R-211A

5

FUNCTION OF IMPORTANT COMPONENTS

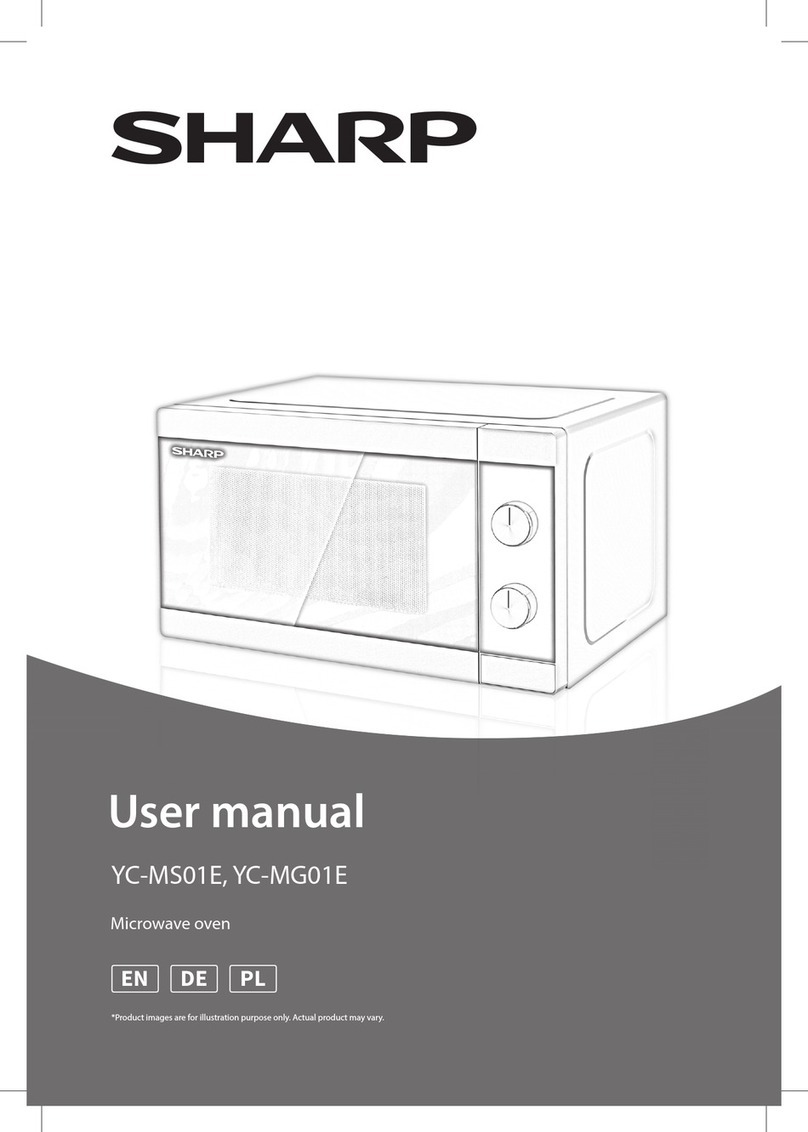

DOOR OPEN MECHANISM

The door is opened by pushing the open button on the

control panel, refer to the Figure D-1.

When the open button is pushed, the open button pushes

theswitchleverupandinturnthelatchheadsarereleased

from latch hook. When the latch heads are released, the

switch lever returns to its original position by its own

weight.

LATCH HOOK

LATCH

HEADS

DOOR

MONITOR SWITCH

1 ST. LATCH

SWITCH

SWITCH LEVER

2ND. LATCH

SWITCH

Figure D-1. Door Open Mechanism

1ST.LATCH SWITCH AND2ND.LATCHSWITCH

1. Whentheovendoorisclosed,thecontacts(COM-NO)

must be closed.

2. When the oven door is opened, the contacts (COM-

NO) must be opened.

MONITOR SWITCH

1. Whentheovendoorisclosed,thecontacts(COM-NC)

must be opened.

2. When the oven door is opened, the contacts (COM-

NC) must be closed.

3. Iftheovendoorisopenedandthecontacts(COM-NO)

ofthe1stlatchswitchand 2nd latchswitchfailtoopen,

the fuse blows simultaneously with closing the con-

tacts (COM-NC) of the monitor switch.

CAUTION: BEFORE REPLACING A FUSE F TEST

THE1STLATCHSWITCHSW1,2NDLATCH

SWITCH, MONITOR SWITCH AND MONI-

TORRESISTOR R FORPROPEROPERA-

TION. (REFER TO CHAPTER "TEST PRO-

CEDURE".)

MONITOR RESISTOR 0.8Ω20W

The monitor resistor prevents the fuse F bursting when

the fuse blows due to the operation of the monitor

switch.

FUSE

1. Thefuseblowswhenthecontacts(COM-NO)ofthe1st

latch switch and 2nd latch switch remain closed with

the oven door open and when the monitor switch

closes.

2. If the wire harness or electrical components are short-

circuited,thefuseblowstopreventanelectricshockof

fire hazard.

TEMPEATURE FUSE 120˚C (OVEN)

The temp. fuse located on the top of the oven cavity is

designedtopreventdamage totheovenifthefoodsinthe

oven catch fire due to over heating produced by improper

settingofcooktimeorfailure of controlunit.Undernormal

operation,thetemp.fuseremainsclosed.However,when

abnormally high temperatures are reached within the

ovencavity,thetemp.fusewillopenat120˚C,causingthe

oven to shut down. The defective fuse must be replaced

with a new one.

THERMAL CUT-OUT 95˚C (MAGNETRON )

The thermal cut-out located on the top of the oven cavity

isdesignedtopreventdamagetothemagnetronifanover

heated condition develops in the tube due to cooling fan

failure,obstructedairguide,dirtyorblockedairintake,etc.

Under normal operation, the thermal cut-out remains

closed.However,whenabnormallyhightemperaturesare

reached within the magnetron, the thermal cut-out will

open at 95˚C, causing the oven to shut down. When the

magnetron has cooled to 75˚, the thermal cut-out closes

and cook cycle will resume.

TURNTABLE MOTOR

The turntable motor drives the roller stay to rotate the

turntable.

FAN MOTOR

Thefanmotordrivesabladewhichdrawsexternalcoolair.

Thiscool air isdirectedthroughthe air vanessurrounding

the magnetron and cools the magnetron. This air is chan-

nelled through the oven cavity to remove steam and

vapours given off from the heating foods. It is then ex-

hausted through the exhausting air vents at the oven

cavity.

TIMER MOTOR (WITH VARI-SWITCH)

Timer switch

1. Whenthetimerisat"0"position,theswitchofthetimer

are opened.

2. When the timer is turned clockwise from "0" position,

the switch of the timer are closed.

Vari-switch

If the variable cooking control is set at HIGH or ME-

DIUM DEFROST, cooking position, Rated voltage is

supplied to the power transformer intermittently within

a 30 seconds time base. The following chart shows the

vari-switch operation in the various modes.

are given.

SETTING