Shibaura TF516MH-AB User manual

FIREFIGHTING PUMP

TF516MH-AB

OWNER’S MANUAL

Please read this operation manual carefully in order to operate the

Shibaura Firefighting Pump in safe and in correct manner. If the pump is

operated incorrectly, any accident may result. If this manual is missing or

damaged, give an order for new one to us or our agent promptly.

○CONTENTS

⚫For safe operation ------------------------------------------- 1

1. Matters to be attended to for safety

1. Warning label locations ---------------------------------- 2

2. Caution marks -------------------------------------------- 3

2. Name of components ---------------------------------------- 7

3. Handling of pump

(Before starting operation) --------------------------------- 9

(Operating method) ---------------------------------------- 13

(Discharging with multiple pumps) ------------------------ 19

(Suction and discharge of water from Fire hydrant) ------ 20

(Operation in cold districts in winter) --------------------- 22

4. Periodical inspections

1. Periodical inspection schedule -------------------------- 23

2. Inspection method -------------------------------------- 24

5. Troubleshooting --------------------------------------------- 29

6. Specifications ------------------------------------------------ 34

7. Wiring diagram ---------------------------------------------- 36

1

●For safe operation

The operation manual is a part of machine.

Keep this manual carefully with the firefighting pump.

⚫In this manual, mark indicates particularly important instructions

for safe operation. You should pay attention specifically to those

marked descriptions and observe such instructions.

Danger

If the machine is operated

incorrectly, there is high possibility

of death or serious injury.

Warning

If the machine is operated

incorrectly, death or serious injury

may result

Caution

If the machine is operated

incorrectly, minor injury or damage

of assets may result

⚫Quality or performance of the machine may be improved or its

components may be modified for the purpose of safety. For this

reason, contents of the text in this manual or photographs or

illustrations may be different from actual ones.

2

1. Matters to be attended to for safety

1. Warning label locations

Warning labels are attached to the positions of the firefighting pump as shown

below. If the labels are peeled off or damaged, please order new ones telling the

part No. as shown for each label.

Recoil starter side

Pump side

3

1. Matters to be attended to for safety

2. Caution marks

(1) General instructions

Warning

The firefighting pump should be operated only by such a man among fire

officers, firemen, volunteer disaster prevention expedition team member,

and maintenance/inspection service men that has been specifically trained

for safe operation.

〈If you do not observe the instruction〉

Serious accident including death may result due to incorrect operation.

Caution

Be sure to carry out periodical maintenance inspections.

〈If you do not observe the instruction〉

Accident due to damage of the machine or components may result or

firefighting activities may be interfered.

Warning

Wear a helmet, shoes with creepers, and clothes without looseness.

〈If you do not observe the instruction〉

You may be caught by the machine, or slip and fall, and injured.

Warning

Do not operate the firefighting pump if you cannot concentrate your attention

on operation as you are drunken, fatigued, sick, or under influence of drug.

〈If you do not observe the instruction〉

Serious accident may result.

Caution

Do not use the firefighting pump for activities other than firefighting such as

civil engineering work, irrigation, water sprinkling, etc.

〈If you do not observe the instruction〉

You may flip some objects to injure people or damage assets around you.

Danger

Do not suck in or discharge substances other than water such as

combustibles, liquid such as chemical.

〈If you do not observe the instruction〉

Explosion, fire, burning, or poisoning may result.

Caution

When throwing away the battery, oil, or grease, entrust a professional

industrial waste disposal dealer with their disposal.

〈If you do not observe the instruction〉

Fire may break out, you may be burned, or environment may be polluted.

4

1. Matters to be attended to for safety

Warning

Use only genuine parts and designated attachments.

〈If you do not observe the instruction〉

Accident, injury, or machine failure may result.

(2) Cautions before starting operation

Warning

Install the pump more than 3 m apart from combustibles.

〈If you do not observe the instruction〉

Fire may be caused because of high temperature exhaust gas.

