ShedPlans 16'x20' Garage Shed Plan Instructions for use

16'x20' Garage Shed Plan

8"

3'-3 1/2"

8"

3'-3 1/2"

8"

3'-3 1/2"

8"

3'-3 1/2"

8"

8" 19'-1 1/2" 8"

20'-5 1/2"

16'-5 1/2"

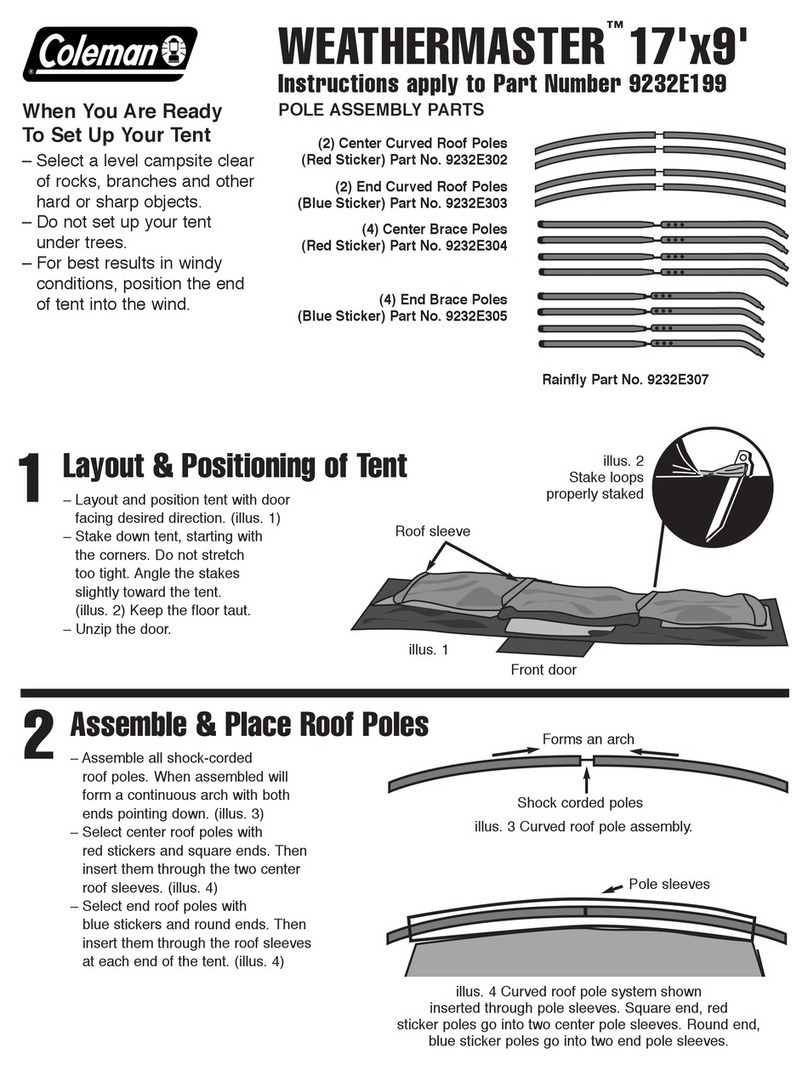

Concrete foundation

Mortar

Bricks

Ground

Foundation Preparation

1.1 Fill the trenches to ground level with concrete and let cure, or harden. Since

curing times vary between brands, read the packaging for recommended curing times.

1.2 Once the concrete has cured, use standard-sized bricks and lay them across

the foundation. You will need roughly 320 bricks for this step.

1.3 Clear the area where you want to build the shed and layout for the foundation.

Use the below illustration as a guide.

1.4 For the foundation, dig the trenches at least 1’ wide and 1’ deep.

STEP 1

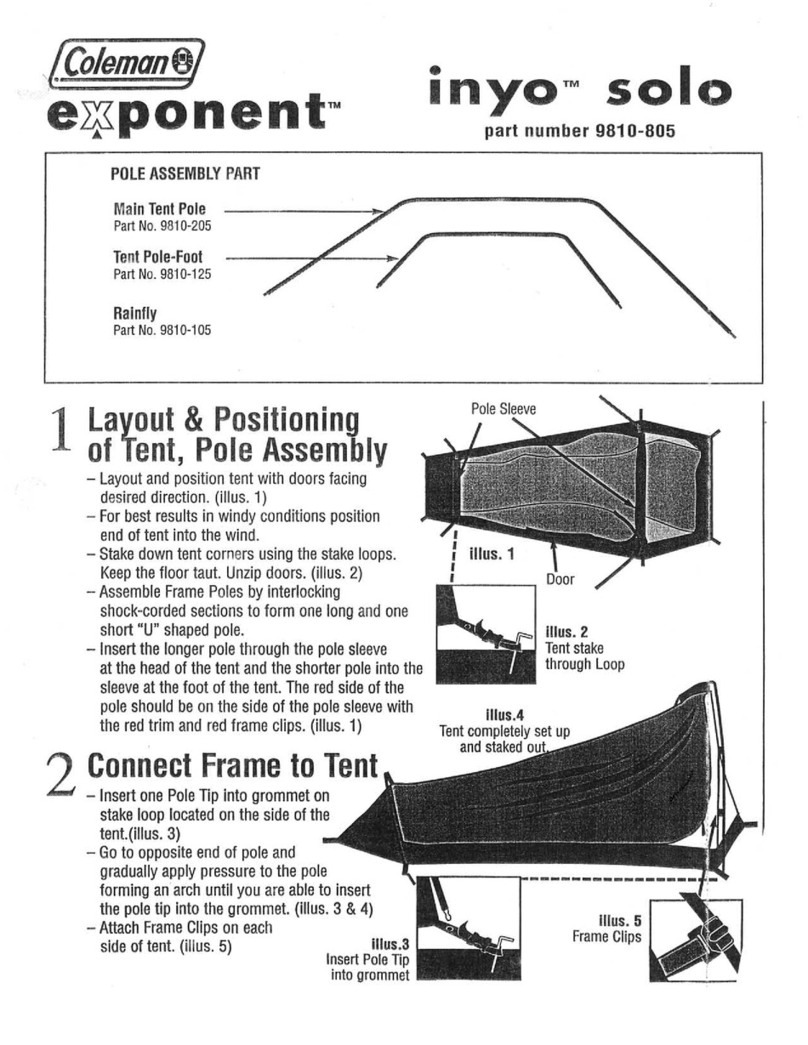

1'- 3/4" 14 x 1'-3" 1'- 3/4"

15'-9"

Framing the Floor

2.1 Assemble the frame using 1 1/2” x 7 1/4” pressure-treated lumber. You will need fifteen

boards cut to 15'-9” that will be the joist.

2.2 Secure the beams with 8x5" wood screws.

2.3 Using a speed square or carpenter's square, check the corners to make sure they are 90°.

STEP 2

Assemble Front Wall Frame

3.1 Using 1 1/2“ x 3 1/2“ and 3 1/2“ x 3 1/2“ pressure-treated lumber, construct front wall

frame using the drawing below as a reference. You will need one board cut to 11" and two

boards cut to 6" that will be the cripple studs, one board cut to 2'-8" that will be the door

header, two boards cut to 3'-4" that will be the window header and rough sill, sixteen

boards cut to 6'-11" and two boards to 2'-10" that will be the studs, two boards cut to 8'-8"

that will be the bottom plates and one board cut to 20' that will be the top plate.

