ShadeTree The Bungalow User manual

Dear Customer:

Thank you for purchasing our ShadeTree®Canopy System. We trust these assembly

instructions will be satisfactory for your installation. If you have any questions, please feel

free to call 1-800-894-3801.

And here’s a special offer we’d like to make to you: Send us a photo of your new

ShadeTree®installation and we will send you $50 if we use your photo in our advertising

materials. Before and after pictures will receive an additional $50. A deck or patio that is

nicely furnished helps us communicate to prospective customers how nice a ShadeTree®

patio can be.

We hope you enjoy your new ShadeTree®patio canopies.

Sincerely,

Colin LeVeque, President

ShadeTree Systems, LLC.

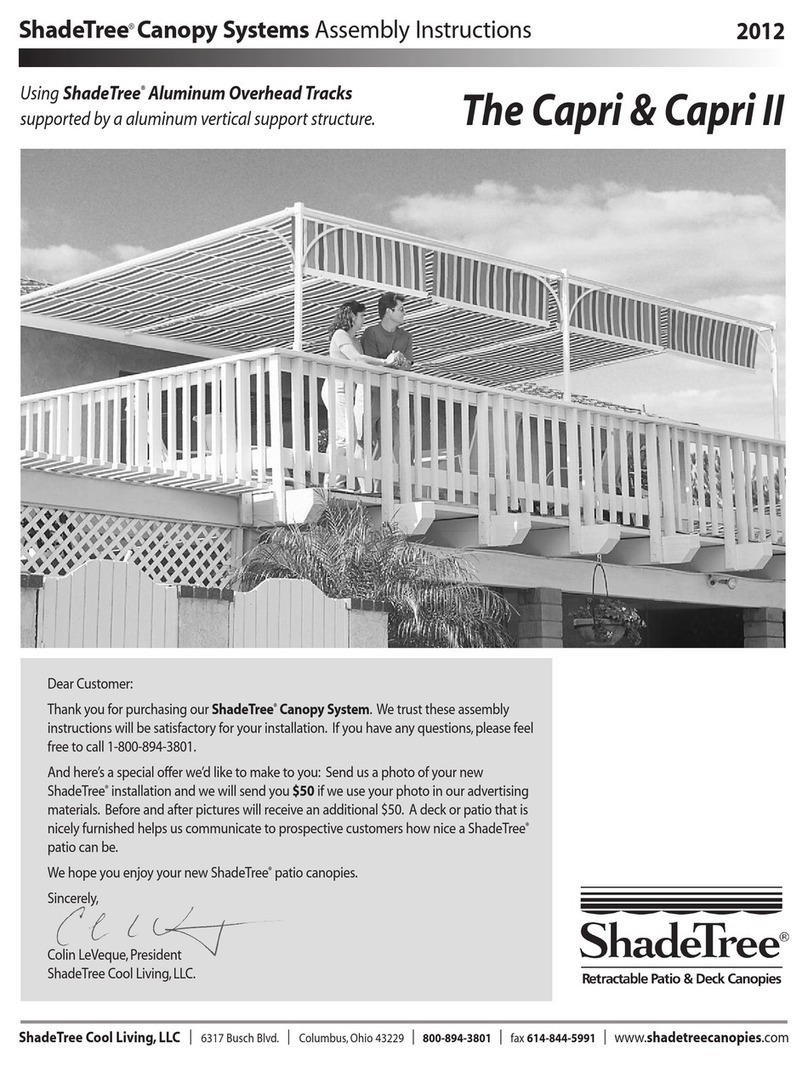

2012

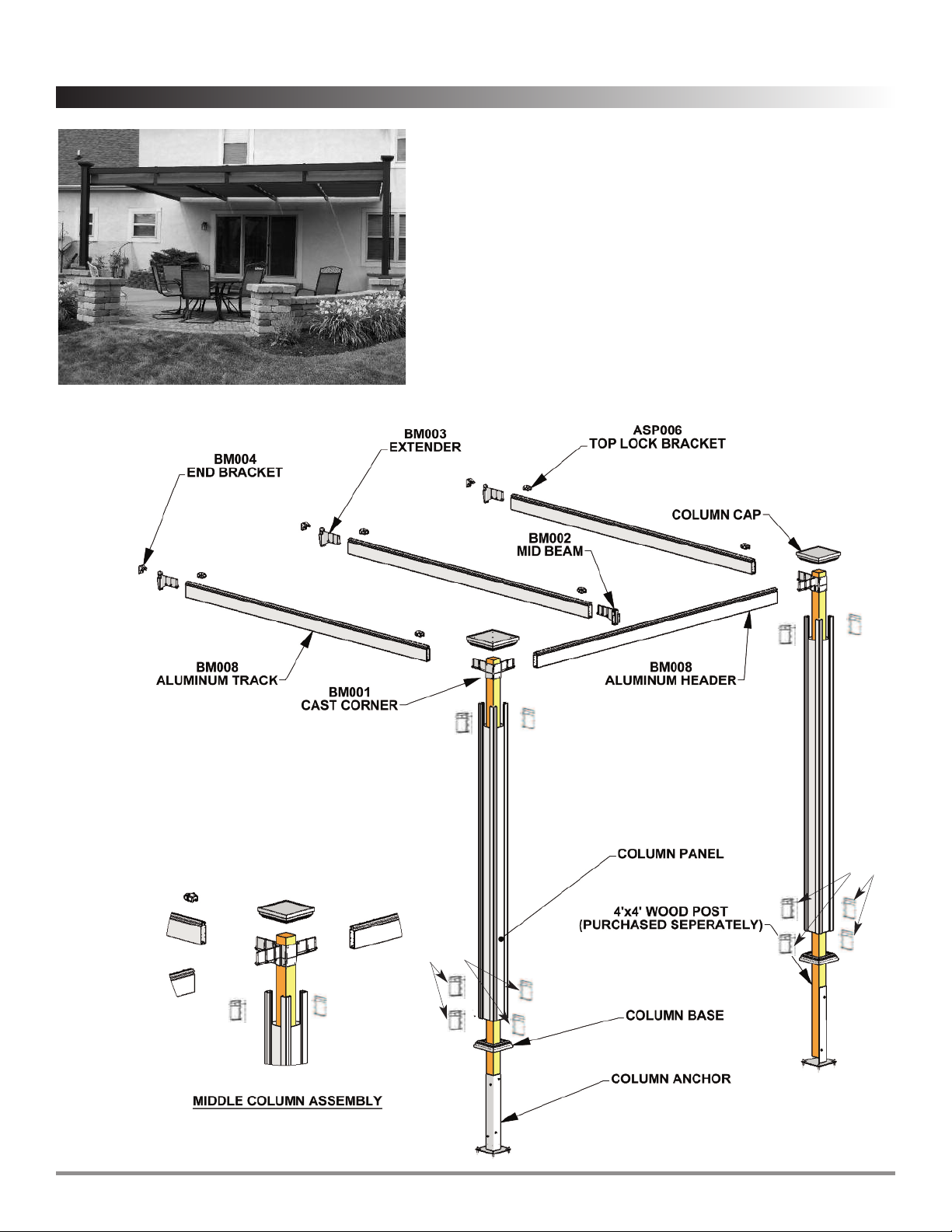

The Bungalow

Using ShadeTree®Aluminum Overhead Tracks supported

by a Bungalow aluminum support structure

ShadeTree®Canopy Systems Assembly Instructions

ShadeTree Cool Living, LLC |6317 Busch Blvd. |Columbus, Ohio 43229 |800-894-3801 |fax 614-844-5991 |www.shadetreecanopies.com

Complete Aluminum System

(supported by an aluminum frame)

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .

2

The Bungalow

ShadeTree®Canopy Systems Assembly Instructions

TRIM PANEL

TRIM PANEL

OTE: You’ll find a second pair of hands (to hold parts as the

unit goes up) to be very helpful in erecting your system.

Other Materials Required:

You will also need 4” x 4” wooden posts for added strength

inside aluminum columns. Pre-selection of pressure-treated

wood is very important. Any warped or oversized lumber will

not fit inside the aluminum columns. If sinking posts into the

ground, treated lumber is required.

If mounting on a deck, patio, the surface must be connected to

solid anchor points. If not, the posts must be sunk inot the

ground. If you wish to cement the posts 3’ into the ground, 12’

posts are needed. The aluminum framework should be

completely assembled before cement is poured into the holes.

If you are sinking posts into the ground, the Column Bases are

optional. If you prefer to use the Column Bases, they should be

assembled onto the wood posts before erecting the system.

ShadeTree®Canopy Systems Assembly Instructions

The Bungalow

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .3

CAD –YOUR PROVIDED CUSTOM BLUEPRI T :

Each ShadeTree Pergola will ships with a custom-designed

CAD drawing showing all of the dimensions neccessary for

installation. Please refer to this CAD for all steps in these

instructions. If a CAD did not come with your ShadeTree

system, please call customer service before proceeding with

installation.

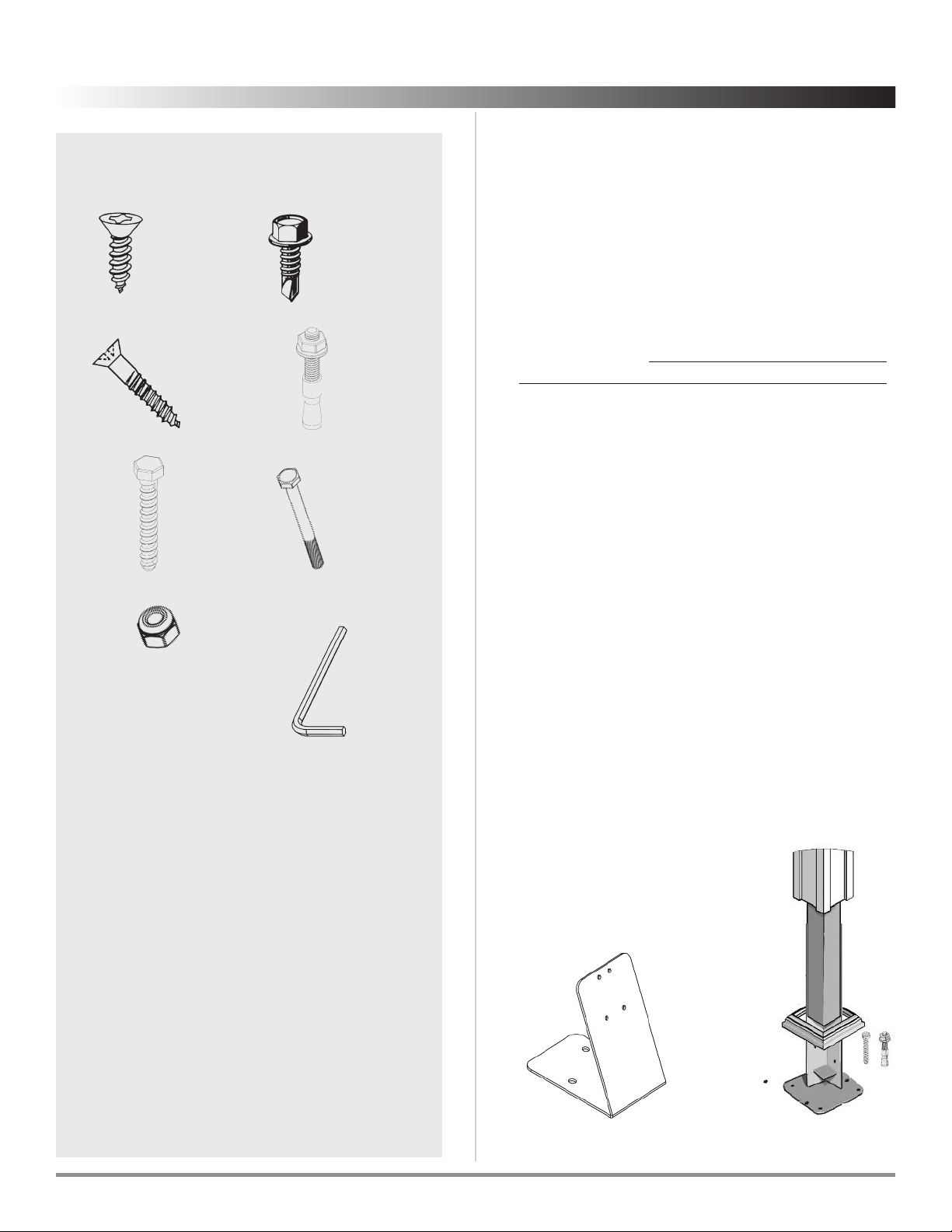

Large Roof

Bracket

Optional installation accessories:

Column

Anchor

Fasteners & hardware provided:

#F010 End and

Base Screw #F011

1” Self-drilling

#10 ex Screw

#F052

3/8” Wedge

Anchor

#F001 Nut Allen Wrench

#F053

Lag Bolt for

Anchor

#F002 2-3/4”

Long Bolt

A. B.

G.

.

D.

E. F.

#F061

3” Wood

Screw

C.

Tools required:

1. Phillips screwdriver

2. and drill

3. 9/64”, 1/4” & 3/4”

drill bits

4. pencil

5. bubble-type level

6. Carpenter’s square

7. tape measure

8. hand saw

9. 8’ ladder

If driving screws with a drill or power screwdriver, set the

torque to a low setting to avoid stripping screw heads.

Mark the center location for each

End Mounting Bracket

on the

house 5-4” or 4’-2” apart (refer to the supplied CAD of your

system). One

End Mounting Bracket

is needed for every

projection beam. Be sure to allow approximately 4” on the

outside of outermost brackets for inserting bolts into brackets.