Warning

Remove dried grass and other objects which may catch fire easily before

installing the pump.

〈If you do not observe the instruction〉

Fire may be caused by the heated muffler.

Danger

Do not bring fire close when supplying fuel.

〈If you do not observe the instruction〉

The fuel may catch fire and explode.

Danger

When supplying fuel, do not allow the fuel level to exceed the “F” mark.

If fuel spills, wipe away immediately and do not bring that cloth close to fire.

〈If you do not observe the instruction〉

The spilled fuel and the cloth may catch fire and explode.

Caution

After supplying fuel, close the fuel tank cap securely.

〈If you do not observe the instruction〉

The fuel may catch fire and explode.

Warning

Do not install the pump indoors or in the tunnel or the like where is badly

ventilated.

〈If you do not observe the instruction〉

You may get poisoned by exhaust gas.

Caution

The firefighting pump should be carried, loaded or unloaded by two persons.

〈If you do not observe the instruction〉

The pump may drop on your foot and injure, or you may get a crick in the

back.

5

1. Matters to be attended to for safety

Caution

Connect the fire hose securely and make sure that it does not fall out.

〈If you do not observe the instruction〉

If the hose falls out while water is being discharged, it may injure people

around it.

Caution

Avoid bending, twisting or sharp turn of the fire hose when installing.

〈If you do not observe the instruction〉

The hose may leap up and injure people around it.

(3) Caution during operation

Caution

After draining the fuel from the carburetor, wipe away the spilt fuel

immediately.

〈If you do not observe the instruction〉

The spilt fuel may catch the fire.

Caution

When starting the engine using a rope, do not allow people to be within 2 m

around the pump.

〈If you do not observe the instruction〉

They may be beaten by your elbow or the rope and injured.

Danger

Before replenishing the fuel during operation, wait until the engine cools

down enough.

〈If you do not observe the instruction〉

The fuel may catch fire and explode.

Caution

Open and close the water discharge valve always after returning the engine

speed to slow.

Hold the play hose positively and wear the back band before discharging the

water.

〈If you do not observe the instruction〉

You may lose control of the play hose and be injured when water discharging

is started.

Caution

Do not direct the nozzle to other people or do not peep into it.

〈If you do not observe the instruction〉

You may be sent flying by high pressure and injured.

Caution

Do not touch the ignition plug or high-tension cord during operation.

〈If you do not observe the instruction〉

You may receive an electric shock.

6

1. Matters to be attended to for safety

Caution

Never touch the muffler and exhaust pipe during operation since they

become very hot.

〈If you do not observe the instruction〉

You may be burned.

(4) Caution for inspections and services

Warning

When the battery cap is removed, do not bring fire close to it.

〈If you do not observe the instruction〉

The electrolyte in the battery may catch fire and explode.

Warning

The electrolyte of the battery is strong acid. Do not allow it to touch your

body or clothes.

If the electrolyte remains, dilute it with water to more than 10 times and then

discard.

〈If you do not observe the instruction〉

You may be burned or clothes or assets may be damaged.

Caution

Before starting inspections or service, stop the engine and wait until it cools

down sufficiently.

〈If you do not observe the instruction〉

You may be hurt or burned and fire may occur.

Caution

When disconnecting the battery cord, remove the (-) cord first and when

installing, install the (+) cord first.

〈If you do not observe the instruction〉

Short circuit may occur and burn you.

Warning

Remove the packing materials from the charger when charging with it.

〈If you do not observe the instruction〉

Fire may break out.

Caution

Install the charger at a dry and well-ventilated place where it does not get

wet.

〈If you do not observe the instruction〉

Electric shock or fire may result.

Caution

Only use a designated charger.

〈If you do not observe the instruction〉

Fire may occur due to overheat or damage of the wiring by a fire.

7

2. Name of components

Recoil starter side

Operating side

8

2. Name of components

Pump side

Non-operation side

9

3. Handling of pump (Before starting operation)

1. Unpacking

(1) Check the name of the machine shown on the box surface to see whether it is

what you ordered.

