1

Thank you for using RHYMEBUS RM6S2/S3 series drive. For proper operations and

safety purposes, please do read and follow specific instructions contained in this manual

before using the product.

Safety Precaution

1. Do Not conduct any wiring during the system power ON to avoid the electric shock.

2. R/L1, S/L2, T are power inputs and U, V, W are drive’s outputs to the motor. Please

do not connenct the wrong wire to the P and PR terminal.

3. Once the wiring is complete, the cover of the drive must be put back to avoid other’s

accidental contact.

4. Do Not connect the power of 346/380/415/440/460/480V to 200V series.

5. The grounding terminal ( ) must be exactly grounded. The grounding method

must compliance with the NEC standard or local electrical code.

6. Please refer to the national or local electric code for the appropriate spec of the

cords and wires.

7. Please install an appropriate Molded Case Circuit Breaker (MCCB) or Fuse at each

path of power lines to a drive.

8. Do Not connect power factor leading capacitor, surge absorber, or non-three-phase

motor to the drive’s U, V, or W side.

9. Do Not touch the drive or performing any unwiring actions in the 5 minutes before

drive indicator light turns off after the power off.

10. At the function A3-14=1 or 3, the

key on the operation panel is ineffective.

Please use an emergency stop switch separately for safe operations.

11. At the function L2-00= 1 or 3, the drive will automatically restart when the power is

restored. Stay away from the motor and machine.

12. The drive can produce high frequency outputs. Before adjusting the frequency,

please check the specs of motor carefully to prevent the motor from unexpected

damages.

13. If any of the protective functions have been activated, and b1-02 is set to 1, first

remove the case and check the all start commands set to OFF. Then press the

key to release the alarm.

1. The RM6S2/S3 series outputs are designed to drive a three-phase induction motor.

Do Not use for single-phase motor or using for other purposes.

2. The main circuit and control circuit must be wired separately; control circuit must use

a shielded or twisted-pair shielded wires to avoid possible interferences.

3. Do Not touch the heat sink or braking resistor due to the high heat.

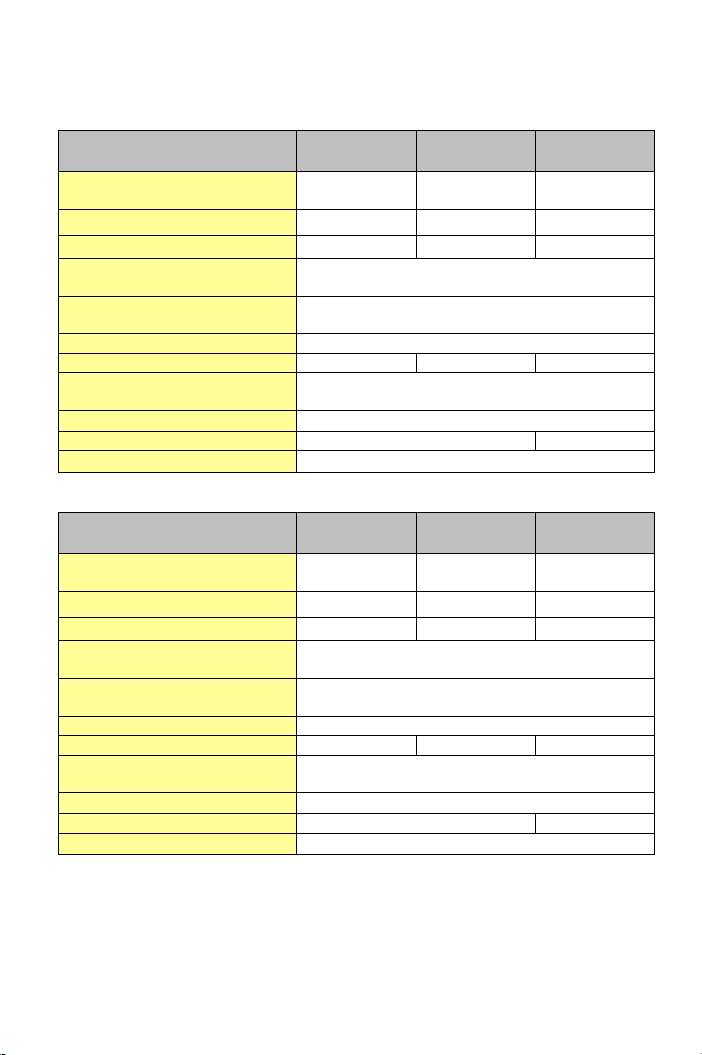

Environmental conditions

Non-corrosive or non-conductive, or non-explosive gas

or liquid, and non-dusty

-10℃~+50℃(14℉~122℉) (Non- condensing and

non-freezing)

95% RH or less (No-condensing atmosphere)

Less than 5.9m/ sec2 (0.6 G)

Less than 1000 m(3280ft.)