2

General Safety Instructions

Contents

Introduction

PAGE

Shindaiwa 230-series hand held power

equipment has been designed and built to

deliver superior performance and reliability

without compromise to quality, comfort,

safety or durability.

Shindaiwa’s high-performance engines rep-

resent the leading edge of 2-cycle engine

technology, delivering exceptionally high

power with remarkably low displacement

and weight. As an owner/operator, you’ll

soon discover for yourself why Shindaiwa is

simply in a class by itself!

IMPORTANT!

The information contained in this owner's/

operator's manual describes units avail-

able at the time of publication.

Shindaiwa Inc. reserves the right to make

changes to products without prior notice,

and without obligation to make alterations

to units previously manufactured.

Attention Statements ...................................2

Safety Information ........................................2

Safety Labels .................................................4

Unit Description ...........................................5

Specifications ................................................5

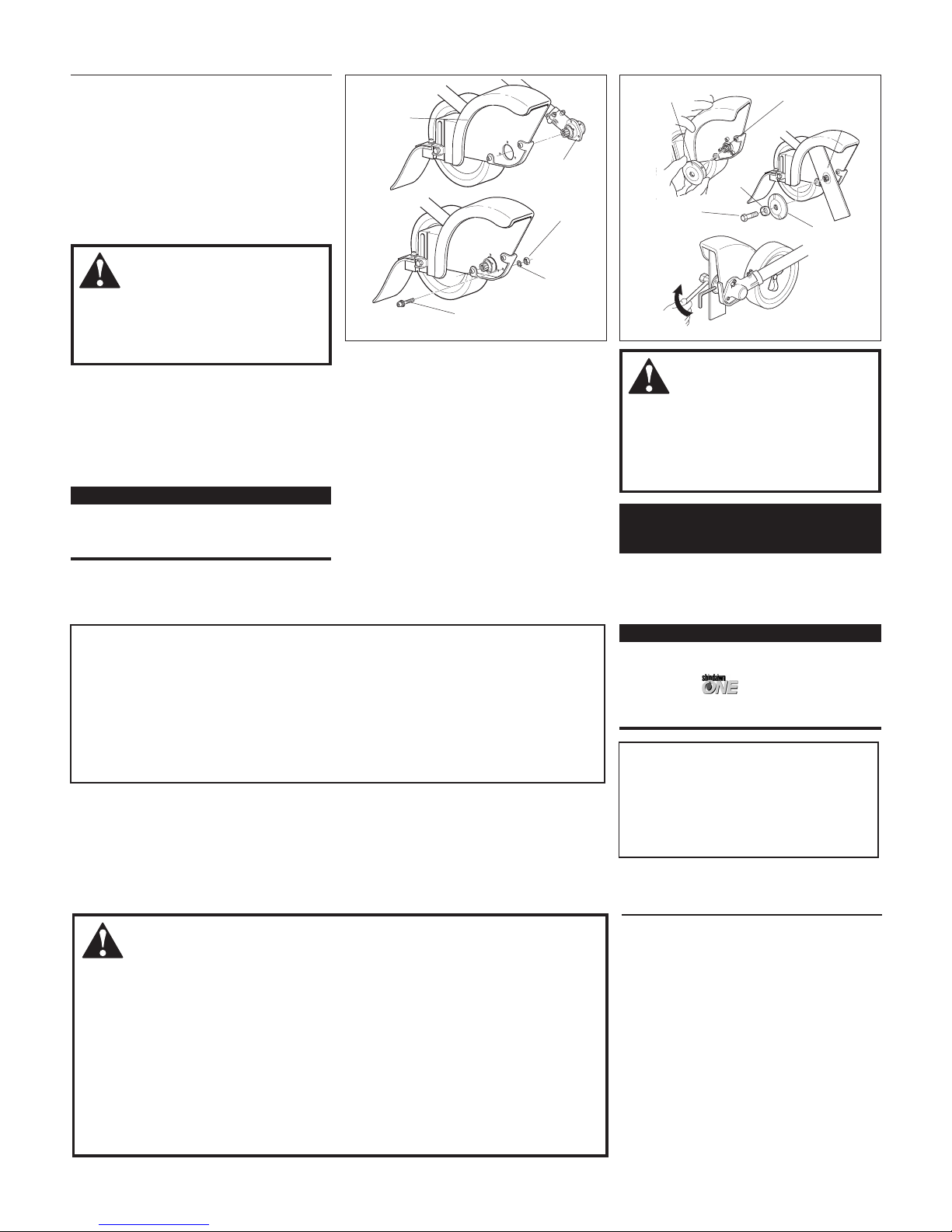

Assembly .......................................................6

Mixing Fuel ..................................................8

Starting the Engine ......................................9

Stopping the Engine ....................................9

Engine Idle Adjustments ...........................10

Checking Unit Condition ..........................10

Using the Edger .........................................10

Maintenance ...............................................11

Long Term Storage ....................................14

Troubleshooting Guide .............................15

Emission System Warranty .......................17

WARNING!