3.2 Connect the beams with 2x4" wood screws.

3.3 Using a speed square or carpenter's square, check the corners to make sure they are 90°.

STEP 3

1'-1" 1'-1"

1'- 1/2"

11 3/4"

1'- 1/2"

1'-1" 1'-1" 1'-3 1/4"

1'-3 1/4"

1'- 1/2" 10 1/2"5 x 1'-1 1/4"

6"

3'-4"

3'-4"

2'-10"

6'-11"

3 1/2" 3 1/2"

11"

2'-8"

6'

8'-8" 8'-8"

20'

3 1/2"

10 3/4" 10 3/4"14 x 1'-1 1/2" 3 1/2"

1 1/2"

6'-11"

1 1/2"

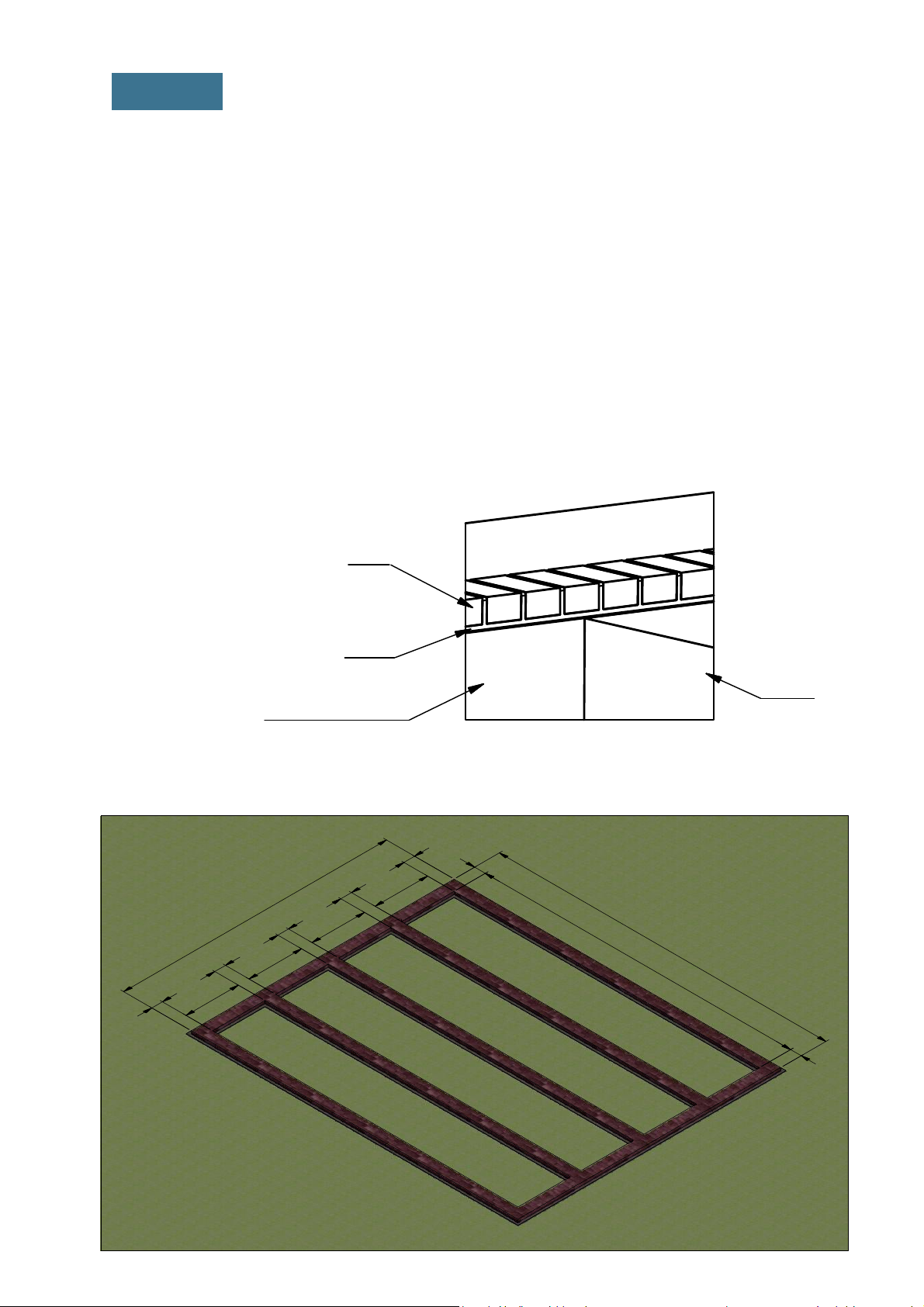

Assemble Back Wall Frame

4.1 Using 1 1/2“ x 3 1/2“ and 3 1/2“ x 3 1/2“ pressure-treated lumber, construct back wall

frame using the drawing below as a reference. You will need seventeen boards cut to 6'-11"

that will be the studs and two boards cut to 20' that will be the top and bottom plates.

4.2 Connect the beams with 2x4" wood screws.

4.3 Using a speed square or carpenter's square, check the corners to make sure they are 90°.

20'

STEP 4

1'-1 1/4" 10 x 1'-2" 1'-1 1/4"

6'-11"

15'-5"

Assemble Right Wall Frame

5.1 Using 1 1/2“ x 3 1/2“ pressure-treated lumber, construct side wall frames using the

drawing below as a reference.

You will need thirteen boards cut to 6'-11" that will be the studs and two boards cut to 15'-5"

that will be the top and bottom plates.

