SHENZHEN FLYING INDUSTRY DEVELOPMENT S4U-AC380 User manual

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

RF Wireless Receiver (Model 0020700 S4U-AC380)

Feature:

Application 1: It can be used in industry automation, agriculture automation and home automation, such as factory, house, farm, pasture, vehicle,

ship, offshore operation, aerial vehicle, field call, etc. It can remote control equipments on land, water and air, such as remote control lights, sirens,

locks, motors, fans, winches, blinds, linear actuators, doors, windows, electric solenoid valves, security alarm, business signs and various devices.

Application 2: It can be used in rolling blinds, rolling doors, projection screens, awnings, pumps, winches, conveyors or other equipments with AC

motor. It can remotely control theAC motor to rotate in the forward or reverse direction.

Wireless control, easy to install.

Universal Power Supply: AC 75~400V, support AC 110V, AC 120V, AC 220V, AC 240V, AC 380V.

Relay Output: This receiver is relay output, it can be used to operate both DC and AC equipments. The terminals are NO / NC (normally open /

normally closed), which serves as a switch. That means you should also connect a separate power supply to equipments.

Each channel can work at maximum current 10A.

With 5 manual buttons: You can press the manual buttons to control the equipments.

With external telescopic antenna, the receiver have a farther working range.

You can control the equipments by using the receiver with transmitter (remote control) from any place within a reliable distance.

Wireless RF signal can pass through walls, floors, doors or windows.

With characteristics of reverse power protection and over current protection.

Reliable control: The code has thousands of different combinations, and the receiver only works with the transmitter which use the same code.

One/several transmitters can control one/several receivers simultaneously.

You can use two or more units in the same place.

Receiver Parameters:

Model No.: S4U-AC380

Power Supply (Operating Voltage): AC 75~400V (110V/120V/220V/240V/380V)

Output: Relay output (Normally open)

Wire range for the terminals: 22-12 AWG

Working Frequency: 433.92MHz

Channel: 4 CH

Control Modes: Self-locking, Momentary, Interlocking, Self-locking + Interlocking

Static Current: ≤6mA

Maximum Load Current: 10A / each channel

Operating Temperature: -20 °C to +70 °C

Case size: 140mm x 85mm x 40mm

Matching Transmitters:

The receiver can work with different transmitters, such as model C-4 (100M), CP-4 (500M) or CB-4(1000M) etc.

Working Range:

With a transmitter (such as CP-4) to form a complete set, the maximum working distance can reach 500M in an open ground.

The maximum working distance is a theoretical data, it shall be operated in an open ground, no barriers, no any interference. But in the practice, it will

be hindered by trees, walls or other constructions, and will be interfered by other wireless signals. Therefore, the actual distance may not reach this

maximum working distance.

If you want to have a further working range, you can use a powerful transmitter, such as CB-4 transmitter.

Usage (with the transmitter CP-4):

The receiver can be used to control AC 110V or 220V pumps, motors and other equipments, or AC 380V equipments by the 380V contactors, and it

can’t directly connected to the 380V equipments.

Notice: The receiver is relay output, not DC/AC power output. Initial state of relay output terminals: Two terminals are Normally Open.

Wiring:

1) If you want to control the AC 110V or 220V equipment, you can connect the receiver, the equipment and the AC power according following circuit

diagram 1, then you use the transmitter to control the equipment.

2) If you want to control the AC 380V equipment, you can connect the receiver, the 380V contactor, the 380V equipment and the 380V power

according following circuit diagram 2, then you use the transmitter to control the AC 380V equipment.

3) If you want to control theAC 380V motor forward and reverse rotation, you can connect the receiver, the 380V contactors, the 380V motor and the

380V power according following circuit diagram 3 or 4, then you use the transmitter to control the AC 380V motor.

Setting different control modes (with the transmitter CP-4):

We have set the receiver as Self-locking control mode before delivery. If you want to use other control modes, do as following operation:

1) Setting Self-locking mode: When the receiver is in the learning status, press button Aof the transmitter.

