Shenzhen Powtech PT200 User manual

Foreword

Thank you for choosing PT200 variable-frequency inverter from Shenzhen

Powtech Co.,Ltd.This product is a kind of variable-frequency inverter which it

can be applied to various industrial machineries, drive and control of the fan and

pump and heavy load of grinding with intermediate frequency; and it is designed

by Shenzhen Powtech Co.,Ltd via its professional production and sales experience

for many years.

This manual includes two series of PT200: general type and specific type;

among them, general type can be divided into P, G, M and H type based on

different load and specific type can be divided into S, T and Z type; and the

detailed description is as follow:

P type: light load;

G type: standard load

M type: heavier load;

H type: heavy load;

S type: specific type for textile machine;

T type: specific type for winding machine;

Z type: specific type for injection molding machine;

This manual provides related notices, such as parameter setting of installation

and operation, diagnosis of malfunctions, daily maintenance and safe use, for user.

Please read this manual in detail before install it in order to guarantee install and

operate this variable-frequency inverter correctly.

Please contact with Powtech local dealers in various places or directly

contact with our company if there is any difficult during your using process; and

our professionals are glad to make service for you!

Please submit this manual to ultimate user and ask the user to keep it properly,

which will be beneficial for later maintenance and other applied occasions. If there

are any troubles during the warranty period, please fill up the warranty card and

fax it to the dealer or our company.

The information may be changed during the improving period of this project

without prior notice. Please consult the website of Powtech when you would like

to obtain the latest information.

Please consult http://www.powtech,cn/en for information of Powtech series

products.

Shenzhen Powtech Co.,Ltd

CATALOGUE

Chapter 1 Inspection and Safety Precautions.............................................................1

1-1 Inspect after unboxing...........................................................................................1

1-1-1 Explanative to nameplate.............................................................................1

1-1-2. Type inverter............................................................................................... 1 1

1-2 Safety attentions....................................................................................................2

1-3. Precautions...........................................................................................................4

1-4 Range of application............................................................................................. 6

Chapter 2 Standard specification................................................................................ 7

2-1 Technical specifications........................................................................................ 7

2-1-1. Technical specifications of PT200..............................................................7

2-1-2 See the following table for rated output current with different

specifications................................................................................................................. 9

2-2 Standard specification......................................................................................... 11

2-3. Dimension.......................................................................................................... 15

2-3-1 Product appearance figure and dimension of installing hole.....................15

Chart2-6 2N9~2N10 Cabinet dimension..........................................................22

2-3-4. Dimension figure of keyboard.................................................................. 22

Chapter 3 Installation and redundant circuit...........................................................24

3-1 Service environment........................................................................................... 24

3-2 Installation direction and room........................................................................... 24

3-3 Wiring diagram................................................................................................... 25

3-3-1 Wiring diagram below 7.5KW(2S1/2S2/2S3).................................26

3-3-2. Wiring diagram for 11KW~22KW(2N1~2N2)................................... 27

3-3-3 Wiring diagram for 30kW~630kW(2N3~2N10)..................................28

3-4. Main circuit terminal (G type)........................................................................... 29

3-4-1.Main circuit terminal of PT200................................................................. 29

3-4-2 Explanation for the function of terminal blocks........................................ 30

3-5 Control circuit terminal.......................................................................................31

3-5-1. Explanation for control circuit terminal....................................................31

3-5-2. Arrangement of control circuit terminal................................................... 32

3-6 Wiring precautions..............................................................................................32

3-7 Redundant circuit................................................................................................ 33

Chapter 4 Operation keyboard........................................................................... 34

4-1. Introduction of operation keyboard........................................................................34

4-2. Introduction for indicator light of the keyboard.................................................34

4-3. Key description of operation panel.................................................................... 36

4-4. Menu style..........................................................................................................37

4-4-1. First-level menu style......................................................................................... 37

4-4-2. Form of secondary menu.......................................................................... 38

4-4-3. Form of three-level menu......................................................................... 38

4-4-4. Common display symbol of LED............................................................. 38

4-4-5. LED displays corresponding sign.......................................................... 39

4-5. Password operation and key lock and unlock functions.................................... 39

4-6. Display of operation panel and key operation................................................... 40

4-6-1. Classification of display state: display state of operation panel can be

divided into 9 types:.................................................................................................... 40

4-6-2. Display status and operation process........................................................41

4-7. Operation examples............................................................................................42

4-7-1. Recover factory parameter........................................................................42

4-7-2. Setup set frequency...................................................................................42

4-7-3. Password setting....................................................................................... 43

4-7-4. Password authentication........................................................................... 43

4-7-5. Password.................................................................................................44

4-8. Setting method of parameter..............................................................................44

Chapter 5 Commissioning..................................................................................... 46

Chapter 6 Inverter of function parameter........................................................... 48

6-1. List of function parameter..................................................................................48

6-1-1. Menu grouping..........................................................................................49

6-1-2. P00 group Monitoring function group......................................................50

6-1-3. P01 group Basic group..............................................................................51