The engine exhaust from this unit con-

tains chemicals known to the State of

California to cause cancer, birth defects

or other reproductive harm.

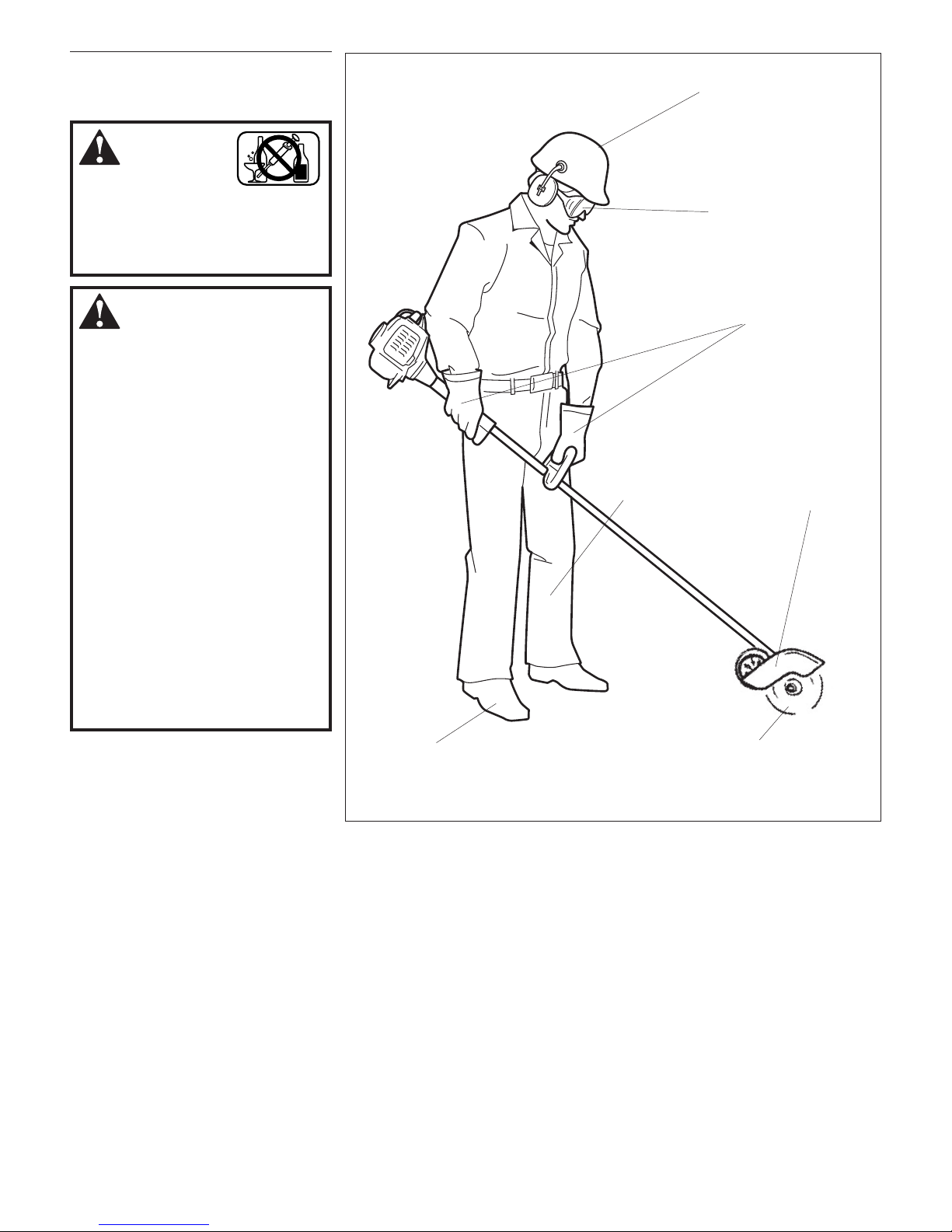

Work Safely

Lawn Edgers operate at very high speeds

and can do serious damage or injury if

they are misused or abused. Never allow

a person without training or instruction to

operate this unit!

WARNING!

Use Good Judgment

NEVER run the engine when transport-

ing the unit.

NEVER run the engine indoors! Make

sure there is always good ventilation.

