UNDERSTANDING THE BASICS 8

UNDERSTAND THE BASICS

SHOCKWAVE SUSPENSION SEATS are designed to mitigate

shock and vibration encountered in high speed vessel operation

in rough seas. Following the recommendations in this section

will ensure that you are getting the most out of the product.

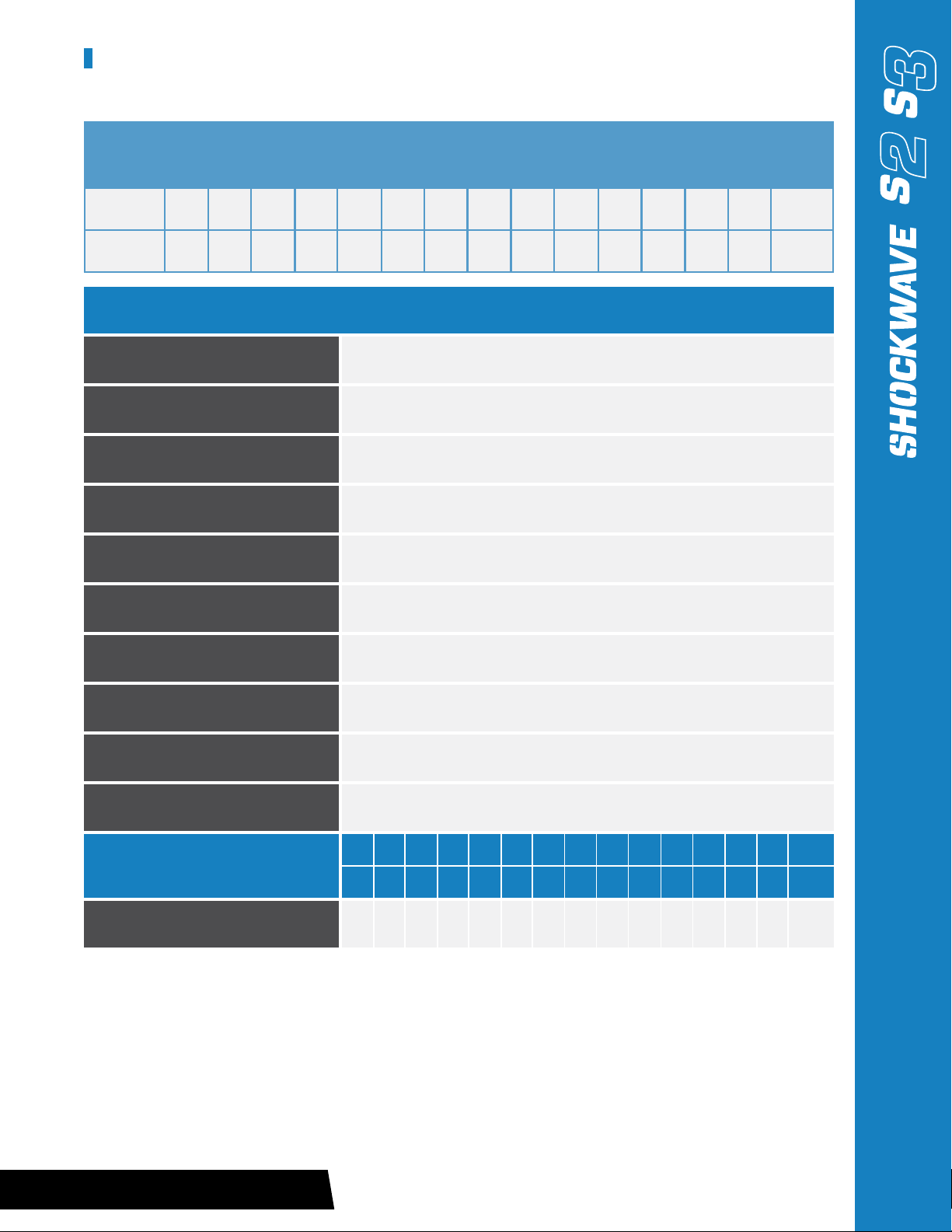

CHECK THE ACCURIDE GAUGE

The ACCURIDE gauge is indication that your shock absorber is

set up correctly. Keep green arrow in the green zone when seat

is occupied and operated.