6-1-4. P02 group Control group for the stop and start........................................ 53

6-1-5. P03 group: Group of electric machine parameter..................................54

6-1-6. P04 group Vector control parameter......................................................... 55

6-1-7. P05 group V/F control parameter............................................................. 56

6-1-8. P06 group Input terminal group..........................................................57

6-1-10. P08 group output terminal group......................................................... 62

6-1-11. P09 group Enhancement group............................................................64

6-1-12. P10 group control group of PID.......................................................... 65

6-1-13. P11 group control group of multistep speed........................................... 66

6-1-14. P12group communication parameter group............................................67

6-1-15. P13 group Protection function group......................................................68

6-1-16. P14 group function group of water supply............................................. 69

6-1-17. P15 group manufacturer’s function group........................................... 70

6-2. inverter of function parameter............................................................................70

6-2-1. P00 group monitoring function group................................................... 70

6-2-2. P01 group basic function group.............................................................71

6-2-3. P02 group control group of the start and stop...........................................78

6-2-4. P03 group motor parameter group............................................................80

6-2-5. P04 group parameter of vector control..................................................... 82

6-2-6. P05 group V/F control parameter............................................................. 83

6-2-7. P06 group input terminal group.............................................................86

6-2-8. P07group human-computer interface group............................................. 92

6-2-9. P08 group output terminal group..............................................................96

6-2-10. P09 group enhancement group............................................................ 98

6-2-11. P10 group PID control group.............................................................103

6-2-12. P11 group control group of multistep speed...................................... 106

6-2-13. P12 group communication parameter group.........................................108

6-2-14. P13 group protection function group.................................................... 111

6-2-15. P14 group water supply function....................................................... 113

6-2-16. P15 group manufacturer’s function....................................................114

Chapter 7 EMC(Electro Magnetic Compatibility)........................................... 115

7-1. Definition......................................................................................................... 115

7-2. Introduction of EMC standard......................................................................... 115

7-3.EMC guidance...................................................................................................115

7-3-1. Influence of harmonic wave....................................................................115

7-3-2.Electromagnetic interference and installation notes................................ 115

7-3-3. Solution for the interference of surrounding electromagnetic equipment

on AC frequency vector inverter................................................................................116

7-3-4. Solution for the interference of AC frequency vector inverter on its

surrounding electromagnetic equipment....................................................................116

7-3-5. Leakage current and disposal..................................................................117

7-3-6. Precautions for installing EMC input filter at the input terminal of the

power supply :........................................................................................................... 117

Chapter 8 Failure checking and removal........................................................... 119

8-1.Failure information and removal method.......................................................119

Chapter 9 Maintenance and overhauling................................................................122

9-1. Inspection and maintenance.............................................................................122

9-2. Device required regular change....................................................................... 123

9-3. Storage and custody......................................................................................... 123

9-4.Measurement and judgment..............................................................................123

Chapter 10 Option.....................................................................................................125

10-1. Optional components..................................................................................... 126

10-2. Moulded case circuit breaker(MCCB)or earth leakage circuit

breaker(ELCB).................................................................................................................... 126

10-3. AC reactor......................................................................................................126

10-4. Noise filter......................................................................................................128

10-5. Contactor........................................................................................................128

10-6. Brake unit and brake resistor (380V).............................................................128

10-7. EMI filter of output........................................................................................130

10-8. AC output reactor...........................................................................................130

10-9.Input filter....................................................................................................... 130

10-9-1.Input filter(380V)............................................................................. 130

10-9-2.Output filter(380V)...........................................................................132

10-10. Input reactor................................................................................................. 133

10-10-1.Output filter(380v)..........................................................................133

10-11 Output reactor................................................................................................134

10-11-1.Output reactor(380V)......................................................................134

10-12.DC reactor.....................................................................................................135

10-13 Specification of breaker, cable and contactor............................................... 136

Chapter 11 Quality guarantee.................................................................................. 138

Attachment RS485 communication protocol......................................................... 140

1. Introduction for use............................................................................................. 140

2. Specification........................................................................................................140

Parameter address and parameter description................................................... 145

parameter description........................................................................................ 145

Reference:................................................................................................................154

Chapter 1 Inspection and Safety Precautions

1

Chapter 1

Chapter 1 Inspection and Safety Precautions

All inverters of Shenzhen Powtech Co.,Ltd are given strict test and quality

inspection before leaving factory. Please firstly check whether the product

package is damaged due to transportation carelessness after your purchasing and

whether the specification and type is consistent with the machine you ordered.

Please contact with dealers of our company in various places or directly contact

with our company if there is any problem.

1-1 Inspect after unboxing

Inspect it includes one machine, a manual and a warranty card. Inspect nameplate

at the side of variable-frequency inverter to confirm the product you obtain is the

product you ordered.

1-1-1 Explanative to nameplate

1-1-2. Type inverter

Chapter 1 Inspection and Safety Precautions

2

Chapter 1

1-2 Safety attentions

Safety precautions are divided into following two types in this manual:

Danger: the danger caused by not operating as required can cause serious injury or

even death.