(2) Cut the band bound on the box.

(3) Pull up the box; the main unit of the machine and accessories will come out.

(4) Check that the following components are included.

A. Main machine unit (One as ordered? Not damaged?) 1

B. Battery 1

C. Charger 1

D. Tool bag 1

E. Pump cover 1

The main unit is covered with a thin vinyl cover. Be sure to remove it before

operating the machine.

2. Mounting the battery

(1) Fix the battery with the supplied rubber band to the battery box.

(2) Connect the two (+) battery cords (red) and then (-) cord (black) with the

attached hexagon bolts and nuts.

○When disconnecting the battery cords, disconnect the (-) cord first and

connecting, connect the (+) cord first.

⚫If not, short circuit may result leading to a fire or you may get burnt.

(3) Charge the battery for 2 to 3

hours.

This battery is sealed type

requiring no water

replenishment. See the

operation manual for the

battery for details.

Caution

10

3. Handling of pump (Before starting operation)

3. Replenishing the fuel

(1) Supply the fuel into the tank (tank capacity 4.2L).

The engine of this firefighting pump is fueled

independently of the lubricating tank. Supply

automobile regular gasoline up to the “F” mark of

the fuel gauge. Do not use mixed gasoline and

Bio-gasoline.

○Do not bring a fire close to the engine when supplying fuel.

○Do not allow the fuel to exceed the “F” mark of the gauge.

○If the fuel spills, wipe it away immediately. Do not bring that cloth to a fire

⚫It may catch fire and explode.

○After supplying fuel, close the fuel tank cap securely.

⚫If not, the fuel may catch fire and explode.

(2) Supply 2-cycle engine oil (tank capacity 0.4L).

The fire pump is a separate filling type. Supply

the 2-cycle engine oil to the engine oil tank

provided on the lower part of the pump.

Caution

Lights when the oil tank level is too low

thereby stopping the engine.

○If you want to supply the 2-cycle oil, please put the oil of same brand and

same grade.

○At the time of 2 cycle oil supply, please prevent water and dirt from the oil

inlet.

⚫Cause of the malfunction or equipment failure of the engine.

○Oil spills, please wipe completely with a cloth or the like.

⚫There is a risk of injury by falling slipped.

Caution

Danger

Caution

Caution

11

3. Handling of pump (Before starting operation)

4. Installation

(1) Place the pump on a flat place close to a water source.

○Install the pump more than 3 m from combustibles.

○Remove dried grass and other objects which may catch fire easily before

installing the pump.

⚫If not, fire may be caused by the heated muffler.

○Do not install the pump indoors or in the tunnel or the like where is badly

ventilated.

⚫If not, you may get poisoned by exhaust gas.

(2) Be sure to attach the strainer and a rattan basket to the water suction port of

the water suction hose and position it more than 30 cm below the water level.

If it is positioned above the specified level, air may be sucked preventing

water discharging.

(3) Arrange the pump so that the water suction height is 3 m or less as low as

possible. When it is too high, the pumping capacity may deteriorate or water

may fall.

(4) Arrange the water suction hose to go up toward the pump and tighten it

positively to the water suction port of the pump. If the hose goes up or down

unevenly, water may not be discharged smoothly.

○Connect the fire hose securely and make sure it does not fall out.

⚫If the hose falls out while water is being discharged, it may injure people

around it.

○Avoid bending, twisting or sharp turn of the fire hose when installing.

⚫The hose may leap up and injure people around it.

Warning

Warning

Caution

Caution

12

3. Handling of pump (Before starting operation)

5. Operator

(1) Though the firefighting pump is small-sized, it is a high-performance

machine generating strong power. If it is operated in a wrong way, serious

accident including death may be caused.

○The firefighting pump should be operated by such a man among fire officers,

firemen, volunteer fire prevention expedition team member, or

maintenance/inspection service man that has been specifically trained for

safe operation.

