1Check and ensure that no raised grain or

splinters are evident on timber components.

Sand down any raised grain or splinters

using fine grade sandpaper.

2Check that all screw, nail and pin heads are

properly tapped home and are not proud of

the timber surface.

3Check and ensure that no screws, nails or

pins protrude through any panel.

4Check and ensure that all parts are properly

secured against reasonable force.

5Do not apply decorative wood

finish/treatments to wet or damp timber.

Please observe the instructions of the wood

finish/treatment manufacturer.

Assembly Completion Checklist

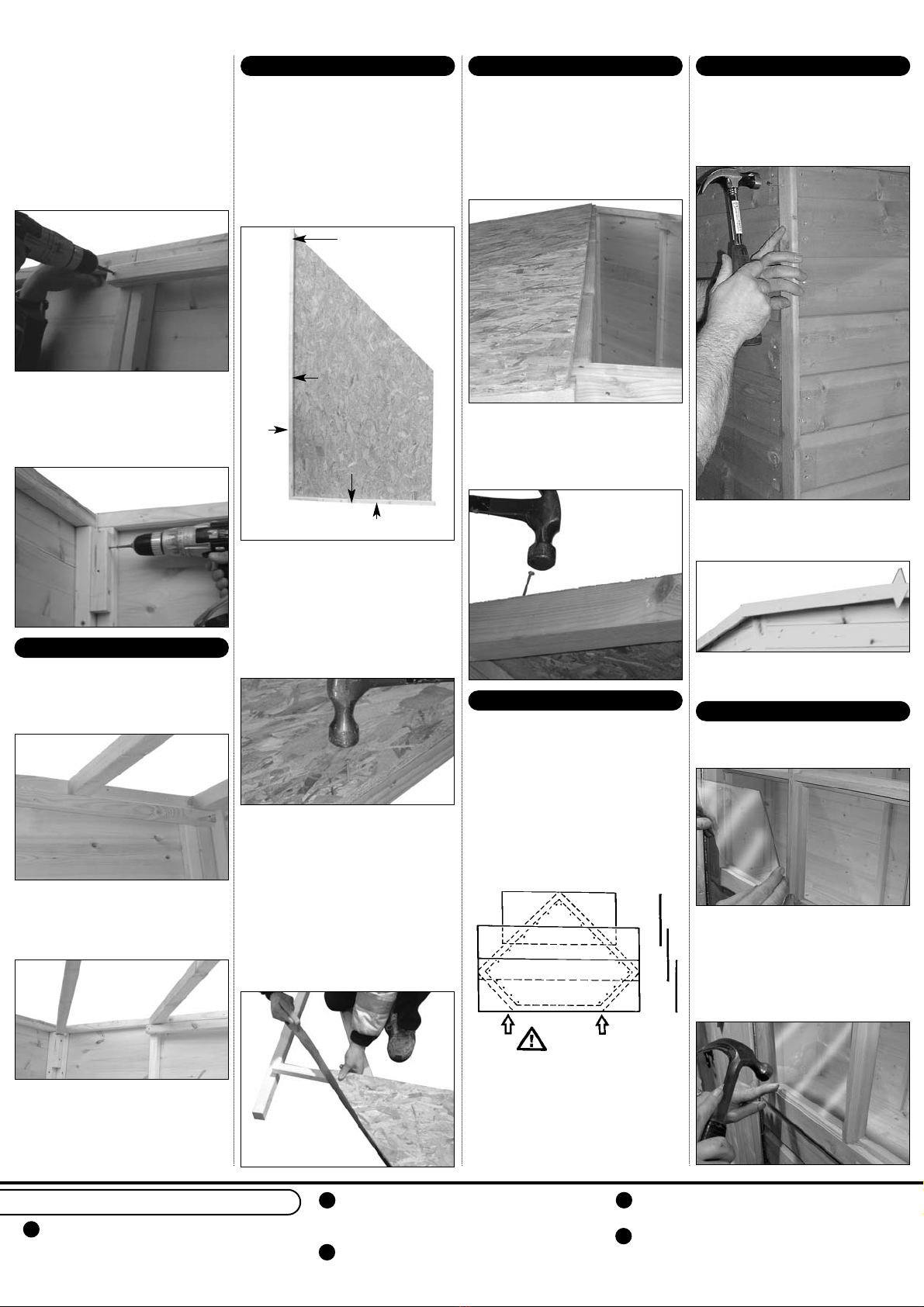

1 Place one large roof section at the

back on one half of the building.

