2. SPECIFICATIONS VM-5P3

-2-

2-1 SPECIFICATIONS

Serial interface Input signal

Hysteresis set value

(shaped waveform circuit)

(CH1)

Hysteresis set value

(shaped waveform circuit)

(CH2)

Alarm reset

system OK

Relay mode

system OK Trigger mode Tropical

spec.

CE

marking

3 Not provided 1 VK,RD,FK Series 0 1.0V 0 1.0V 0 AUTO-RESET 0 Auto

1 0.1V 1 0.1V 1 SELF-HOLD 0 NORMALLY

DE-ENERGIZED 1 Manual

2 0.2V 2 0.2V

3 0.5V 3 0.5V 1 NORMALLY

ENERGIZED

ABNORMAL INPUT

ALARM FUNCTION

SETUP

ON(enabled) or OFF(disabled)

Preset to OFF(disabled)

(Can be changed using the internal jumper)

TRANSDUCER

POWER SUPPLY

-24VDC±1V, 20mA

POWER SUPPLY OK

INDICATOR

PWR SUPPLY OK : (green LED)

SEQUENCE STATE

INDICATOR

SEQUENCE ENABLE : (yellow LED)

TRIGGER INDICATOR TRIGGER : (yellow LED)

TEMPERATURE

RANGE

Operating temperature : 0 to 65°C (32 to 149°F REF.)

Storage temperature : -30 to +85°C (-22 to +185°F REF.)

Relative humidity : 20 to 95%RH (noncondensing)

FINISH Face plate : Munsell N-4.0 (equiv.)

DIMENSION OF TARGET(Model VK,RD,FK)

CAUTION) To detect a projection(gear),provide surface A of the projection with a concentric

curve. Do not make it flat.