OPERATE IN THE VESSEL’S DESIGN ENVELOPE

Driving the boat beyond its limitations can have damaging

effects on the hull, engines and equipment. SHOCKWAVE Seats

are designed to provide shock mitigation to the occupant. They

will not protect the occupants from injury caused from operating

the vessel outside of its operational envelope.

OPERATE THE VESSEL IN YOUR CREWS PHYSICAL

CONDITIONING ENVELOPE

Personal fitness is a limiting factor to the amount of

sustained G Loads a person can endure without injury. If you

have inexperienced, relatively unfit or overweight persons

aboard extra caution must be exercised to prevent injury. The

helmsman must be keenly aware of the shock loads being

transmitted to others not in a suspension seat or standing as

serious injury can occur. Installation of SHOCKWAVE Seats

provides an extra level of protection but they will not protect

a person from ALL shock loads.

OPERATE IN YOUR OWN ABILITY ENVELOPE

SHOCKWAVE Seating will increase the confidence of the

helmsman. Over confidence can lead to loss of boat control.

Generally, the seats will permit greater control of the vessel

and the helmsman should focus on using the control advan-

tages of shock mitigated seating to better care for the vessel

and crew.

DO NOT TIE THE BOAT UP WITH THE SEATS

As tempting as it may be SHOCKWAVE Seats are not designed

to tie up the boat. A sudden surge or wave with likely bend the

seats or attachment brackets and compromise performance.

ENSURE THAT SEAT IS FUNCTIONING PROPERLY

Refer to the Danger, Caution, Warning and Important notes in

the Operations and Service Manual. The following is provided

as a general checklist.

Do not operate the seat if:

• The shock absorber setting or ride height is incorrect.

• Components are loose, broken or missing.

• The seat makes a strange noise.

USE SEAT BELTS - IF SUPPLIED

Seat belts prevent occupants from being ejected from the

vessel and the seat. When not in use, the seat belt buckle

clasps should be fastened to prevent damage to the seat, seat

belt and the suspension module.

ADJUST HEIGHT AND FORE AND AFT ADJUST

CORRECTLY - IF SUPPLIED

Correct ergonomics and posture enhances the ability to

operate the vessel safely and reduces the risk of shock and

vibration related injury. Take the time to adjust the seat so

that it is comfortable.

DO NOT SIT IN SEATS WITH HARD OR SHARP OBJECTS.

DO NOT WALK ON SEATS

Ensure that sharp objects and heavy gear are worn so that

they will not tear upholstery.

RINSE SEATS WITH FRESH WATER AFTER EACH USE

Rinse seat with fresh water after each use or every week if

being stored outside to prevent a buildup of salt and debris.

COVER SEATS WHEN NOT IN USE

Seat covers are available from SHOCKWAVE to cover all

seat. These are a custom order item and can be ordered by

contacting SHOCKWAVE.

TIE EVERYTHING DOWN

Pay attention to how you have stowed your gear. Elastic

shock cords and ratchet tie downs should be used to secure

all gear. Plastic containers of oil and other fluids must be

protected from chafing and puncture. Electronic equipment

must be secured to prevent damage from shock loads.

CHECK ALL EQUIPMENT

Conventional mounting brackets for heavy items such as fire

extinguishers are subject to much more loading than without

shock mitigation. Make sure all of your equipment brackets are

tight. Recheck major equipment bolts regularly. Wiring, cables

and fluid hoses should be bundled tightly and not allowed to flail.

Do not allow any objects under the seats or footrests. They will

limit the stroke of the seat, damage the objects or damage the

seat.

REMOVE OR PAD BODY STRIKE HAZARDS

Hard objects, particularly in the head strike zone, need to

be rounded and padded. When assessing your body strike

hazards take into account a generous portion of clearance,

as the body will stretch in a high G situation.