Shira Trains D-10h User manual

THANK YOU FOR YOUR SUPPORT!

is OPERATORS manual will cover the details of the D-10h model that you have purchased, including how to service* and operate

the functions on your new model. Like all models, these models should be handled with care. Our models are meant to be enjoyed

with your eyes and ears, and should not be handled unless when needed; is isn’t because of faulty or shoddy construction, but so

the oils on your hands do not settle on the boiler or other parts causing unsightly ngerprints. ere are also several small compo-

nents on your model that could be jarred loose from over handling, and as such, let us reiterate, it should always be handled with

care - in any service procedure or operations session.

e D-10h Locomotive features the following DIE-CAST** parts:

boiler, boiler support, tender chassis, leading truck centre weight, gear housing as well as other smaller parts. Needless to say there

is a lot of weight in your model due to the metals. Please take care that your locomotive does NOT come into contact with any live

wires other than the intended powered track. is may lead to a disastrous outcome and is not covered by warranty, written, implied

or otherwise stated.

SAFETY WARNING:

Your locomotive and tender have been checked at the factory and has had approx. 15-20 minutes of run time already

on it. While we strive to nd all the faults before they get out, we are only human. Please check your locomotives oper-

ation on a test track to ensure that it is funtioning as intended.

FAILURE TO DO SO MAY RESULT IN UNWANTED SHORTS OR LAYOUT DAMAGE WHICH WE CANNOT BE

HELD RESPONSIBLE FOR AS WE HAVE NO CONTROL OVER THE TESTING ENVIRONMENT.

READ ME!

Just like us, we are sure you hate reading manuals, but you should. Really. ere is important stu in here.