Mode Self-locking: Press -> On; Press again -> Off.

Press button A of the transmitter or buttonA of the receiver: The relay 1 is activated, and the equipment 1 is turned on.

Press button A of the transmitter or buttonA of the receiver again: The relay 1 is deactivated, and the equipment 1 is turned off.

Press button B of the transmitter or button B of the receiver: The relay 2 is activated, and the equipment 2 is turned on.

Press button B of the transmitter or button B of the receiver again: The relay 2 is deactivated, and the equipment 2 is turned off.

Press button C of the transmitter or button C of the receiver: The relay 3 is activated, and the equipment 3 is turned on.

Press button C of the transmitter or button C of the receiver again: The relay 3 is deactivated, and the equipment 3 is turned off.

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

Press button D of the transmitter or button D of the receiver: The relay 4 is activated, and the equipment 4 is turned on.

Press button D of the transmitter or button D of the receiver again: The relay 4 is deactivated, and the equipment 4 is turned off.

2) Setting Momentary mode: When the receiver is in the learning status, press button B of the transmitter.

Mode Momentary: Press and hold -> On; Release -> Off.

Press and hold button A of the transmitter or buttonA of the receiver: The relay 1 is activated, and the equipment 1 is turned on.

Release buttonA of the transmitter or buttonA of the receiver: The relay 1 is deactivated, and the equipment 1 is turned off.

Press and hold button B of the transmitter or button B of the receiver: The relay 2 is activated, and the equipment 2 is turned on.

Release button B of the transmitter or button B of the receiver: The relay 2 is deactivated, and the equipment 2 is turned off.

Press and hold button C of the transmitter or button C of the receiver: The relay 3 is activated, and the equipment 3 is turned on.

Release button C of the transmitter or button C of the receiver: The relay 3 is deactivated, and the equipment 3 is turned off.

Press and hold button D of the transmitter or button D of the receiver: The relay 4 is activated, and the equipment 4 is turned on.

Release button D of the transmitter or button D of the receiver: The relay 4 is deactivated, and the equipment 4 is turned off.

3) Setting Interlocking mode : When the receiver is in the learning status, press button C of the transmitter.

Mode Interlocking (Channel 1 and 2): Press -> On; Press another button -> Off. Channel 3 and 4 are useless.

Note: This mode is suitable for AC 380V motor forward and reverse rotation (see following circuit diagram 3), and two channels 1 and 2 cannot be

activated at the same time.

Press button A of the transmitter or buttonA of the receiver: The relay 1 is deactivated, and the 380V motor rotates in the positive direction.

Press button C of the transmitter or button C of the receiver: The relay 1 is deactivated, and the 380V motor stops.

Press button B of the transmitter or button B of the receiver: The relay 2 is activated, and the 380V motor rotates in the reversal direction.

Press button D of the transmitter or button D of the receiver: The relay 2 is deactivated, and the 380V motor stops.

4) Setting Self-locking + Interlocking mode: When the receiver is in the learning status, press button D of the transmitter.

Mode Self-locking (Channel 1) + Mode Interlocking (Channel 2 and 3), Channel 4 is useless.

Note: This mode is suitable for AC 380V motor forward and reverse rotation (see following circuit diagram 4), and two channels 2 and 3 cannot be

activated at the same time.

Press button A of the transmitter or buttonA of the receiver: The relay 1 is activated, and the power of 380V motor is turned on.

Press button A of the transmitter or buttonA of the receiver again: The relay 1 is deactivated, and the power of 380V motor is turned off.

Press button B of the transmitter or button B of the receiver: The relay 2 is deactivated, and the 380V motor rotates in the positive direction.

Press button D of the transmitter or button D of the receiver: The relay 2 is deactivated, and the 380V motor stops.

Press button C of the transmitter or button C of the receiver: The relay 3 is activated, and the 380V motor rotates in the reversal direction.

Press button D of the transmitter or button D of the receiver: The relay 3 is deactivated, and the 380V motor stops.

Manual button "Stop" of the receiver:

In any case, pressing this manual button will deactivate all relays.

