Shimaden SD16 series User manual

SD16 Series

Digital Indicator

Instruction Manual

Thank you for purchasing the Shimaden SD16 Series. Please check that the delivered product is the correct

item you ordered. Please do not begin operating this product until you have read this instruction manual

thoroughly and understand its contents.

Notice

Please ensure that this instruction manual is given to the final user of the instrument.

- 2 -

Preface

This instruction manual is meant for those who will be involved in

the wiring, installation, operation and routine maintenance of the

SD16 series.

This manual describes items concerning safety cautions,

installation, wiring, functions and operating method for SD16

series. Always keep this manual close at hand when handling this

instrument.

lease observe the descriptions in this manual whenever you use

this instrument.

Matters of attention concerning safety, damages on machines and

equipment, additional explanations and commentaries are

described under the following headings.

WARNING

Items concerning matters that may lead to an accident involving

human injury or death, if the warning is not observed.

CAUTION

Items concerning matters that may lead to an accident involving

damages to machines or equipment, if the caution is neglected.

Note

Additional explanations and commentaries.

The symbol expresses the terminal of protective conduction.

lease make sure to arrange wire connection for grounding.

Safety Cautions

SD16 series indicator is designed to indicate temperature,

humidity and other physical data of general industrial

equipment. Do not apply this instrument to other objects in a

way that may give grave effects on safety of human life. For

such uses involving possible risks, proper safety measures have

to be provided. In case of an accident by operation without

safety countermeasures, sellers shall not take any

responsibility.

To avoid damage to the connected equipment, facilities or the

product itself due to a fault of the product, safety countermea-

sure must be taken before usage, such as proper installation of

the fuse and the overheating protection device. No warranty,

express or implied, is valid in the case of usage without having

implemented proper safety countermeasures.

Regarding the alert symbol mark on the plate attached

to this instrument:

On the terminal nameplate attached to the case, an alert

symbol is printed. This is to give a caution not to

touch the electrical charging part when power is being

supplied so as to avoid the risk of electrical shock.

Install a switch or breaker on the external source power

circuit connecting to the source power terminal as a means

of shutting down the power.

The switch or breaker should be installed adjacent to the

instrument at a position which allows easy access of the

operator. ut up a sign indicating that this switch is for

shutting down the power of the instrument.

Regarding the fuse:

Since this instrument has no built-in fuse, make sure to

install a fuse in the electric circuit connecting to the source

power terminal.

Install the fuse at a position between the switch or breaker

and the instrument and attach it to the L side of the source

power terminal.

Fuse Rating: 250V AC 1.0A/Time-lag(T), Low-breaking

capacity (L)

Use a fuse which meets the requirements of IEC127.

The load of voltage and current to be applied to the output

terminal (analog output) and the alarm terminal have to be

within the rated range. If the range is exceeded, the

instrument will overheat and, as a result, there is a risk of

the instrument being damaged and the life reduced.

As for the rating, please refer to "7. Specification" on page

8.

The unit connected to the output terminal should conform to

the requirements of IEC1010.

Do not apply over-rated voltage or current to the input

terminal. There is a risk of the instrument being damaged

and the life reduced.

As for the rating, please refer to "7. Specification" on page

8.

In case the input type is voltage (mV or V) or current (4 ~

20mA), the unit connected to the output terminal should

conform to the requirements of IEC1010.

The instrument has a ventilating hole for heat radiation.

Take care to prevent metal or other foreign matter from

obstructing it. It will cause damages to the instrument and

may even result in fire.

Do not block the ventilating hole. Also avoid dust

accumulation. Any rise in temperature or insulation

failure may result in a shortening of the life of product

and/or problems with the product. As for the clearance

space for installing the instrument, refer to "2-3 External

dimensions and panel cutout" on page 4.

Repeating withstanding tests on voltage, noise, surging may

lead to deterioration of the instrument. lease be careful.

Strictly refrain from remodeling and using the instrument

improperly.

WARNING

CAUTION

In using this product, be certain to house it, for example, in

•

a control panel so that the terminals cannot come into

contact with personnel.

Do not take this instrument out of the case or put your han

d

•

or any conductor inside the case. Such conduct may lead to

•

an accident which endangers life or causes serious injury

due to electric shock.

Do not fail to ground the earthing terminal in use.

