PAGE 5

PAGE 4

FOR SAFE OPERATION

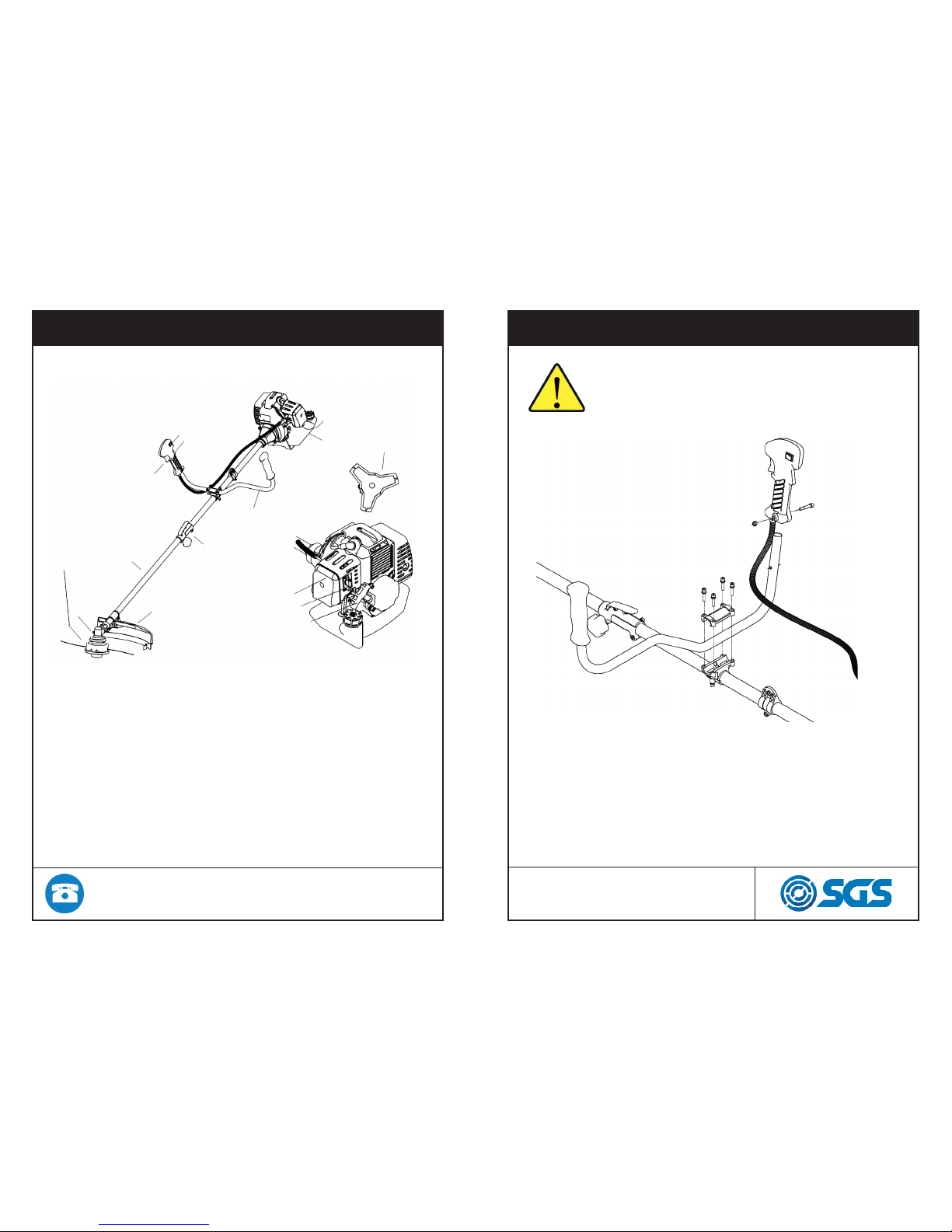

The only accessories you can operate with this en-

gine unit are the cutting attachments we recommend.

Never use wire, rope, string, etc.

Never use the machine if you are tired, if you have

drunk alcohol, or if you are taking medication that

could affect your vision, your judgment or your

coordination.

Never use the machine in extreme weather conditions

such as severe cold, very hot and/or humid climates.

Never use a machine that has been modified in any

way from its original specification.

Wear personal protective equipment.

Never use a machine that is faulty. Carry out the

checks, maintenance and service instructions de-

scribed in this manual. Some maintenance and service

measures must be carried out by trained and qualified

specialists.

