PAGE 5

PAGE 4

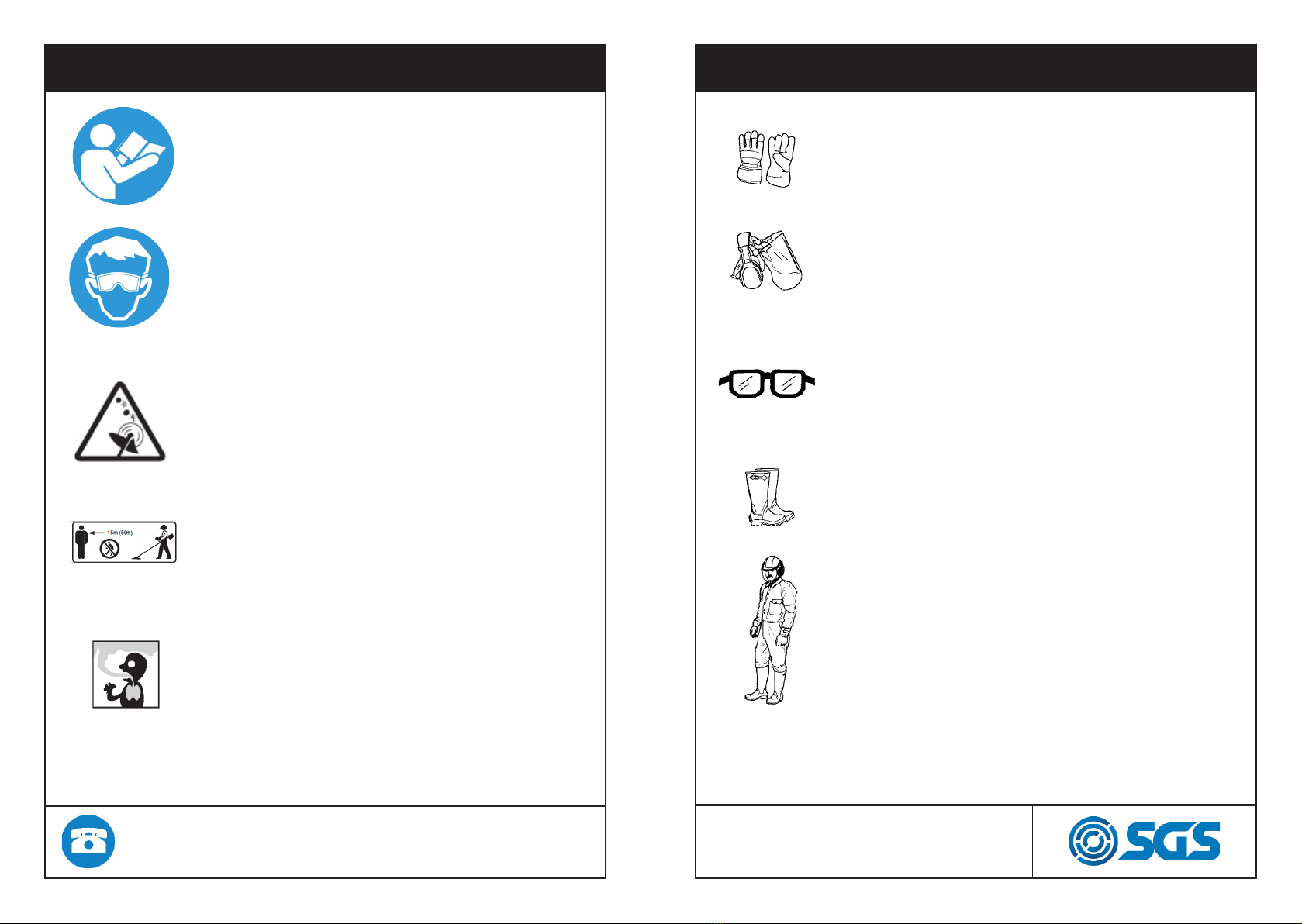

FOR SAFE OPERATION

Do not wear loose clothing, jewelry, short trousers,

sandals, or go barefoot. Do not wear anything

which might be caught by a moving part of the unit.

Secure hair so it is above shoulder length.