Notice: the danger caused by not operating as required can cause

moderate harm or minor injury and damage of the equipment.

Process Type of safety matters Content of safety precautions

Pre-

installation danger

●Please don’t install when it is found that control system

has water, the part is insufficient or damaged when the

box is opened.

●Please don’t install when the packing list is in consistent

with the matter time!

●Lift and put lightly when it is moved, or there will be

danger of destroying the equipment!

●Please don’t use the actuator with damage or AC

frequency vector inverters with missing parts, or there

will be danger of being injured!

● Don’t touch the component of the control system with

your hand, or there will be danger of static destroy!

Installation

danger

●Please install on flame retardant objects like metal; Be

far away from combustible material. Or it may cause fire

alarm!

●Don’t screw fixed bolt of the equipment component

randomly, particularly the bolt with red sign!

notice

● Don’t drop wire head or screw into the actuator. Or it

may cause the damage of the actuator!

● Please install the actuator at a certain place with litter

vibration and direct sunlight.

● Please pay attention to the installation location when

put two inverters into one cabinet to guarantee the effect

of heat dissipation.

Wiring danger

●Please follow the guidance of this manual and the

construction should be made by professional electrical

engineering staff, or unexpected danger will appear!

●AC frequency vector inverters and power source should

separated by circuit breaker, or it may cause fire alarm!

●Please confirm that the power source is at zero energy

state before the wiring, or it will have electric shock

hazard!

●Please make a correct and standard ground connection

for the AC frequency vector inverters based on the

standard, or it will have electric shock hazard!

● Never connect input power with output terminals (U, V

and W) of the inverter. Pay attention to the sign of

terminal blocks; don’t connect the wire with mistake, or it

may cause the damage of the actuator!

●Make sue circuit matched meets the requirement of

EMC and the safety standard in its region. Please refer to

the suggestion of this manual for wire diameter of the

wire used . Or it may have accident!

● Never connect break resistor between (+) and (-)

terminals of DC bus, or it may cause fire alarm!

●Encoder must use shielded wire; moreover, shielding

layer must guarantee reliable ground connection of a

single terminal.

Chapter 1 Inspection and Safety Precautions

3

Chapter 1

Before

electrifying

notice

●Please confirm whether the voltage class of input power

is consistent with rated voltage class of inverter, whether

the circuit connected is firm enough, or it may cause the

damage of the actuator!

● There is no need in making pressure test for any part of

the inverter; the product is made such as test when it

leaves the factor, Or it may have accident!

danger

●The AC frequency vector inverters must be electrified

after its covered plates is covered well. Or it will have

electric shock hazard!

●The wiring of all outside accessories must strictly follow

the guidance of this manual; and their wirings should be

connected correctly based on the circuit connect menthol

provided by this manual. Or it may have accident!

After

electrifying danger

●Don’t open the cover plate after the electrifying. Or it

will have electric shock hazard!

● Don’t use a wet hand to touch actuator and peripheral

circuit.. Or it will have electric shock hazard!

●Don’t touch any input or output terminal of the inverter.

Or it will have electric shock hazard!

●At the beginning of electrifying, the AC frequency

vector inverters will automatically make a security

detection for outside return circuit of the strong current; at

that time, never touch U, V and W terminal blocks of the

actuator, or it will have electric shock hazard!

● Parameter identification should be made and please pay

more attention to the hazard hurting people during the

rotation of electric machine. Or it may have accident!

● Please don’t change manufacturer’s parameter of the

AC frequency vector inverters randomly. Or it may have

hazard of damaging the equipment!

In service

danger

●Never touch the cooling fan or discharge resistance to

feel out the temperature. Or it may cause burning.

● Non-professional technician can’t detect the signal

during the operation process. Or it may cause personal

injury or equipment damage!

notice

● Anything should be avoided to drop into the equipment

during the operation process of the inverter. Or it may

cause equipment damage!

● Don’t use contractor switching to control the start and

stop of the actuator. Or it may cause equipment damage!

Maintenance danger

● Please don’t repair and maintain the equipment with

electricity. Or it will have electric shock hazard!

● Maintenance and preparing can be made to the actuator

only after confirming the AC frequency vector inverters

voltage is lower than 36V, subject to two minutes after

power failure. Or residual charge on capacitance will

harm people.

● Anybody without professional training can’t make

maintenance or preparing to the inverter.

Or it may cause personal injury or equipment damage!

● Parameter setting must be made after changing the

inverter; all pluggable parts must be inserted or seized

under the condition of power failure!

Chapter 1 Inspection and Safety Precautions

4

Chapter 1

1-3. Precautions

No.

Types of attention Precautions contents

1Insulation inspection of the

motor

Insulation inspection of the motor should be made for the initial use

of the motor, reusing after long-term placing when the motor is

used or given regular inspection to avoid damaging the AC

frequency vector inverters due to the insulation failure of machine

winding, motor connection must be separated with the AC

frequency vector inverters when insulation inspection is made; it is

suggested to use mega meter with 550V voltage type and guarantee

the insulation resistance detected can’t be smaller than 5MΩ.