5.2 Connect the beams with 2x4" wood screws.

5.3 Using a speed square or carpenter's square, check the corners to make sure they are 90°.

STEP 5

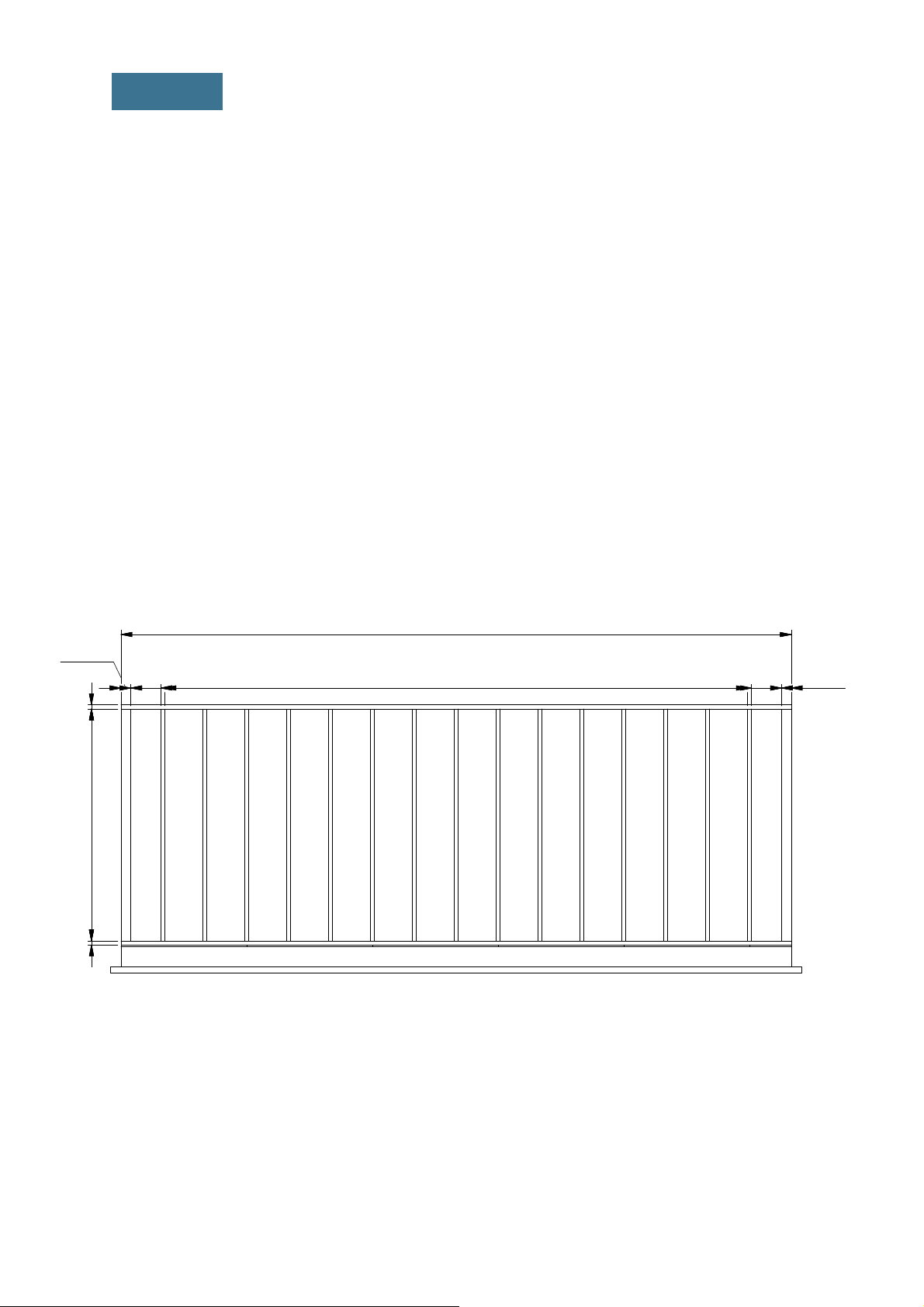

Assemble Left Wall Frame

6.1 Using 1 1/2“ x 3 1/2“ and 3 1/2“ x 3 1/2“ pressure-treated lumber, construct left wall

frame using the drawing below as a reference. You will need eight boards cut to 6'-11" that

will be the studs, two boards cut to 3'-8 1/2" that will be the bottom plates and one board

cut to 15'-5" that will be the top plate.

6.2 Connect the beams with 2x4" wood screws.

6.3 Using a speed square or carpenter's square, check the corners to make sure they are 90°.

STEP 6

1'- 1/2"

1'-1 1/4"

10 1/2" 8' 10 1/2"

1'-1 1/4"

1'- 1/2"

15'-5"

3'-8 1/2" 3'-8 1/2"

6'-11"

1

4

x

1

'

-

3

1

/

2

"

2

0

'

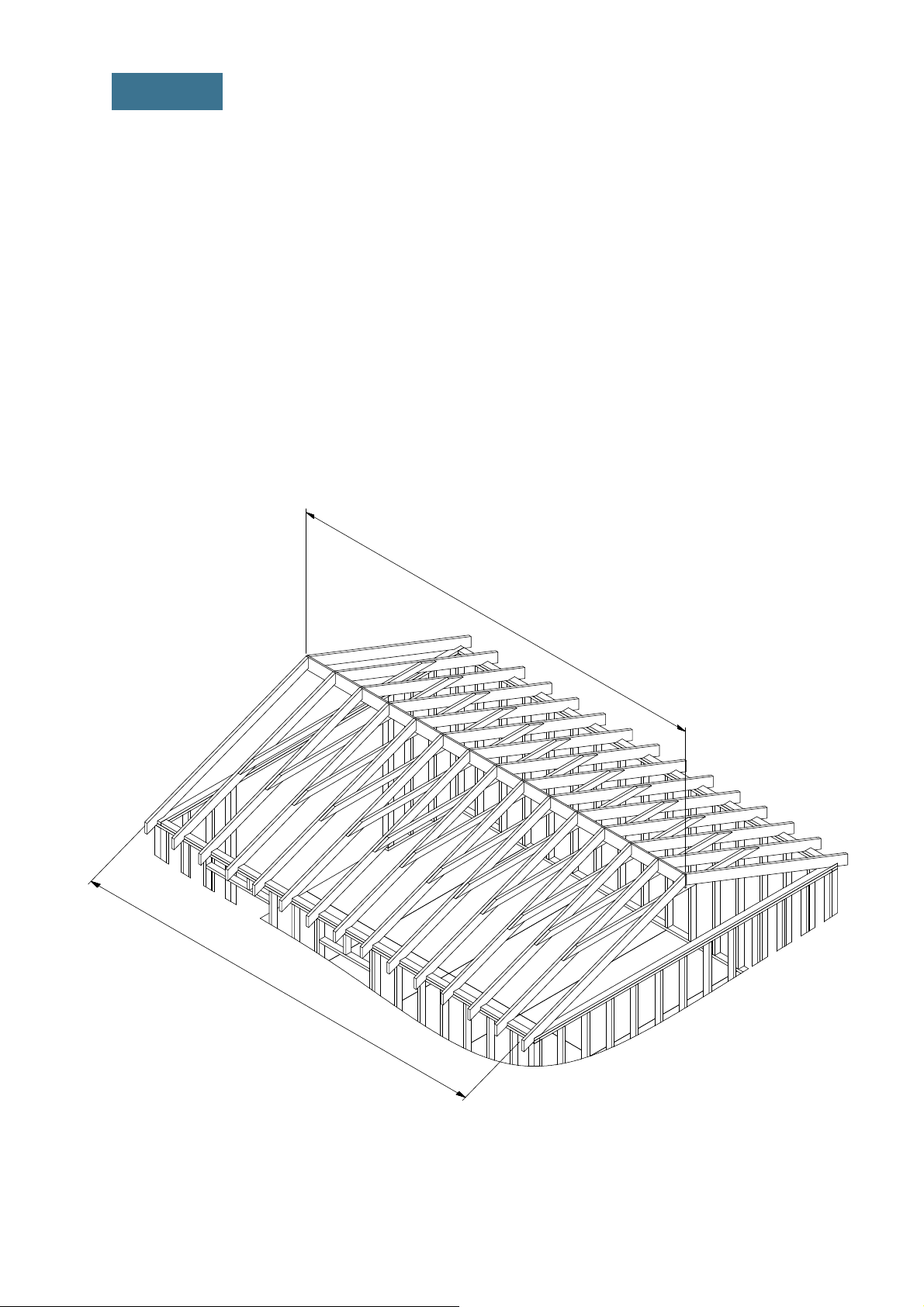

Assemble the Roof Frame

7.1 Using 1 1/2 “ x 5 1/2 “ pressure-treated lumber, cut thirty rafters 9'-3 3/4" long

according to the dimensions.

7.2 Using 1 1/2 “ x 3 1/2 “ pressure-treated lumber, cut thirteen collar ties 10'-4"

long according to the dimensions.

