Shat-R-Shield Incoplas User manual

4.

3.

Silicone Bead

⁄X20 Thumbscrew

2.

1.

A.

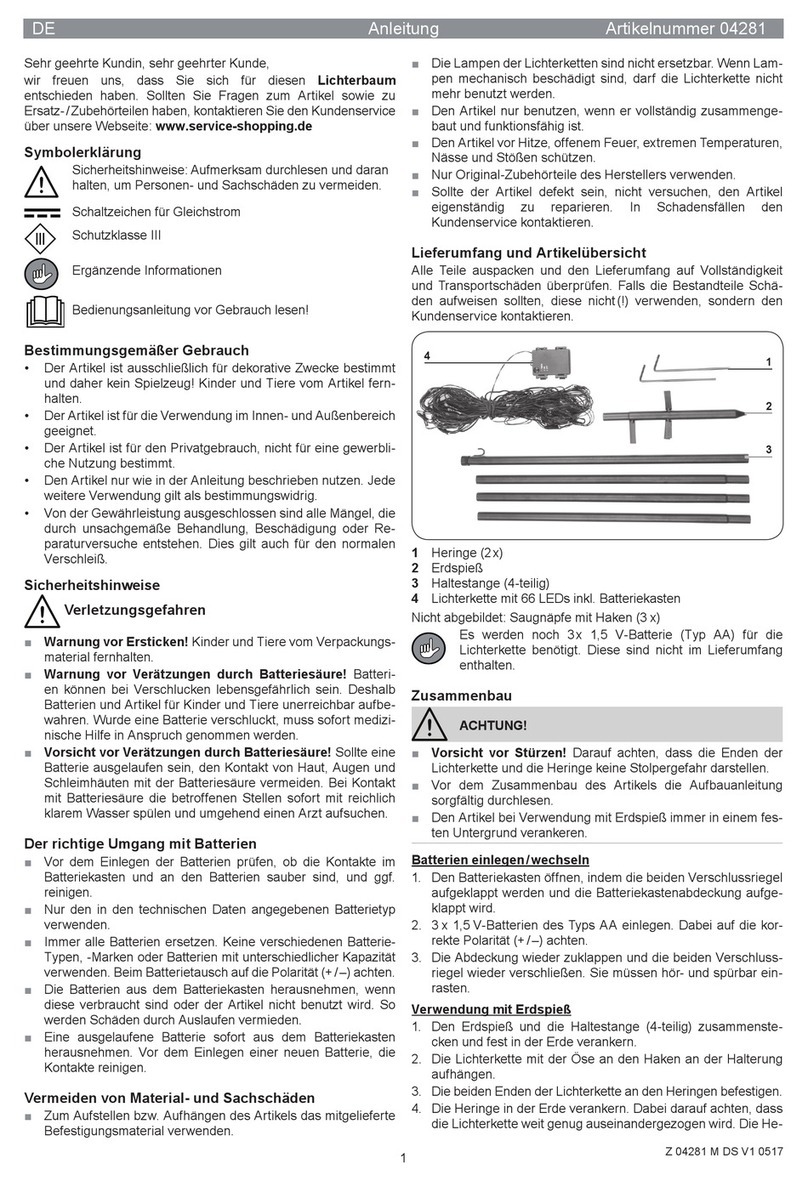

SURFACE MOUNT

Note: Surface mounng the fixture directly to a J-box will require an appropriate gasket material (not supplied) to be

used between the plasc juncon box top of the fixture and the AC supply J-box. Alternavely, a bead of

waterproof silicone caulking (not supplied) can be used to seal around mang surfaces.

1. Remove the thumbscrew and remove juncon box top from the fixture.

22. Determine screw mounng locaons. Drill mounng holes in the plasc fixture juncon box top at the appropriate

points. Drill an access hole in the juncon box top to allow for roung branch wire power. Secure the fixture juncon

box top to the AC supply J-box in the desired mounng posion using the appropriate mounng screws with washers

(not supplied) being sure to follow all UL, NEC, and minimum load rangs guidelines.