The machine is only designed for trimming grass.

FOR SAFE OPERATION

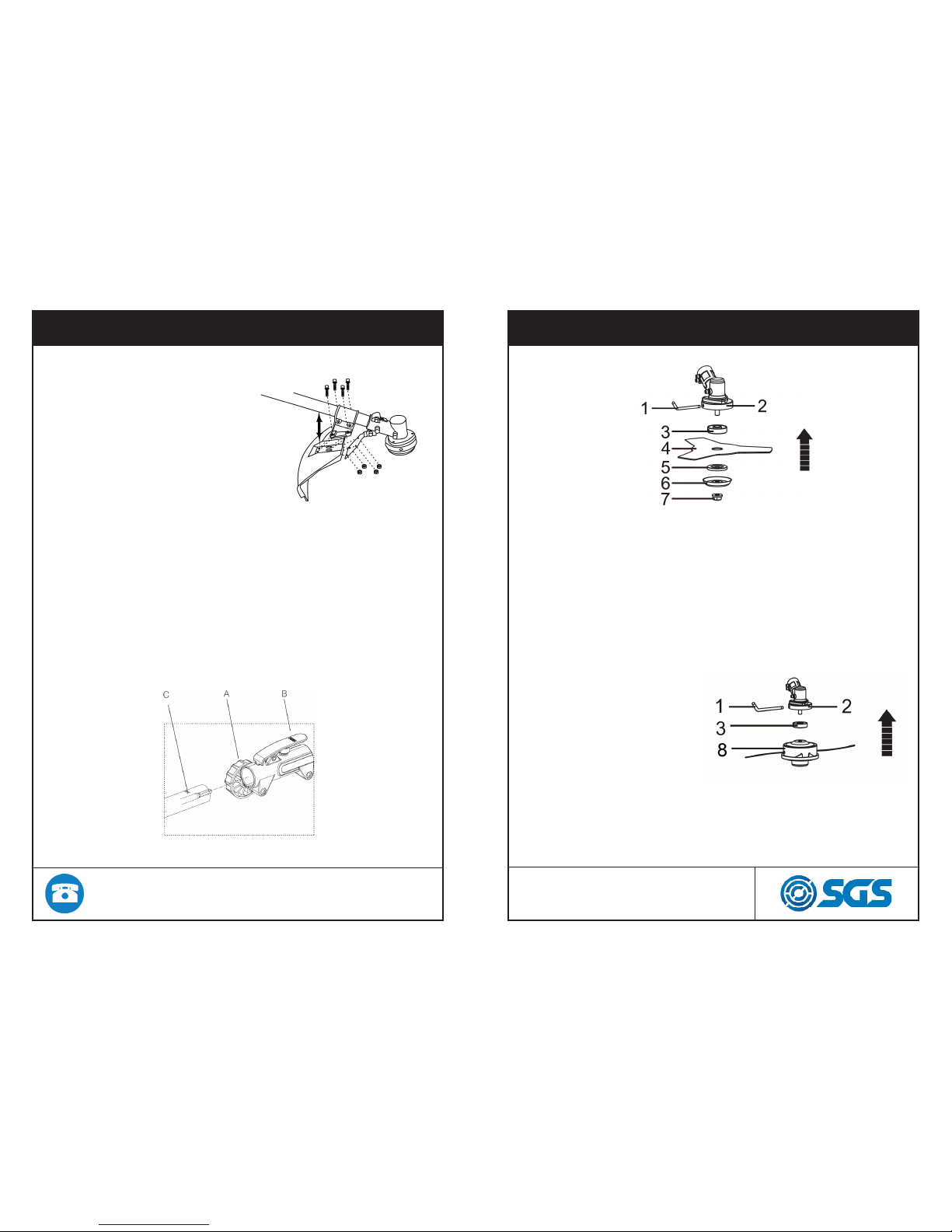

All covers and guards must be fitted before starting.

Make sure the spark plug cap and lead are not dam-

aged. Otherwise you could get an electric shock.

The machine operator must ensure that no people

or animals come closer than 50 feet (15 meters) while

working. Stay clear of spinning line.

Secure or remove loose clothing or clothing with

loosely hanging ties, straps, tassels, etc. They can be

caught in moving parts.

Being fully covered also helps protect you from debris

and pieces of toxic plants thrown by spinning line.

Always keep the engine on the right hand side of your

body. Hold the unit firmly with both hands.

Keep trimmer head below waist level.

Keep handles free of oil and fuel.