7.3 Using 3/4 “ x 7 1/4 “ pressure-treated board, cut the ridge board 20' long according

the illustration below.

7.4 Connect the beams with 2x3" wood screws.

STEP 7

G( 1 : 8 )

H ( 1 : 8 )

G

H

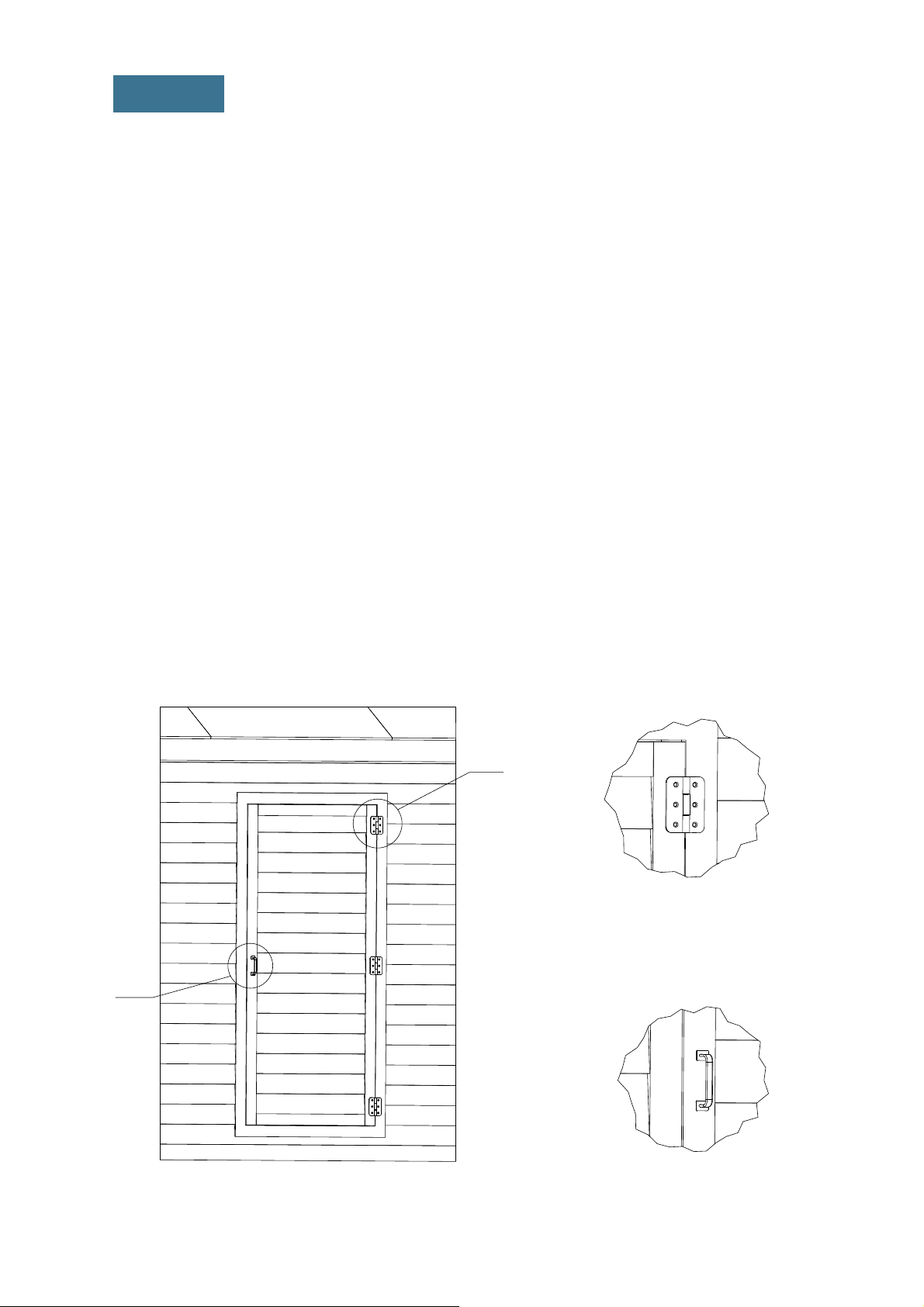

Assemble and Install Shed Door

8.1 Build the door frame for the shed using 1 1/2 “ x 3 1/2 “ pressure-treated lumber and

secure with 5” wood screws. You will need two boards cut to 5'-11 3/4" that will be the

vertical girts and two boards cut to 2'-3/4" that will be the horizontal girts.

8.2 Prepare the 9/16" plywood sheet with dimensions 2'-7 3/4" x 5'-11 3/4" for the door

according to the drawing.

8.3 Use 2 1/2 “ x 3/4 “ pressure-treated lumber for the door trim and fasten with 2” wood

screws. You will need two boards cut to 2'-2 3/4" and two boards cut to 5'-11 3/4".

8.4 Using 1/4 “ x 3/4 “ pressure-treated lumber, cut and install a starter course 2'-2 3/4" long.

8.5 For the exterior siding on the door, use 1/2 “ x 6” wood siding boards and the illustration

below as a reference.

8.6 Assemble siding shields with 2" galvanized nails.

8.7 Install three 3" door hinges using 6x1" wood screws. Finish the doors installation by

attaching 6" door pull.

STEP 8

9'-8 1/4"

9'-8 1/4"

20'-10"