Step 2 Attach End Mounting Brackets

Mount the

End Mounting Brackets

on each center mark, using

the center notch as a guide. The brackets should be mounted

so that the the slanting edge of the bracket is to the top (as in

illustration). Be sure to mount the brackets level with each

other. Use a 9/64” drill bit to drill pilot holes. Wood screws are

included (1-1/4” screw c). . . any other type of screws (such as

masonry screws for brick or stone) can be purchased from

your hardware store. The Bracket can be used as its own

template for marking pilot holes.

5’4”

or

4’2-1⁄4”

5’4”

or

4’2-1⁄4”

5’4”

or

4’2-1⁄4”

4” min

When mounting to house, brackets must be attached to

well-secured wood, brick or stone.

• If mounting to a house with wood siding, or to wood trim,

use the 1-1/4” #10 wood screws with the painted heads.

• If mounting to a masonry wall (brick or stone) concrete

fastening screws must be used. Consult your hardware

store for the best fastener for your situation.

Center notch for 5’-4”

or 4’-2-1/4”alignment

Allow 2” beyond

center of bracket

2”

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .

4

The Bungalow

ShadeTree®Canopy Systems Assembly Instructions

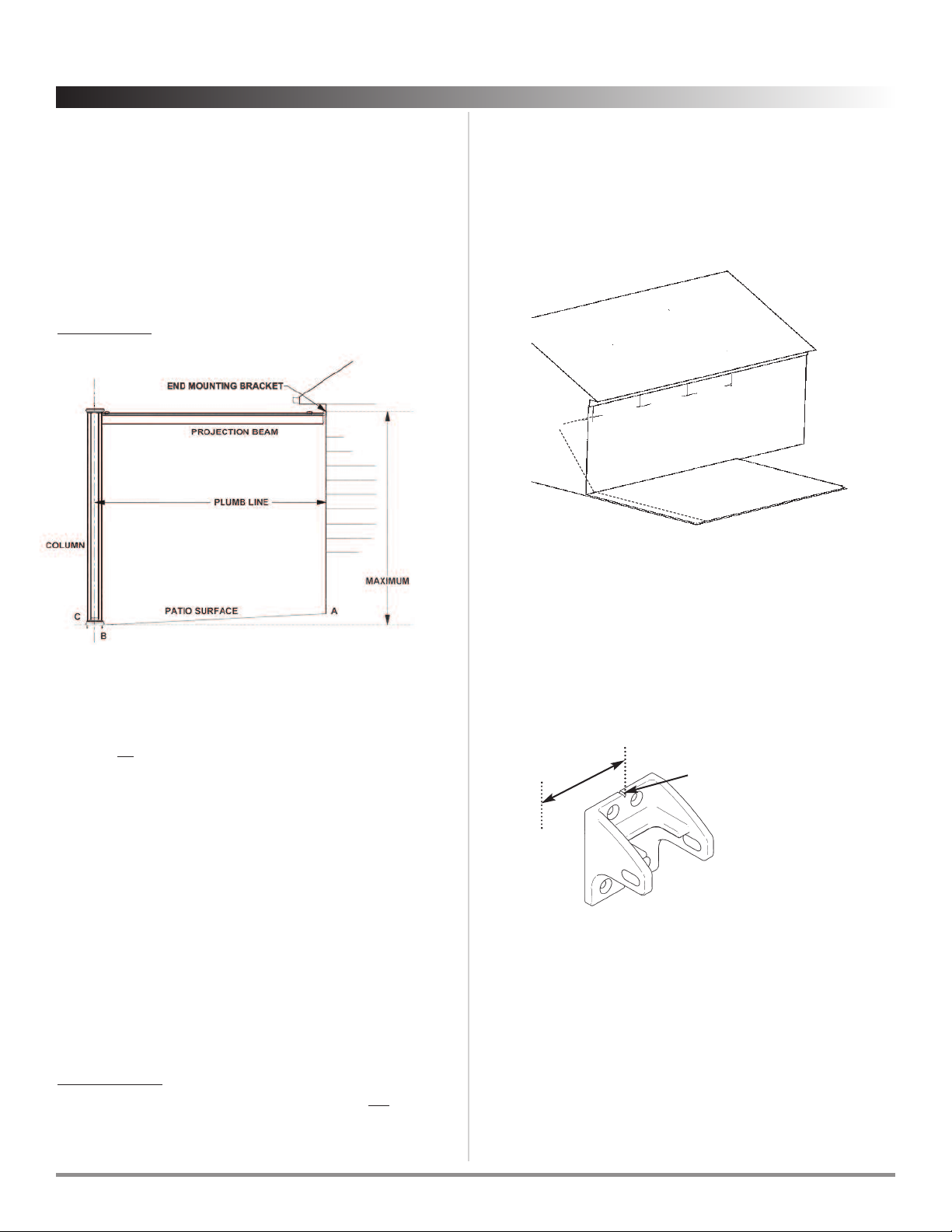

If there is no “fall” in your deck or patio surface (in most cases,

there is some fall so rain will drain away from the house), you

can place the End Mounting Bracket as high as 9’ 2-3/4” from the

patio surface at the house (A). owever, if there is fall from your

house (A) to the place where the columns are to be placed (C),

it is necessary to adjust the height of the End Mounting

Brackets to accommodate for this difference in surface levels.

See the CAD drawing that came with the system to determine

distance from house to center of Column (B). To determine the

“fall” from your house to the surface on which the columns will

be anchored (C), extend a string level from base of house (A) to

the to center line of Column (B) and measure the distance (fall)

from level line at (B) to mounting surface (C).

Subtract the “fall” dimension from 9 ’2-3/4” to determine the

maximum height (based on 10’ columns, if you are using 12’ or

higher columns, add 2’ respectively) at which the top of the

mounting bracket can be installed. Mark this position

temporally on the house.

See following illustration and dimensions to determine

maximum height of End Mounting Bracket on the house.

Step 1 Determine the height of your ShadeTree®

Bungalow System

To determine the height at which to place the End

Mounting Brackets (which hold the Pro ection Beams ) on the

house, it is important to know the maximum height of the

mounting bracket relative to the maximum height of the

aluminum columns.