Place the smaller piece in front.

The framework of both sections

should be positioned to go on the

outside of the building. Repeat with

other roof sections.

2 Secure roof to beams and walls

using 40 mm nails - 4 in each beam,

6 in the door section, 3 in each

window panel and 6 in each side.

I- Fit Roof

1 Coverstrips 'I' are fitted at the two

corners where the window panels

meet the sides and where both side

panels meet. Secure using 4x 40

mm nails per strip

2 Fit profiled cover strips where front

meets window panels. Secure using

4x 40mm nails per strip.

3 Fit diamond 'K' where facia joins

above doors using 2x 40 mm nails.

K- Fit Facia, Diamonds & Coverstrips

1 Cut 2 strips of felt measureing 3.42

mtr long. Cut another piece 2 mtr

long. Place the 2 mtr strip at the

back corner and allow an overhang

of felt of approx 50 mm all round.

Place a length 3.42 mtr long

overlapping the existing strip of felt

with the new piece and the final

3.42 mtr piece overlapping this,

leaving approx 50 mm all round.

2 Check that the whole roof felted

and that the overlaps are even.

Secure using 13 mm felt nails

spaced about 75 mm apart, across

the centre of each overlap and all

around the edge of the building.

J- Felt Roof

1 Place a pane of glazing material

'C3' in one aperture.

2 Hold into position with four pieces

of beading 'C4'. The beading may

need to be swapped around to get

the best fit. When satisfied secure

into position using 2x 15 mm panel

pince per piece of beading.

Repeat.

L- Glazing

1 Take one large shaped panel ‘G1’.

Attach piece of framework 1240mm

long ‘G3’. G3 should be flush in the

bottom right-hand corner on the

bottom edge; the opposite end will

overhang. Secure into place using

5x 40mm nails. Note: The picture

shows where the studwork goes

and which panel it should overhang.

2 Attach roof frame ‘G4’, 2137mm

long, flush with ‘G3’ timber; the

opposite end should also overhang.

Secure into place using 7 x 40mm

nails. Repeat with the other large

roof panel ‘G1’. IMPORTANT: make

sure you assemble the mirror image

of the first panel.

3 Take one smll roof triangle panel

‘G2’. Attach piece of framework

1340mm long ‘G3’. Place G3 flush

in the right-angled corner of the roof

panel. Secure with 4x 40mm nails.

Repeat with other small roof panel.

IMPORTANT: make sure you

assemble the mirror image of the

first panel.

Saw off all overhanging

pieces of studwork flush with the

edges of all the roof panels.

H- Construct Roof

4 On the centre framework of one

plain panel in the corner measure

and mark at 78mm. On the outer

frame of the plain panel next to it

mark and measure 78mm. Take

another roof beam support ‘E1’,

position the bottom of the support

on the marks and drill/screw into

position using 2x 60mm screws.

Repeat at other side.

5 In back corner, measure and mark

44 mm from the top. Place the top

of block 'E3' on the mark and

drill/screw into position using 2x 60

mm screws.

1 Take longest support 'F1' and place

back corner to centre of door gable.

The shaped end of the support fits

into the back corner.

2 Take another roof support ‘F2’ and

place on roof beam support at front

and back on one side. Repeat at

other side.

3 Check the building is square. The

gap between roof beams should be

approx. 556mm. Secure beams to

supports using 1x 60mm screw per

beam/support.

G- Fit Roof Beams

Back Corner

Side Panel

Window Panel

G3

G4