Shoe Systems Plus SUPREME MGP34 User manual

SUPREME MGP34

BENCH SANDER

Operator Manual

Shoe Systems Plus, Inc.

249 W Main St.

Goshen, NY 10924

www.shoesystemsplus.com

800-354-6278

MGP34 Operator Manual

Supreme Bench Sander

1

SUPREME MGP34 BENCH SANDER

INTRODUCTION

The Supreme Bench Sander is a compact, durable machine designed for fast,

complete finishing work. It will deliver efficient, dependable service when used

correctly and with care. As with any piece of specialized equipment, for best

performance the manufacturer’s instructions must be followed.

BEFORE USING THE SUPREME BENCH SANDER, BE AWARE OF THE

FOLLOWING SAFETY RULES:

WARNING: For your own safety, read operating instructions manual

before operating tool.

BE PREPARED FOR JOB

•Wear proper apparel. Do not wear loose clothing, gloves,

neckties, rings, bracelets or other jewelry which may get caught in

moving parts of machine.

•Wear protective hair covering to contain long hair.

•Wear safety shoes with non-slip soles.

•Wear safety glasses. Everyday glasses have only impact

resistant lenses. They are NOT safety glasses.

•Wear face mask or dust mask if operation is dusty.

•Be alert and think clearly. Never operate power tools when tired,

intoxicated or when taking medications that cause drowsiness.

PREPARE WORK AREA FOR JOB

•Keep work area clean. Cluttered work areas and work benches

invite accidents.

•Do not use power tools in dangerous environments. Do not use

power tools in damp or wet locations. Do not expose power tools

to rain.

•Work area should be properly lighted.

•Proper electrical plug should be plugged directly into properly

grounded, three-prong receptacle.

•Extension cords should have a grounding prong and the three

wires of the extension cord should be of the correct gauge.

•Keep visitors at a safe distance from work area.

•Keep children out of the workplace. Make workshop childproof.

MGP34 Operator Manual

Supreme Bench Sander

2

TOOL SHOULD BE MAINTAINED

•Always unplug tool prior to inspection.

•Consult manual for specific maintaining and adjusting

procedures.

•Keep tool clean for safest operation.

•Remove adjusting tools. Form habit of checking to see that

adjusting tools are removed before turning machine on.

•Keep all parts in working order. Check to determine that the

guard or other parts will operate properly and perform their

intended function.

•Check for damaged parts. Check for alignment of moving parts,

binding of moving parts, breakage of parts, mounting and any

other condition that may affect a tool’s operation.

•A guard or other part that is damaged should be properly repaired

or replaced. Do not perform makeshift repairs. (Use the parts list

to order replacement parts.)

KNOW HOW TO USE TOOL

•Use right tool for job. Do not force tool or attachment to do a job

for which it was not designed.

•Disconnect tool from power when changing accessories such as

grinding wheels, buffing wheels and the like.

•Avoid accidental start-up. Make sure that the switch is in the off

position before plugging in.

•Do not force tool. It will work most efficiently at the rate for which

it was designed.

•Keep hands away from moving parts and grinding surfaces.

•Never leave a tool running unattended. Turn the power off and

do not leave tool until it comes to a complete stop.

•Do not overreach. Keep proper footing and balance.

•Never stand on tool. Serious injury could occur if tool is tipped

over.

•Know your tool. Learn the tool’s operation, application and

specific limitations.

•Use recommended accessories. Understand and obey all safety

instructions supplied with accessories. The use of improper

accessories may cause risk of injury to persons.

•Always use guard.

Dust generated is FLAMMABLE – DO NOT SMOKE when using

Sander.

MGP34 Operator Manual

Supreme Bench Sander

3

DESCRIPTION

Supreme Bench Grinders are equipped with a totally enclosed ball bearing

motor. Armature assembly is dynamically balanced for smooth operation. Motor

housing is compact so long pieces of work can press against wheels without

touching the motor frame. Removable wheel guards allow for easy changing of

wheels.

UNPACKING

Check for shipping damage. If damage has occurred, a claim must be filed with

the carrier immediately. Check for completeness. Immediately report missing

parts to dealer.