2Thermal protection of the

motor

Make sure to adjust relevant parameter value of motor protection in

the AC frequency vector inverters or install thermal relay before the

motor to protect the motor when the rated capacity of the selected

motor doesn’t match with that of the inverter, particularly when the

rated power of the AC frequency vector inverters is bigger than that

of the motor.

3Operation above the

power frequency

This AC frequency vector inverters can provide 0Hz~400Hz

output frequency. If the customer wants to make operation above 50

Hz, please take the endurance of the mechanical device into

consideration.

4Vibration of mechanical

device

The setting for hopping frequency in the AC frequency vector

inverters can be used to avoid mechanical resonance point of the

load device which might be met by the AC frequency vector

inverter sat some locations of output frequency.

5About heating and noise of

the motor

Compared with the operation of power frequency, the temperature

rise, noise and vibration of the motor will increase slightly because

the output voltage of the AC frequency vector inverters is PWM

wave.

6

Pressure-sensitive device or

capacitance improving the

power factor at the output

side

If the side the AC frequency vector inverters has capacitance

improving the power factor or voltage dependent resistor for

lighting protection, it will cause instant over current of the AC

frequency vector inverters or damage the AC frequency vector

inverters because the output voltage of the AC frequency vector

inverters is PWM wave. Please don’t use it.

7

Switching element such as

contactor used by input and

output terminal of the

inverter

If contactor between the power supply and input end of the AC

frequency vector inverters is installed, then it won’t allow this

contactor to control the start and stop of the inverter. If it is

necessary to use this contactor to control the start and stop of the

inverter, the interval can’t be bigger than one hour. Frequent

charge-discharge easily shortens the service life of the capacitor in

the AC frequency vector inverters. If switching element such as

contactor installed between output terminal and the motor, it should

be guaranteed that the switching operation of the AC frequency

vector inverters should be made without output. Or it easily causes

the module damage in the inverter.

8Use beside rated nominal

voltage value

It is improper to use PT200 AC frequency vector inverters by and

the voltage range stipulated in this manual; or it easily causes the

device damage in the inverter. If it is necessary, please use

corresponding rising and dropping equipment to make

transformation disposal.

9Change three- phase input

to two-phase input

Don’t change three-phase AC frequency vector inverters of PT 200

to two-phase for use. Or it may cause breakdown or damage the

inverter.

Chapter 1 Inspection and Safety Precautions

5

Chapter 1

No.

Types of attention Precautions contents

10

Protection of lightning

impulse

The AC frequency vector inverters has protection device for

lighting strike and over current; and it has certain self-defensive

ability for the inductive thunder. The customer should install

protection device before the AC frequency vector inverters at

frequent occurrence of the lightning.

11

Use of altitude and derating

It is necessary to use it via derating in the region where the altitude

is above 1000m due to the weakening cooling effect of the AC

frequency vector inverters caused by thin air. Please make a

technology consulting to our company for such a condition.

12

Some special usages

Please consult our company if it is necessary for the customer to

use the connection method beyond the suggestions provided in this

manual, like DC bus.

13

Attention for the

abandonment types of AC

frequency vector inverters

It may cause explosion when the electrolytic capacitor of main

circuit and printed board burn. And the burning of plastic parts will

cause poisonous gas. Please dispose it as industrial refuse.

14

About adaptive motor

1)Standard adaptive motor is asynchronous induction like a

quadruples squirrel cage. If it is not the above motor, please select

the AC frequency vector inverters based on the rated current of the

motor.

2)Cooling fan

3)Zx67y non-variable frequency motor and rotor spindle is

connected with the same axis; cooling effect of the fan reduces

when the rotate speed reduces; therefore, install powerful cooling

fan or replace variable frequency motor when the motor is too hot.

3)The AC frequency vector inverters has been installed with

standard parameter of adaptive motor; it is necessary to make

parameter identification or modify default value according to

practical situation to correspond with the actual value; or it may

affect the operation effect or protection performance.

4)short circuit in the cable or motor will cause the alarm of the

AC frequency vector inverters or even explosion of the motor, so

please make a short-circuit test of insulation for the motor with

initial installation; and it is necessary to make such a test in daily

maintenance. Notice: make sure to completely disconnect the AC

frequency vector inverters with the part required to be testing when

such a test is made.

15

Others

1)Never connect alternating current power supply with terminals

like U, V and W for output end of the inverter.

2)The panel must be fixed and locked before electrifying in order

to avoid personal injury caused by harmful components like

internal capacitance.

3)Tasks such as wiring and inspection can’t be made after the

power is connected.

4)After the electrifying of this device, please don’t touch its

interior circuit and component to avoid electric shock hazard.

5)Don’t touch the circuit board or any component in the motor

within five minutes shown on keyboard after the power is off; what

is more, the meter should be used to confirm the capacitance in the

motor has been discharged and then the task in the motor can be

made; or it may have hazard of electric shock.