3. Connect the fixture to the mounted lid and let hang to facilitate wiring. See wiring instrucons above.

44. Close the fixture taking care to ensure all wires are inside juncon box and the juncon box is seated properly on the

gasket. Push the fixture upward to compress the gasket and install the ⁄ x 20 black nylon thumbscrew and ghten.

A. Surface B. Pendant C. Wall pack w/wo

cover plate

D. Adjustable wall

pack w/wo cover

plate

E. Flood F. Surface Trunnion

READ CAREFULLY BEFORE INSTALLING FIXTURE. RETAIN THESE INSTRUCTIONS FOR FUTURE REFERENCE. Must be wired in

accordance with the Naonal Electrical Code and all applicable local codes. THIS PRODUCT MUST BE INSTALLED IN

ACCORDANCE WITH THE APPLICABLE INSTALLATION CODE BY A PERSON FAMILIAR WITH THE CONSTRUCTION AND

OPERATION OF THE PRODUCT AND THE HAZARDS INVOLVED. WARNING: Make certain power is OFF before installing or

maintaining fixture. No user serviceable parts inside.

IMPORTANT NOTE: When drilling large holes for cable glands in the plasc J-box, it is

HIGHLY RECOMMENDED to use a step drill bit or unibit to lessen the chances of personal injury

oor damage to the fixture.

Determine the method of mounng.

*Installaon of oponal occupancy and photo cell located at end of this installaon guide.

When mounng fixture to either juncon cover or wall pack brackets hinge pin, be careful not to knock fixture off hinge when wiring. LOCKING

THUMBSCREW IS STANDARD ⁄X20 THREAD. ANY ⁄X20 BOLT WILL WORK.

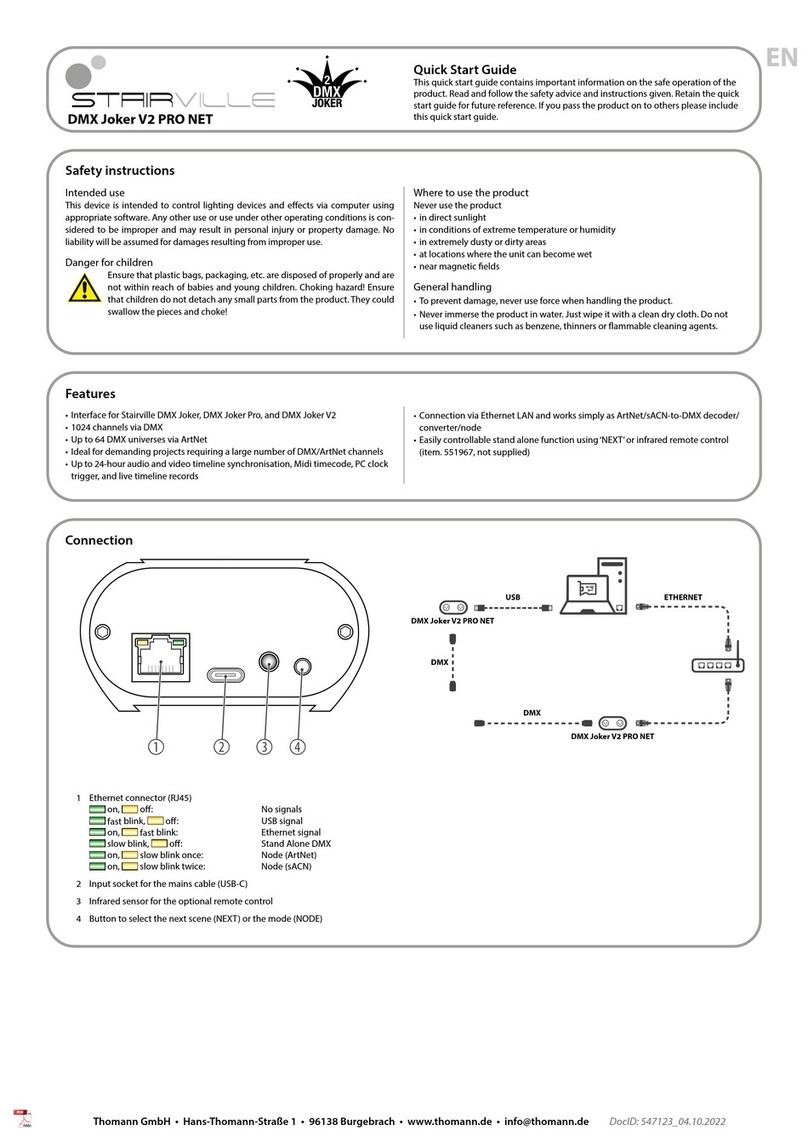

WIRING INSTRUCTIONS

BBlack and white wires on one side of driver are the Power Input wires: 1. Black=120-277V 2. White=Neutral/Common