SMT 0100: CANADIAN PACIFIC D-10h # 1057

Includes: SHORT head lamp. DCC decoder with sound

installed. Extras include: smoke deector, pilot step, extra sand

dome, grease, extra gear, operating tender coupler, instruc-

tions, bell wire, warranty card.**

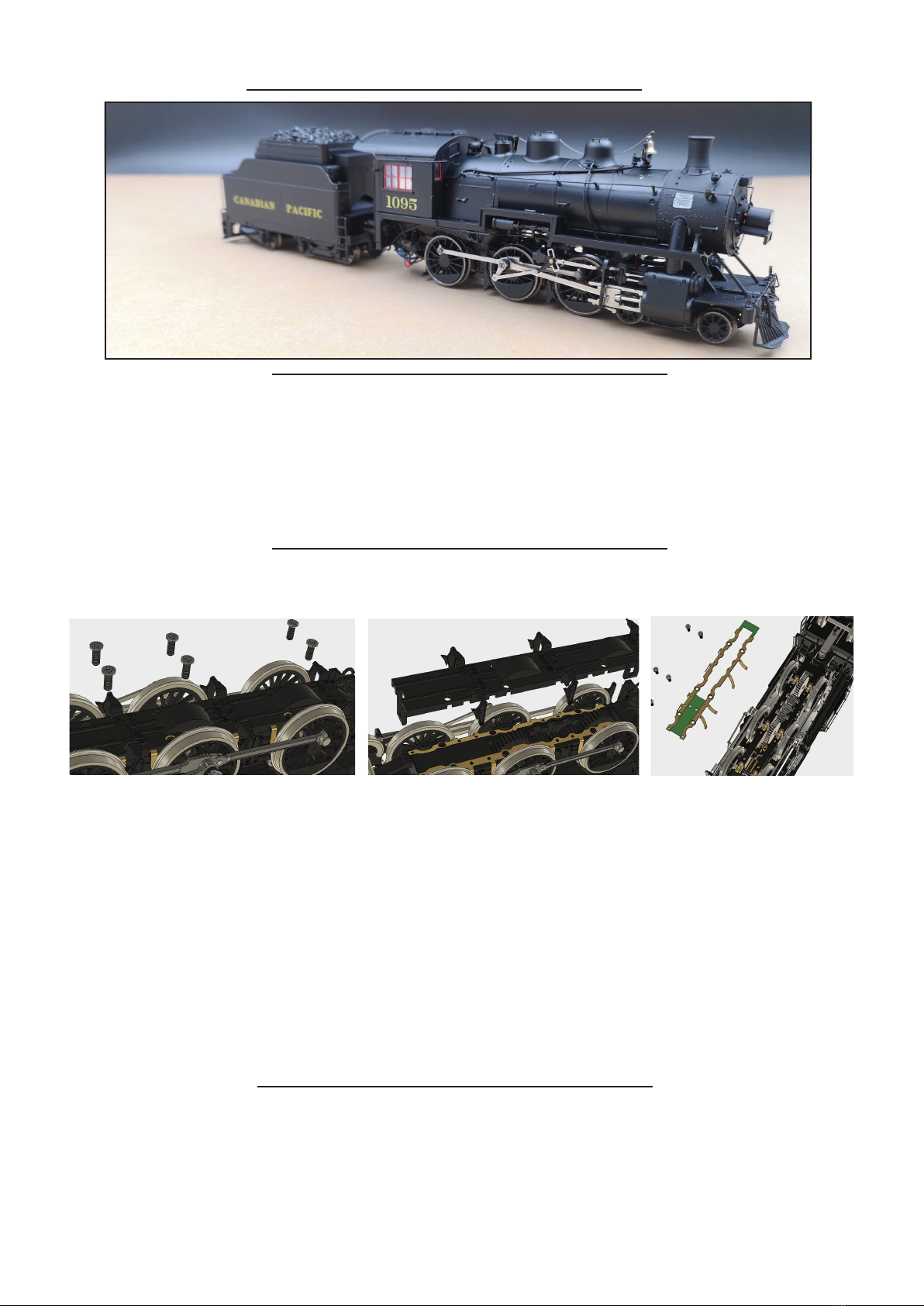

SMT 0101: CANADIAN PACIFIC D-10h # 1095

Includes: LONG head lamp, smoke deector. DCC decoder

with sound installed. Extras include: pilot step, extra sand

dome, grease, extra gear, operating tender coupler, instruc-

tions, bell wire, warranty card.**

SMT 0102: CANADIAN PACIFIC D-10h # 1100

Includes SHORT lamp, front pilot step. DCC decoder with

sound installed. Extras include: smoke deector, extra sand

dome, grease, extra gear, operating tender coupler, instruc-

tions, bell wire, warranty card.**

SMT 0103: CANADIAN PACIFIC D-10h #

A limited amount of UN NUMBERED D-10h units will

be available. Included with these units are all option parts

(smoke deector, pilot step, extra sand dome, grease, extra

gear, operating tender coupler, instructions, bell wire and

warranty card. Includes SMT 0104.**

SMT 0104: D-10h DECAL SHEET

IWater slide decals for our SMT 0103. Colours match lettering

as well as have included white, black and gold lettering as well

as size charts. Decals are extremely thin to maintain realism

and as such, we have given extras in case errors occur.

* - Service should only be performed by a qualied technician. Service not done by a qualied technician may lead to voiding your warranty.