(2) Clothing should be suited to work.

○Wear a helmet, shoes with creepers, and clothes without looseness.

⚫You may be caught by the machine, or slip and fall, and get injured.

(3) Do not operate the firefighting pump when you are sick.

○Do not operate the firefighting pump if you cannot concentrate your attention

on operation as you are drunken, fatigued, sick, or under influence of drug.

⚫If you do not follow the instruction, serious accident may result.

6. Transportation

(1) Transport the firefighting pump holding at the frame.

○The firefighting pump should be carried, loaded or unloaded by two persons.

⚫The pump may drop on your foot and injure, or you may get a crick in the back.

Warning

Warning

Warning

Caution

13

3. Handling of pump (Operating method)

1. Starting the engine

Before starting the engine, close the water discharge valve and pump drain cock.

Water discharge valve Pump drain cock

(1) Open the fuel cock ①

Pull down the fuel cock lever to the lowest point to

open it.

※Operation of tickler

○Pressing the tickler button for several

seconds while the engine is cold will facilitate

the engine start.

○When the engine is still warm after the

operation, never press the tickler.

○If the engine is not started because the tickler

is operated excessively, close the fuel cock,

discharge the fuel from the carburetor drain

valve and then start the engine.

○After operating the tickler or discharging the fuel from the carburetor, wipe

away the spilt fuel immediately.

⚫It may catch fire and explode.

Caution

14

3. Handling of pump (Operating method)

(2) Set the throttle dial ② to the “START”

position. (When the engine is warmed by

the warming-up process, set the throttle

dial ② to the “RESTART” or “SLOW”

position.)

(3) Turn the main switch ③ fully clockwise to

the “START” position.

After the engine is started, leave your

hand from the switch.

(4) When using the rope to start the engine,

pull the recoil starter handle ③forcibly.

○In case an engine does not start so well due to an excessive fuel like after

running for warm-up, turn off the fuel cock, drain all of gasoline in carburetor,

then start the engine again.

After the engine starts, turn on the fuel cock. When it stops, just take the

stating operation again.

○When you drain the fuel of the carburetor, please wipe the immediately flowed

out fuel.

⚫It may catch fire and explode.

Caution

15

3. Handling of pump (Operating method)

2. Sucking up the water

(1) Set the throttle dial ② to the “SUCTION”

position.

(2) Pull the water suction lever ④ toward

you and operate the vacuum pump to

suck up the water.

○When the pointer on the pressure

gauge starts to move, return the

water suction lever promptly.

3. Discharging the water

(1) Open the water discharge valve lever ⑤

gradually to “→O” position until it stops.

○Communicate with the person at the snout and discharge water

adjusting the pressure with the throttle dial ② depending on the

situation of the fire site.

○Keep the pointer on the pressure gauge and compound gauge in the

green range when discharging the water.

(2) By inserting the search light plug into the receptacle, the lamp lights up.

○Open and close the water discharge valve lever always after returning the

engine speed to low speed.

○Hold the nozzle at the end positively and wear the back band before charging

the water.

⚫It not, you may lose control of the nozzle at the end and be injured when water

charging is started.

○Do not direct the nozzle to other people or do not peep into it.

⚫You may be sent flying by high pressure and injured.

Caution

Caution

16

3. Handling of pump (Operating method)

○Do not touch the ignition plug or high-tension cord during operation.

⚫You may receive an electric shock.

○During operation or immediately after operation, the exhaust pipe becomes

very hot. Never touch them

⚫You may be burnt.

4. Stopping the engine

(1) Set the throttle lever ② to the “SLOW”

position.

○If the engine is hot, cool it down by

continuing low speed operation for

about 1 minute.

(2) Turn the water discharge valve lever in the

“→ Close” direction and close the water

discharge valve.

(3) Set the main switch ③ to the “Stop” position.