SPECIFICATIONS

Horsepower.......................................................................0.75

Voltage...............................................................................120

Amperes..............................................................................7.0

Hertz ....................................................................................60

Phase............................................................................. Single

RPM.................................................................................3450

Rotation (viewed from left side)................................Clockwise

OPERATING THE SUPREME BENCH SANDER

WARNING: Eye protection should always be worn by the operator

and others in the work area when the Sander is in use.

Eye protection is required for protection from flying

debris and dust, which could cause eye injury.

MGP34 Operator Manual

Supreme Bench Sander

4

INSTALLATION

The Supreme Bench Sander should be located on a flat, firm surface, in an area

free of obstructions that could interfere with the safe operation of the equipment.

The Bench Sander should be positioned and leveled on a solid bench or stand to

obtain quiet operation with a minimum of vibration.

DUST COLLECTOR HOSE (on model with dust collecting system):

A dust collector hose has been provided with grinder. Mount the hose by sliding

both ends over the exhaust port and the exhaust on the side of the blower

housing. Tighten the hose collars.

DANGER: Be sure to empty dust bag frequently.

SANDING WHEEL ON BAYONET:

Install the sanding wheel on the motor shaft. Slide the narrow side of the

bayonet into the hole at the end of the motor shaft. The bayonet will lock in place

just by turning it in the motor shaft.

WARNING: All electrical work must be performed by a qualified

electrician and must conform to all state and local

ordinances.

Do not, under any circumstances, tamper with, modify,

or adapt the electrical plug and cord provided with this

machine.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of equipment grounding conductor

can result in the risk of electrical shock. Equipment

should be grounded while in use to protect operator

from electrical shock.

•Check with a qualified electrician if grounding instructions are not

understood or if in doubt as to whether the tool is properly grounded.