** - Specications are subject to change without notice.

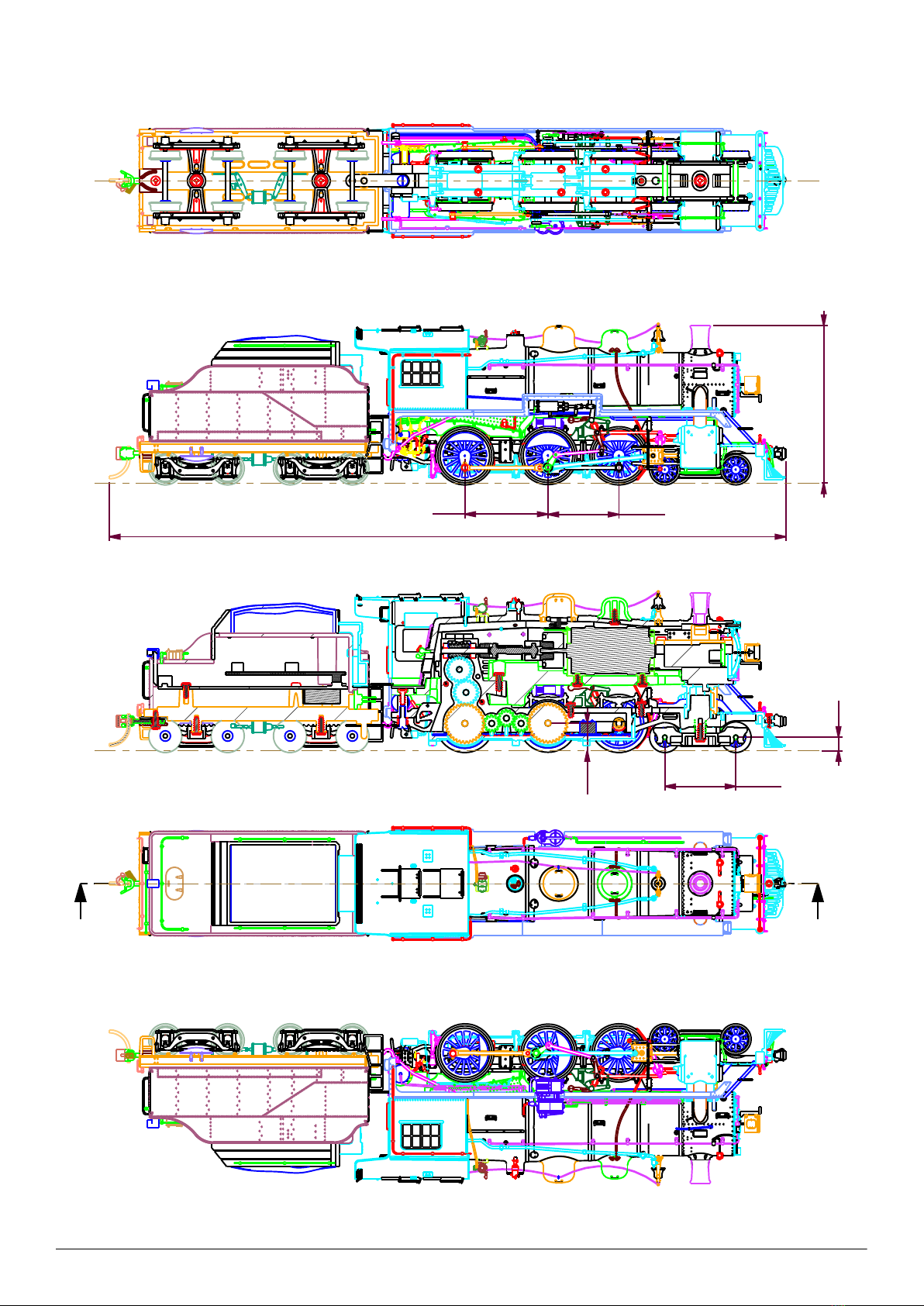

A A

28 23,9

53,05

35,6

23,9

4,53

9,28

227,78

截面 A-A

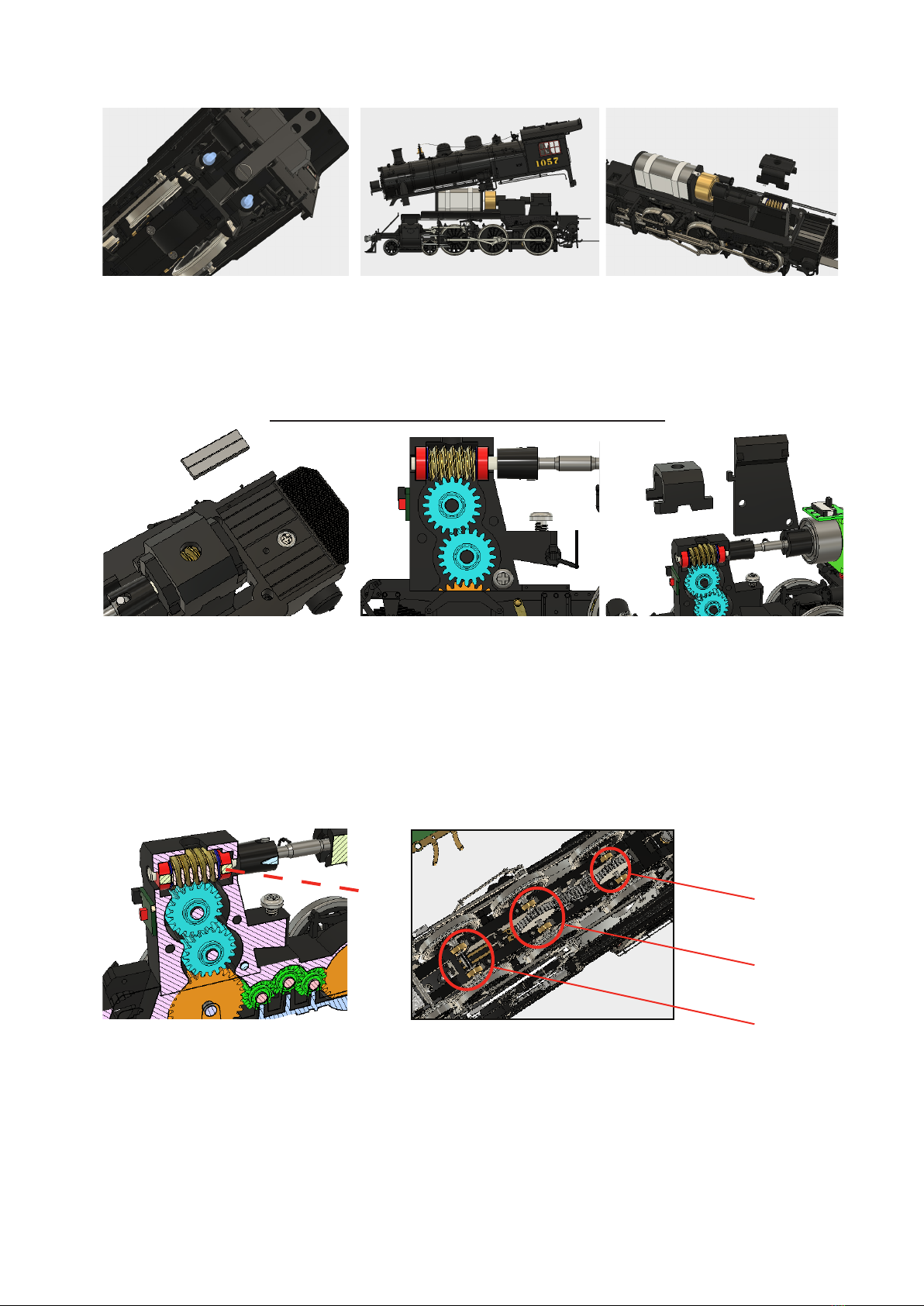

Regular maintenance is a vital part of any electrical device. While we have tried to make service intervals as infrequent as possible, you

should be aware that lubrication service may need to be performed at some time. Our Bronzite bushings use a self-lubricating formula,

as the axles turn and generate heat, the bushings release an oil that both lubricates and polishes the axle at the contact point, allowing

for better electrical connection, and less need for servicing. Small bits of debris may stick to the lubrication and axles during operation.

Aer operation; or if you notice erratic running, Check the axles for layout bits, hair or other loose items that may nd there way into

the operational area. When handling the locomotive, please be careful as there are small parts that can be bent out of place or broken o.

