7

Dynaset

Oy

|

Menotie

3,

33470

Ylöjärvi

|

puh.

03

3488

200

|

[email protected] |

www.dynaset.c

om

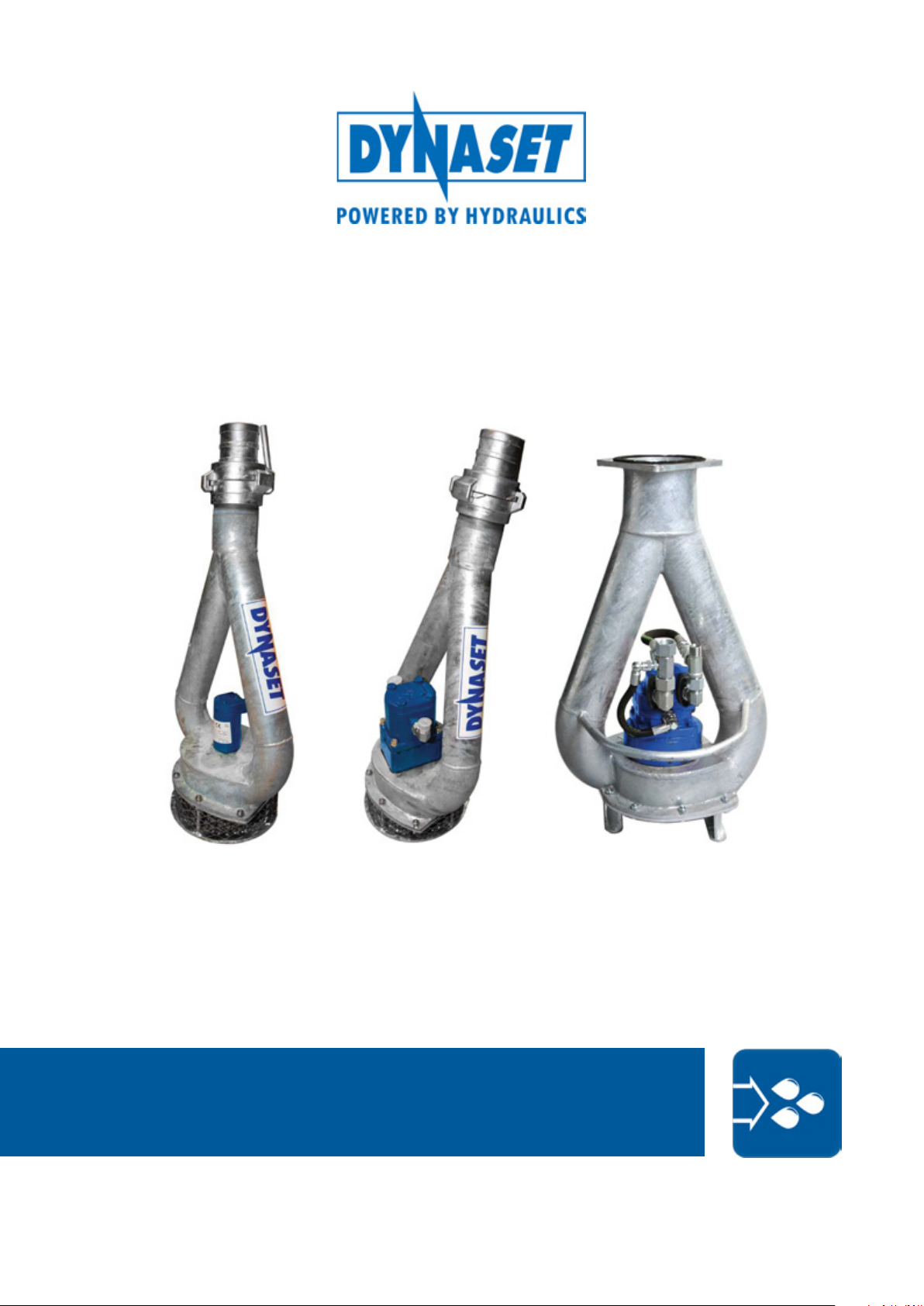

HYDRAULIC SUBMERSIBLE PUMPS

GENERAL

1. GENERAL

This manual contains general information about assembly, installation, operation

and maintenance of the DYNASET HSP hydraulic submersible pumps.

ATTENTION!

Read this user manual before installation, use or maintenance of the HSP

pump to ensure proper handling, operation and maintenance right from

the beginning. Pay attention to warnings and safety instructions. READ

CHAPTER ”2. SAFETY” for more information. for more information.

1.1. PRODUCT INFORMATION

Dynaset HSP hydraulic submersible pumps are designed for fast and efficient

pumping of water and other liquids. The volute and impeller of the HSP pump

are made of wear-resistant material which makes it a perfect choice for pumping

liquids containing impurities and solids

DYNASET submersible pumps can be used in municipal services, civil engineering,

industry, agriculture, off shore etc.