WARNING

CAUTION

- 3 -

CONTENTS

Page

1. Introduction............................................................................ 3

1-1. Check before use ............................................................. 3

1-2. Caution for use ................................................................ 3

2. Installation and wiring .......................................................... 3

2-1. Installation site (environmental conditions) .................... 3

2-2. Mounting......................................................................... 3

2-3. xternal dimensions and panel cutout ............................. 4

2-4. Wiring.............................................................................. 4

2-5. Terminal arrangement...................................................... 4

2-6. Terminal arrangement table ............................................. 4

3. Instruction for front panel..................................................... 4

3-1. Front illustration and the name of parts........................... 4

3-2. Instruction for front panel................................................ 4

4. Explanation of each screen .................................................... 5

4-1. List of screen sequence.................................................... 5

4-2. Mode 0 screen group ....................................................... 6

4-3. Mode 1 screen group ....................................................... 6

4-4. Table of measuring range code........................................ 7

4-5. Table of alarm type code ................................................. 7

4-6. Method of shifting screens .............................................. 7

5. Supplementary explanation................................................... 7

5-1. Display update cycle (Screen No.1-2)............................. 7

5-2. Alarm output action (option)........................................... 7

5-3. Analog output action (option) ......................................... 7

5-4. Auto-return function........................................................ 7

6. Error message......................................................................... 7

. Specification ........................................................................... 8

1. Introduction

1-1. Check before use

The instrument passes thorough quality checks before shipment.

When the instrument is delivered, please confirm the type code

number, then check the external conditions and the list of

accessories. Make sure that there are no apparent damages or

discrepancies.

Confirmation of the type code: Collate the type code printed on the

label attached to the packing case with the following schema and

confirm that the delivered goods meet your order.

SD16- 8 90- 0 0 0 0 Item Reference code and contents

1. Series SD16 : 48 × 96 DIN size Digital Indicator

2. Input 8: Multi-input, thermocouple, R.T.D.,

Voltage (mV, V), Current (mA)

3. Power supply 90-: 100 240V AC ±10% (50/60Hz)

08-: 24V AC (50/60Hz)/DC ±10%

4. Alarm (option) 0: None 1: Alarm output

5. Analog output (option)

0: None

3: 0~10mV DC (output resistance 10 )

4: 4~20mA DC (load resistance 300 max.)

6: 0~10V DC (load current 1mA max.)

6. Communication (option)

0: None

5: RS-485

7: RS-232C

7. Remarks 0: Without 9: With

Accessory list check:

Instruction Manual 1 copy

Unit decal 1 sheet

Communication Instruction Manual 1 copy

(In case of optional communication selected)

Note: Contact our representative concerning any problems

with the product, accessories or related items.

1-2. Caution for use

(1) Avoid operating keys of the front panel with hard or sharp

objects or motions. Lightly touch the operating keys with

finger tip for operation.

(2) When cleaning, do not use solvent like thinner. Wipe the

instrument with dry cloth lightly.

2. Installation and wiring

2-1. Installation site (en ironmental conditions)

Do not install the instrument at a place of environmental

conditions as listed below. Otherwise, it will cause damages

to the instrument and may even result in fire.

(1) Where flammable or corrosive gas, oil soot or dust that

deteriorates insulation is generated or abundant.

(2) Where ambient temperature is below −10°C or above 50°C.

(3) Where ambient humidity is higher than 90% RH, or below dew

point.

(4) Where strong vibrations or impact is generated or transferred.

(5) Where there is a high-tension electrical circuit in the

neighborhood, or induction interference.

(6) Where under exposure to direct sun light or dew drops.

(7) Where the elevation is higher than 2000m.

(8) Outdoors

Note: The environmental conditions belong to the installation

category II of I C 664 and the degree of pollution is 2.

2-2. Mounting

(1) Cut a fitting hole by referring to the panel cutout plan in item

2-3.

(2) Applicable thickness of the panel is 1.0 ~ 4.0mm.

(3) The instrument has catching claws to fix it in position.

Just push it in from the front panel.

Note: SD16 is a panel installation type indicator. When the

instrument is used, make sure to mount it on a panel.