To avoid the spread of oils on your model, it is recommended that you use rubber gloves or nger cots - if you do get nger prints on

your model, you can clean them a cotton swab. DO NOT USE ACETONE or other harsh cleaning checmicals, as this may damage your

model. For information on how to service your model, please read on.

Operators Service Manual - PROCEDURE FOR GREASE AND LUBRICATION.

- REQUIRED - #0 Phillips screw driver, lite oil, lite grease, work station

On the bottom of your locomotive, there are a se-

ries of 6 (six) screws that secure the gear cover on.

Placing the locomotive on a secure work station,

such as a foam cradle, remove these screws. Place

these screws somewhere where you will not lose

them. A small dish or container is suggested to

hold these screws and stop them from rolling o

your work station.

Aer you have removed the screws and placed

them in a safe location, li o the GEAR

COVER. Li the cover STRAIGHT UP taking

care not to damage the moulded brake supports.

is will expose the IC and PICK-UPS and 6

more screws. Remove these 6 (six) screws and

the IC and PICK UPS. Please take notice: DO

NOT BEND THE ELECTRICAL PICK UPS!

Creasing or crimping them will result in erratic

pickup and will cause running issues not

covered by any warranty..

At this stage, you have successfully

gained access to the DRIVE TRAIN,

axles and gears. A small amount of

lubrication placed on the teeth of

the gears, and light oil placed on the

axles will ensure smooth, trouble

free operation. e locomotive has

these applied at the factory and will

NOT require these as new. Only do

this if you notice erratic operation.

At this point aer lubrication is

completed, you can reassemble the

drive. Service is complete.

Operators Service Manual - MOTOR REPLACEMENT

is servicing requires a steady hand, knowledge of electrical circuits and time. Do not perform this service if you are uncertain of

your skill. Like all motors or things with moving parts, parts have a tendency to wear down, even when maintained. As the main

source of power for your locomotive, your motor undergoes stresses such as voltage variation, torque fatique, fatigued springs or worn

brushes and commutator. At some point, your motor may require servicing or replacement. To gain access to the motor, the boiler will

need to be removed. We have made this as easy as we could while maintaining aesthetics and operational validity.

CONT’D

- REQUIRED - #0 Phillips screw driver, grease, soldering iron, ux, small at head screw driver

SERVICING THE D-10h MODELS*

Please note that servicing the SMT models by any none authorized dealer may void your warranty.

Please note that ANY modication to electronics in your locomotive will void your warranty.

CONT’D

To remove the boiler, you will need to

remove the 2 (two) screws as highlighted in

the rendering above. Place these screws in a

safe, secure location

Tilting the boiler from the BACK forward

(as depicted in the render) slide the boiler

o. is will leave exposed the motor,

universal, worm gear cover, and ywheel.

Place the boiler in a safe place where no

damage will occur.

Using a small at head screwdriver, pry

o the worm gear cover, exposing the

worm gear. At this point, you can service

the motor by de-soldering the leads and

replacing or changing. Please note that

changing any electronics in your locomotive

will void your warranty.

Now maybe a good time to access the drive

mechanism should you need to lubricate

and service. With the boiler and motor

removed you will need to remove the screw

cover on the cab oor. e two screws

secure the boiler bottom, which can now li

straight out.

CONTINUED SERVICE

With the chassis exposed, you can put lite

GREASE in the service hole of the drive

mechanism. Not much grease is needed,

and be carefull NOT to over pack the

drive with grease. ere is a CAM located

on the front axle that will not function

correctly if covered in grease. You can also

remove the 2 cover screws to access the

worm gear, idler gear and counter gears.

While there is rarely need for servicing in

this area, it may happen.

If grease gets between the worm gear

assembly (worm gear, washer, bronzite

bushings) you should remove the grease

and use lite oil. e metal on metal con-

tact surfaces require lite oil to penetrate

the tight tolerances. GREASE WILL NOT

CORRECTLY LUBRICATE THE WORM

GEAR WASHERS AND BUSHINGS AND

MAY RESULT IN MECHANISM FAIL-

URE IF NOT CORRECTLY APPLIED.

e bronzite bushing requires lite oil for

correct lubrication and operation! is

cross section shows the gears in operatioal

order. Modication of gears will result

in erratic running. DO NOT USE ANY

OTHER GEARS FOR OPERATION.