For a standard 10’ column, the maximum height to top edge of End

Mounting Bracket is 9’ 2-3/4” from surface on which columns will be

anchored. (See vertical arrow at far right side of diagram above. )

FIGURE 1

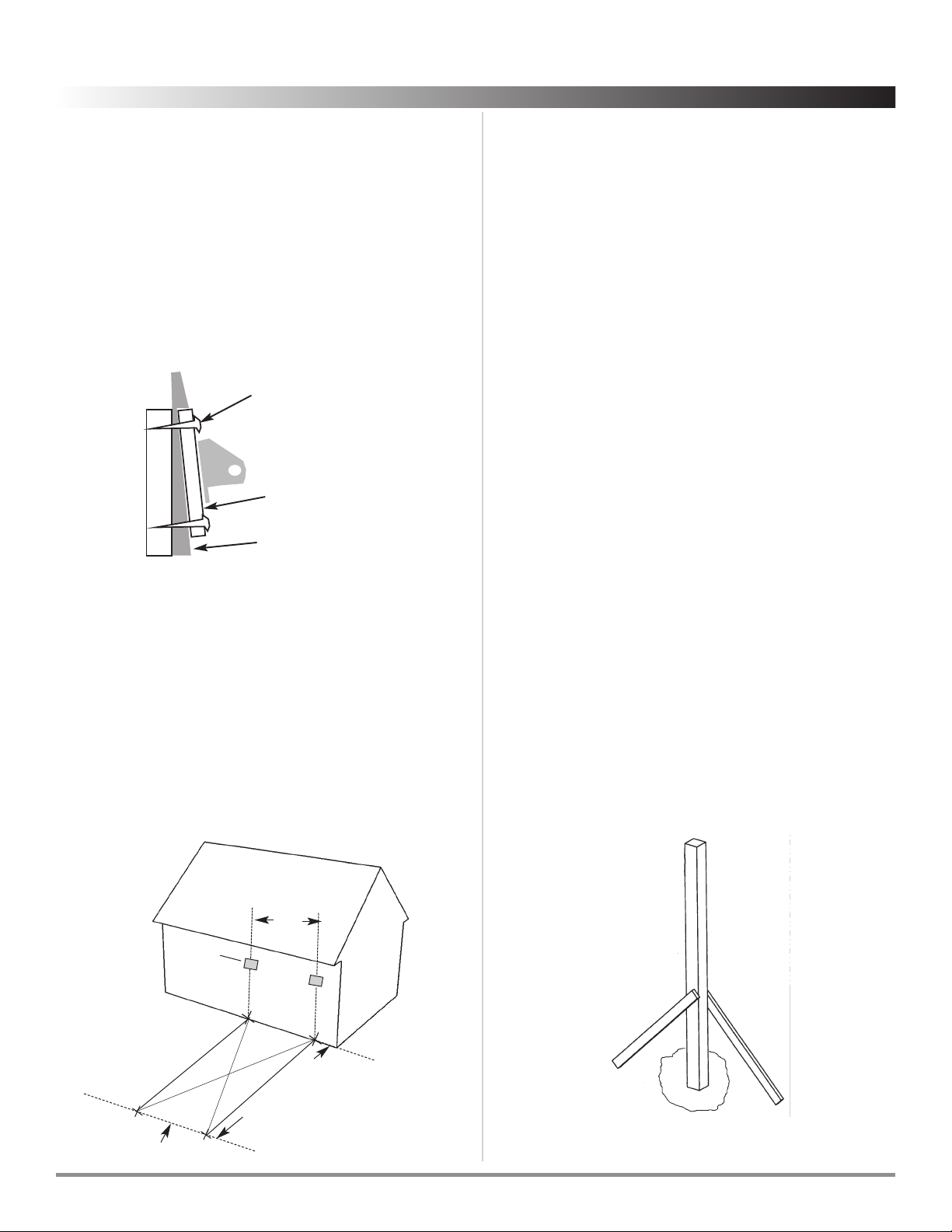

Screw or nail into

studs to support

1” x 4” board

Aluminum or

vinyl siding

1” x 4” board

Stud

• If attaching to stucco, aluminum, or vinyl siding, the screws

must make contact with wood. On two story houses, this can

usually be done in the area of the second floor joists. When

no wood can be found to carry the canopy load, it is

recommended to attach a 1’’ x 4” board to the home (see

illustration below) . . . horizontally at the height desired for

the canopy. The board can then be secured by screws into

each stud. On aluminum or vinyl siding, tighten the bottom

screws only enough to hold board snugly. Over-tightening

can compress the siding. The board can be painted or

stained to match the siding.

Using the CAD for your system, measure out from the house to

the location of your first Aluminum Column(A). Measure out

from the house a second time to the location of your second

Aluminum Column(B). Be sure that points A & B are on a line (C)

that is parallel with the wall to which the End Mounting

Brackets are attached.

To ensure that your system will be square, measure the distance

from point B to point D. Then measure the distance from point

A to point C. Move points A and B right or left to get B to D and

A to C equal.

5’-4”

or 4’-21⁄4”

End

Mounting

Bracket

FIG 1

Line C

Step 3 Determine location of Aluminum Columns

B

C

D

A

Post location

measurement

ShadeTree®Canopy Systems Assembly Instructions

The Bungalow

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .5

Step 4 – Preparing the surface

If you do not have a level surface (most patios have a slight

slope to shed water), you may need to cut the columns that

are to be placed on the high side of the mounting surface. You

should first establish the difference in elevation (you can use

a level and tape measure if necessary). Next measure up, from

the bottom of the column, the difference in elevation, and

place a mark on the column. (You should only cut the

column from the bottom). It is important that your

ShadeTree structure be built so the beams and headers are

level. A deck or patio is an ideal surface. Another option is to

set 4x4s into 3’ deep hole and encase in concrete.

Step 5 - Internal Post assembly

(set or surface-mounting)

Step 5 - Option A: Wood posts set in concrete:

Dig holes and secure posts

You will need 12’ or longer 4x4 posts when setting posts into

concrete. We recommend that you use pressure treated

lumber for this application. Once you have determined the

post locations, you can begin digging the holes. You should

dig the holes to a depth of 3 feet. Put posts in holes; check

that wood posts are plumb and square using a bubble level,

and extend above ground level at least 1’ higher than your

ultimate system height. Stabilize the posts temporarily by

attaching scrap lumber into the posts as illustrated in Figure

5A. Mix concrete according to manufacturer’s instructions

and pour into holes & resume assembly once cement is dry.

4x4 wood post

in concrete with

scrap lumber supports

FIG 5A

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .

6

The Bungalow

ShadeTree®Canopy Systems Assembly Instructions

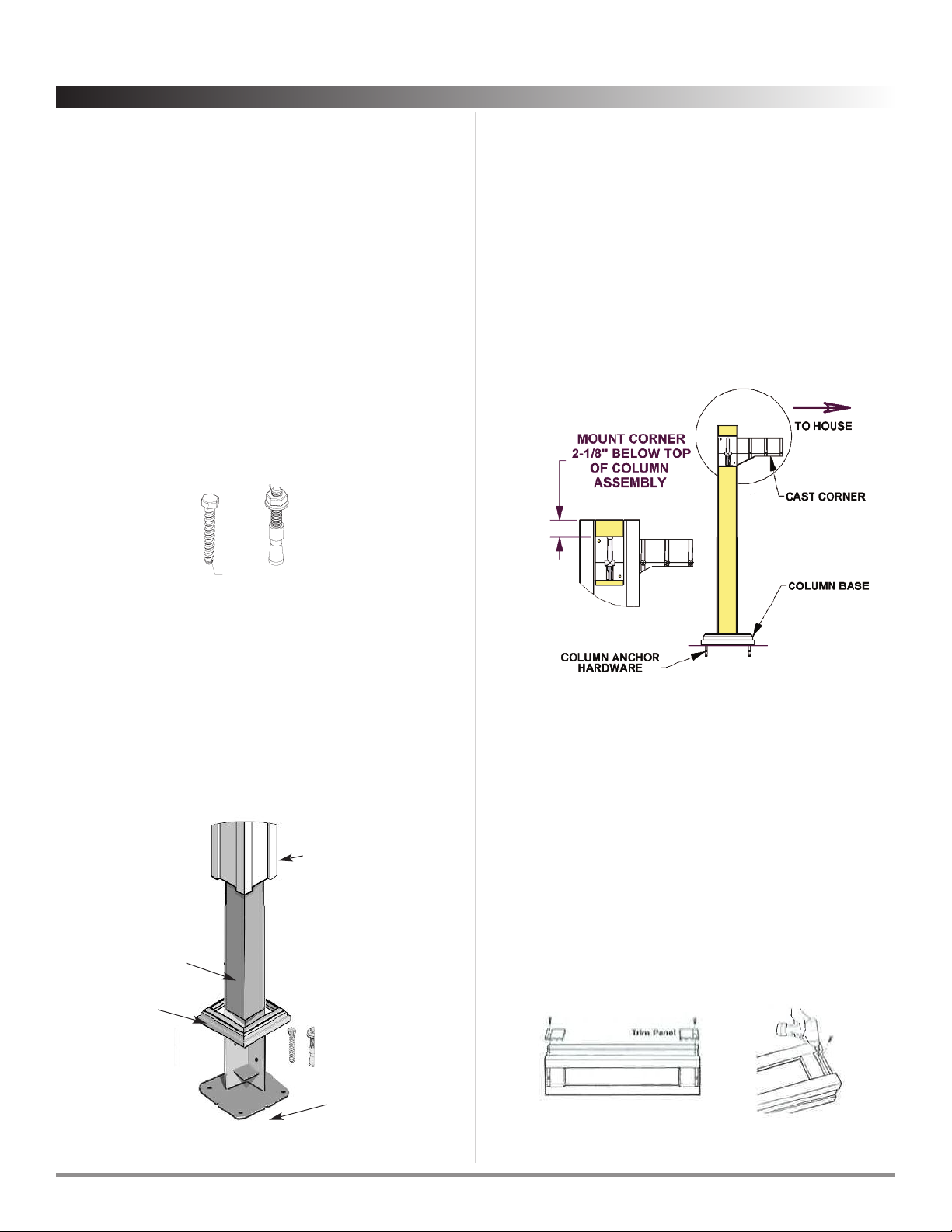

Step 6 Attach Corner Brackets

Slide the Cast Corner Bracket into th the top of the Column

Assembly. Position the Bracket so that it is 2 1/8” below the top

of the Column Assembly and then screw the Bracket into the

wood post. Ensure that the vertical Column Assembly is square

with the mounting surface and with the house. Place a bubble

level on top of the Header Beam to confirm that it is level. If it

is not, reposition the Corner Brackets and lower or raise the

Corner Brackets on the Wood Post as necessary. Once level,

fasten each corner with eight #10 x 3” wood screws F061.

Step 8 Attach Trim Panels

Locate the Top and Bottom Trim Panels in recessed area of

column quarter staves with grooves nearest ends of column

quarter staves. Position Trim Panels so grooved edge is flush

with outer end of quarter stave.

Using the hole in the trim panel groove as a template, drill a

1/8” hole through Column Assembly and attach Trim Panel to

the column with a 8” x 3 /4” large Phillips flat head stainless

sheet metal screw (furnished). Follow the same procedure on

all four staves. Each Column Assembly will have two Trim

Panels at the top and four at the bottom.

Attach wood post to Column Anchor

With Anchor in vertical position on the ground, attach each

wood 4x4x10’ post onto the Column Anchor. Install the 4

screws through the steel support into the 4x4 wood posts.

FIG 5B

Step 5 Option B – Surface-Mounting using Column

Anchors

BW006

COLUMN BASE

4X4 LUMBER

(CUSTOMER SUPPLIED)

BW013 (4 PANELS)

COLUMN ASSEMBLY

AS022

POST ANC OR

If attaching to a wood surface Use the Column Anchor as a

template and pre-drill - using the inner holes, not the outer -for

the 3/8” x 2 1/2” lag bolts that will secure the Column Anchor to

your surface (using a 1/4” drill bit).

If attaching the posts to concrete. Use the Column Anchor as

a template and pre-drill - using the inner holes, not the outer -

for the wedge anchors with a 3/8” masonry bit, and use the

provided 3/8” x 3 long wedge anchors. After pre-drilling the

holes, put the wahser and nut on the threads of the wedge

anchors and then use a hammer to drive in the wedge anchors.

F053 3/8” x 2.5” long

ex ead Lag Bolt

F052 3/8” x 3” long

Wedge Anchor

If anchoring Column Assemblies, before drilling holes into

the surface, be sure that the Column Anchors are aligned with

the centers of the other anchors and placed according to the

measurements on the CAD.

With any of the Column Anchor options listed below, it’s best

to insert the nuts but leave them loose to make attaching the

tracks and headers easier. Once all of the tracks and headers

are in place, lift the column panels enough to slip a wrench

under to permanently tighten the anchors.