CAUTION

Ω

Ω

–

- 4 -

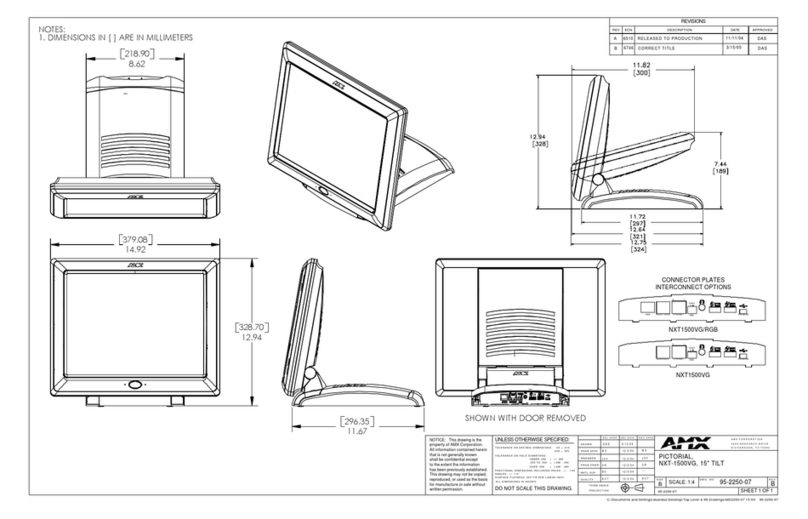

2-3. External dimensions and panel cutout

SD16 External dimension

SD16 Panel cutout

2-4. Wiring

When making wire arrangement, be sure to cut the power

supply OFF. There is a risk of electric shock.

Make sure the protective conductor terminal ( is

grounded. Otherwise, a serious electric shock may result.

After completing wiring arrangement, do not touch the

terminals and electrically charged parts while power is ON.

(1 Arrange wiring according to the terminal layout in item 2-5

and the terminal arrangement table in item 2-6. Confirm

that all connections are made correctly.

(2 Use crimp-style terminals of 7mm or narrower width to meet

M3.5 screws.

(3 In case of thermocouple input, use a compensation wire with

the type of thermocouple selected. The external resistance

should be100 or less.

(4 In case of R.T.D. input, the resistance value per lead wire

should be 5 or less and all the 3 wires should have the same

resistance value.

(5 Avoid arranging the input signal line to pass through in the

same conduit or duct with high-tension circuit.

(6 Shield wire (one-point grounding is effective to eliminate

the electrostatic induction noises.

(7 An effective way of eliminating the magnetic induction

noises is to twist the input wire in short and equal intervals.

(8 For source power connection, use wire or cable having a

cross section of 1mm2 or larger and performance capacity

equivalent to 600V vinyl insulation wire.

(9 Grounding wire should have a cross section of 2mm2 or

larger and the grounding work should ensure ground

resistance of 100 or less.

(10 Screw up the terminal connection securely.

Tightening torque 1.0N·m (10kgf·cm

(11 Noise filter

In case the instruments are affected by the power supply

noise, install a noise filter to avoid operation errors.

Mount the noise filter on the grounded panel and connect the

noise filter output and the power supply terminal of the

indicator with shortest possible distance.

Recommended noise filter: TDK product ZMB22 3-13

2-5. Terminal arrangement

2-6. Terminal arrangement table

Name of terminal and contents Terminal

No.

Power supply terminal

100 − 240V AC ± 10% 50/60Hz 11VA

24V DC 7W/24V AC ± 10% 50/60Hz 11VA

1-2

Protective conductor terminal ( 3

Input terminal

Vo l t a g e ( V ·Current: +

R.T.D. A, thermocouple/voltage (mV : +

R.T.D. B, thermocouple/voltage (mV, V ·current: −

R.T.D. B

5

6

7

9

Alarm output (option terminal

COM contact point rating 240V AC, 1.5A (load

resistance

AL1

AL2

11

12

13

Communication (option terminal SG, SG

SD, +

RD, −

15

16

17

Analog output (option terminal +

−18

19

Note: In case of thermocouple, voltage and current input,

keep terminal No. 9 open.

3. Instruction for front panel

3-1. ront illustration and the name of parts

Name of each part

Display part for measured

value

LED for monitoring

Key switch operating part

3-2. Instruction for front panel

: Display part for measured value (red

Mode 0, Current PV value is displayed on the basic screen.

Type of parameters is displayed on each parameter

character screen.