MODIFICATIONS TO THE DRIVE OR ELECTRONICS WILL VOID ANY AND ALL

WARRANTIES ASSOCIATED WITH THIS PRODUCT

NOTE: e front driver axle has a CAM on it

and is NOT a geared driver. is allows the

chu option to synchronize with the drivers as

they push the pistons.

geared driver

geared driver

cam-driver

! !

DO NOT GREASE THIS DRIVER

2021 SHIRA MODEL TRAINS. USED WITH PERMISSION.

FUNCTION TYPE

F0 Head Light

F1 Bell

F2 Whistle

F3 Coupler Sound

F4 Coast Mode

F5 Rear Light

F6 Numberboard

F7 Switching Mode

F8 Drive Sounds

F9 Heavy Load Mode

F10 Independent Brake

F11 Coal Shoveling

F12 Dimmer

F13 ----

F14 Air Pump (variabler)

F15 Air Pump (slow)

F16 Injector

F17 Auto Brake Set/Rel

F18 Ash Dump

F19 Blowdown

F20 Safety Valve

F21 Air Horn

F22 Rods

**If you change your settings, and wish to revert back to the FACTORY DEFAULT settings, set CV8 to 8.

For optimum performance, your new model comes equipped with an all-wheel electrical pick up. To ensure that wheels and track surfaces

are clean, use a non-abrasive track / wheel cleaning product to remove carbon deposits that could interfere with operation. ese are

available from your local hobby retailer.

Warranty

Each locomotive leaves the factory aer inspection and running to ensure that all mecha-

nisms and features are operative. While damage may occur from handling by shipping and

courier companies, we have designed our packaging to absorb most of the jolting that may

occur. Small parts that become dislodged, loose or fall o during transport are NOT covered

under warranty for service, however, pieces that may have become damaged in transit we

will replace for you under warranty with a valid proof of purchase. If you have purchased

the unit directly from us, there is no need to provide additional paperwork. If you receive

your locomoitve completely damaged beyond what you may consider an acceptable amount,

please DO NOT USE your locomotive.

Your locomitve has been designed in CANADA by SHIRA TRAINS and assembled with pride in Dongguang City, Guangdong province at the YIHE ARTS AND CRAFTS CO., LTD.

CONTACT INFORMATION:

HEAD OFFICE SERVICE DEPT

Email: sup[email protected]