A= mm

B= mm

C= mm

D= mm

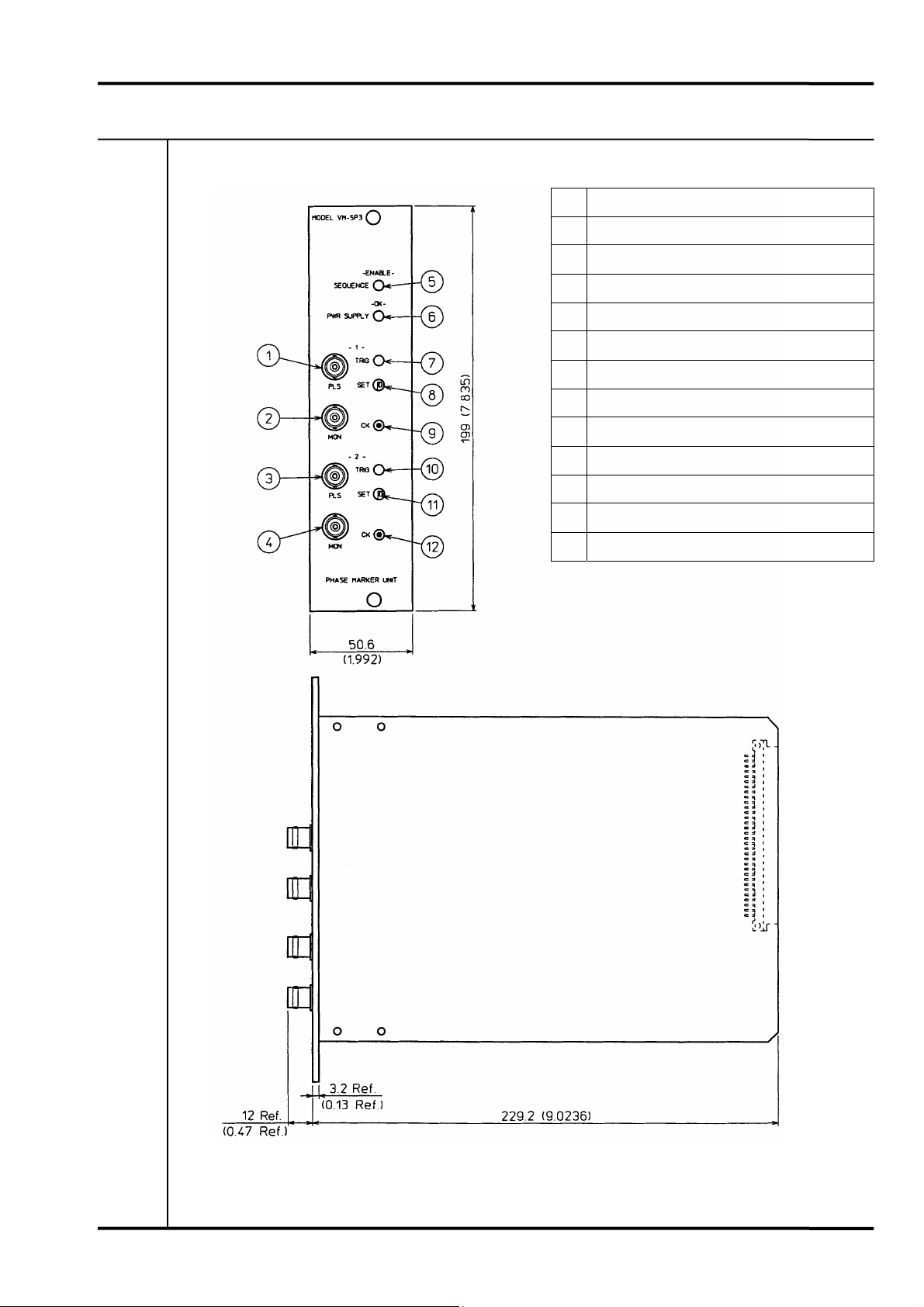

MASS Unit : max.0.6kg (max.1.4lb REF.)

Standard Specifications

POWER SUPPLY Supplied from instrument rack (VM-5H3 or VM-5W1)

PHASE MARKER

SIGNAL

Phase marker : 2ch Max.

Input impedance : Approx.10kΩ

INPUT VOLTAGE 0 to 25VDC

BUFFER OUTPUT Phase marker signal : 2ch

Output voltage : -1 to –20VDC

Output impedance : 50Ω

PULSE OUTPUT Shaped pulse signal is output via a buffer amplifier.

Signal level : -1 to +1V(P

L

), 4 to 6V(P

H

)

Output impedance : 50Ω

OTHER

Note) Model VM-5P3 Phase marker unit can be installed on 1 unit(VM-5P3)/1 rack(VM-5H3 or VM-5W1 Instrument

Rack), can not be installed on Model VM-5G Single Unit Instrument Rack.

The system OK alarm contacts on the instrument rack are not functional unless the VM-5P3 is mounted.

