Operating Manual S210E

Safety Instructions

2

2.0 Warnings and symbols

The following denominations and symbols are used in the Operating

Instructions to highlight areas of particular importance:

Symbol of operational safety.

This symbol will be shown in these Operating

Instructions next to all safety precautions that are to

be taken in order to ensure prevention to life and

injury. Follow always these instructions and take

special care in these circumstances. In addition to

these instructions, the general safety precautions and

the local accident prevention guidelines are also to be

followed. Please check, whether there are special

regulations for the particular job side.

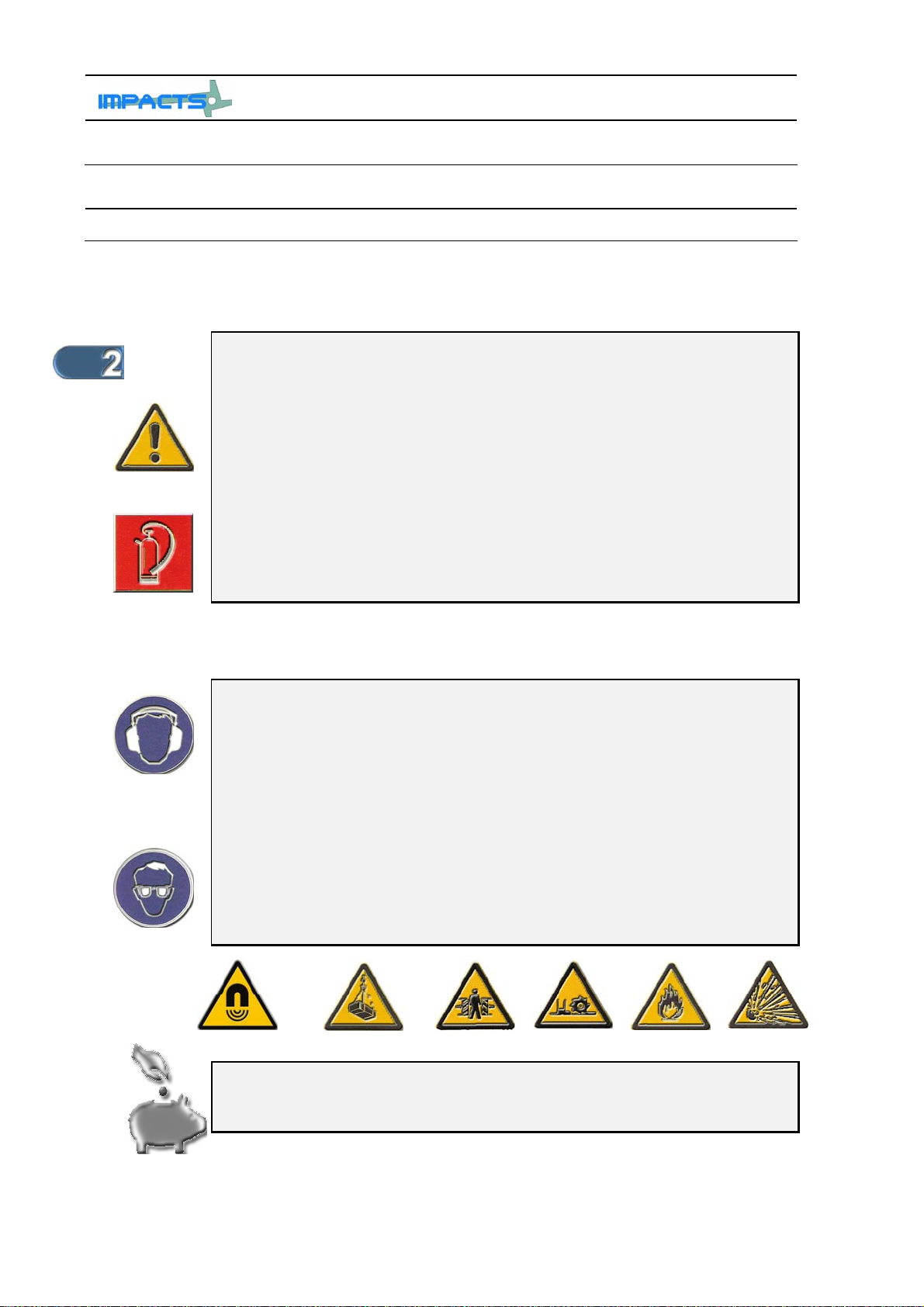

Information, instructions and restrictions with regards

to possible risks to persons or extensive material

damages.

Particular details regarding the economical use of the

equipment