6)Electrostatic on human body will seriously affect MOS field

effect transistor; don’t use your hand to touch any internal

component such as printed circuit board and IGBT without anti-

static precautions; or it may cause breakdown.

Chapter 1 Inspection and Safety Precautions

6

Chapter 1

No.

Types of attention Precautions contents

7)Grounding terminal of the AC frequency vector inverters(E or

)7)should be correctly and reliably connected to the ground

based on salty requirement of national electricity and other related

standards. Don’t stop the motor via operating a switch or

interruption of power supply; and the power can be off only after

the stop of the motor operation when it is used .

8)It must select input filter accessory if it want to meet CE

standard.

1-4 Range of application

※This AC frequency vector inverters can be applied only to general three-

phase AC induction motor of industry.

※This AC frequency vector inverters can be only used in places approved by

our company; it may cause accidents like fire, electric shock and explosion in

the places not approved by our company.

If it used for the equipment (e.g. Lifting appliance, aviation system and safety

equipment)which may cause personal injury due to the AC frequency vector

inverters failure, such an occasion must be cautiously disposed and reported to our

company.

This device is only allowed to be operated by the staff with

qualified training. Please carefully read the content about safety,

installation, operation and maintenance in this introduction before your

use. Safe operation of this device depends on the correct transportation,

installation, operation and maintenance.

Chapter 2 Standard specification

Chapter 2

7

Chapter 2 Standard specification

2-1 Technical specifications

2-1-1.Technical specifications of PT200

AC frequency

vector inverters

type

Input voltage output

rating (kW)

Rated input

current(A)

Rated output current

(A)Adaptive motor

PT200-0R4G-1B

Single

phase 220V

±15

%

0.4 5.4 2.4 0.4

PT200-0R7G-1B 0.75 8.2 4.5 0.75

PT200-1R5G-1B 1.5 14.2 7.0 1.5

PT200-2R2G-1B 2.2 23.0 10 2.2

PT200-004G-1B 3.7 34.0 16 3.7

PT200-0R7G-2B

Three phase

220V

±15%

0.75 5.0 4.5 0.75

PT200-1R5G-2B 1.5 7.7 7 1.5

PT200-2R2G-2B 2.2 11.0 10 2.2

PT200-004G-2B 3.7 17.0 16 3.7

PT200-5R5G-2B 5.5 21.0 20 5.5

PT200-7R5G-2B 7.5- 31.0 30 7.5

PT200-011G-2B 11.0 43.0 42 11.0

PT200-015G-2 15.0 56.0 55 15.0

PT200-018G-2 18.5 71.0 70 18.5

PT200-022G-2 22.0 81.0 80 22.0

PT200-030G-2 30.0 112.0 110 30.0

PT200-037G-2 37.0 132.0 130 37.0

PT200-045G-2 45.0 163.0 160 45.0

PT200-055G-2 55.0 200.0 200.0 55.0

PT200-0R7G-3B Three phase

380V

±15%

0.75 3.4 2.5 0.75

PT200-1R5G-3B 1.5 5.0 3.7 1.5

PT200-2R2G-3B 2.2 5.8 5 2.2

PT200-004G-3B/

PT200-5R5P-3B 4.0/5.5 10/15 9/13 4.0/5.5

PT200-5R5G-

3B/ PT200-

7R5P-3B

5.5/7.5 15/20 13/17 5.5/7.5

PT200-7R5G-

3B/ PT200-011P-

3B

7.5/11.0 20/26 17/25 7.5/11.0

PT200-011G-3B/ 11.0/15.0 26/35 25/32 11.0/15.0

Chapter 2 Standard specification

Chapter 2

8

AC frequency

vector inverters

type

Input voltage output

rating (kW)

Rated input

current(A)