MGP34 Operator Manual

Supreme Bench Sander

5

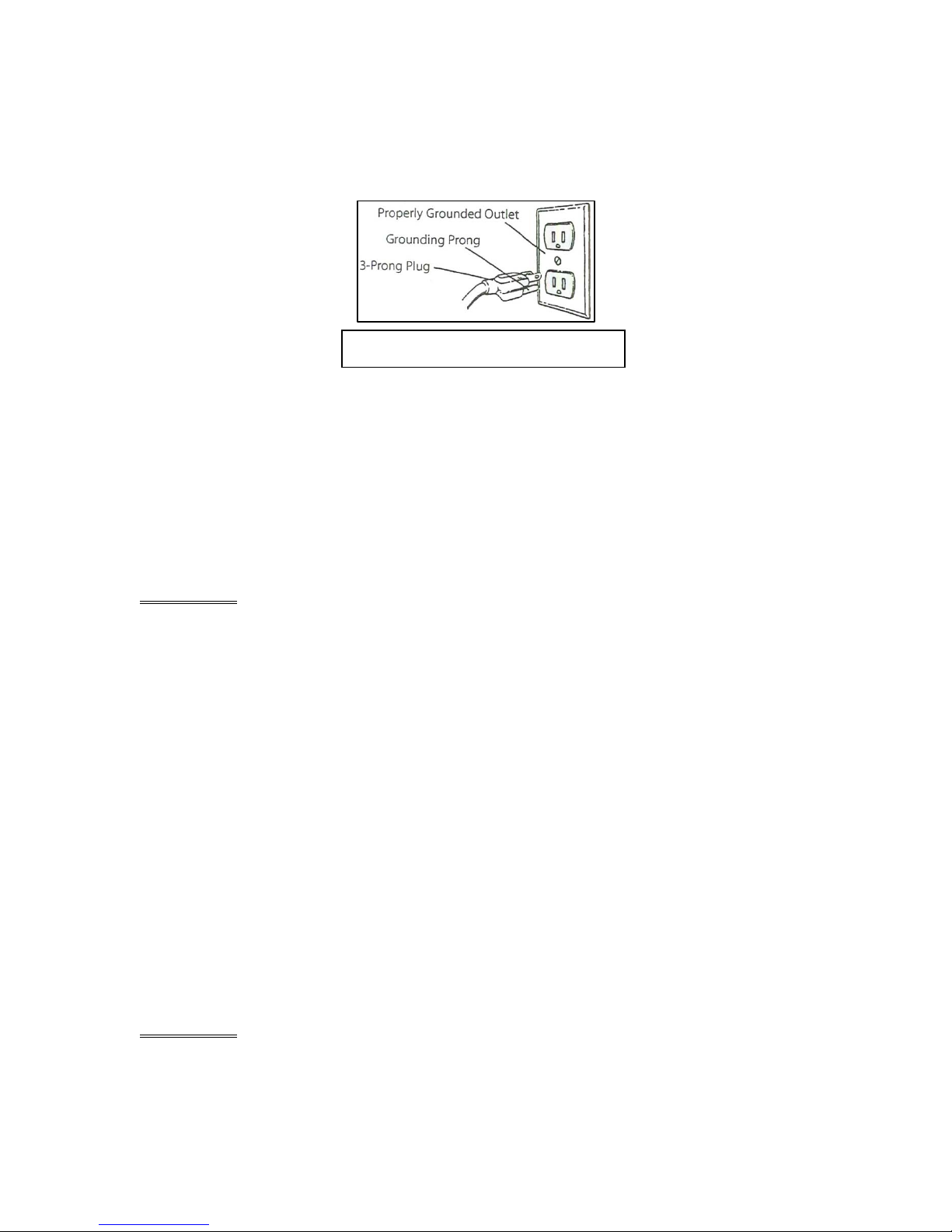

•This grinder is equipped with an approved 3-conductor cord rated at 300V

and a 3-prong, grounding type plug (See Figure 1) for your protection

against shock hazards.

•Grounding plug should be plugged directly into a properly installed and

grounded 3-prong grounding-type receptacle (See Figure 1).

•Do not remove or alter grounding prong in any manner. In the event of a

malfunction or breakdown, grounding provides a path of least resistance

for electrical shock.

WARNING: Do not permit fingers to touch the terminals of plug

when installing or removing from outlet.

•Plug must be plugged into matching outlet that is properly installed and

grounded in accordance with all local codes and ordinances. Do not

modify plug provided. If it will not fit in outlet, have proper outlet installed

by a qualified electrician.

•Inspect tool cords periodically, and, if damaged, have repaired by an

authorized service facility.

•Green (or green and yellow) conductor in cord is the grounding wire. If

repair or replacement of the electric cord or plug is necessary, do not

connect the green (or green and yellow) wire to a live terminal.

•Where a 2-prong wall receptacle is encountered, it must be replaced with

a properly grounded 3-prong receptacle installed in accordance with

National Electric Code and local codes and ordinances.

WARNING: This work should be performed by a qualified electrician.