Set value is displayed on each parameter setting screen.

: LED for monitoring

(1 AL1 (Alarm 1 output monitoring LED (red

LED lights when an assigned alarm is ON.

(2 AL2 (Alarm 2 output monitoring LED (red

LED lights when an assigned alarm is ON.

(3 SET (parameter setting monitoring LED (green

LED lights when screen display is other than the basic

screen.

(4 COM (communication monitoring LED (green

LED lights when communication mode is on remote

control.

: Key switch operating part

(1 (Parameter key

By pressing this key, display changes from a screen to

the next in each screen group.

By pressing this key for 3 seconds or longer, the key

works as the shifting key to shift the screen from the

basic screen of Mode 0 screen group to the initial

parameter screen of Mode 1 screen group.

(2 (down key

By pressing this key on each screen, the decimal point

of the last digit blinks and the data value is decreased

or the decimal point shifts downward.

(3 (up key

By pressing this key on each screen, the decimal point

of the last digit blinks and the data value is increased or

the decimal point shifts upward.

(4

ENT

(entry/register key

This key works for mutual shifting between the

parameter character display screen and the parameter

setting screen. (when light of the decimal point of the

last place is OFF

On each screen of Mode 0 and Mode 1 screen groups,

the data changed by the or key is

established. (when light of the decimal point of the last

place is also OFF

WARNING

Ω

Ω

Ω

1

2

3

1

2

3

110min. (Unit : mm)

92+0.8

0

60min.

45+0.6

0

96

SD16

COM

AL1

SET

AL2

48

ENT

100

111

11

44.

6

X

9

1.

6

50/60Hz

100-240V AC

L N

1211 13 14 1615 17 201918

T.C.

mV

mA

V

R.T.D.

AB B

+-

+-

-+

AL1 AL2

RS-232C

RS-485 SG

SG SD RD

+- -+

CommunicationAnalog output

12345678910

(250Ωregister

attached externally)

R.T.D.

- 5 -

4. Explanation of each screen

4-1. List of screen sequence

Alarm

- 6 -

4-2.Mode 0 screen group

Basic screen

Current V value is indicated.

V bias value setting screen

Initial value: 0 or 0.0, Setting range: −200 ~ 200 unit

Used for compensating input errors by sensor, etc.

When bias is applied, compensated V indication value is

displayed.

V filter time setting

Initial value: 0 second

Setting range: 0 ~ 100 seconds

Used for reducing the effect of excessive input fluctuation

and repeating noise.

Alarm 1 level setting screen

This screen is displayed when the following setting code is

selected on the code selection screen of Mode 1 setting

screen. On this screen, setting of alarm action point is

available.

In case of the system without alarm option, this screen is

not displayed.

Alarm type Code Initial value Setting range

Higher limit HL__, HL_S Higher limit value Within range

Lower limit LL__, LL_S Lower limit value Within range

Alarm 2 level setting screen

Same as the above Alarm 1 setting screen

4-3. Mode 1 screen group

arameter initial screen

This is the heading screen of Mode 1.

Key lock mode setting screen

Initial value: OFF, Setting range: OFF, ON

When key lock ON is set, data is protected and cannot be

changed.

Indication renewal time setting screen

Initial value: 0.5 second

Setting range: 0.5 ~ 5.0 seconds

Setting of the time of renewing V value indication is made

on this screen. Time is set by every 0.5 second.

Measuring range selecting screen

Initial value: 05

Setting is made by selecting the code from the measuring

range code table in item 4-4.

Input unit setting screen

Initial value: °C, Unit selection: °C or °F

The input unit is selected.

In case of linear input (mV, V, mA), this screen is not

displayed.

Input scaling decimal point position

Initial value: 0.0

Setting range: No decimal point, 0.0, 0.00, 0.000

The decimal point setting is made at the time of linear input

(mV, V, mA) scaling.

For sensor input, this setting is not possible, where

monitoring only will do.

Input scaling lower limit

Initial value: 0.0, Setting range: −1999 ~ 9999 units

The lower limit value setting is made at the time of linear

input (mV, V, mA) scaling.

The span with the higher limit = 10 ~ 5000 counts

Reverse scaling is possible.

For sensor input, this setting is not possible, where

monitoring only will do.

For details, refer to item 4-6 (4).