Rated output current

(A)Adaptive motor

PT200-015P-3B

PT200-015G-3B/

PT200-018P-3B 15.0/18.5 35/38 32/37 15.0/18.5

PT200-018G-3B/

PT200-022P-3B 18.5/22.0 38/46 37/45 18.5/22.0

PT200-022G-3B/

PT200-030P-3B 22.0/30.0 46/62 45/60 22.0/30.0

PT200-030G-3/

PT200-037P-3 30.0/37.0 62/76 60/75 30.0/37.0

PT200-037G-3/

PT200-045P-3 37.0/45.0 76/90 75/90 37.0/45.0

PT200-045G/

PT200-055P-3 45.0/55.0 90/105 90/110 45.0/55.0

PT200-055G-3/

PT200-075P-3 55.0/75.0 105/140 110/150 55.0/75.0

PT200-075G-3/

PT200-093P-3 75.0/93.0 140/160 150/176 75.0/93.0

PT200-093G-3/

PT200-110P-3 93.0/110.0 160/210 176/210 93.0/110.0

PT200-110G-3/

PT200-132P-3 110.0/132.0 210/240 210/250 110.0/132.0

PT200-132G-3/

PT200-160P-3 132.0/160.0 240/290 250/300 132.0/160.0

PT200-160G-3/

PT200-185P-3 160.0/185.0 290/330 300/340 160.0/185.0

PT200-185G-3/

PT200-200P-3

185.0/200.0 330/370 340/380 185.0/200.0

PT200-200G-3/

PT200-220P-3 200.0/220.0 370/410 380/420 200.0/220.0

PT200-220G-3/

PT200-250P-3 220.0/250.0 410/460 420/470 220.0/250.0

PT200-250G-3/

PT200-280P-3 250.0/280.0 460/500 470/520 250.0/280.0

PT200-280G-3/

PT200-315P-3 280.0/315.0 500/580 520/600 280.0/315.0

PT200-315G-3/

PT200-350P-3 315.0/350.0 580/620 600/640 315.0/350.0

PT200-350G-3/

PT200-400P-3 350.0/400.0 620/670 640/690 350.0/400.0

PT200-500G-3/

PT200-560P-3 500.0/560.0 835/920 860/950 500.0/560.0

PT200-560G-3/

PT200-630P-3 560.0/630.0 920/1050 950/1100 560.0/630.0

PT200-630G-3/

PT200-700P-3 630.0/700.0 1050/1250 1100/1300 630.0/700.0

PT200-700G-3 700.0 1250 1300 700.0

Three

phase

380V

±15%

Chapter 2 Standard specification

Chapter 2

9

2-1-2 See the following table for rated output current with different

specifications

G/P/M/H

Voltage 220V

1Ф

220V

(240V)

380V

(415V)

460V

(440V) 575V 660V

Power (KW)

Current (A) Current (A) Current (A) Current (A) Current (A) Current (A)

0.4 2.4 2.4 1.2 - - -

0.75 4.5 4.5 2.5 2.5 - -

1.5 7 7 3.7 3.7 - -

2.2 10 10 5 5 - -

4 16 16 9 8 - -

5.5 - 20 13 11 - -

7.5 - 30 17 15 - -

11 - 42 25 22 17 15

15 - 55 32 27 22 18

18.5 - 70 37 34 26 22

22 - 80 45 40 33 28

30 - 110 60 55 41 35

37 - 130 75 65 52 45

45 - 160 90 80 62 52

55 - 200 110 100 76 63

75 - 260 150 130 104 86

93 - 320 176 147 117 98

110 - 380 210 180 145 121

132 - 420 250 216 173 150

160 - 550 300 259 207 175

185 - 600 340 300 230 198

200 - 660 380 328 263 218

220 - 720 420 358 287 240

250 - - 470 400 325 270

280 - - 520 449 360 330

315 - - 600 516 415 345

350 - - 640 570 430 370

400 - - 690 650 520 430

500 - - 860 800 650 540

560 - - 950 900 730 600

630 - - 1100 1010 820 680

700 - - 1300 1120 910 750

Chapter 2 Standard specification

Chapter 2

10

2-2 Standard specification

Item Standard

Power supply Level of voltage frequency

Single phase 200~240V, 50/60Hz three phase 200~

240V,50/60Hz

three phase 380~415V, 50/60Hz three phase 440~

460V,50/60Hz

three phase 575V,50/60Hz three phase 660V,

50/60Hz

three phase 1140V, 50/60Hz

Allowable fluctuation Voltage :±15% frequency: ±5%

Control

performance

Control system AC frequency vector inverters with vector control based

the high performance of DSP

Output frequency G/P/Z/S/T/M type: 0.00~400.0Hz,

The highest frequency can be set among 10.00~400.0Hz

Control method

V/F control, vector control for flux with open loop 1,

vector control for flux with open loop 2,

vector control for PG

Lifting function

of automatic torque

Torque control for low frequency (1Hz) and great output

in the control method of V/F

Control on accelerating and

decelerating

Setting method for subsections of accelerating and

decelerating S curve; the longest operation time 9600 h

Control on programmed

operation

Operation for speed program of 16 sections; the longest

operation time 888.88 h

Image resolution of

frequency setting

Figure: 0.01Hz(below300Hz),0.1Hz( above300Hz)

simulation: 0.05Hz / 60Hz

Frequency accuracy Common difference of speed control 0.01%(25℃±10℃)

V/F curve method User defines V/F curve for linear and multiple power

Overload capacity

G/S type: rated current 150%-1 minute, rated current

200%-0.1 second

P type :rated current 120%-1 minute,rated current

150%-0.1 second

Z/M/ T type: rated curren180%-1minute,rated

curren250%-0.1 second

H type :rated current 250%-1 minute, rated current

300%-0.1 second

Slippage compensation 50~100%, compensation for automatic slippage

The highest frequency 400Hz

Carrier frequency 0.5KHz~15KHz; carrier frequency can be adjusted

based on the load characteristics

Image resolution of output

frequency

Figure setting: 0.01Hz simulation setting: the highest

frequency × 0.1%

Starting torque G motor: 0.5Hz/180%

P motor: 0.5Hz/120%

Speed range 1:200

Accuracy of speed

stabilizing Vector control for flux with open loop:≤±0.5% (rated

Chapter 2 Standard specification

Chapter 2

11

Item Standard

(accuracy of speed control) synchronous speed)