Figure 1. 3-Prong Receptacle

MGP34 Operator Manual

Supreme Bench Sander

6

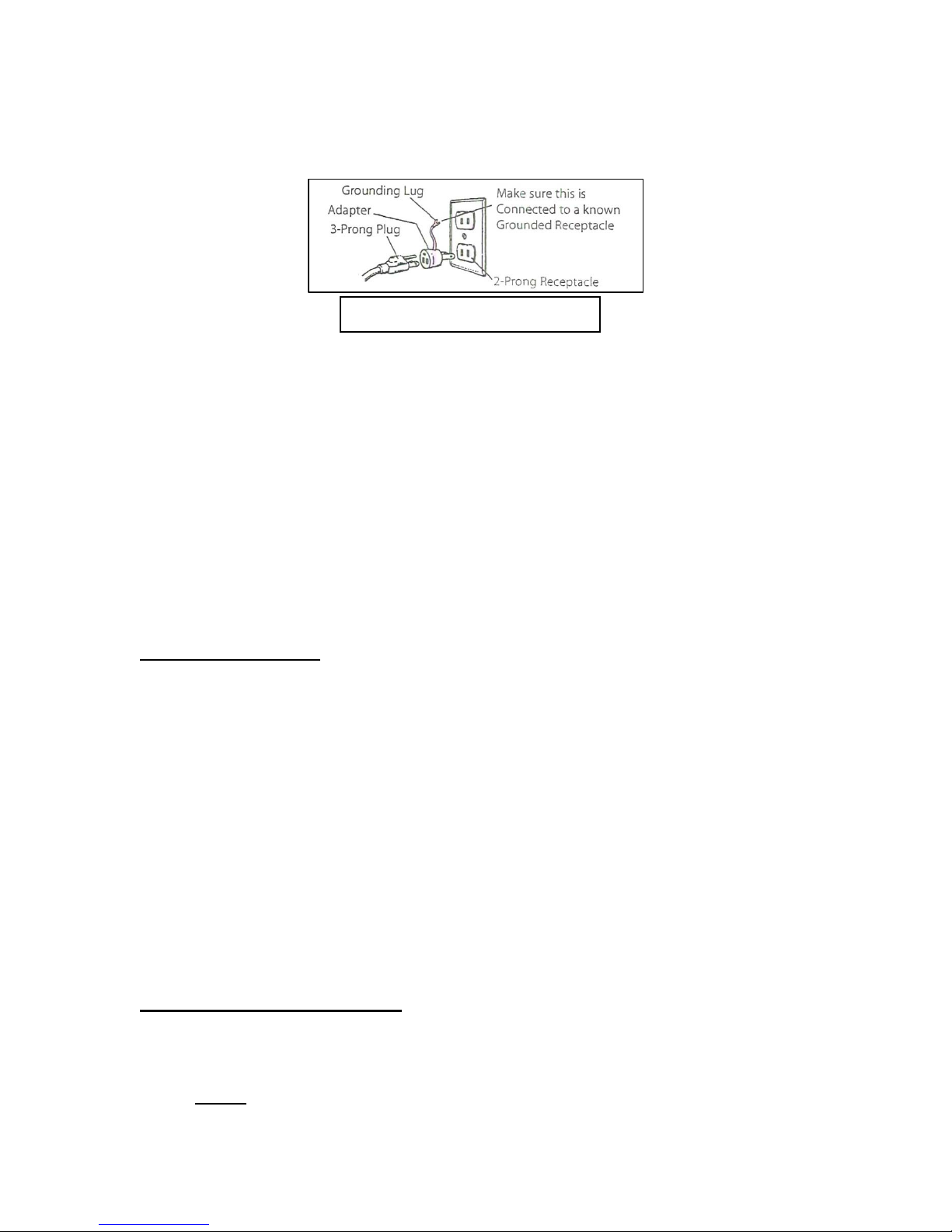

•A temporary 3-prong to 2-prong grounding adapter (See Figure 2) is

available for connecting plugs to a two pole outlet if it is properly

grounded.

•Do not use a 3-prong to 2-prong grounding adapter unless permitted by

local and national codes and ordinances.

(A 3-prong to 2-prong grounding adapter is not permitted in Canada.)

Where permitted, the rigid green tab or terminal on the side of the adapter

must be securely connected to a permanent electrical ground such as a

properly grounded water pipe, a properly grounded outlet box or a properly

grounded wire system.

•Many cover plate screws, water pipes and outlet boxes are not properly

grounded. To ensure proper ground, grounding means must be tested by

a qualified electrician.

EXTENSION CORDS

•The use of any extension cord will cause some drop in voltage and loss of

power.

•Wires of the extension cord must be of sufficient size to carry the current

and maintain adequate voltage.

•Running the unit on voltages which are not within ±10% of the specified

voltage may cause overheating and motor burn-out.

•Use the table to determine the minimum wire size (A.W.G.) extension

cord.

•Use only 3-wire extension cords having 3-prong grounding type plugs and

3-pole receptacles which accept the tool plug.

•If the extension cord is worn, cut or damaged in any way, replace it

immediately.

EXTENSION CORDS LENGTH

Wire Size.......................................................................A.W.G.

Up to 25 ft. (8 m) ..................................................................16

NOTE: Using extension cords over 25 ft. (8 m) long is not recommended.

Figure 2. 2-Prong Receptacle

MGP34 Operator Manual

Supreme Bench Sander

7

ELECTRICAL CONNECTIONS

WARNING: All electrical connections must be performed by a

qualified electrician. Make sure tool is off and

disconnected from power source while motor is

mounted, connected, reconnected or anytime wiring is

inspected.

WARNING: If the electrical cord, plug or wiring should become

frayed or damaged, replace it at once. Do not attempt to

operate the machine with faulty wiring as it could result

in severe injury or death.

WARNING: Do not start Sander before checking for proper

installation of the bayonet on the machine.

MGP34 Operator Manual

Supreme Bench Sander

8

START-UP

WARNING: Eye protection should always be worn by the operator

and others in the work area when setting up the

machine. Eye protection is required for protection from

flying debris and dust, which could cause eye injury.

Before shipment, your Supreme Sander was checked at the factory for proper

adjustment and operation. However, due to the possibility of jarring or damage

during handling and shipping, it is necessary to check that the machine is in

proper working order before use.