5. Draining the water

After the firefighting pump was operated, much water remains inside. If the water

is left in the pump, rust may be generated or the pump may be damaged due to

frozen water in the cold season. Be sure to drain water before storing the

firefighting pump.

(1) After sea water or dirty water is used, be sure to keep clear water discharged

for more than 5 minutes.

(2) Close the water discharge valve lever.

(3) Open the pump drain cock, discharge the water completely and then close

the pump drain cock.

(4) Screw in the cap of the water inlet.

(5) Start the engine and pull the water suction lever for about 5 seconds.

(6) Stop the engine.

(7) Open the pump drain cock, release the vacuum and close the drain cock

again.

If the vacuum is not released, rubber of valves may be deformed shortening

its service life.

Caution

Caution

17

3. Handling of pump (Operating method)

6. Connecting a hose

○Insert the plug-in intermediate fixture until clicking. Hold the receiving fixture

and pull the plug-in fixture to check that the claw is hitched on the collar and

joined firmly.

⚫In case of a screw type intermediate fixture, tighten positively until the packing

of the receiving fixture (female screw) touches the plug-in fixture (male screw).

○While the plug-in type intermediate fixture is used (while water is being

discharged), never touch the pushing ring. If the pushing ring is pushed in

while the water is being sent, the fixture may be disconnected, causing an

accident resulting in injury or death.

7. Lamp

(1) When the engine is started, and you

leave the hand from the main switch, the

lamp of the meter goes out. By returning

the switch position by one, the lamp

lights up.

(2) By inserting the search light plug into the

plug receptacle, the lamp lights up.

Warning

18

3. Handling of pump (Operating method)

8. Storing the pump

The firefighting pump is such a machine that is usually out of operation after being

operated for a short time.

Therefore, storing it under proper condition is essential in order that the pump

operates satisfactorily when required next time or to secure its long life.

(1) Environment

Place the pump at a dry and cool place avoiding dust or direct sun beams.

(2) Supply fuel and lubricating oil to specified level.

(3) Drain the fuel in the carburetor from the drain cock positioned under the

pump.

○After operating the tickler or discharging the fuel from the carburetor, wipe off

the spilt fuel immediately.

⚫It may catch fire and explode.

(4) Cover the pump.