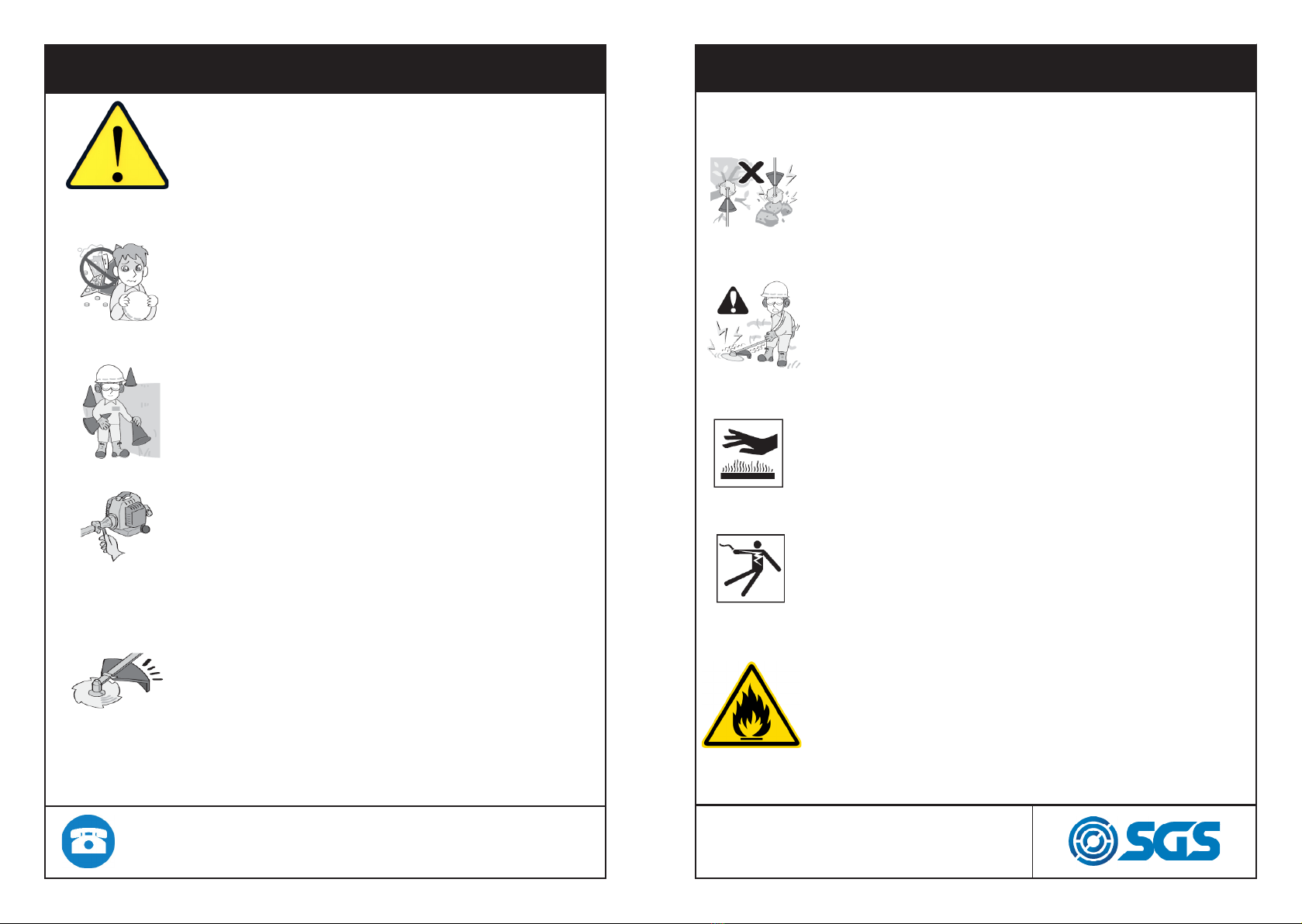

Never use the product when the ground is slippery,

in the nightime or in the bad weather conditions.

Never use this product when tired, under the

influence of alcohol, or if you are taking medication

that could affect your vision, your judgment or your

coordination.

Check the condition of working area to avoid any

accident by hitting hidden obstacles such as stumps,

stones, cans, or broken glass.

Remove any obstacle before beginning work. Inspect

the entire unit for loose fasteners and fuel leakage.

Make sure that the cutting attachment is properly

installed and securely fastened. Be sure the cutting

attachment guard is firmly attached in place. Always

use the harness. Adjust the strap for comfort before

starting the engine. The strap should be adjusted so

the left hand can comfortably hold the handlebar

grip approximately waist high.

When starting the engine, place the product onto

the ground in a flat clear area and hold it firmly in

place so as to ensure that neither the cutting contact

with any obstacle when the engine starts.

FOR SAFE OPERATION

After starting the engine, check to make sure that the

cutting attachment stops rotating when the throttle is

moved fully back to its original position.

Cut only materials recommended by the manufacturer.

Use only for tasks explained in the manual.

