R-9H56

6

AH SENSOR COOKING SEQUENCE

1. In case the AH sensor cooking condition is started, the

coil of shut-off relays (RY1+RY6) are energized, the

oven lamp and cooling fan motor are turned on, but the

power transformer is not turned on.

NOTE: The oven should not be operated on AH SENSOR

COOKING immediately after plugging in the unit.

Wait five minutes before cooking on AH SENSOR

COOKING CONDITION.

2. Afterabout16seconds,thecookrelay(RY2)isenergized.

The power transformer is turned on, microwave energy

is produced and first stage is started. The 16 seconds is

thecoolingtime required toremoveany vapour fromthe

oven cavity and sensor.

Figure O-2

NOTE: Duringthisfirststage,donotopenthedoorortouch

STOP/CLEAR pad.

3. TheovenwillgototheMixCookingConditionatthe2nd.

or 3rd. stage when Reheat pie, Casseroles or Desserts

has been chosen. (Figure O-4)

4. When the sensor detects the vapour emitted from the

food,thedisplayswitchesovertothe remaining cooking

time and the timer counts down to zero. At this time, the

door may be opened to stir food, turn it or season, etc.

NOTE: Incasewhereasmallquantityoffoodiscooked,the

oven will stop without displaying the remaining

cooking time.

5. Whenthe timer reaches zero, an audible signal sounds.

The shut-off relay (RY1+RY6) and cook relay (RY2) are

de-energized and the power transformer, oven lamp,

etc. are turned off.

6. OpeningthedoorortouchingtheSTOP/CLEARpad,the

timeofdaywill reappear onthedisplay and theovenwill

revert to an OFF condition.

MULTI COOK

MULTI COOK will automatically compute the oven tem-

perature,microwavepowerandcookingtimeforbakingand

roasting. Set the desired program by touching the MULTI

COOK pad, and number pad. Enter the weight by touching

the Number pads. When the START pad is touched, the

following operations occur:

1. TheCOOKindicatorwilllightandtheMicrowaveSymbol

and/or the Convection Fan Symbol will rotate.

2. The cooking time will appear on the display and start

counting down to zero. The cooking time is adjusted

automatically according to the weight of the food.

3. The shut-off relays (RY1, RY3, RY5 and RY6) are

energized, turning on the oven lamp, turntable motor,

cooling fan motor and convection motor. The power

supply voltage is added to the convection heater.

4. Now, the oven is in the convection cooking mode.

5. Whentheoventemperaturehasreachedtheprogrammed

convection temperature, the oven goes into the

programmed cooking mode.

6. At the end of the MULTI COOK cycle, the damper is

returned to the open position and the oven will go to the

offcondition.Thecoolingfanwillremainonuntiltheoven

has cooled.