Caution

Table of contents

Other Shibaura Water Pump manuals

Popular Water Pump manuals by other brands

Graco

Graco HIGH-FLO 243737 instructions

KSB

KSB Ama-Drainer-Box Mini Supplementary Operating Manual

ProFlow

ProFlow PFETP-1000 owner's manual

Dynaset

Dynaset HSP 2600 user manual

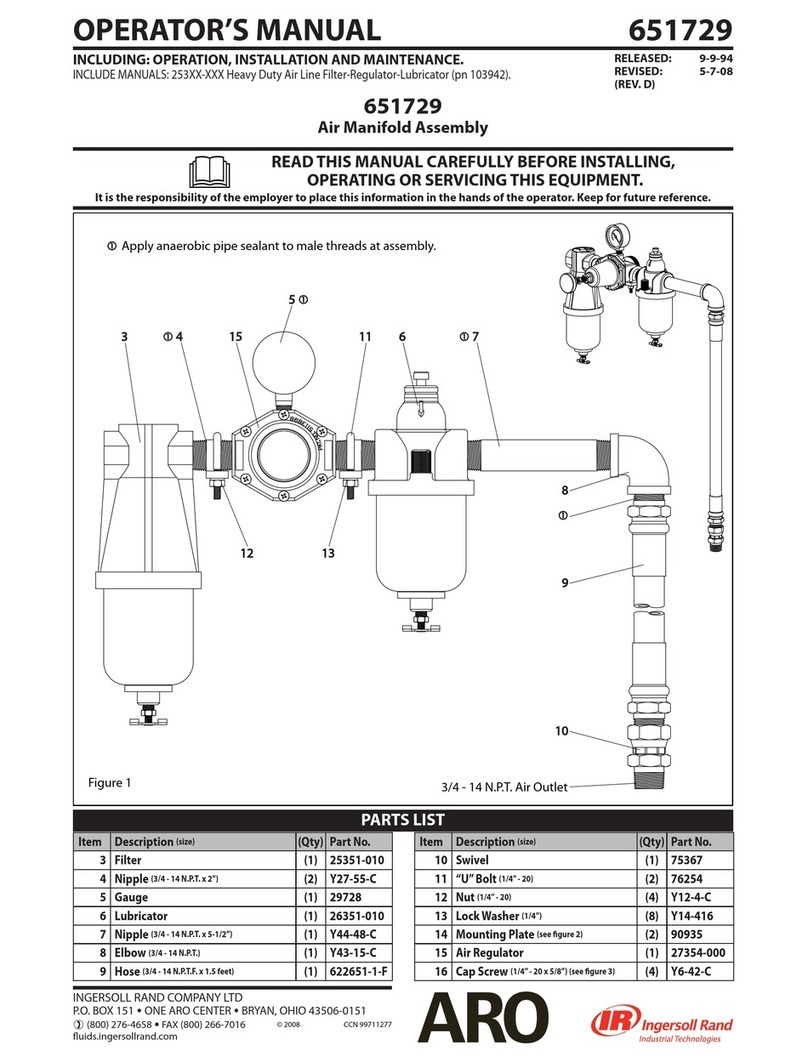

Ingersoll-Rand

Ingersoll-Rand ARO 651729 Operator's manual

Emerson

Emerson PENBERTHY GL Installation, operation and maintenance instructions