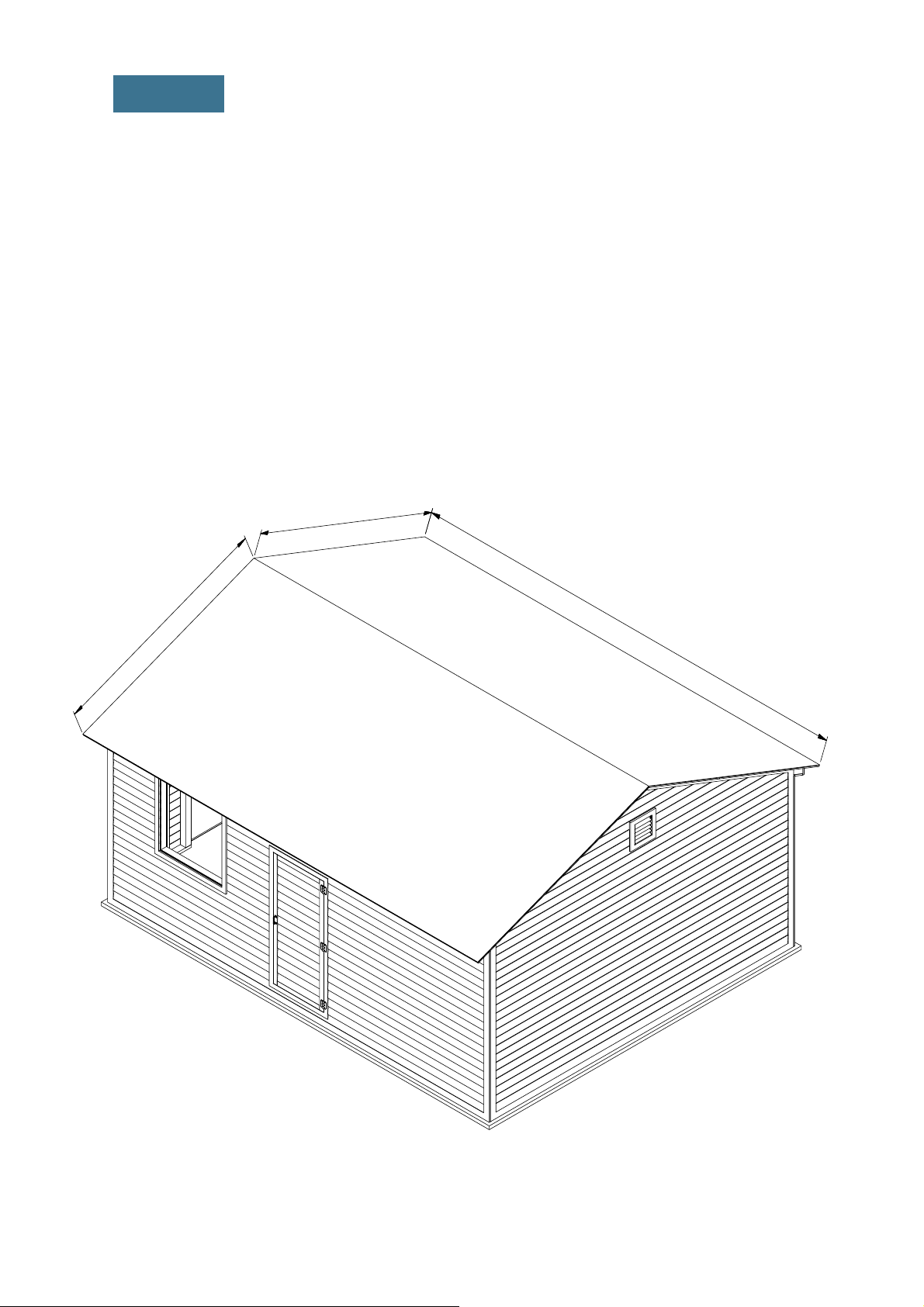

Roof Sheathing Installation

9.1 You will need 405 Sq Ft of asphalt shingle roofing.

9.2 Add the metal drip edge to the fascias.

9.3 Cover the plywood with building paper.

9.4 Install asphalt shingle roofing using an industrial stapler.

STEP 9

J( 1 : 12 )

K( 1 : 4 )

J ( 0,06 : 1 )

Window Installation for the Front Wall

10.1 Using 1 1/2 “ x 2 1/2 “ pressure-treated lumber, assemble the outer frame for the window as

shown in the drawing below. You will need two boards cut to 3'-1" that will be the vertical girts and two

boards cut to 3'-4" that will be the horizontal girts. Additionally, add vertical 2'-11 1/2" long and

horizontal 3'-1" long supports using 3/4“ x 1“ lumber and cut the recesses for the window hinges.

10.2 Use 1 1/2 “ x 1 1/2 “ pressure-treated material to make the inner frame and secure with 3”

wood screws. You will need two boards cut to 2'-9 3/4" that will be the vertical girts and two boards

cut to 3'-3/4" that will be the horizontal girts. Mill a recess for the glass panes and for the hinges.

10.3 Use 1 1/4 “ x 1 1/2 “ pressure-treated material to make the inner frame supports and secure

with 3” wood screws. You will need two boards cut to 2'-9 3/4" and mill a recess for interconnection.

10.4 Prepare and install glass into inner frame groove and fasten it by window beading from four

sides. Use 1/2" galvanized nails.

10.5 Install two hinges (3") with 6x1" wood screws and assemble the window. Install a lock on the

inner side of the window.

STEP 10

K

J

N( 1 : 10 )

O( 1 : 10 )

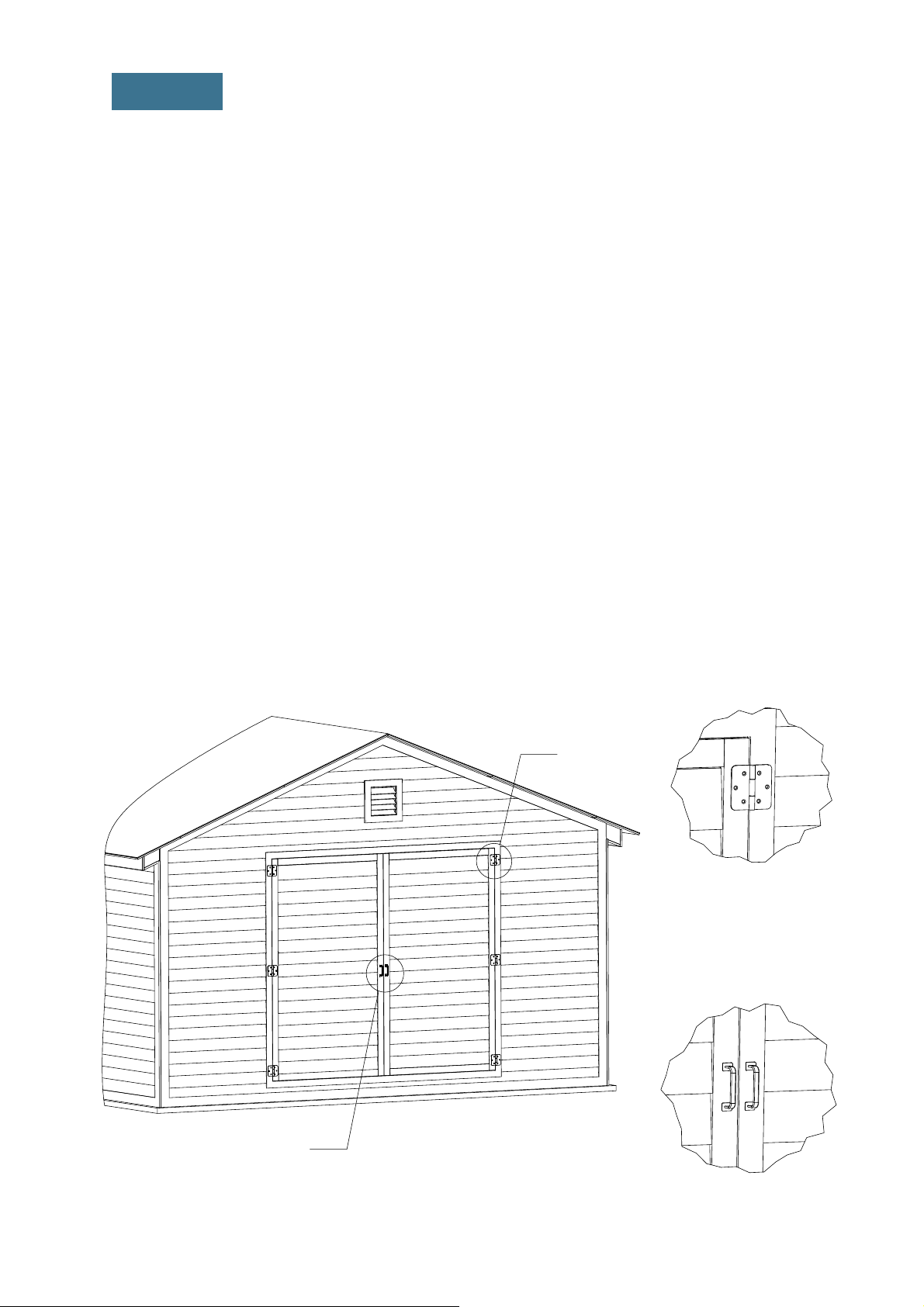

Assemble and Install Car Doors

11.1 Build the door frames for the shed using 1 1/2" x 3 1/2" pressure-treated lumber and

secure with 5" wood screws. You will need two boards cut to 6'-5 1/4" that will be the vertical

girts, two boards cut to 3'-11 3/4" that will be the horizontal girts, two boards cut to 4'-7" that

will be cross braces and one board cut to 3'-4 3/4" that will be middle girt.