WARNING: Before initial start up, turn the motor shaft by hand to

ensure that all parts are free.

BEFORE CONNECTION TO AN ELECTRICAL POWER SUPPLY:

1. Check that the switch is off.

2. Check that the bayonet with the sanding wheel is locked in place on the

motor shaft.

WARNING: As with any piece of electrical equipment, there is an

ever present hazard of electrical shock when operating

or touching the Sander. Ensure the machine is properly

grounded at all times.

Do not force the equipment. It will do the job better and

safer at the rate for which it was designed.

SANDING BELT REPLACEMENT

WARNING: Eye protection should always be worn by the operator

and others in the work area when changing sanding belt.

Eye protection is required for protection from flying

debris and dust, which could cause eye injury.

(Sanding belts can be obtained in various grit to suit your needs and are easily

changed.)

WARNING: Some sanding belts are constructed to rotate in one

direction only. Check arrow inside sanding belt for

rotation. Incorrect installation can cause sudden belt

failure resulting in serious injury to operator and others

in the work area.

MGP34 Operator Manual

Supreme Bench Sander

9

To replace the belt:

1. Take off the bayoneted sanding wheel from the motor shaft.

2. Unscrew the nut at the end of the rubber wheel to release

pressure. You do not need to take it off. Only unscrew the nut.

3. Slide the sanding belt out of the rubber wheel.

4. Remove the sanding belt and replace with the new one.

5. Tighten the nut with enough pressure to avoid the sliding of the

sanding belt.

6. Install the bayonet on the motor shaft.

WARNING: Do not start Sander before checking for proper

installation of the bayonet on the motor shaft.

Never leave machine running while unattended. Turn it

off.

