We advise the use of non slip protective gloves throughout

the assembly process.

We advise the use of steel capped protective footwear

throughout the assembly process.

We advise the use of protective headwear and safety

goggles throughout the assembly process.

Where a ladder is in use another person must hold the

ladder.

Do not attempt to work in windy conditions.

We advise the use of a scaffold tower when fitting the roof,

for felting or if you cannot reach from the ground.

Do not allow children near the tools and work area.

Follow any safety precautions quoted by the manufacturer

for any equipment you use.

We advise that you use a helper to hold the glass in position

whilst you nail the beading in place.

Check all parts before assembly.

Only use child and animal safe wood preservative.

Do not use creosote.

Allow the wood preservative to fully dry before use.

Regularly check the building for wear and tear.

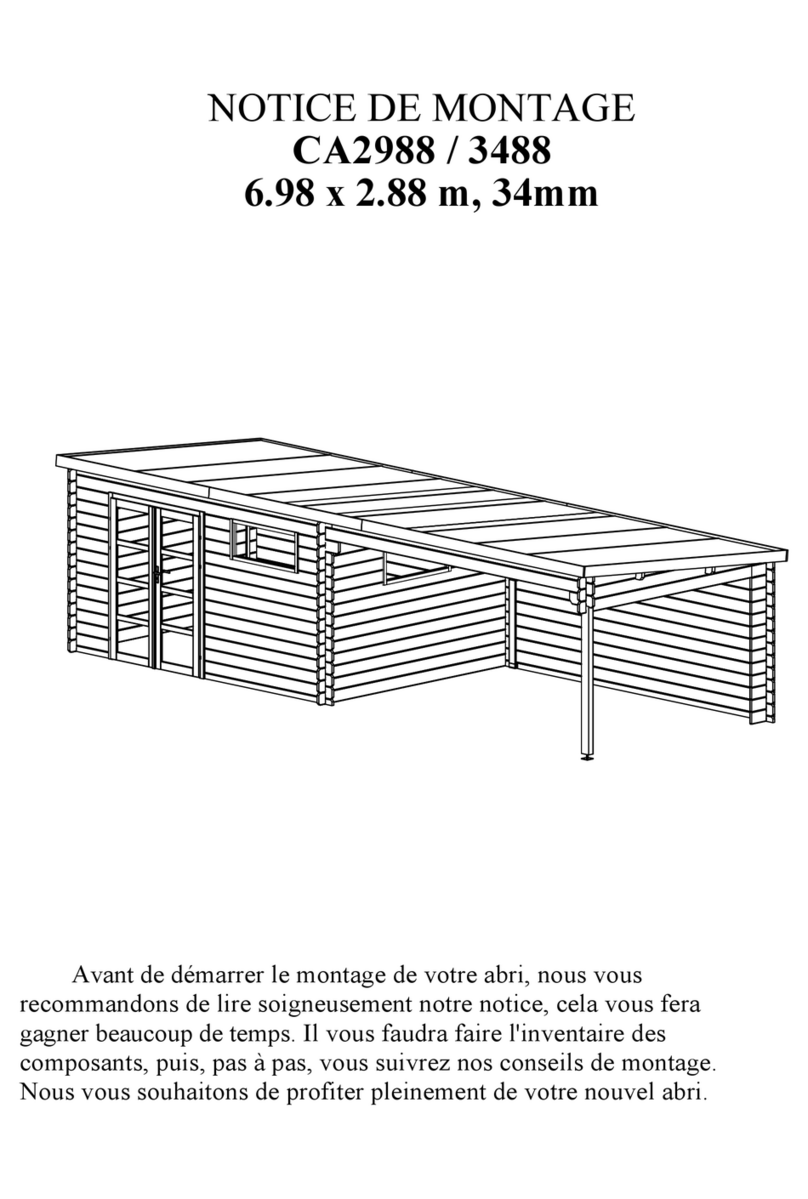

Getting Started…..