How to pair the transmitter to the receiver:

1) Press the setting button of the receiver for 5~6 seconds until signal LED on the receiver flashes 3 times, then release the setting button. The

receiver enters into the learning status.

2) Press any button on transmitter within 5 seconds, if signal LED flashes 5 times then turns off, it means learning is successful.

3) The receiver can learn several transmitters with different codes.

Delete all transmitters:

We have learned the transmitter to the receiver. If you don’t want the receiver to work with the transmitter, you can delete all codes of the transmitters

which are stored in the receiver.

Operation: Pressing the setting buttons of the receiver for 10~12 seconds until the signal LED on the receiver flashes 5 times, then release the

setting button. This means all stored codes have been deleted successfully.

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

Circuit Diagram 1

L

N

AC 110V/220V POWER

L

N

Equipment 4

L

N

Equipment 3

L

N

Equipment2

L

N

Equipment 1

S4U-AC380

NO2

Relay2

Signal LED

COM1

COM2

NO1

L1

L2

NO4

COM3

COM4

NO3

RF module

LED 1

LED 2

LED 3

LED 4

Setting/Stop

D

C

B

A

CH 1

CH 2

CH 3

CH 4

Relay1

Relay3

Relay4

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

A2

14

NO

A2

Circuit Diagram 2

L1

L2

L3

AC 380V POWER

AC 380V Contactor 4

L1

1

L3

L2

5

3

A2

13

NO

A1

T1

2

T3

T2

6

4

14

NO

A2

L1

L2

L3

AC 380V Equipment 4

L1

L2

L3

AC 380V Equipment 3

L1

L2

L3

AC 380V Equipment 2

L1

L2

L3

AC 380V Equipment 1

S4U-AC380

NO2

Signal LED

COM1

COM2

NO1

L1

L2

NO4

COM3

COM4

NO3

RF module

LED 1

LED 2

LED 3

LED 4

Setting/Stop

D

C

B

A

CH 1

CH 2

CH 3

CH 4

Relay2

Relay1

Relay3

Relay4

AC 380V Contactor 3

L1

1

L3

L2

5

3

A2

13

NO

A1

T1

2

T3

T2

6

4

14

NO

A2

AC 380V Contactor 1

L1

1

L3

L2

5

3

13

NO

A1

T1

2

T3

T2

6

4

AC 380V Contactor 2

L1

1

L3

L2

5

3

A2

13

NO

A1

T1

2

T3

T2

6

4

14

NO

A2

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

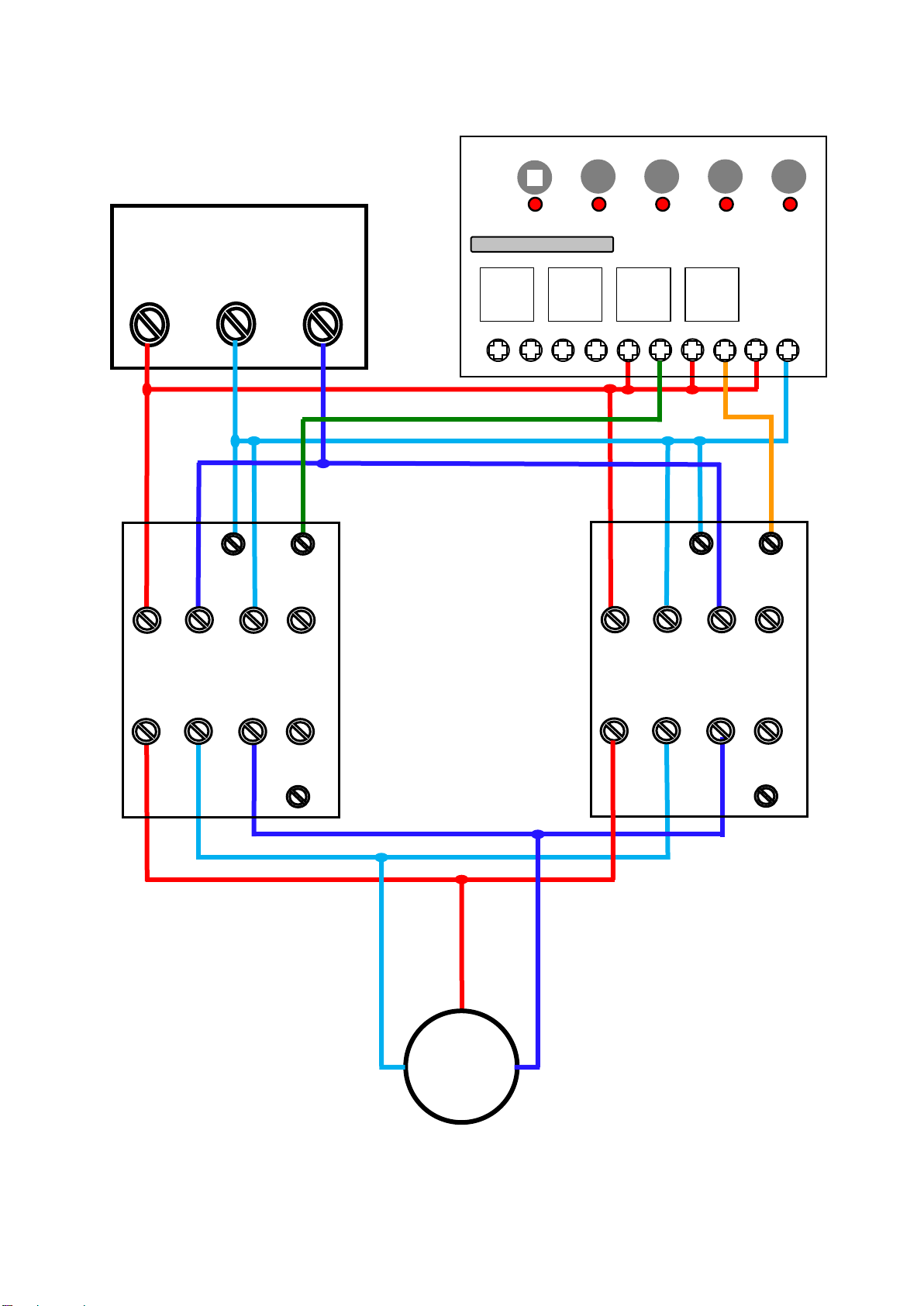

Circuit Diagram 3

L1

L2

L3

AC 380V POWER