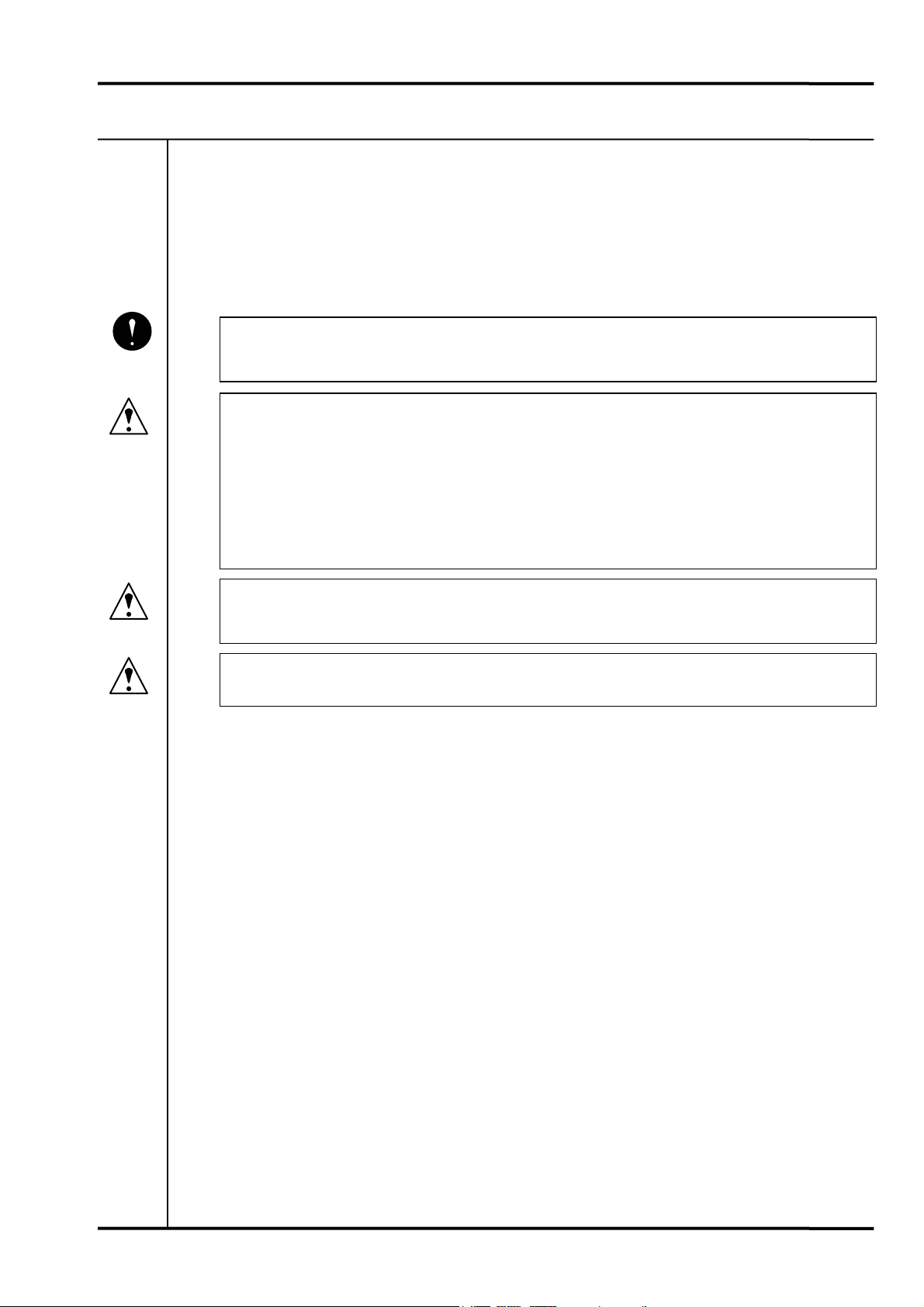

Alarm contact operation

Monitor power ON

Monitor alarm relay mode Monitor power OFF Normal state Alarm state

NO contact NORMALLY DE-ENERGIZED OPEN OPEN CLOSE

NO contact NORMALLY ENERGIZED OPEN CLOSE OPEN

NC contact NORMALLY DE-ENERGIZED CLOSE CLOSE OPEN

NC contact NORMALLY ENERGIZED CLOSE OPEN CLOSE

VM-5P -

Ordering Information Standard Specifications

-

1

- - /TRP/CEM

Model Code / Additional Spec. Code( )

No entry if additional

spec. code is not specified.

3

30007E1.5

Input

VK-202A

RD-05A

FK-202F

VK-452A

FK-452F VK-302P

A ≥6 ≥16 ≥8

B ≥7 ≥20 ≥8

C ≥2.5 ≥4.5 ≥2.5

Dimension of target

[recommended]

(mm) D ≥16 ≥36 ≥20

Set gap

[recommended](mm) 1.0 to 1.5 2.5 to 3.5 1.0 to 1.5

D D

CBC