GB

IE

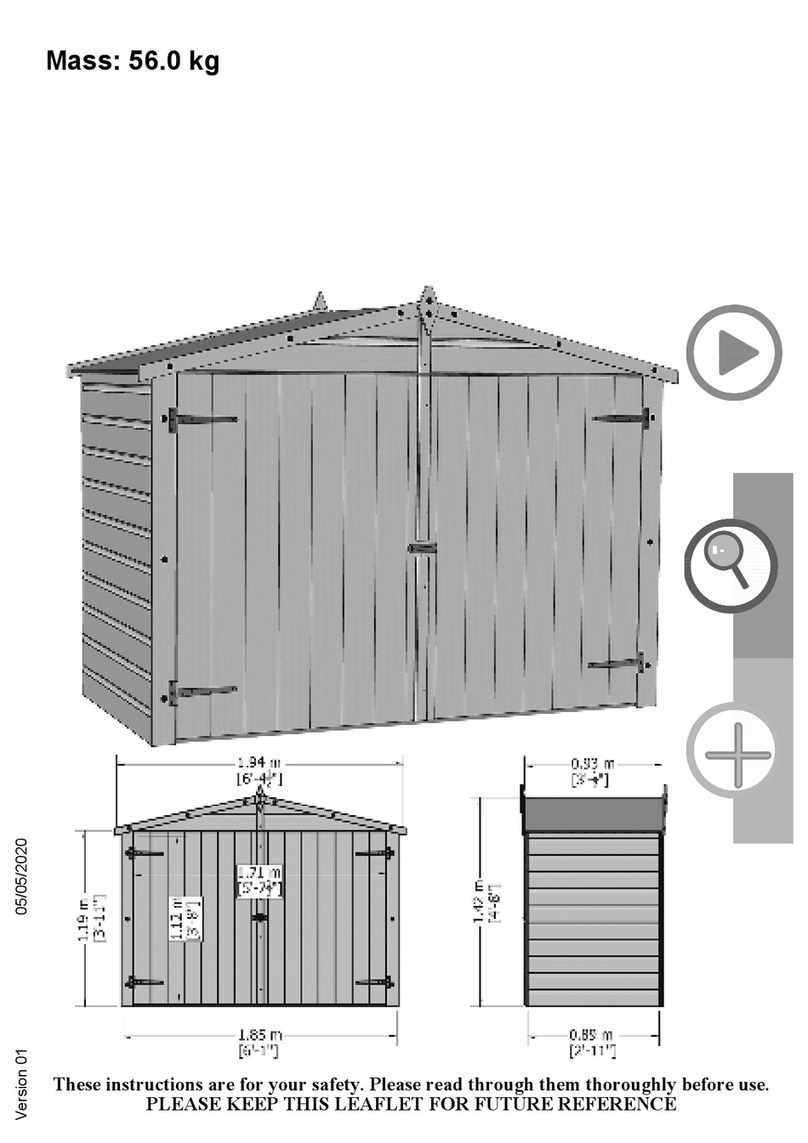

EVERY PRECAUTION IS TAKEN TO ENSURE THAT YOUR BUILDING HAS NO

ELEMENT INCORRECTLY PLACED OR POSSIBLY HAZARDOUS, HOWEVER

PRIOR TO USE PLEASE CHECK ALL SURFACES FOR THE FOLLOWING:

(1) RAISED GRAIN, SPLINTERS: Sand down timber to smooth finish

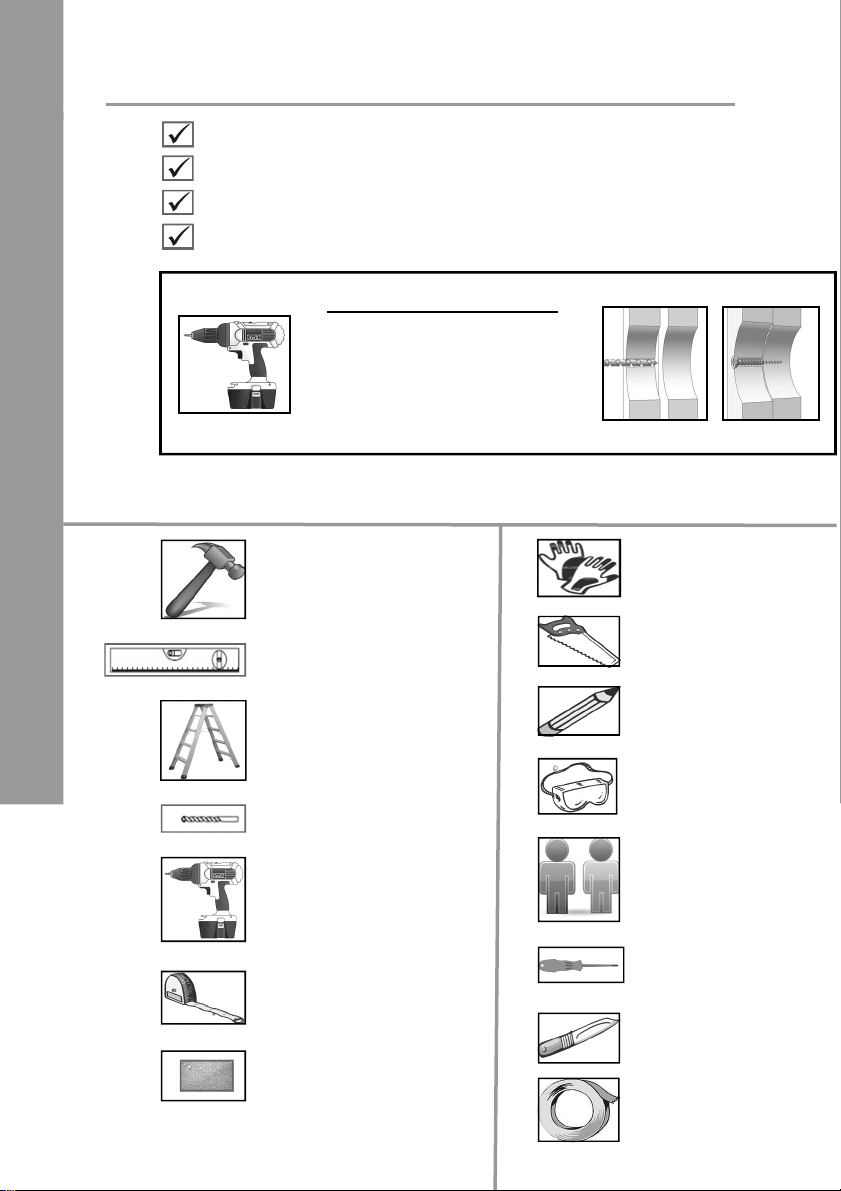

(2) NAIL/SCREW/PIN HEADS PROUD: Tap home to be flush with surface of

timber

(3) DAMAGED SCREW HEADS RESULTING IN SHARP SPLINTERS OF

(4) METAL: Replace

(5) SHARP ENDS OF NAILS/ SCREWS/ PINS PROTRUDING THROUGH THE

PANEL: Remove and reposition

(6) ENSURE ALL PARTS ARE SECURED AGAINST REASONABLE FORCE:

Remove and refit

(7) ENSURE THERE ARE NO LOOSE PARTS: Remove and refit/discard

Important!

Safety

IMPORTANT ! For your safety please

read carefully the safety warnings

Check that you have noted all the following instructions:

03