11.2 Use 2 1/2" x 3/4" pressure-treated lumber for the door trim and fasten with 2" wood

screws. You will need two boards cut to 3'-6 3/4" and two boards cut to 7'-1/4".

11.3 Using 1/4" x 3/4" pressure-treated lumber, cut and install a starter course 3'-6 3/4"

long using Node F on page 26 as a reference.

11.4 For the exterior siding on the door, use 1/2" x 6" wood siding boards and the

illustration below as a reference.

11.5 Assemble siding shields with 2" galvanized nails.

11.6 Install six 3" door hinges using 6x1" wood screws.

Finish the doors installation by attaching 6" door pulls (see nodes N, O).

STEP 11

N

O

8'-2 3/4"

5 1/2"

3/4"

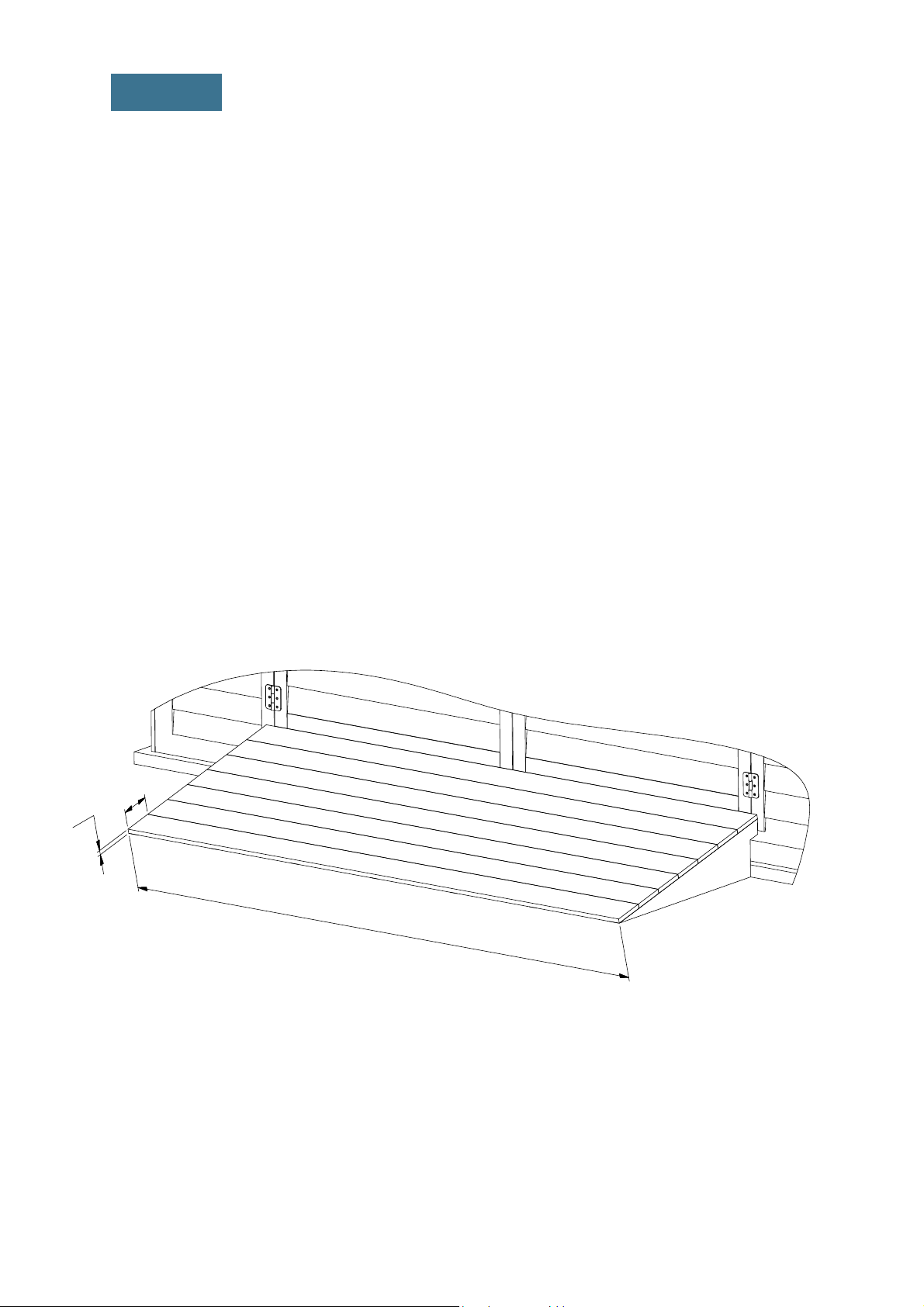

Assemble and Install Door Ramp

12.1 Assemble the seven door ramp frames from pressure-treated lumber and secure with 3" and 5"

wood screws. For each frame you will need one 1 1/2" x 1 1/2" board cut to 1'-9 1/2"; one 1 1/2" x 2

1/2" board cut to 3'-2 1/2" and one 1 1/2" x 3 1/2" board cut to 6 1/4".

12.2 Connect and secure all frames using one 1 1/2" x 2 1/2" board 8'-1 1/2" long and 3" wood screws.

12.3 Using 5 1/2" x 3/4" pressure-treated lumber, prepare seven boards 8'-2 3/4" long and install with

2" wood screws to the frames.

12.4 Cut two 9/16" plywood sheets with dimensions 9 1/4" x 3'-1 1/4" for the sides.

12.5 Assemble siding shields with 2" galvanized nails.

STEP 12

Thank You

Now that your shed is all done, you are ready to decorate it any way you want using your

favorite paint, stain, or preservative.

STEP 13

Copyright

The text and illustrations that appear here are the exclusive property of shedplans.org and are

protected by federal copyright laws. The duplication, sale or distribution of any portion of these

plans without prior written consent from the original designer will be subject to the appropriate

penalties for copyright infringement. Sharing this plan on the web is only permited with an