Input scaling higher limit

Initial value: 100.0

Setting range: −1999 ~ 9999 units

The higher limit value setting is made at the time of linear

input (mV, V, mA) scaling.

The span with the lower limit = 10 ~ 5000 counts

Reverse scaling is possible.

For sensor input, this setting is not possible, where

monitoring only will do.

For details, refer to item 4-6 (4).

Alarm 1 code Initial value: HL__

Selected from alarm type code table in item 4-5.

In case of the system without alarm option, this screen is

not displayed.

Alarm 1 hysterisis

Initial value: 5 unit, Setting range: 1 ~ 999 unit

This screen is for setting Alarm 1 hysterisis.

In case of the system without alarm option, this screen is

not displayed.

Alarm 2 code Initial value: LL__

Selected from alarm type code table in item 4-5.

In case of the system without alarm option, this screen is

not displayed.

Alarm 2 hysterisis

Initial value: 5 unit, Setting range: 1 ~ 999 unit

This screen is for setting Alarm 2 hysterisis.

In case of the system without alarm option, this screen is

not displayed.

Analog output lower limit value scaling

Initial value: Measuring range lower limit value

Setting range: Lower limit ~ higher limit of measuring

range

Setting of lower limit value of analog output scaling is

made.

Span with higher limit value = 1 count

Reverse scaling is possible.

In case of the system without analog output option, this

screen is not displayed.

For details, refer to item 4-6 (5).

Analog output higher limit value scaling

Initial value: Measuring range higher limit value

Setting range: Lower limit ~ higher limit of measuring

range

Setting of higher limit value of analog output scaling is

made.

Span with lower limit value = 1 count

Reverse scaling is possible.

In case of the system without analog output option, this

screen is not displayed.

For details, refer to item 4-6 (5).

Communication mode

Initial value: Loc (local), Setting range: Loc, Com

Communication mode is set.

Front key operation can change Com → Loc only.

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

Communication address

Initial value: 1, Setting range: 1 ~ 255

When plural machine is connected, the number of the

machines is set.

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

Communication data

Initial value: 7E1, Setting range: 7E1, 8N1

Setting of communication data format is set.

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

Start character

Initial value: STX, Setting range: STX, ATT

The character at the head of communication is set.

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

Communication speed

Initial value: 1200bps

Setting range: 1200, 2400, 4800, 9600, 19200bps

Transmitting speed of communication data is set.

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

Delay time

Initial value: 80, Setting range: 0 ~ 500

The delay time from receipt of communication command

till starting transmission is set.

Delay time = 0.1 × Setting value (in milli-second)

For details, refer to separate Instruction Manual for

communication.

In case of the system without communication option, this

screen is not displayed.

- 7 -

4-4. Table of measuring range code

Measuring range

Input type Code °C°F

B 0 ~ 1800 0 ~ 3300

R 0 ~ 1700 0 ~ 3100

S 0 ~ 1700 0 ~ 3100

K−199.9 ~ 800.0 −300 ~ 1500

K 0 ~ 1200 0 ~ 2200

E 0 ~ 700 0 ~ 1300

J 0 ~ 600 0 ~ 1100

T−199.9 ~ 300.0 −300 ~ 600

N 0 ~ 1300 0 ~ 2300

*1 U −199.9 ~ 300.0 −300 ~ 600

*1 L 0 ~ 600 0 ~ 1100

Thermo-

couple

*2 WRe5-26 0 ~ 2300 0 ~ 4200

−200 ~ 600 −300 ~ 1100

R.T.D. t100 −100.0 ~ 100.0 −150.0 ~ 200.0

0 ~ 10mV

0 ~ 5V

1 ~ 5V

Vo l t a g e

0 ~ 10V

Current 4 ~ 20mA

Initial value: 0.0 ~ 100.0

Scaling range: −1999 ~ 9999 count

Span: 10 ~ 5000 count

Thermocouple: B, R, S, K, E, J, T, N: JIS/IEC

*1 Thermocouple U, L: DIN43710

*2 Thermocouple WRe5-26: Hoskins product

R.T.D. Pt100: New JIS/IEC

Note: When the measuring range is changed, data related to measuring range,

such as set value and alarm setting value are initialized.

4-5. Table of alarm type code

Alarm code can be assigned each for AL 1 and AL 2 independently.