Fumes from engine exhaust can cause

serious injury or death.

ALWAYS stop the unit immediately if

it suddenly begins to vibrate or shake.

Inspect for broken, missing or improp-

erly installed parts or attachments.

ALWAYS keep the unit as clean as

practical. Keep it free of loose vegeta-

tion, mud, etc.

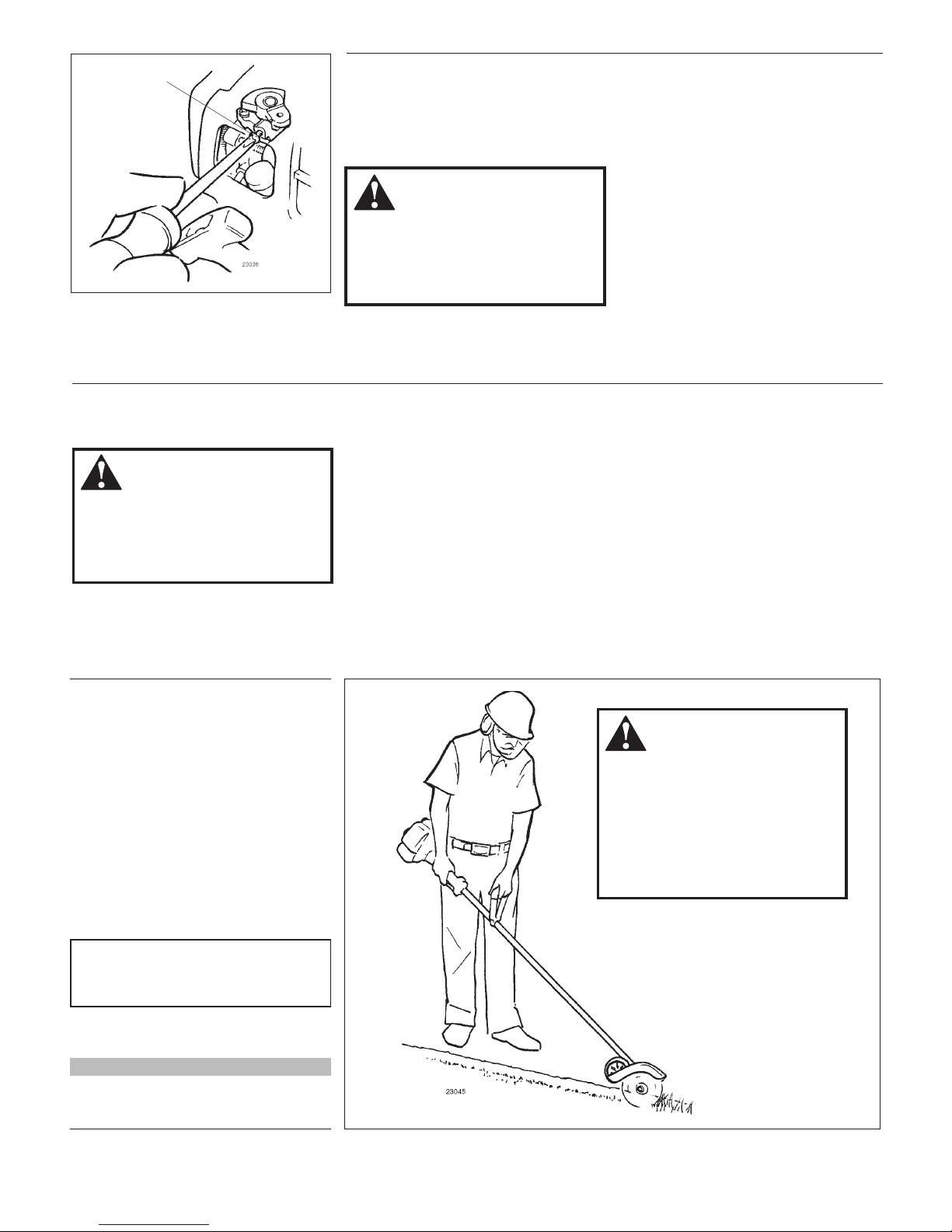

ALWAYS hold the unit firmly with both

hands when cutting or trimming, and

maintain control at all times.

ALWAYS keep the handles clean.

ALWAYS disconnect the spark plug

wire before performing any

maintenance work.