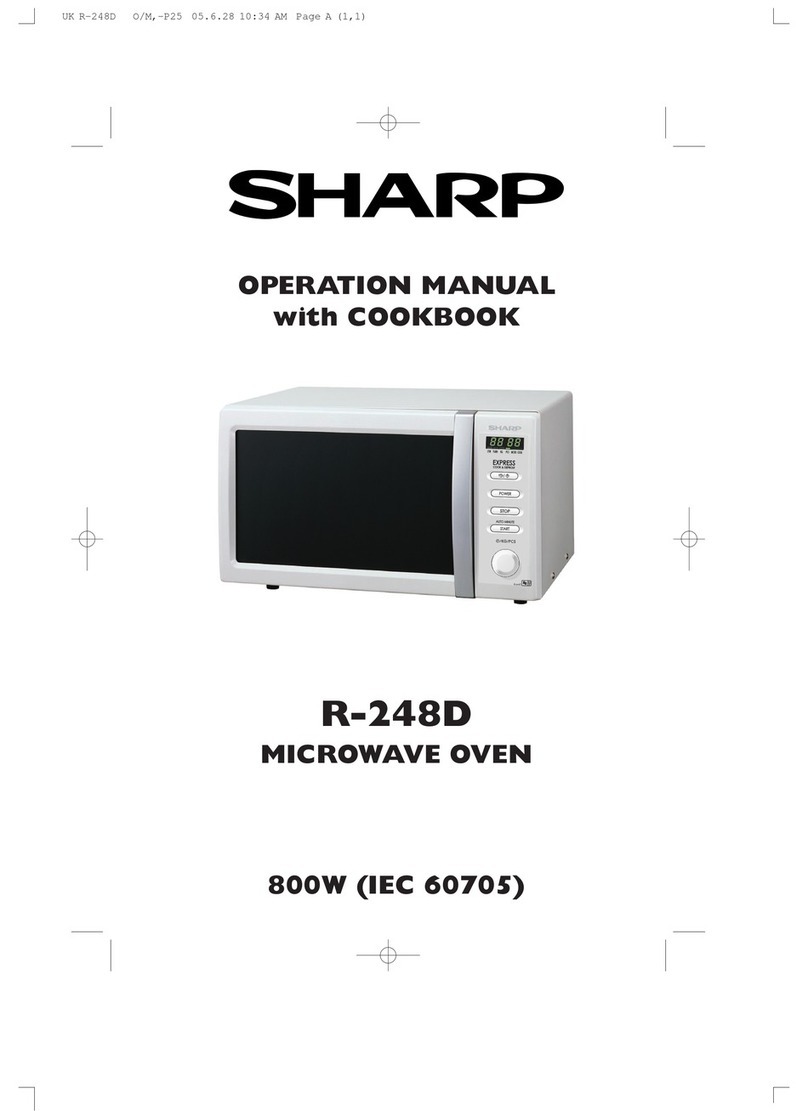

EASY DEFROST COOKING

TheEASYDEFROSTkeyisaspecialfunctionkeytodefrost

meats and poultry faster and better.

EASY DEFROST key has 4 defrost stages.

EASY DEFROST automatically defrosts roast beef, etc.

When EASY DEFROST is selected and the food weight is

entered by using the number pads, the oven will cook

according to the special cooking sequence. (Figure O-2)

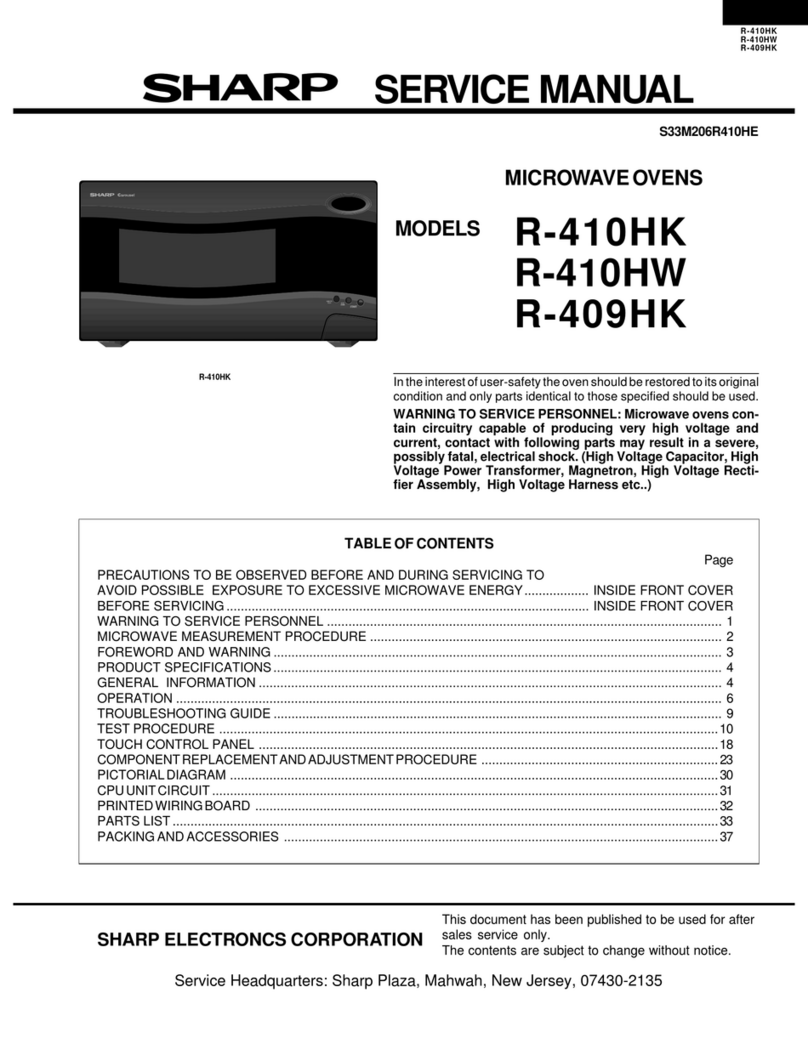

FIRE SENSING FEATURE (MICROWAVE MODE)

This model incorporates a sensing feature which will stop

theoven'soperationifthereisafireintheovencavityduring

microwave cooking.