S4U-AC380

NO2

Signal LED

COM1

COM2

NO1

L1

L2

NO4

COM3

COM4

NO3

RF module

LED 1

LED 2

LED 3

LED 4

Setting/Stop

D

C

B

A

CH 1

CH 2

CH 3

CH 4

Relay2

Relay1

Relay3

Relay4

A2

13

NO

14

NO

A2

AC 380V Contactor 2

L1

L3

L2

5

3

A1

T1

T3

T2

6

4

A2

13

NO

14

NO

A2

AC 380V Contactor 1

L1

L3

L2

5

3

A1

T1

T3

T2

6

4

1

1

2

2

M

AC 380V Motor

SHENZHEN FLYING INDUSTRY DEVELOPMENT CO.,LTD

http://www.carymart.com E-Mail: sale@carymart.com

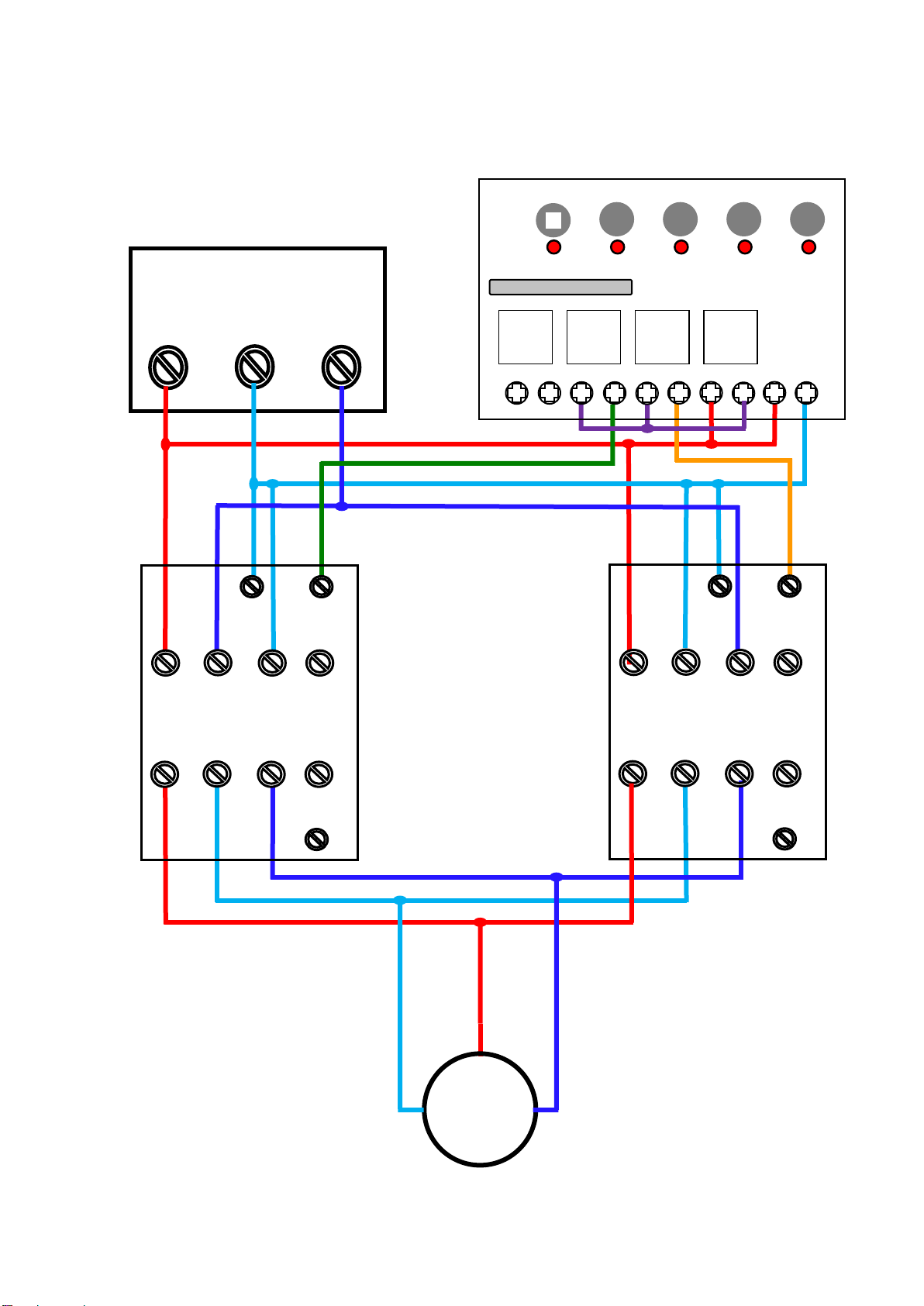

Circuit Diagram 4

L1

L2

L3

AC 380V POWER

S4U-AC380

NO2

Signal LED

COM1

COM2

NO1

L1

L2

NO4

COM3

COM4

NO3

RF module

LED 1

LED 2

LED 3

LED 4

Setting/Stop

D

C

B

A

CH 1

CH 2

CH 3

CH 4

Relay2

Relay1

Relay3

Relay4

A2

13

NO

14

NO

A2

AC 380V Contactor 2

L1

L3

L2

5

3

A1

T1

T3

T2

6

4

A2

13

NO

14

NO

A2

AC 380V Contactor 1

L1

L3

L2

5

3

A1

T1

T3

T2

6

4

1

1

2

2

M

AC 380V Motor

This manual suits for next models

1

Table of contents

Other SHENZHEN FLYING INDUSTRY DEVELOPMENT Receiver manuals