indicated original source: https://shedplans.org

For more great HOW-TO plans please visit: https://shedplans.org

Table of contents

Popular Tent manuals by other brands

Jysk

Jysk DOME 913-15-1003 quick start guide

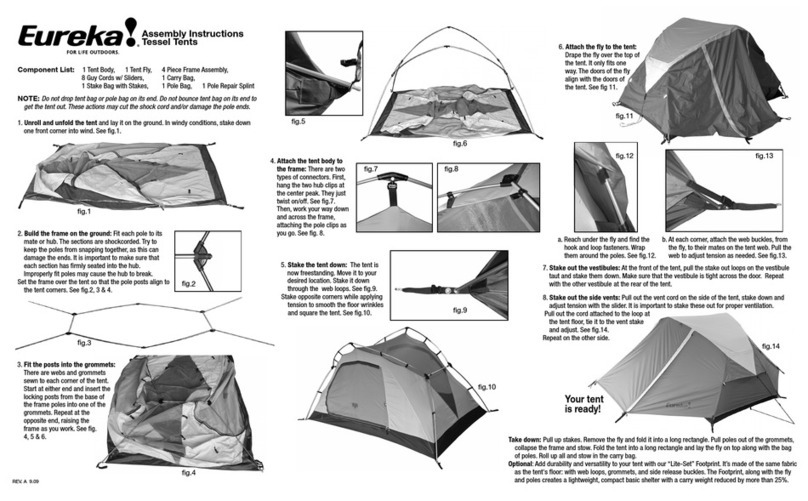

Eureka

Eureka Tessel Assembly instructions

Awntech

Awntech Dallas Retro RR22 Assembly and installation instructions

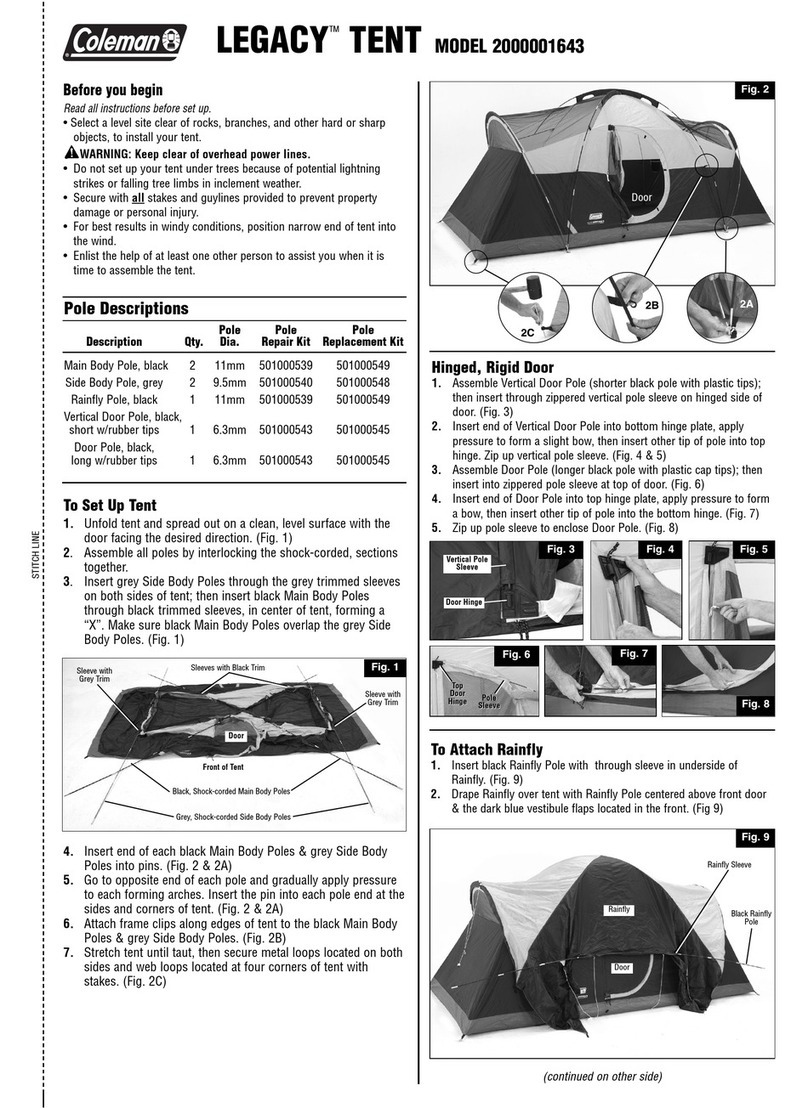

Coleman

Coleman LEGACY 2000001643 user manual

DARCHE

DARCHE NEBULA+ 1550 SWAG instruction manual

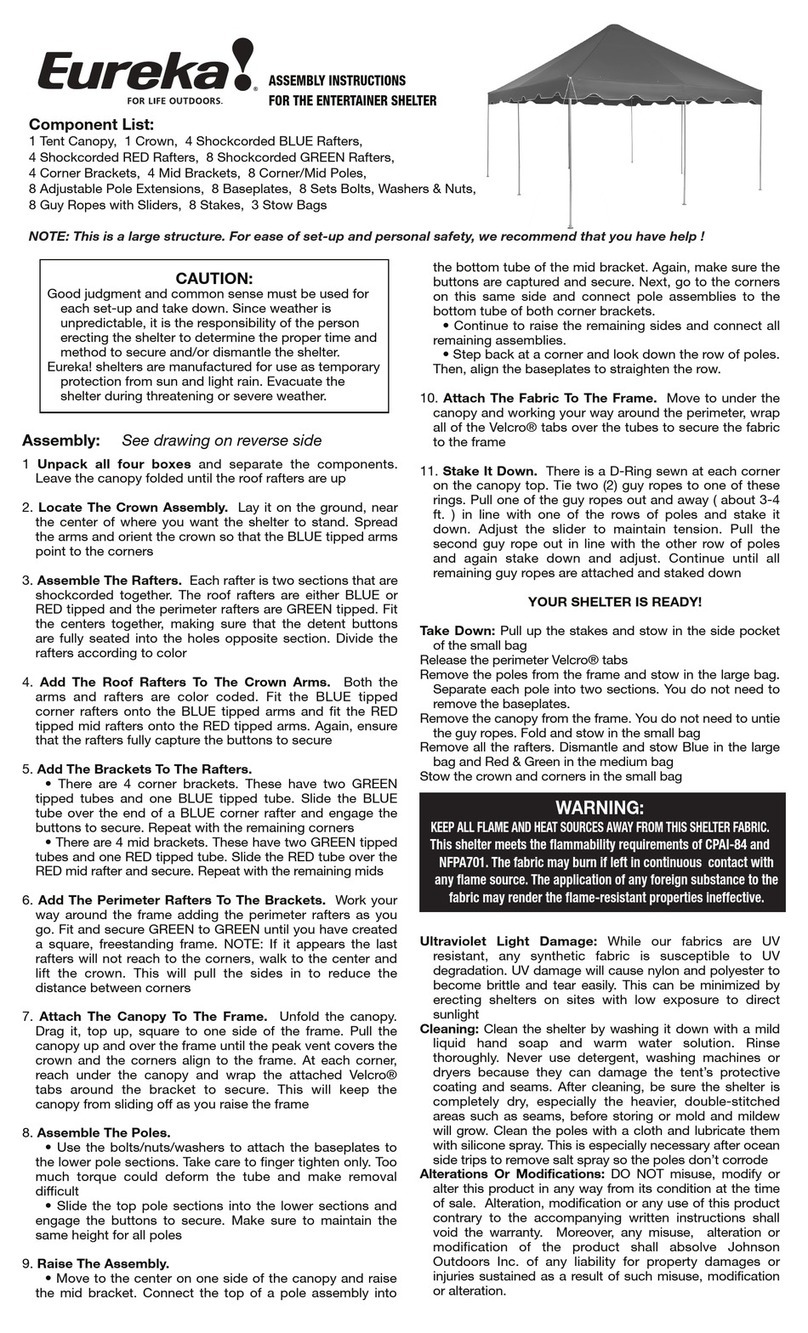