Alarm

code Alarm t

yp

eInhibit

action

*1

Communic

ation

Remarks

HL

_

_

No 1

HL

_

S

Higher

limit

absolute

value

Yes 2

Output ON, also in case of sensor

b

reaka

g

e or hi

g

her limit scale-ove

r

LL

_

_

No 3

LL

_

S

Lower limi

t

absolute

value Yes 4

Output ON, also in case of lower

limit scale-over

*1 During communications, Read and Write become possible at the above values.

4-6. Method of shifting screens

(1) Method of shifting between Mode 0 screen group and Mode 1 screen

group

By pressing the key on the basic screen for 3 seconds or longer,

the display changes to the parameter heading screen of Mode 1

screen group. To return to the basic screen, keep pressing the

key again for 3 seconds or longer.

(2) Method of shifting screen within Mode 0 screen group

By each pressing of the key, screen shift takes place.

When the light of decimal point of the lowest digit place is OFF, by each

pressing of

ENT

key, the screen shifts alternately between the parameter

character indicating screen and the parameter setting screen.

(3) Method of shifting screen within Mode 1 screen group

By each pressing of the key, screen shift takes place.

When the light of decimal point of the lowest digit place is OFF, by each

pressing of

ENT

key, the screen shifts alternately between the parameter

character indicating screen and the parameter setting screen.

(4) Method of setting input scaling screen in Mode 1 screen group

On condition that "Lower limit value < Higher limit value", when the lower

limit value is set with a difference less than 10 counts from that of the higher

limit value, the higher limit value is forcibly changed to a new value at lower

limit value plus 10 counts.

As a result, when the higher limit exceeds 9999 counts, it is changed to the

value of the lower limit value minus 10 counts. Also, when a lower limit

value is set at a value with a difference exceeding 5000 counts from the higher

limit value, the higher limit value is forcibly changed to a new value at lower

limit value plus 5000 counts (−5000 counts).

On condition that "Lower limit value < Higher limit value", when the higher

limit value is set with a difference less than 10 counts from that of the higher

limit value, the lower limit value is forcibly changed to a new value at higher

limit value minus 10 counts.

As a result, when the lower limit exceeds −1999 counts, it is changed to the

value of the higher limit value plus 10 counts. Also, when a higher limit

value is set at a value with a difference exceeding 5000 counts from the lower

limit value, the lower limit value is forcibly changed to a new value at higher

limit value minus 5000 counts (+5000 counts).

On condition that "Lower limit value > Higher limit value", when the lower

limit value is set with a difference less than 10 counts from that of the higher

limit value, the higher limit value is forcibly changed to a new value at lower

limit value minus 10 counts.

As a result, when the higher limit exceeds −1999 counts, it is changed to the

value of the lower limit value plus 10 counts. Also, when a lower limit value

is set at a value with a difference exceeding 5000 counts from the higher limit

value, the higher limit value is forcibly changed to a new value at lower limit

value minus 5000 counts (+5000 counts).

On condition that "Lower limit value > Higher limit value", when the higher

limit value is set with a difference less than 10 counts from that of the higher

limit value, the lower limit value is forcibly changed to a new value at higher

limit value plus 10 counts.

As a result, when the lower limit exceeds 9999 counts, it is changed to the

value of the higher limit value minus 10 counts. Also, when the higher limit

value is set at a value with a difference exceeding 5000 counts from the lower

limit value, the lower limit value is forcibly changed to a new value at higher

limit value plus 5000 counts (−5000 counts).

(5) Method of setting analog output scaling screen in Mode 1 screen group

On condition that "Lower limit value < Higher limit value", when the lower

limit value is set at the same value of the higher limit, the higher limit value is

automatically changed to the lower limit value +1 count. As a result, when

the higher limit exceeds the higher limit of the measuring range, it is changed

to the value of lower limit −1 count.

On condition that "Lower limit value < Higher limit value", when the higher

limit value is set at the same value of the lower limit, the lower limit value is

automatically changed to the higher limit value −1 count. As a result, when

the lower limit exceeds the lower limit of the measuring range, it is changed to

the value of higher limit +1 count.

On condition that "Lower limit value > Higher limit value", when the lower

limit value is set at the same value of the higher limit, the higher limit value is

automatically changed to the lower limit value −1 count. As a result, when

the higher limit exceeds the lower limit of the measuring range, it is changed

to the value of lower limit +1 count.