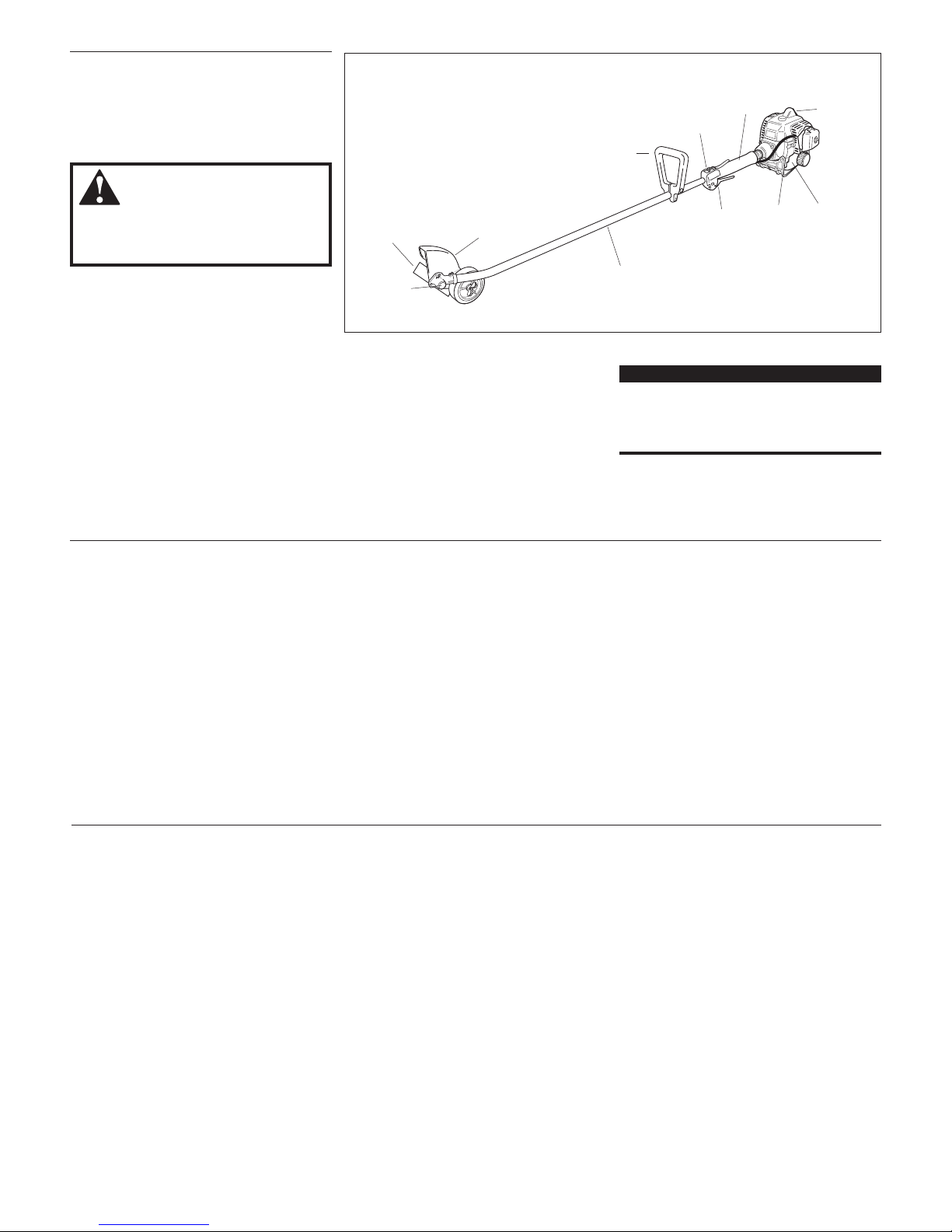

WARNING!

Never make unauthorized attachment

installations.

WARNING!

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

Throughout this manual are special

“Attention Statements.”

WARNING!

A statement preceded by the trian-

gular attention symbol and the word

“WARNING” contains information that

should be acted upon to prevent seri-

ous bodily injury.

CAUTION!

A statement preceded by the word

“CAUTION” contains information that

should be acted upon to prevent me-

chanical damage.

IMPORTANT!

A statement preceded by the word

“IMPORTANT” is one that possesses

special significance.

NOTE:

A statement preceded by the word “NOTE”

contains information that is handy to know

and may make your job easier.

Attention Statements

IMPORTANT!

The operational procedures described in

this manual are intended to help you get

the most from unit as well as to protect

you and others from harm. These proce-

dures are guidelines for safe operation un-

der most conditions, and are not intended

to replace any safety rules and/or laws

that may be in force in your area. If you

have questions regarding your Shindaiwa

power tool, or if you do not understand

something in this manual, your Shindaiwa

dealer will be glad to assist you. You may

also contact Shindaiwa, Inc. at the ad-

dress printed on the back of this manual.