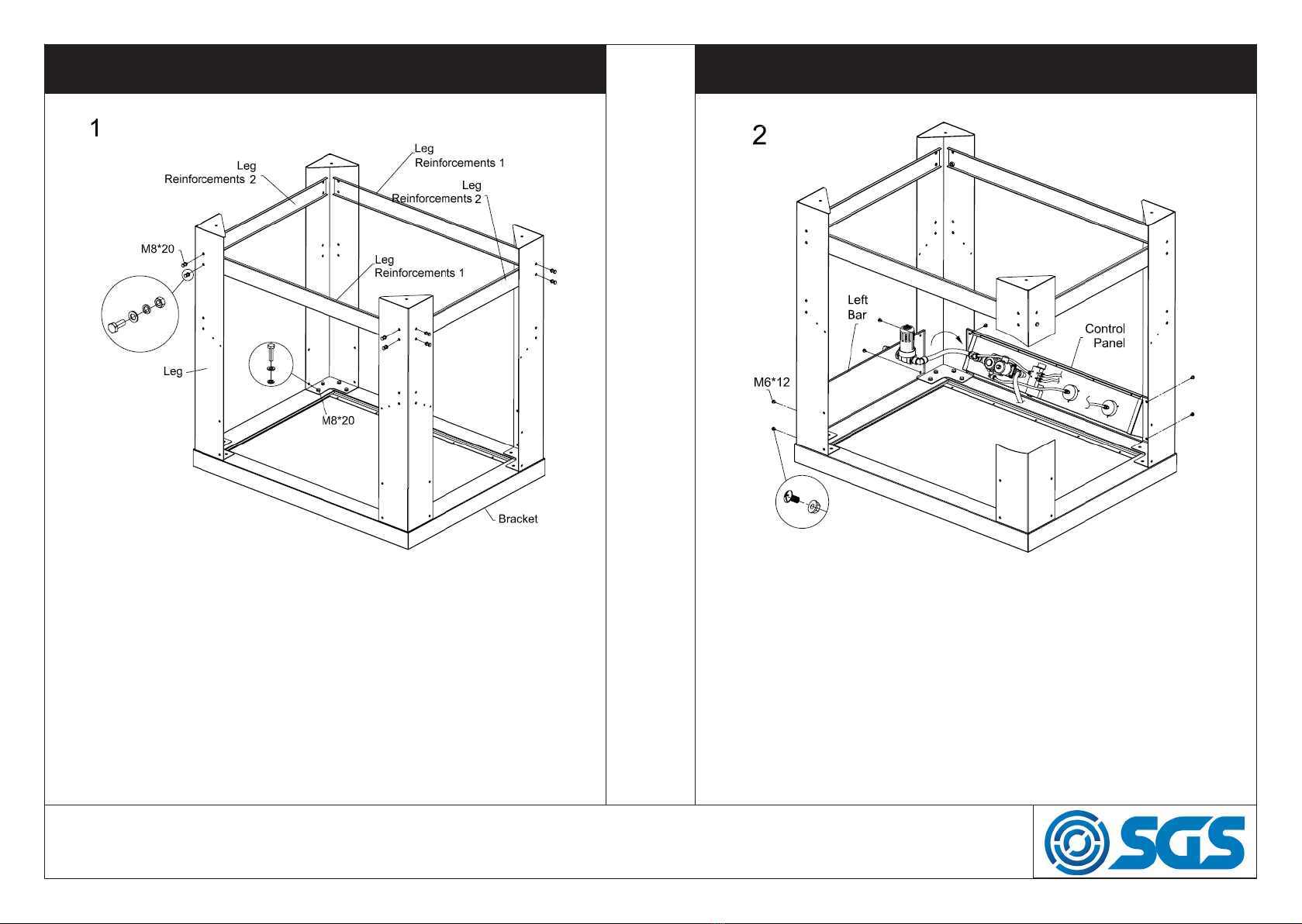

3 Bolt M6x16 (matched with φ6 x 16 washers) 22 905933 38 Switch Box 1 905968

4 PSA foam 1 905934 39 Front Door Latch 2 905969

5 Bracket 1 905935 40 Latch Seat 2 905970

6 Cover grid 1 905936 41 Handle 2 905971

7 Funnel 1 905937 42 Glove Clamp 2 905972

8 Rear Bar 1 905938 43 Seal Ring of Glove 2 905973

9 Left Bar 1 905939 44 Front Door 1 905974

10 Bolt M6*12 24 905940 45 Front Bar 1 905975

11 Control Panel 1 905941 46 Glove 24” 1 905916

12 Tank Assembly 1 905942 47 Glove Seat 2 905977

13 Right Bar 1 905943 48 Nozzle Nut 1 905978

14 Bolt M8 x 20 32 905944 49 Nozzle 1 905979

15 Leg 4 905945 50 O-Ring 1 905980

16 Leg Reinforcements 2 905946 51 Nozzle Retainer 1 905981

17 Leg Reinforcements 2 905947 52 Abrasive Hose 1 905982

18 Stand 1 905948 53 Hook 1 905983

19 Foot Pedal 1 905949 54 Nozzle Seat 1 905984

20 Dust Collector 1 905950 55 Dust Baffle 1 905985

21 DC with power switch 1 905951 56 Pressure Hose Clamp 3 905986

22 Bolt M6 x 32 12 905952 57 Nozzle Retainer Adapter 1 905987

23 Window Frame 1 905953 58 4.2*12 screw 12 905988

24 Window Outer Lens 1 905954 59 Tee Joint Adapter 1 905989

25 Window Inner Lens 1 905955 60 Tee Joint Nut 1 905990

26 Window Underlay 1 905956 61 O-Ring 1 905991

27 PSA foam of Viewing Window 1 905957

28 Rubber Door Seal 1 905958

29 Lamp Housing 1 905959

30 LED Light 3 905960

31 Light Lens 1 905961

32 Light Lens Underlay 2 905962

33 Rubber Seal of Light Lens 1 905963

34 Cover Plate 2 905964

35 Main Support Pole 2 905965

WWW.SGS-ENGINEERING.COM

62Filter 1907032