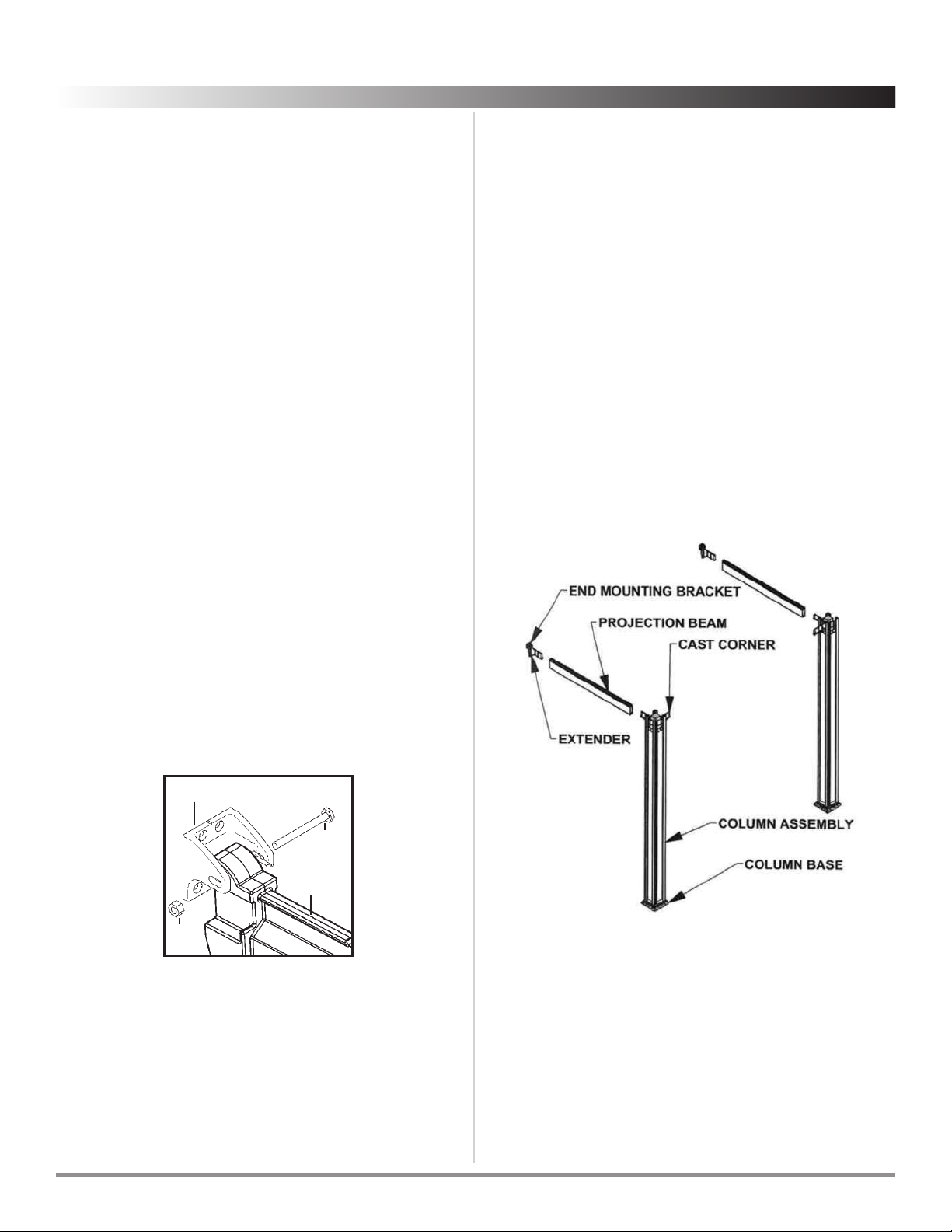

Step 11 Connect outside Projection Beams

Bungalow systems that are attached to a house or building

will have an notch on the Extenders that allow for the insertion

of the canopy rollers. On free-standing systems, Pro ection

Beams have notches cut in the tracks that allow for the

insertion of the canopy rollers. The outside Pro ection Beams

are notched on one side only; the side of the beam that is not

notched faces outside of the structure and the side that is

notched faces inside. The Pro ection Beams that are notched

on both sides go on the inside of the structure.

Remove the Extender from the End Mounting Bracket on the

wall. Assemble the outside Pro ection Beam by inserting the

arm of the Corner Bracket and the arm of the Extender into the

Pro ection Beam.

To help secure the Pro ection Beam during the assembly

process, insert two 7/8” tapping screws (A) into the Pro ection

Beam through both the Extender and the Corner Bracket.

Step 9 Temporarily Attach Extenders

Attach an

Extender

to each the two OUTSIDE End

Mounting

Brackets

on the house using the 2-3/4” bolts (F) and nuts (G)

provided. Be sure the top of the

Extender

is up (as shown.)

Loosely hand-tighten the nuts.

End Mounting Bracket

F

Extender

G

ShadeTree®Canopy Systems Assembly Instructions

The Bungalow

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .7

Step 10 Attach a Projection Beam/Column Assembly

to the Wall Bracket

Attach one

Pro ection Beam/Column Assembly

to one of the

outside End

Mounting Brackets

on the house using the 2-3/4”

bolts (F) and nuts (G) provided. Be sure the top of the

Extender

is up (as shown.) Loosely hand-tighten the nuts.

Step 7 Assemble the Columns

Each Bungalow Aluminum Column consists of 4 panels that

simply snap together. Lay down a panel on a clean smooth

surface with the channel and ridge side facing up. Position a

second panel that has a notch so that the channel of the

second is over the ridge of the first panel. Using a rubber

mallet, gently hammer the edge of the second panel so the

ridge of the first locks into the channel of the second. Slide

the bottom of the two assembled panels into position in the

column base.

Repeat the process above with a third and fourth panel (one

with and one without a notch). Then stand upright the

second set of assembled panels and put around the post but

do not insert into base yet. Slide the bottom of the second set

of assembled panels into position in the column base.

Starting from the bottom of the column, snap together the

first and second sets of assembled panels; stop when you get

half way up the column. Get on a ladder above the Column

Assembly and use a rubber mallet to tap the top of the second

set until it slides into place and the top of the Column

Assembly panels are aligned.