3. Green and Yellow=Ground DIMMING 4. Purple=Posive 5. Gray=Negave 6. Orange=Not Used

Step drill bit

INCOPLAS

™

LED Hybrid

USER GUIDE

5.

3.

2.

B.

PENDANT MOUNT

Use ¾" NPT(1" outer diameter) fixture conduit stem threaded on both sides, wire of desired length and a commercial flexible fixture

hanger or swivel hanger. Other pendant mounng systems can be used. Determine if mounng pipe and hardware is rated for the

applicaon environment.

1. Posion the hanging pendant mounng terminaon at the desired locaon and feed the AC supply wires through the

end of the pendant.

22. Remove lid from fixture.

3. Drill the appropriate size hole in the center of the top of the black plasc juncon box to accommodate the pendant

mounng hardware (Use step drill bit). Secure the juncon box top to the pendant mount in the desired mounng

posion. Use waterght connector or silicone caulking to completely seal the pendant connecon to the juncon box to

ensure a weatherproof installaon.

4. Mount the fixture to the mounted lid and let hang to facilitate wiring. See wiring instrucons above.

5. Close the fixture, taking care to ensure all wires are inside juncon box. Push the fixture upward to compress the

ggasket and install the ⁄ x 20 black nylon thumbscrew and ghten.

C.

WALL PACK MOUNT WITH/WITHOUT OPTIONAL MOUNTING COVER

*Oponal wall pack mounng cover will mask area of removed old wall pack.

Installaon instrucons for mounng wall pack bracket to LED Hybrid Fixture.

1. Drill two ⁄” holes in driver box on both sides of the center line. Center points of drill locaons are on the top of the

lines.

2. Drill .875” hole using a step drill or unibit using the top of the middle line as a drill center point.

33. Assemble the wall pack bracket onto the fixture driver box with the (2) supplied ⁄ x 1.75” long bolts. Secure bolts

on inside of driver box using supplied washers and nylon locking nut. Secure ghtly. SEE FIGURE C3

NOTE: If replacing exisng wall pack and oponal wall pack cover plate is NOT used, proceed to Step 8.

4. Posion oponal mounng plate to cover footprint from original removed wall pack and determine mounng

holes and drill for mounng hardware (not supplied). Make sure the mounng plate hole locaons are drilled

to a strong support of the building to support the weight of the fixture.

55. Drill hole to allow for wiring to pass through using step drill in center area of plasc oponal mounng

cover plate to allow access to wires.

6. Mount the cover plate on to the building and use waterght silicone caulking to completely seal the

mounng plate where it meets the surface to ensure a weatherproof installaon. SEE FIGURE 9 ON NEXT PAGE.

7. Route building power wires through wall pack mounng plate hole.

8. Remove the thumbscrew from the wall pack mounng bracket and remove the mounng plate from the fixture.

Drill ⁄” holes

Mounng plate

B.

C.

Step drill bit

Step drill bit

1.

3.

8.

9. Mark and drill screw mounng locaon and drill holes in the plasc fixture wall pack mounng plate. Use waterght

silicone caulking to completely seal the mounng plate where it meets the surface to ensure a weatherproof installaon.

Secure the mounng plate to the wall J-box or oponal mounng cover plate using the appropriate mounng screws

with washers (not supplied). Adjust mounng plate using installed level and secure mounng plate.

10. Mount the fixture to the mounng plate and let hang to facilitate wiring.

1111. Remove the thumbscrew from the fixture top and open to access wires. Feed the power wires through the back of

the fixture into the juncon box of the fixture.

