VB-500/A/B

1.

FEATURES

1)

Remote

controlled

operation

2)

May

be

stopped

at

any

point

using

<J>

and

stop

keys.

3)

In

addition

to

1-frame

copy,

compressed

copying

is

AVAILABLE

for

A

2

frame

consecutive

copy

and

A

4

frame

copy.

4)

Direct

selection

of

A

desired

FRAME

1

to

5.

(FRAME

5

cannot

be

copied.)

5}

Additional

printing

can

be

made

even

after

comple-

tion

of

printing.

(Last

Copy

IN

MEMORY.)

2.

SPECIFICATIONS

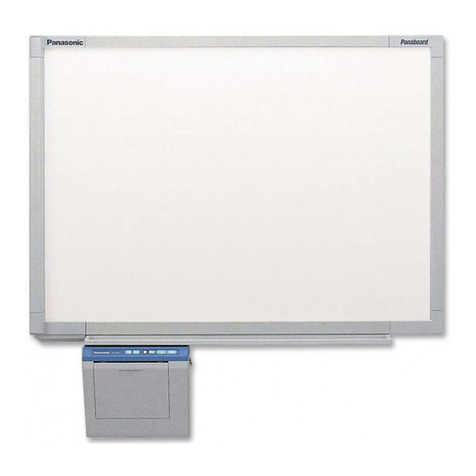

WHITE

BOARD

Board

Surface

Size

92.0

x

128.0

cm

(36-742

x

50-%

inches)

Effective

Width

of

Board

Surface

88.0

x

124.0

cm

(34-242

x

48-1%6

inches)

Number

of

Frames

5

Frames

Number

of

Copyable

Frames

4

Frames

RECORDER

Recording

Paper

Heat

sensitive

recording

paper

Copy

Size

A4

size

(210

x

297

mm)

Copy

Speed

20

sec/sheet

(ist

copy)

10

sec/sheet

(From

2nd

copy)

5.9

dots/mm

1

~

99

(Number

of

copies

can

be

increased

by

pushing

the

addi-

tional

printing

key.)

Copy

Color

Black

Recording

Density

Number

of

Copies

Picture

Memory

One

white

sheet

(256

KB)

Outside

Dimensions

149.0

(W)

x

66.3

(D)

x

196.5

(H)

(58-232

xX

26-Ve

X

77-1V32

inches)

Weight

Approx.

65

kg

(143

LBS.)

Power

Source

AC200-—240V

(50/60

Hz}

Power

Consumption

Approx.

180

W

during

operation

BTU:

Approx.

90

W

during

stand-by

ACCESSORIES

Heat

sensitive

recording

Paper

..........cccesseeeseeeenenes

1

Markers

(Black,

Blue,

Red)

..........ccscccccccseessnseeeereees

1

Each

EASOR

eecsvcsuvstccaciecienisitevizsicesedtvasedivaiecgers

oussuatiauevedne

1

MQ

MG

t

sisi

ccccssetdicsecepaseciearcasseencand

covsscuvsaizeccesseviariasees

1

Remote

control

transmitter

..........ccccccssseeessreeeeeeenees

1

Battery:

sissivisvs

sostaseesssacsvsvess

indeessivedanvesscecswiasadecstess

cee

2

Instruction

Manual

o........

ce

eeeesssseesseeceereesesseseeeeseenes

1

Manual

for

Unpackaging

and

Assembly

...........

1

*Specifications

subject

to

change

without

notice