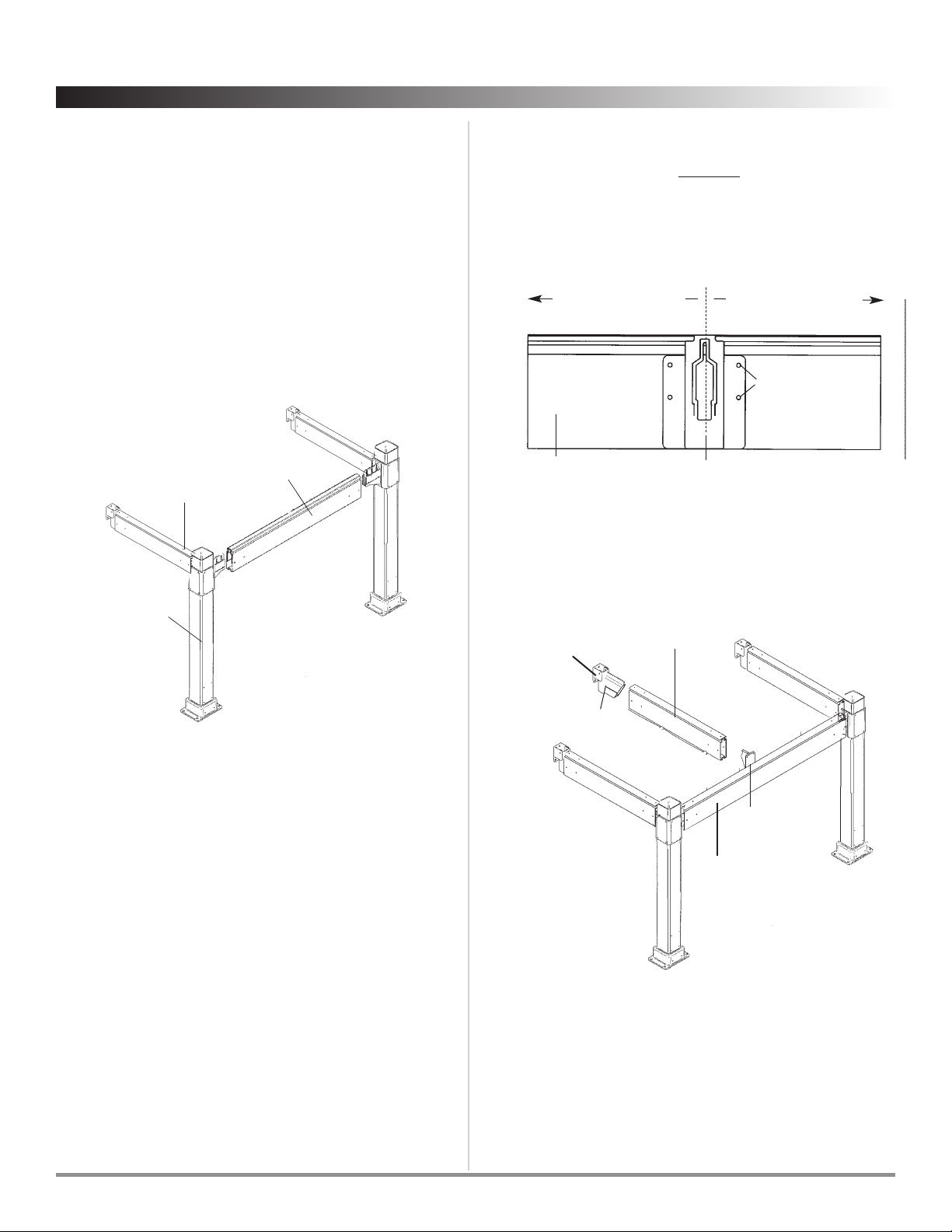

Measure inward from the centerline of the outside track 5’-4”.

Place the Mid-beam Bracket on the cross beam at this distance.

This location should be directly across from the End Mounting

Bracket on the house (step 1.) Secure the Mid-beam Bracket in

place with four 7/8” Tapping Screws (A).

Step 14 Assemble Mid-beam Bracket

eader beam Mid-beam Bracket

5’-4” to centerline

of outside track. See CAD

5’-4” to centerline

of outside track. See CAD

Mounting holes

Insert the arm of the Extender and the arm of the Mid-beam

Bracket into the Middle Pro ection Beam. Secure the beam by

inserting two 7/8” Tapping Screws (A) into the beam at each end.

Step 15 Connect Middle Projection Beam

Mid-beam

Bracket

Middle

Projection Beam

Extender

End Mounting

Bracket

eader

Beam

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .

8

The Bungalow

ShadeTree®Canopy Systems Assembly Instructions

Lift the Column Base and use something to prop it up while you

position the Base Plate(s). Once in position pre-drill the holes and

then secure the Base Plate(s) with the screws. Then put the

Column Base back into it’s place at the bottom of the column.

Step 16 Connect Column Base Plates

Insert the arm on the Corner Bracket of the attached Pro ection

Beam/Column Assembly into the end of the Header Beam.

Attach the other Pro ection Beam/Column Assembly to the End

Mounting Bracket on the wall.

To secure the Header Beam, screw two 7/8” Tapping Screws

(A) through the pre-drilled holes on the top of the Header

Beam into the Corner Brackets at both corners.

Step 12 Connect Column Assemblies

eader

Beam

Projection

Beam

Column

Assembly

Step 13 Check to make sure the Assembled Outer

Frame is SQUARE

Measure the distance from one

Pro ection Beam/Column

Assembly

to the opposite outside End

Mounting Bracket

on the

house. Then measure the distance from other

Pro ection

Beam/Column Assembly

to the opposite outside End

Mounting

Bracket

on the house. Both measurements must be the same

for the system to be considered square. You must make any

necessary adjustments to ensure that it is square before

permanently anchoring the Columns.

ShadeTree®Canopy Systems Assembly Instructions

The Bungalow

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .9

Step 17 Installing the Canopies

You can now insert the Canopies, starting at the end of the

beams closest to the house. Insert the Rollers at the ends of

each Cross Member; insert the front Cross Member first. The front

Cross Member is the one that has a Slide Lock on each end.

When inserting, ensure that the Lock Tab is pointing up as

shown here. Be sure that the canopy is oriented so that the

Fabric Clamp is facing up as shown, while the aluminum Cross

Member is oriented down. Continue inserting the remaining

rollers until the entire Canopy is up. Install remaining Canopies

using the same procedure.

Step 18 Locking the end of the canopy

Fabric

Clamp on

Front Cross

Member

Lock Tab

(Tab must

point upward)

Slide

Lock

Roller

If existing obstacles (casement

windows, doors, etc.) keep canopies

from retracting against the house,

extra canopy roller lock pins can be

put into the next rollers on the

canopies. As a result, canopies will

retract only to the desired position,

clearing the obstacle. It will be necessary to insert a grommet

hole in the locked out panel to allow the rain to drain.

A

Roller Lock Pin

is provided to hold the

Cross Member

nearest

the house in a fixed position. It will arrive already inserted in

the canopies in the last cross member. Once in place, it can

be secured with set screws. The locking pin will hold the last

Cross Member firmly in place. Repeat on each track. (On

masonry houses, it is

necessary to leave a few

inches between the canopy

and the house to prevent

scuffing of the canvas

during windy weather).

Roller

Lock Pin

Back/End

Top Cross

Member

Pull each canopy section out to the position where you want it to

end. Place a

Top Lock Bracket

on the top of the track in the

orientation shown in Fig. 2A. Tighten set screw 1 on both sides of

the

Top Lock Brackets

with the Allen wrench provided (I) . . .

making sure that the

Top Lock Brackets

are completely pushed

down on the track before tightening.

Test the snap-in Top Lock Bracket and tighten or loosen the

adjusting screws as required for the desired tension. The

recommended tension setting procedure is to turn the adjust

screw clockwise until it stops, and then back the adjust screw out

six full revolutions Repeat this step on each lock mechanism.

Step 19 Installing the Top Lock Brackets

Pull each canopy back to the fully retracted position. Place

another

Top Lock Bracket

on each track at this point, in the

orientation shown in Fig. 2A. Tighten the set screws.

OTE: The locking system is designed to release the canopies in

high winds to protect the canopies. The adjusting screws can be

used to adjust the tension. Do not over-tighten, as this could

increase the chance for canopy damage in high winds.

Adjusting

screws Stop

Stop set

screw

Set

screw 1

To posts To house

FIG 2-A

Step 20 Adjusting the handle height (optional)

Each canopy has the handle overhang approximately 18” from

the tracks. This drop handle is for opening and closing the

canopies. owever, if you must have less than an 18” overhang,

follow the instructions below for shortening the handle.

1. Remove all screws in the handle and open the

handle the entire width.