On condition that "Lower limit value > Higher limit value", when the higher

limit value is set at the same value of the lower limit, the lower limit value is

automatically changed to the higher limit value +1 count. As a result, when

the lower limit exceeds the higher limit of the measuring range, it is changed

to the value of higher limit −1 count.

5. Supplementary explanation

5-1. Display update cycle (Screen No.1-2)

Setting of V display update cycle on the basic screen is made.

The setting of value is made every 0.5 second.

5-2. Alarm output action (option)

(1) Setting of alarm higher limit value

For setting the alarm higher limit value, the alarm hysterisis is set by selecting

the higher limit alarm on the alarm code screen of Mode 1 screen group (when

alarm option is attached).

The higher limit alarm is output when the process value exceeds the alarm

level value. The output goes off when the process value comes down below

the alarm level value minus the alarm hysterisis.

(2) Setting of alarm lower limit value

For setting the alarm lower limit value, the alarm hysterisis is set by selecting

the lower limit alarm on the alarm code screen of Mode 1 screen group.

The lower limit alarm is output when the process value comes down below the

alarm level value. The output goes off when the process value exceeds the

alarm level value plus hysterisis.

5-3. Analog output action (option)

The analog output is a function that outputs the analog voltage or analog

current corresponding to the process value. They are used for input signal

into a recorder and data accumulation equipment.

Within the measuring range specified by the lower and higher limit value of

the analog output scaling, analog output signal to correspond to the process

value is available.

Scaling output diagram

5-4. Auto-return function

On any screen other than 0-0 basic screen, if no key operation is made for 3 minutes

or longer, the screen shifts to the basic screen (auto-return).

6. Error message

Abnormal input of process value (indicated on the basic screen of Mode 0 screen

group)

This message is indicated when the thermocouple or A of R.T.D. is

burnt out, also when V value exceeds the higher limit of the

measuring range by about 10%.

When V value is below the lower limit of the measuring range by

about 10%, by reason such as wrong polarity of input wiring.

When the t B (terminal No.7) wire breaks.

When the cold junction (CJ) is abnormal on the higher side in

thermocouple input.

When the cold junction (CJ) is abnormal on the lower side in

thermocouple input.

When the B wire (terminal No.9) breaks, or when plural number of

wires out of A· B · B break.

Note: When abnormality occurs, please contact our sales agent or to our business

office directly.

7. Specification

Display

Digital display : rocess value ( V) 7 segment Red LED 4 digits

Action indication: 1 point of parameter display (SET) by green LED

1 point of communication display (COM) by green LED

2 points of alarm (AL1, AL2) by red LED

Display accuracy : ±(0.3% FS+1 digit) within measuring range

Excluding cold junction temperature compensation accuracy in

the case of thermocouple input

±5%FS for temperature below 400˚C of thermocouple B

When the thermocouple [T, U] indication value is –100 ~ 0˚C,

±0.5%FS and when it is below –100˚C, ±1%FS

Display accuracy

range

:23˚C±5˚C (18 ~ 28˚C)

Display

resolution

: Depends on measuring range (0.001, 0.01, 0.1, 1)

Measured value

display range

: –10 ~ 110% of measuring range (Accuracy guaranteed for value

is within measuring range only)

For R.T.D. input of –200 ~ 600 : 210 ~ 680˚C˚C

For thermocouple [K] input of –199.9 ~ 800.0˚C: –273.1 ~

900.0 ˚C

Display update

cycle

: 0.5 ~ 5.0 seconds (0.5 Steps)

When 0.5 second or more is set, there may occur a difference

among the displayed value, the analog output and the

communication data.

Setting

Setting : By four (4) front key switches

Setting range : Same as measuring range

Input

Type of input : Multiple input of Thermocouple, R.T.D., Voltage (mV, V) and

Current (mA)

Thermocouple : B, R, S, K, E, J, T, N, {U, L (DIN43710)}, WRe5-26

Refer to measuring range code table.

External

resistance

: 100Ω max.

Input impedance : 500KΩ min.