Stability of speed control

vector control for flux with open loop :≤±0.3%(rated

synchronous speed)

Torque response ≤40ms (vector control for flux with open loop)

Torque boost

Automatic torque boost; manual torque boost 0.1%~

30.0%

acceleration and

deceleration line

Linear acceleration and deceleration time; 4 acceleration

and deceleration time; time scope for acceleration and

deceleration 0.0s~3600.0s

DC braking

DC braking frequency :0.0Hz~maximum frequency,

braking tine:

0.0~50 second,current value for braking movement:

0.0%~150%

Electronic control

Range of jog frequency :0.00Hz~maximum frequency;

Acceleration and deceleration time of jog: 0.0s~3600.0s

Operation on multi sections

Realize the maximum operation of 16 sections via

control terminals

Build-in PID

Realize closed-loop control system with process control

conveniently:

Automatic voltage

regulation (AVR)

Automatically make the output voltage constant when the

network voltage changes

Torque limitation and

control

Excavator characteristics: automatic limitation on torque

during the operation period and prevention for frequent

over current trip; and vector model of close loop can

realize the torque control

Personalized

function

Self-checking for outside

equipment safety of

electrifying

Realize the security detection of electrifying on outside

device like ground connection and short circuit

Function of DC bus Realize the function for many inverters to share DC bus

M F

key

Programmable key: function choice for positive and

negative operation and jog operation

Pendulous control of textile Multi control functions of triangular wave

Current -limiting function

of the carrier

Built- in current-limiting algorithm of waveband reduces

the probability for the AC frequency vector inverters to

report over current and improve the whole motor’s ability

on resisting disturbance

Timing control Timing control function: setting time scope 0h~65535h

Standardization for extension

cord of the keyboard

The customer can use the standard network cable to

prolong the keyboard

Operation Inputting

signal

Operation

method Keyboard/terminal/communication

Frequency

setting

Six frequency source in total: setting of keyboard,

analogue voltage, analogue current, operation for

multiple sections, PID control, remote communication

and presetting of keyboard potentiometer can be changed

via multiple methods

Starting

signal forward and reversion

Speed of

Speed for 16 sections can be set at most (using

Chapter 2 Standard specification

Chapter 2

12

Item Standard

multiple

sections

multifunction terminal or program execution)

Acceleration

of multiple

sections

Acceleration 4 sections can be set at most (using

multifunction terminal )

Emergency

stop Interrupt controller output

Swing-

frequency

running

Operation of process control

Jog Operation with low speed

Fault

resetting

Automatically or manually reset the fault state when the

protection function is at an effective state

PID feedback

signal

Including DC 0~10V, DC 1~5V, DC 0~20mA and DC

4~20mA

Outputting

signal

Operating

condition

Motor situation showing stop, acceleration and

deceleration, constant speed and state of programmed

operation

Fault output Output of sensitive point-AC 250V 5A, DC 30V 5A

Analog

output

Two analog outputs can choose 8 signals such as

frequency, current, voltage and so on; and output signal

scope can be set randomly among 0~10V/0~20mA.

Output of

digital

quantity

Up to three output signals; every output signal has nine

signals for choice

Operation function

Limiting frequency, avoiding frequency, slippage

compensation, invert protection, self-adjusting and PID

control

Braking of direct current

Built-in PID adjusts brake current and protects sufficient

braking torque without over current

Run command channel

Three channels: presetting of operation panel, control

terminal and serial communication. The change via

various methods

Input terminal

Six digital input terminals can be compatible with active

loudspeaker PNP or two input terminals of analog of

NPN input method; among them, AI1 and AI2 can be

input as voltage or current. (if it necessary to expand the

function of input and output terminals, please use IO

expansion cards)

Output terminal

One digital output terminal (bipolar output), a relay output

terminal, and an analog output terminal can respectively

choose 0/4mA~20mA or 0/2V~10V and realize the

output of physical quantities such as setting frequency,

output frequency and rotate speed

Protection

function

AC frequency vector

inverters protection

Overvoltage protection, low-voltage protection, over

current protection, overload protection, overheat

protection, protection of over current and speed reduction,

protection of overvoltage and speed reduction, protection

of default phase (optional functions), external fault,

communication error, abnormal feedback signal of PID

and PG fault

IGBT temperature display Display current IGBT temperature

Control of AC frequency

Starting temperature for the fan can be set

Chapter 2 Standard specification

Chapter 2

13

Item Standard

vector inverters fan

Instant power failure and

then restarting

Less than 15 millisecond: Continuous operation

More than 15 millisecond: automatically detect the motor

speed and restart after instant power failure

Tracking method of rotate

speed

Automatically track motor speed at the start of the

inverter

Protection function of

parameter

Protect the AC frequency vector inverters parameter via

setting supervisor password and decode

Display

LED/O

LED

show

keyboar

d

Operation

information

18 monitoring objects of the operation in total: operation

frequency, setting frequency, rated current of the motor,

current percentage, DV bus voltage, output voltage, actual

speed of the motor, accumulative operation time, IGBT

temperature, PID given value, feedback value of PID, state

of input terminal, state of output terminal, value of analog

AI1, value of analog AI2A, current number for speed of

multiple sections and setting value of torque

Error message

Keep five error messages at most and inquire fault type,

voltage, current, frequency and working condition when

the fault occurs

LED display Display parameter

OLED display Options available; inverter in Chinese/English

Parameter copy

Using special keyboard of parameter copy can realize the

quick copy of the parameter (limited too OLED)