2. Cut the fabric to the desired length.

3. Carefully close the handle and re-insert the screws

provided - do not overtighten.

4. Reinstall the top caps in the end of the handle.

ShadeTree Cool Living, LLC — For questions or assistance call 800-894-3801 .

10

The Bungalow

ShadeTree®Canopy Systems Assembly Instructions

ow to remove ShadeTree®Canopies

for end-of season storage:

1. Remove the Top Lock Brackets at the “retracted” end of

each track (see step 16.)

2 Remove the Roller Lock Pin which holds the last Cross

Member in a fixed position (see step 15.)

3. Then simply roll the Cross Members out of the “retracted”

end of the track. The tracks can remain up year-round.

4. If a canopy is dirty and requires washing before storage,

simply spread the canopy on a driveway or other flat

surface. Wash, using a broom and bucket of warm water

and a mild soap, such as Ivory Snow.

Be sure to rinse well by hosing with a clear water. Allow to

air-dry completely in the sun before rolling canopies up for

storage. (Do not store wet canopies!)

ere’s a chance to earn $50!

We regularly use pictures in our advertising materials. If

you send us reproducible pictures of your new

ShadeTree®canopy installation, and we use them in any

of our advertising, we will send you $50. Interesting

before-and-after pictures will receive an additional $50.

Of course, attractive landscaping and patio furniture

will be a factor in selecting pictures to be used.

Architects, builders and installers will receive credit

mentions in the advertising.

Care and cleaning of your ShadeTree®Canopies

1. ShadeTree®tracks should be cleaned regularly to keep

debris and dirt from accumulating and interfering with

the rollers. Simply use a mild detergent with a small soft

brush, such as a toothbrush, and gently wipe or brush

along the inside of the tracks. To maintain a smoothly

operating system, apply a paste car wax such as KitTMor

TurtlewaxTMto the roller tracks. Allow the wax to dry then

wipe off with a clean, soft cloth. ote: Do OT use oil or

any wet lubricant, such as WD-40, on the tracks as it

would attract more dirt. For ultimate performance, use

ShadeTree®EasyRider Track Lubricant.

2. Fabric should be cleaned regularly before substances such

as dirt, roof particles, etc., are allowed to accumulate on

and become embedded in the fabric. The fabric can be

cleaned without being removed from the cross members.

Simply brush off any loose dirt, roof particles, etc.; hose

down and clean with a mild natural soap in lukewarm

water (no more than 100º F.) Rinse thoroughly to remove

soap. DO NOT USE DETERGENTS! For ultimate

performance, use ShadeTree®Canopy Cleaner Mold &

Mildew Stain Remover.

3. For stubborn stains soak the fabric for approximately 20

minutes in a solution of no more than 1/4 cup (2 oz.)

natural soap per gallon of water at approximately 100º F.

Rinse thoroughly in cold water to remove all of the soap.

Note: Excessive soaking in bleach can deteriorate sewing

threads. This method of cleaning may remove part of the

water repellency and the fabric should receive an

application of an air-curing water-repellent treatment,

such as APCO, UNISEAL, SUNSEAL or similar products, if

water repellency is a factor. For ultimate performance, use

ShadeTree®Canopy Cleaner Mold & Mildew Stain

Remover and ShadeTree®Water Repellent.

4. When washing or cleaning, DO NOT SUBJECT TO

EXCESSIVE EAT as the fabric will shrink. DO NOT STEAM

PRESS OR DRY IN ELECTRIC OR GAS DRYERS, but allow to

air dry.

5. In cases where canopies are taken down & stored, they

should be cleaned and allowed to air dry, before being

stored in a dry, well ventilated area.

Other ShadeTree Tent manuals

Popular Tent manuals by other brands

RioOutdoors

RioOutdoors 6F-DC installation instructions

Tentandtable.com

Tentandtable.com 40 Hex Assembly instructions

Big Sky

Big Sky Wisp 1P Moon View quick start guide

Khyam

Khyam AIRTEK KAMPER PRO 1 Pitching & Striking Instructions

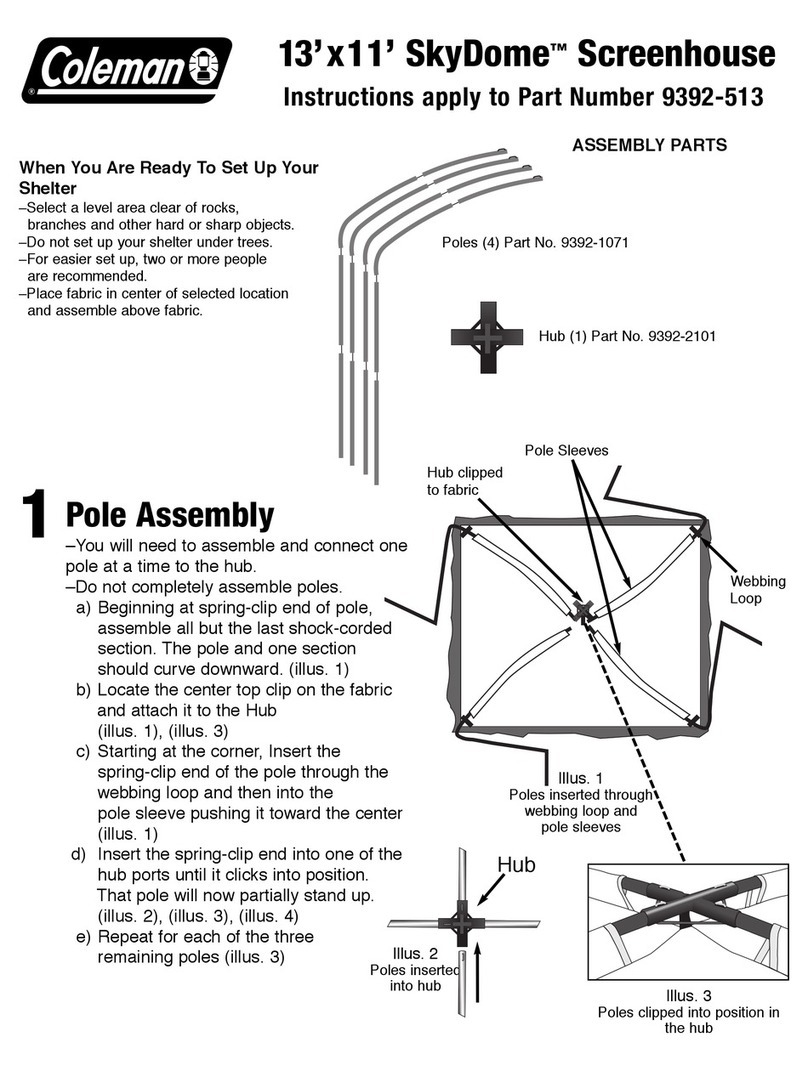

Coleman

Coleman SKYDOME 9392-513 instructions

toolport

toolport economy 3x9 m Series Assembly instruction