Marantz SR620 User manual

Other Marantz Receiver manuals

Marantz

Marantz SR4300 User manual

Marantz

Marantz SR2000 User manual

Marantz

Marantz NR1605 User manual

Marantz

Marantz M-CR510 User manual

Marantz

Marantz Slim-line NR1501 User manual

Marantz

Marantz SR7010 User manual

Marantz

Marantz SR5012 User manual

Marantz

Marantz 2215 User manual

Marantz

Marantz SR5008 User guide

Marantz

Marantz SR680 User manual

Marantz

Marantz 2265B User manual

Marantz

Marantz QUADRADIAL 4 User manual

Marantz

Marantz ER3000 User manual

Marantz

Marantz SR9200 User manual

Marantz

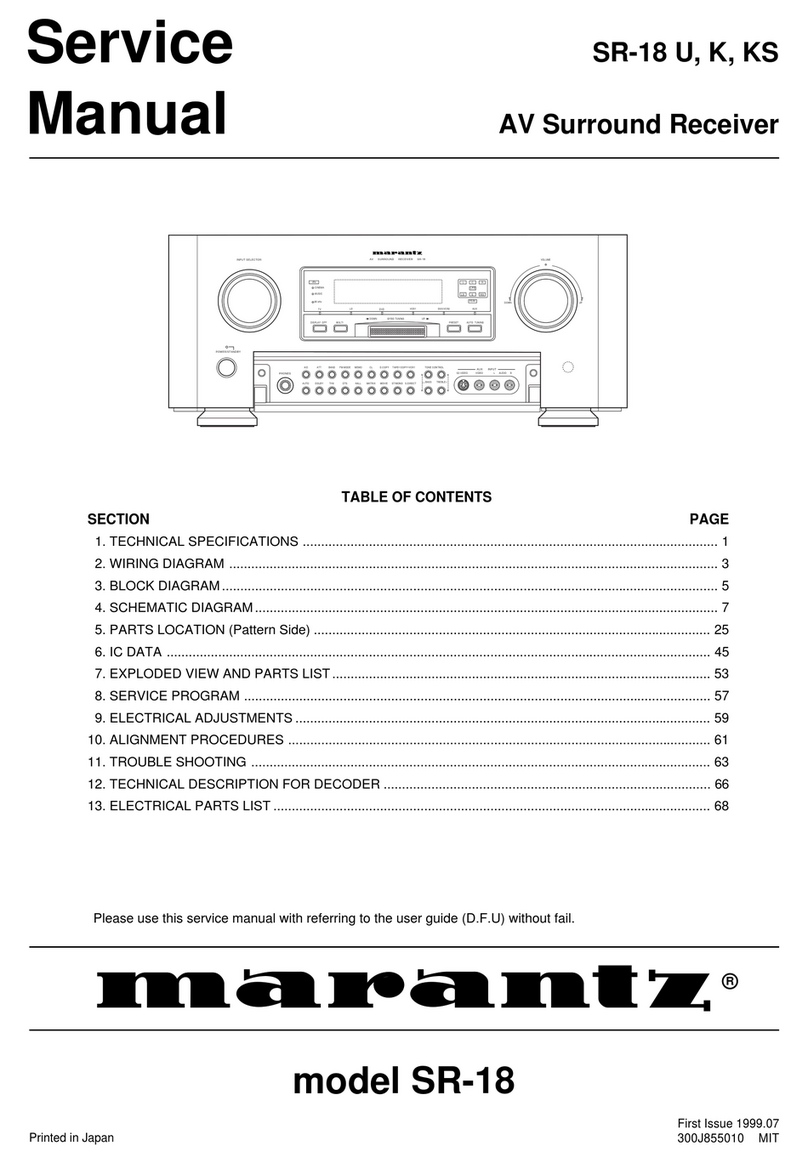

Marantz SR-18 User manual

Marantz

Marantz NR1604 User manual

Marantz

Marantz SR5013 User manual

Marantz

Marantz M-ER803 User manual

Marantz

Marantz SR5008 Product information sheet

Marantz

Marantz NR1607 User manual