Key lock and function

choice

Realize partial or complete lock of the button; define the

effect scope of partial buttons to prevent wrong operation

Communicati

on RS485/RS232

It can choose isolated RS485/RS232 communication

module to realize the communication with the upper

computer

Environment

Environment temperature -10℃~40℃( environment temperature is among 40℃~

50℃; please use it with derating)

Storage temperature -20℃~65℃

Environment humidity Less than 90 % R.H,not exceeding 90 % R.H

Height; vibration Below 1000 m, below 5.9m/s²(=0.6g)

Application place

Indoor, without sunlight or corruption, explosive gas or

water vapor, dust, combustible gas, oil mist, water vapor,

dropping water or salinity

Altitude Belong 1000m

Pollution degree 2

Product

standard

The product implements

safety standard IEC61800-5-1:2007

The product implements

EMC standard IEC61800-3:2005

Cooling method Forced cooling and natural air cooling

Table of contents

Popular DC Drive manuals by other brands

Pfeiffer Vacuum

Pfeiffer Vacuum TC 1200 EC operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley PowerFlex 755 installation instructions

Trane

Trane TR200 Series Programming guide

Rhymebus

Rhymebus RM6S2 Series Parameter manual

Danfoss

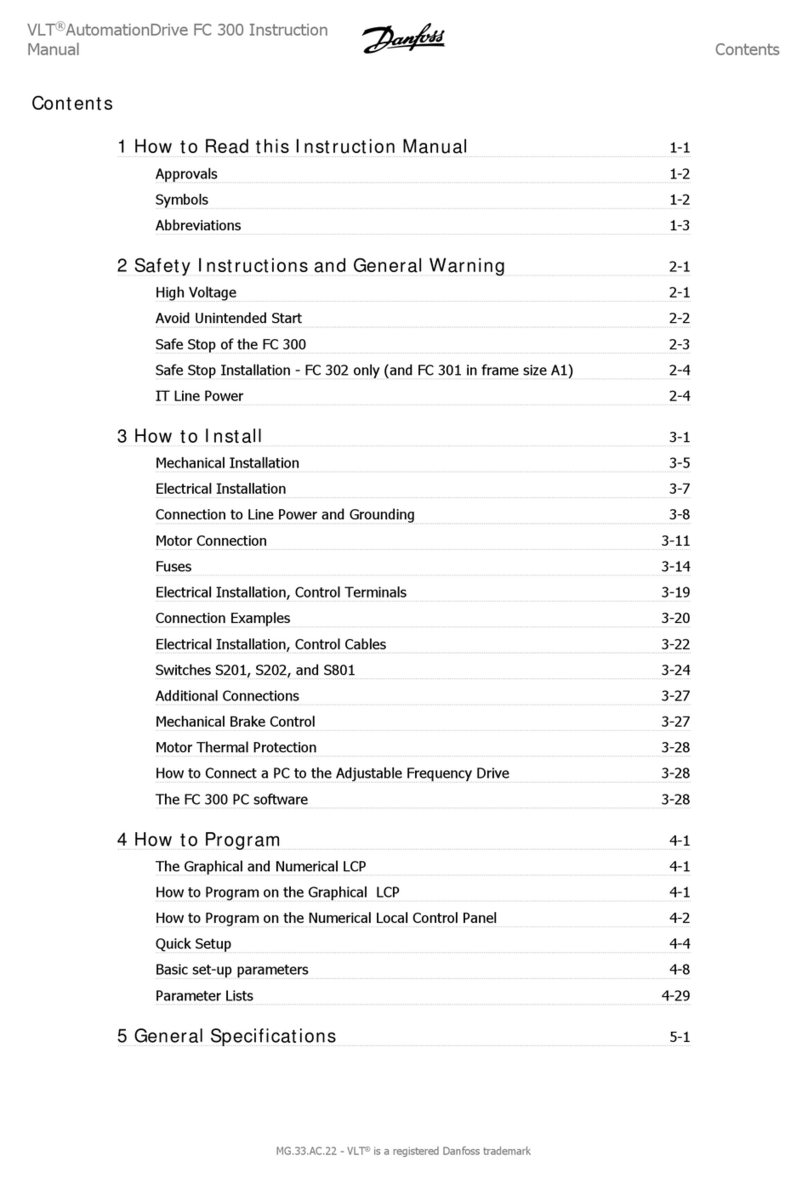

Danfoss VLT AutomationDrive FC 300 instruction manual

Genesis

Genesis KBMK Series Installation and operation manual