Pfeiffer Vacuum

Pfeiffer Vacuum OKTA 8000 G ATEX operating instructions

Wayne

Wayne VIP50 Operating instructions and parts manual

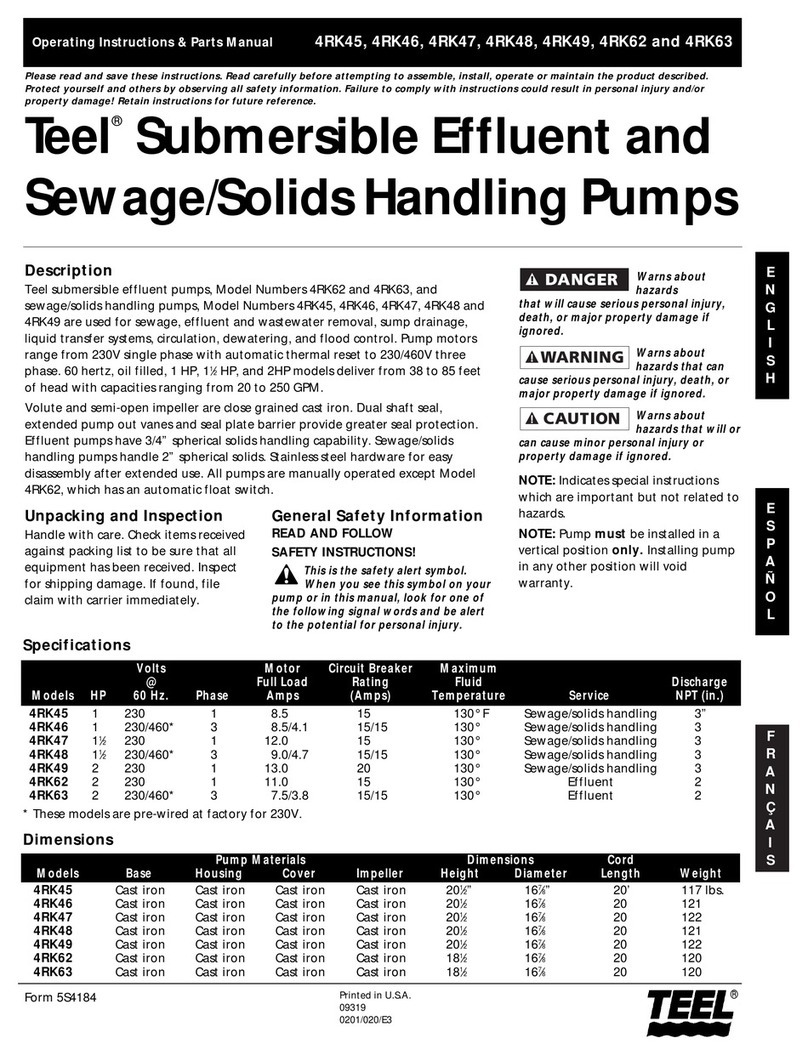

teel

teel 4RK45 Operating instructions and parts manual

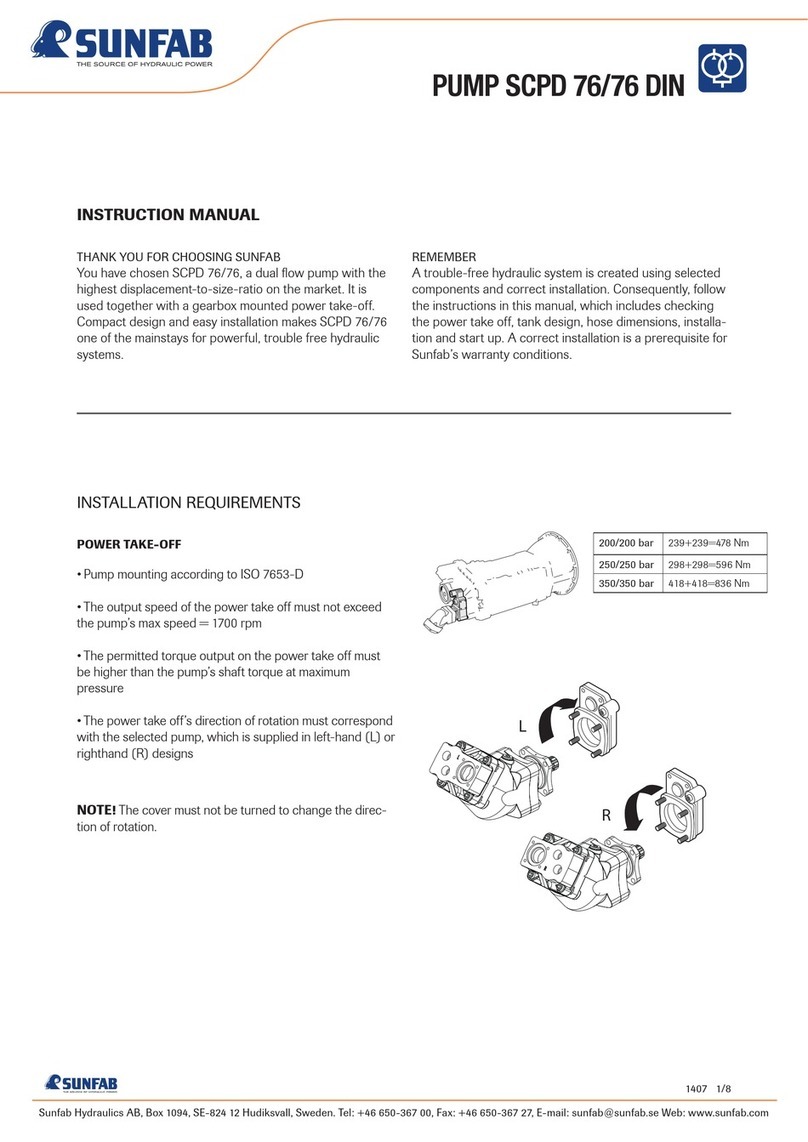

Sunfab

Sunfab SCPD 76 instruction manual

Trotec

Trotec TWP 4005 E operating manual

Parts2o

Parts2o FPPK50-P2 Repair instructions