12. Push the fixture up to close the back wall plate connecon and securely aach with thumbscrew.

13. Close the fixture taking care to ensure all wires are inside juncon box. Push the fixture upward to compress the

gasket and install the ⁄ x 20 black nylon thumbscrew and ghten.

D.

ADJUSTABLE WALL PACK MOUNT

Installaon instrucons for mounng adjustable bracket to LED Hybrid Fixture.

11. Drill two ⁄” holes in driver box on both sides of the center line. Center point of drill locaon is the top of the lines.

2. Drill a .875” hole using a step drill bit or unibit using the top of the center line as a drill center point.

3. Assemble the adjustable bracket onto the fixture driver box with the (2) supplied ⁄ x 20 bolts. Secure bolts on inside of

driver box using supplied washers and nylon locking nut. Secure supplied

cable gland onto driver box ghtly.

4. Connue to steps below to mount fixture to wall surface.

NOTE: If replacing exisng wall pack and oponal wall pack cover plate is NOT used, proceed to Step 8.

55. Posion oponal cover plate to cover footprint from original removed wall pack and determine mounng holes and

drill for mounng hardware (not supplied). Make sure the mounng plate hole locaons are drilled to a strong support of

the building to support the weight of the fixture. Drill large hole using step drill in center area of plasc oponal mounng

cover plate to allow access to wires.

6. Connect building power wires with supplied power cord and secure with wire nuts.

J-Box

Cover plate

5.

Drill ⁄” hole

C.

D.

Drill .875” hole using

step drill bit

Driver Box

Cable Gland

13.

Cover plate

12.

11.

Mounng plate

10.

Silicone Bead

Cover plate

Level

9.

12.

11.

10.

9.

8.

Ø0.27

Ø0.85

0.27

1.5

7

.

7. Remove outer swivel metal bracket from the fixture by removing two nuts and lock washers and align bracket on

oponal mounng plate hole and mark two holes making sure the bracket is parallel to the top and boom edges of the

mounng plate. Drill holes in mounng bracket using desired hardware (not included). The slot holes will allow for ¼”

hardware.

8. If mounng to a wall juncon box, remove outer swivel metal bracket from the fixture by removing two nuts and lock

washers. Install bracket onto supplied mounng plate with supplied gasket and hardware (not supplied).

99. Mount supplied cable gland onto bracket and feed the wire through the cable gland. Tighten cable gland securely to

seal cord. Apply waterght silicone caulking to the back of the mounng plate to completely seal the mounng plate

where it meets the building surface and mount the plate to the building using hardware.

10. Re-assemble fixture to the metal bracket and posion at desired angle and ghten with lock washers and ¼ x 20 nut.

1111. Remove the thumbscrew from the top lid of the fixture juncon box and swing open lid. Feed power cable through

cable gland on back of juncon box and connect to the fixture driver AC input wires to black (line), white (neutral), and

green (ground) using wires nuts or UL approved wire connectors. Make sure all cable glands are ght for waterght

connecon.

12. Close the fixture taking care to ensure all wires are inside juncon box and the juncon box is seated properly on the

gasket. Push the fixture upward to compress the gasket and install the ¼” x 20 black nylon thumbscrew and ghten.

E./F.

FLOOD AND TRUNNION MOUNTING

TThe trunnion and flood version can be mounted from a ceiling, wall, ground or used with a variety of standard beam

clamps and bullhorns to use on poles (supplied by others).

1. See D1 for Instrucons on mounng adjustable bracket to LED Hybrid Fixture to mount bracket to fixture.

2. Remove the outer adjustable bracket and securely mount to desired surface, clamp or adapter depending on mounng

applicaon and surface using ¼ x 20 hardware rated for applicaon environment. See Figure 10.

3. Extend power wires into fixture using supplied cable gland. Reference adjustable wall pack instrucons above.

4. Mount fixture and complete wiring.

55. Occupancy Sensor -- Using a unibit or step drill bit, drill. 875” hole in front of the juncon box using the top of the line

as the center point. Install and wire sensor per supplied instrucons.

J-Box Lid

2.44

1.72

1.22

Outer

Adjustable

Bracket

Silicone Bead

Thread

Wire

Table of contents