This accomplished by the LSI repeatedly measures the

voltage across the temperature measurement circuit (ther-

mistor) during it's 32-seconds time base comparing the

obtainedvoltagemeasurements.Ifthemostrecent voltage

measuredis300mVgraterthanthepreviousvoltagemeas-

ured, the LSI judges it as a fire in the oven cavity and

switches off the relays to the power transformer, fan motor

and convection motor. The LSI also stops counting down

andclosesthedamperdoorsothatnofreshairwillenterthe

oven cavity. Please refer to the following section for a more

detailed description.

Operation

Please refer to the timing diagrams below.

1. The thermistor operates within a 32-seconds time base

and it is energized for three (3) seconds and off for 29

seconds. Two (2) seconds after the thermistor is

energized, the voltage across the temperature

measurement circuit is sampled by the LSI and twenty

one (21) seconds after the thermistor is cut off the LSI

turns on the cooling fan for six (6) seconds.

2. The above procedure is repeated. If the difference

between the first voltage measured (in step 1) and the

voltagemeasuredwhentheprocedureisrepeated(step

2) is greater than 300mV the LSI makes the judgment

thatthereisafireintheovencavityandwillswitchoffthe

relaystothepowertransformer,fanmotorandconvection

motor.TheLSIalsostops counting downandclosesthe

damper door so that no fresh air will enter the oven

cavity.

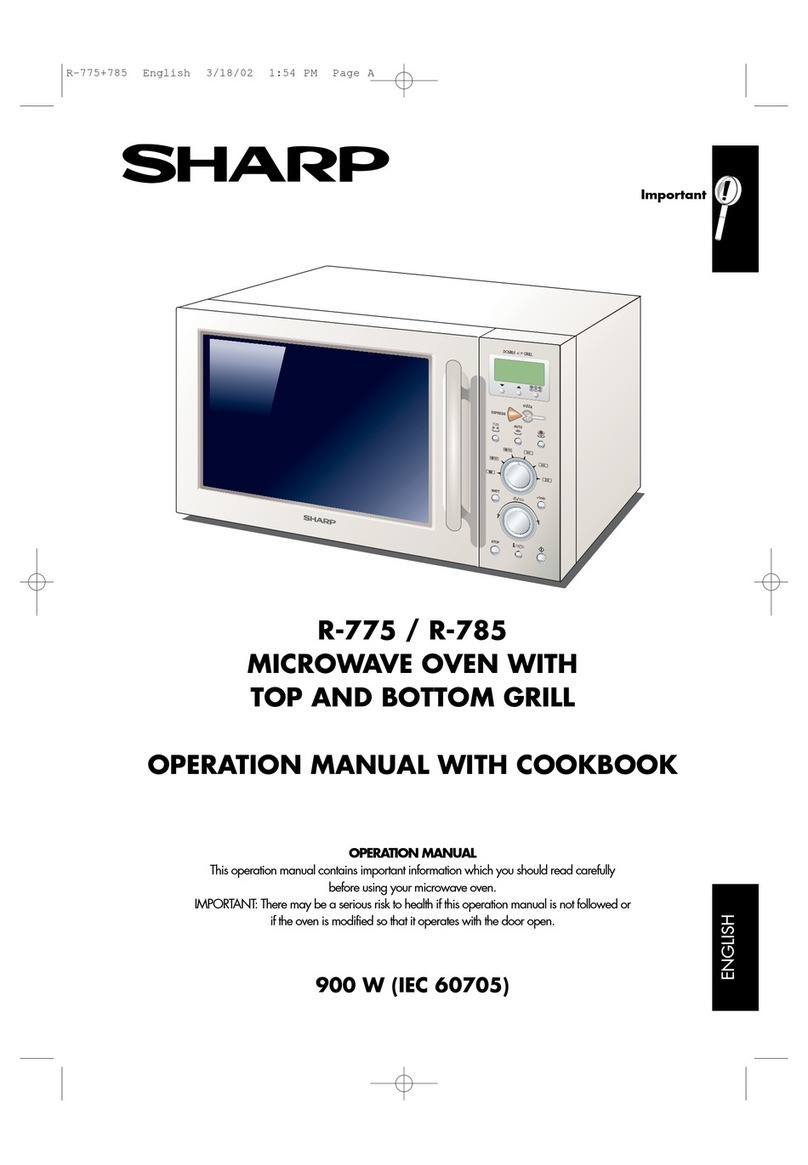

ment with each food category and inputted into the LSI.

An example of how sensor works:

1. Potatoesatroomtemperature.

Vapour is emitted very slowly.

2. Heat potatoes. Moisture and

humidityisemittedrapidly.You

cansmellthearomaasitcooks.

;

3. Sensor detects moisture and

humidity and calculates

cooking time and variable

power.

MICROWAVE

MICROWAVE

AH SENSOR