Maintain the speed of the engine at the level required

to perform cutting work, and never raise thespeed of the

engine above the level necessary.

If the unit starts to shake or vibrate, turn off the engine

and check the whole unit. Do not use it until the trouble

has been properly corrected.

Never touch the muffler, spark plug, or other metallic

parts of the engine while the engine is in operation or

immediately after shutting down the engine. Doing so

could result in serious burns or electrical shock.

Approaching or contacting electric power lines with

pruning saw may cause serious injury or death from

electrocution.

Always be sure to turn off the engine and disconnect the

spark plug wire before performing any maintenance or

checking procedures.

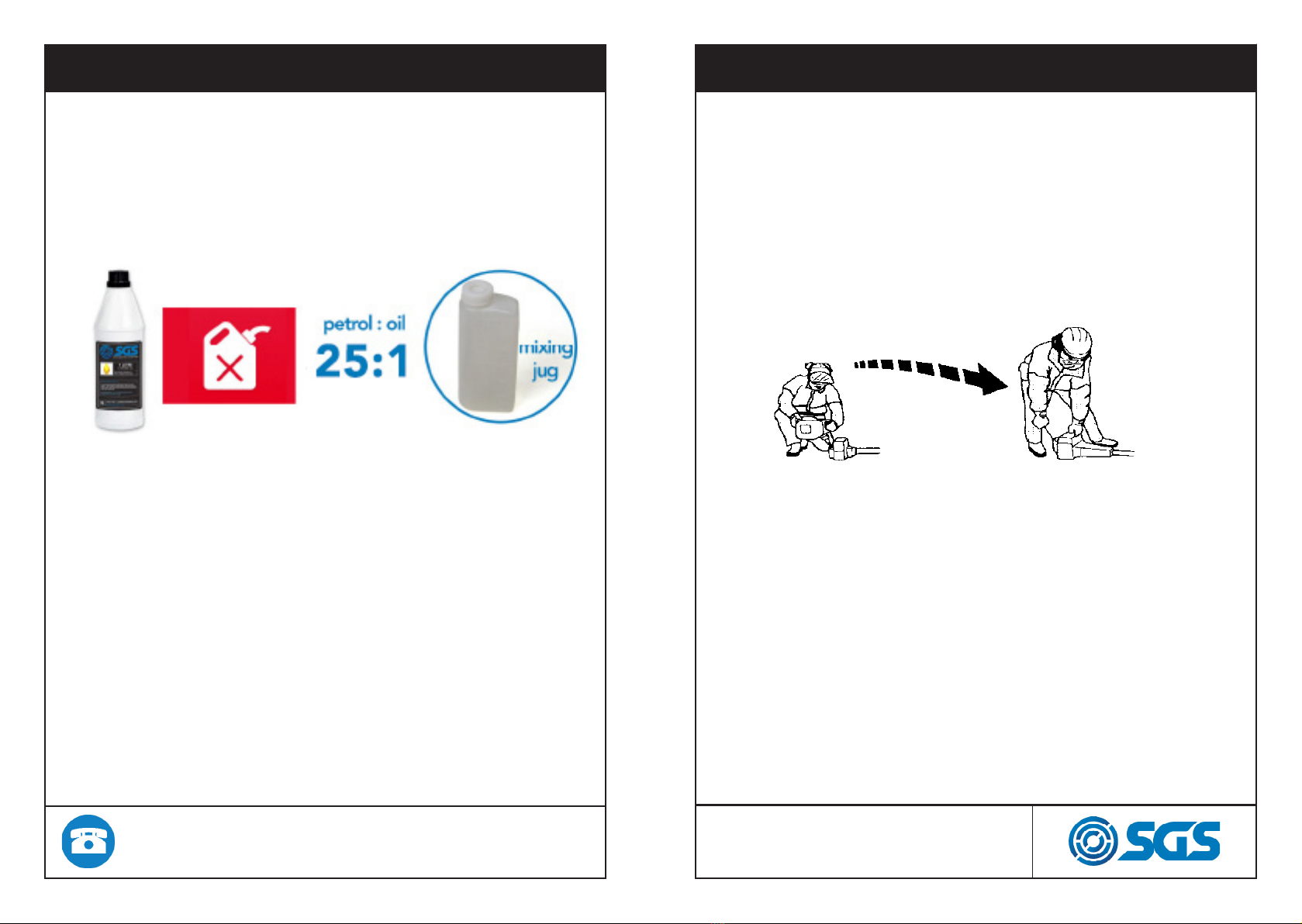

The engine of the product we offer is designed to run

on a mixed fuel, which contains highly flammable

gasoline.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE: 01332 576 850