Eureka

Eureka Entertainer Shelter Assembly instructions

Costway

Costway NP10844 Assembly instructions

ShelterLogic

ShelterLogic Grow-It Greenhouse-in-a-Box user manual

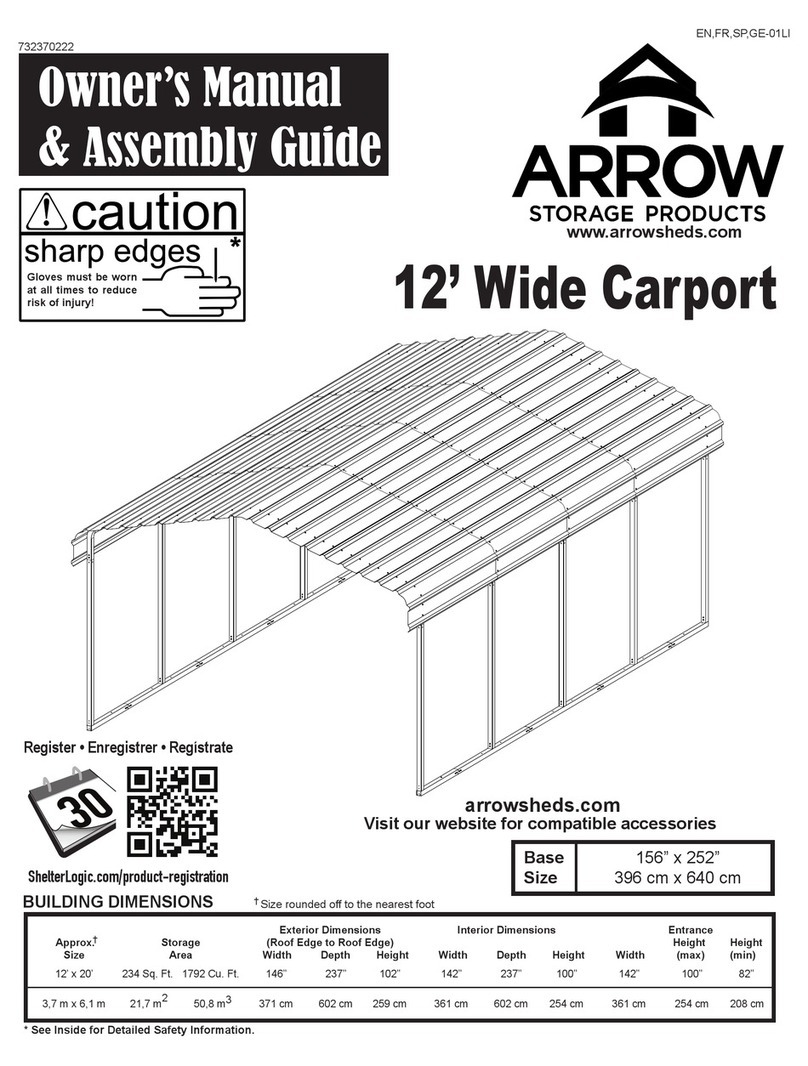

Arrow Storage Products

Arrow Storage Products CPHC122909 Owner's manual & assembly guide

Anchor

Anchor Event Series installation instructions

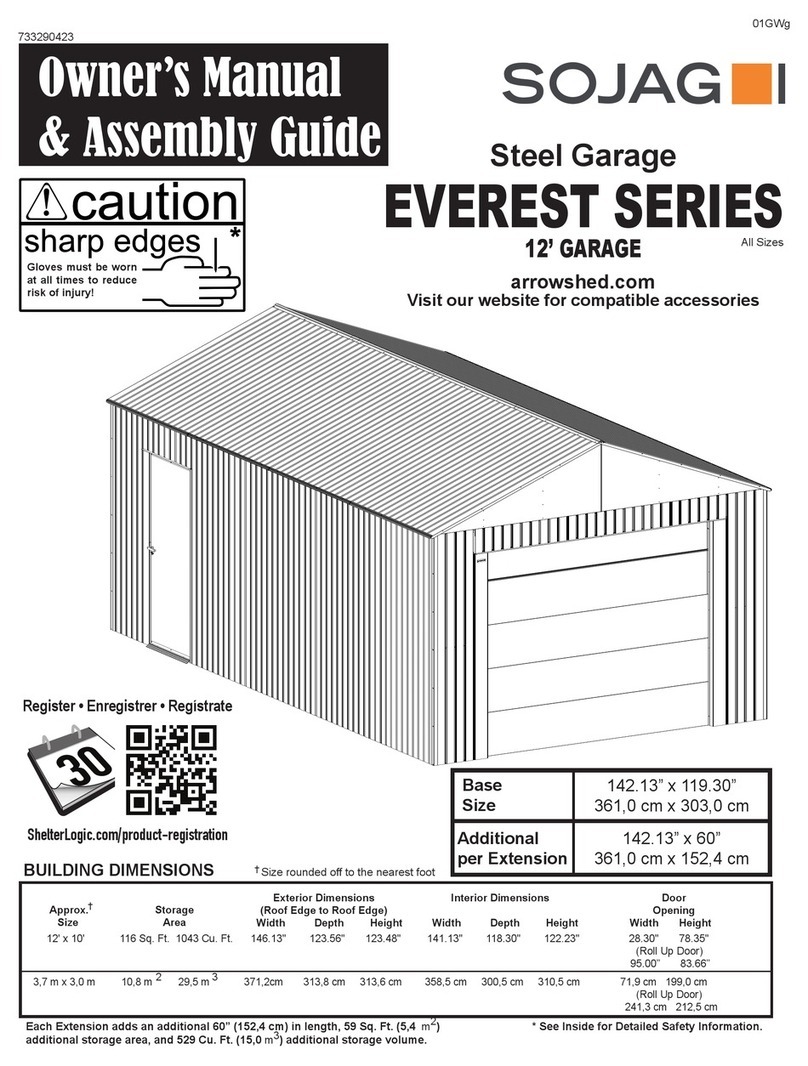

Sojag

Sojag EVEREST Series Owner's manual and assembly guide

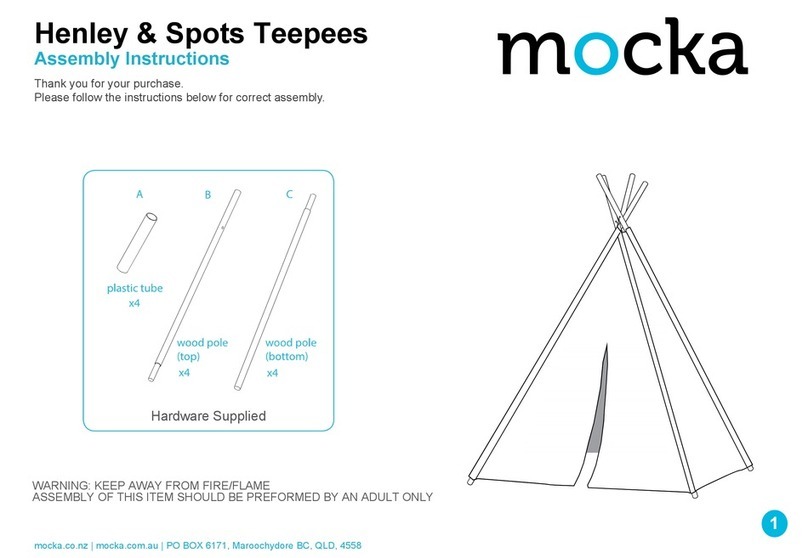

Mocka

Mocka Henley Teepees Assembly instructions