Burnout : Standard feature (Up-scale)

Cold junction

temperature

compensation

accuracy

: (18 ~ 28 range)

±2˚C

±1˚C

(5 ~ 18˚C ˚C

˚C

, 28 ~ 45 range)

(±5˚C to the negative side of measuring range in case of T and

U input)

R.T.D. : JIS t100 3-wire type

Amperage : Approx. 0.25mA

Lead wire

tolerable

resistance

: 5 max. / wire (3 lead wire should have same resistance)

When the resistance value of each wire is same

0 ~ 5Ω: 0.05˚C max., 5 ~ 10Ω: 0.2˚C max., 10 ~ 20Ω: 0.6˚C

max., 20 ~ 30Ω: 1.4˚C max.

Voltage (mV

)

:0 ~ 10mV DC

(V) : 0 ~ 5V, 1 ~ 5V, 0 ~ 10V DC

Input impedance : 500KΩ min.

Current : 4 ~ 20mA DC

Input impedance : 250Ω [A shunt resistor (option) needs to be connected to the

terminal.]

Input scaling

function

: Scaling possible for voltage (mV, V) or current (mA) input and

inverse scaling possible.

Scaling range : –1999 ~ 9999 count

Span : 10 ~ 5000 count

osition of

decimal point

: None, 0.0, 0.00, 0.000

Sampling cycle : 0.5 seconds

V bias : ±200 unit

V filter : 0 ~ 100 seconds (0 = without filter)

Isolation : Between input and analog output

Alarm output (option)

Number of alarm

points

: 2 (AL1 and AL2) for both normal open and common

Alarm type : Selectable from combinations of the following 4 types

Higher limit absolute value without inhibit action

Higher limit absolute value with inhibit action

Lower limit absolute value without inhibit action

Lower limit absolute value with inhibit action

Alarm setting

range

: Within measuring range or within full scaling range

Alarm action : ON-OFF action

Alarm sensitivity : 1 ~ 999 unit (within measuring range)

Alarm output/

rating

: Contact 1a (common) / 240V, AC1.5A (resistive load)

Alarm output

update cycle

: 0.5 seconds

Analog output (option)

Analog output

type

: 0 ~ 10mV (output resistance: 10Ω)

0 ~ 10V (load current: 1mA max)

4 ~ 20mA (load resistance : 300Ω max)

Output

resolution

: Approx. 0.03% (1/3000)

Output accuracy : ±(0.3%FS + 1 digit) of display value

Output scaling : Within measuring range (inverse scaling possible)

Output update

cycle

: 0.5 seconds

Communication (option)

Communication

type

: RS-232C, RS-485

Communication

system

: Half duplex start-stop synchronized system

Communication

speed

: 1200, 2400, 4800, 9600, 19200 bps

Data bit length : 7 bit even parity 1 stop bit

8 bit non parity 1 stop bit

Communication

address

: 1 ~ 255

Multi-drop

connection

: 31 max (with RS-485)

Communication

delay

: 0 ~ 50.0 milli-seconds

Others

Data storage : By non volatile memory (EE ROM)

Ambient conditions for use

Temperature/

humidity

: –10 ~ 50˚C /90%RH max (on condition that there is no dew

condensation)

Height : 2000m above sea level or lower

Installation

category

: Category II

Degree of

pollution

: Degree 2

ower supply

voltage

: 100 – 240V AC±10%, 50/60Hz

24V AC/DC ±10%

ower

consumption

: 11VA (AC) max., 7W (DC) max.

Applicable standard

Safety : IEC1010-1, 1992

EMC : EMI (emission) EN50081-2, 1993

EMS (immunity) EN50082-2, 1995

(EMC testing display accuracy: ±5% FS)

Dust proof/drip

proof

: I 66 equivalent

: Between input/output terminal and power supply terminal:

500V DC 20MΩ minimum

Insulation

resistance

: Between input/output terminal and protective conductor

terminal: 500V DC 20MΩ minimum

Dielectric

strength

: 1 min. at 2300V AC between input/output terminal and power

supply terminal

: 1 min. at 1500V AC between power supply terminal and

protective conductor terminal

Case material : O resin molding (equivalent to UL94V-1)

External

dimensions

: H48 W96 D111 mm

Mounting : ush-in panel (one-touch mount)

anel thickness : 1.0 ~ 4.0 mm

anel cutout : H45 W92 mm

Weight : Approx. 250g

×

××

Ω

Table of contents