Website: www.shiratrains.ca

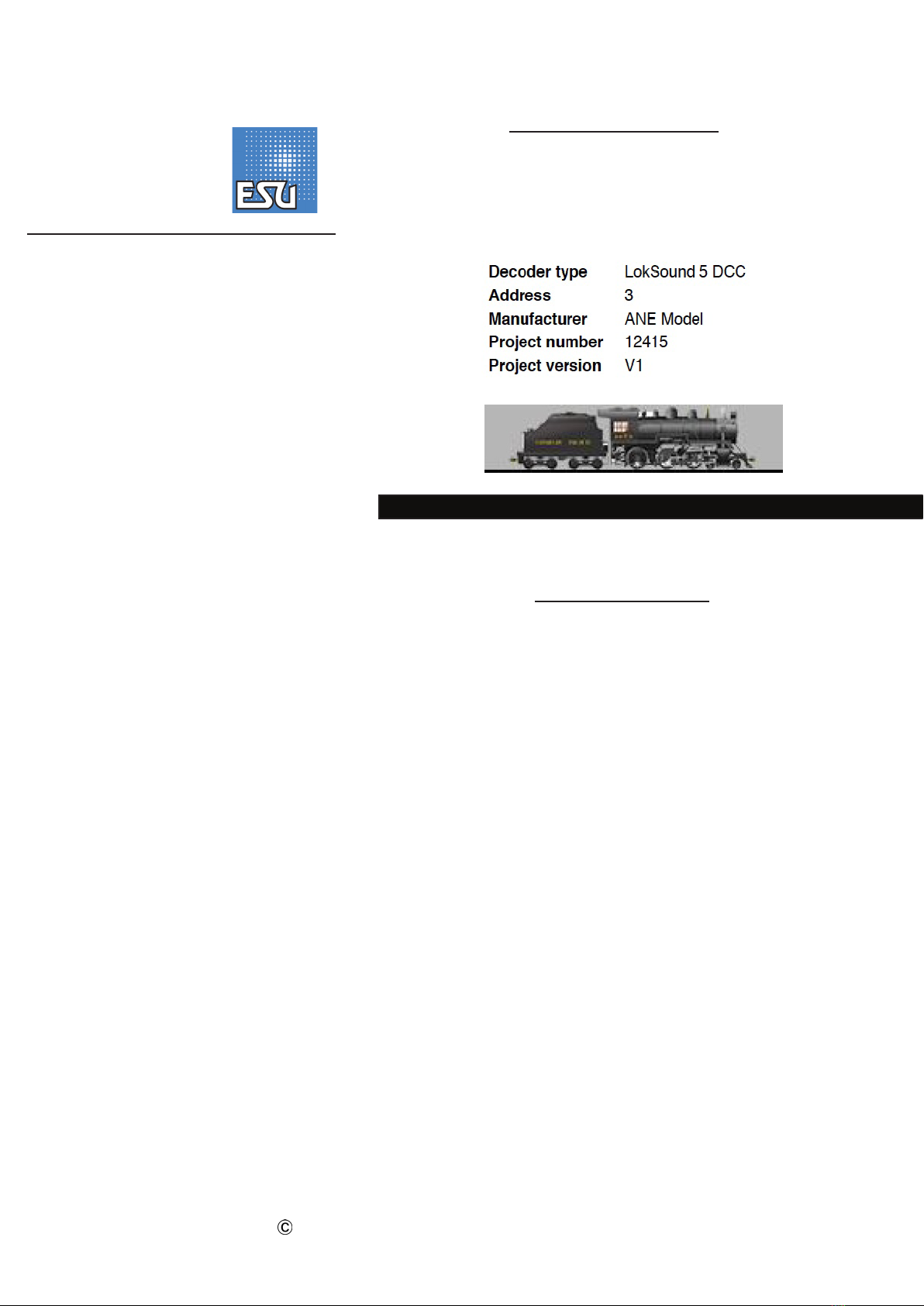

DCC/DC/SOUND

Your new D-10 model comes equipped with an ESU

decoder. e included LOKSOUND 5 is ready to use on

your analogue or digital layout. For more information on

your ESU LOKSOUND 5, please visit www.loksound.com

If you change any CV settings on your locomotive, you can

reset your decoder to its factory defaults by setting CV8 = 8.

THE FINE PRINT.

1)Products are covered for 6 months when purchased from an authorized dealer and covers the ORIGINAL purchaser only and is non-transferrable.

2)Repairs must include the original sales receipt.

3)All products must be registered to receive any warranty work. Please register your locomotive.

4)All products are warranted against manufacturers defect in material or workmanship.

5)At our discretion, we will credit, repair or replace the defective parts without charge for parts or labour. Credits are in credit form against future products.

6) Locomotives over 2 years from DATE OF PURCHASE or that have been modied are not covered under this warranty.

7) is warranty DOES NOT cover damages caused by transit, over usage, modication, alteration, customization, improper handling or usage or abuse.

8) is warranty DOES NOT cover regular usage parts such as LEDs, Pick-up wires, or moving parts, acts of God, re, unforseen accidents or anything that remains out of the

control of the manufacturer.

Other manuals for D-10h

1

Table of contents

Other Shira Trains Toy manuals