MGP34 Operator Manual

Supreme Bench Sander

10

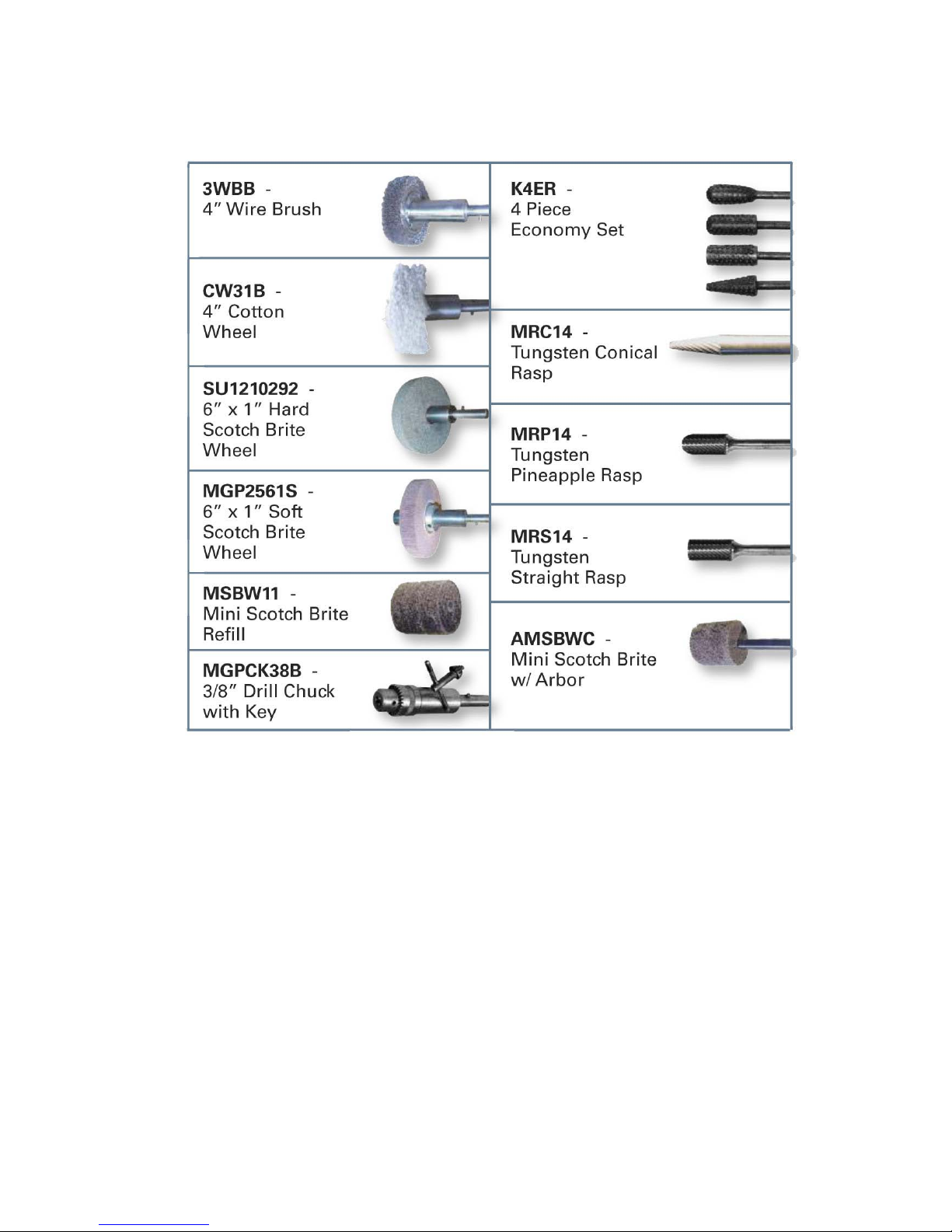

ACCESSORIES

WARNING: Eye protection should always be worn by the operator

and others in the work area when using the accessories

supplied with the Supreme Sander. Eye protection is

required for protection from flying debris and dust,

which could cause eye injury.

MGP34 Operator Manual

Supreme Bench Sander

11

MGP34 Operator Manual

Supreme Bench Sander

12

MAINTENANCE

A properly maintained machine will give you years of satisfactory service,

whereas an abused machine will not. We strongly recommend that you observe

the following procedures for your own benefit and safety.

WARNING: Eye protection should always be worn by the operator

and others in the work area when servicing the machine.

Eye protection is required for protection from flying

debris and dust, which could cause eye injury.

DAILY AND WEEKLY MAINTENANCE

1. Clean your Supreme Bench Sander daily.

2. Shake dust bag and empty it daily.

The cleaner you keep the dust bag, the less likely you are to burn a hole in

them. Failure to shake the dust bag and empty it daily will only increase

this likelihood, but also cause a significant loss of dust extraction.

WARNING: Dust from Sander is combustible. Do not smoke while

cleaning the machine and dust collector.

Damaged dust bag will allow the escape of combustible

materials causing a fire hazard around the machine.

Check damaged parts. Before further use of a tool,

guard or other part that is damaged, check carefully to

determine that it will operate properly and perform its

intended function. Check for mounting or any other

condition that may affect its operation. A tool, guard or

other part that is harmfully damaged should be properly

repaired or replaced.

If the electrical cord, plug or wiring should become

frayed or damaged, replace it at once.

After making adjustments, remove all wrenches and

other tools before operating the Sander.

Use extra caution when starting the Sander for the first

time after installing a new tool or part.

MGP34 Operator Manual

Supreme Bench Sander

13

MONTHLY MAINTENANCE

1. Take off the hose from the blower housing and look at the fan to see if

there are small particles stuck to the fan.

N.B. Those small particles can create vibrations of the bench sander.

2. Clean your dust bag with a shop vac or a vacuum cleaner.

N.B. You should change your dust bag at least every 2 years to increase the

efficiency of the dust collector.

LUBRICATION

Your Supreme Sander is equipped with sealed bearings throughout, which

should be replaced if they ever wear out.

Other parts should not require any lubrication, only cleaning the parts is required.

Lubrication will only attract dust and would be more harmful than helpful.

MOTOR REPLACEMENT

WARNING: Motor replacement requires working with electrical

wiring and can be hazardous. If you are not familiar with

electrical procedures, please call a qualified electrician.

To remove the motor, these procedures should be followed:

1. Disconnect the electrical power supply.

2. Take off the back panel to have access to the motor.

3. From the bottom of the machine, remove the four (4) bolts holding the

motor.

4. Disconnect the wiring from the switch and from the electric cord.

5. Mark the electrical wires to the motor such that you will be ABSOLUTELY

CERTAIN where to reconnect them on the new motor.

6. Reassemble with new motor in reverse order to the above procedures.

MGP34 Operator Manual

Supreme Bench Sander

14

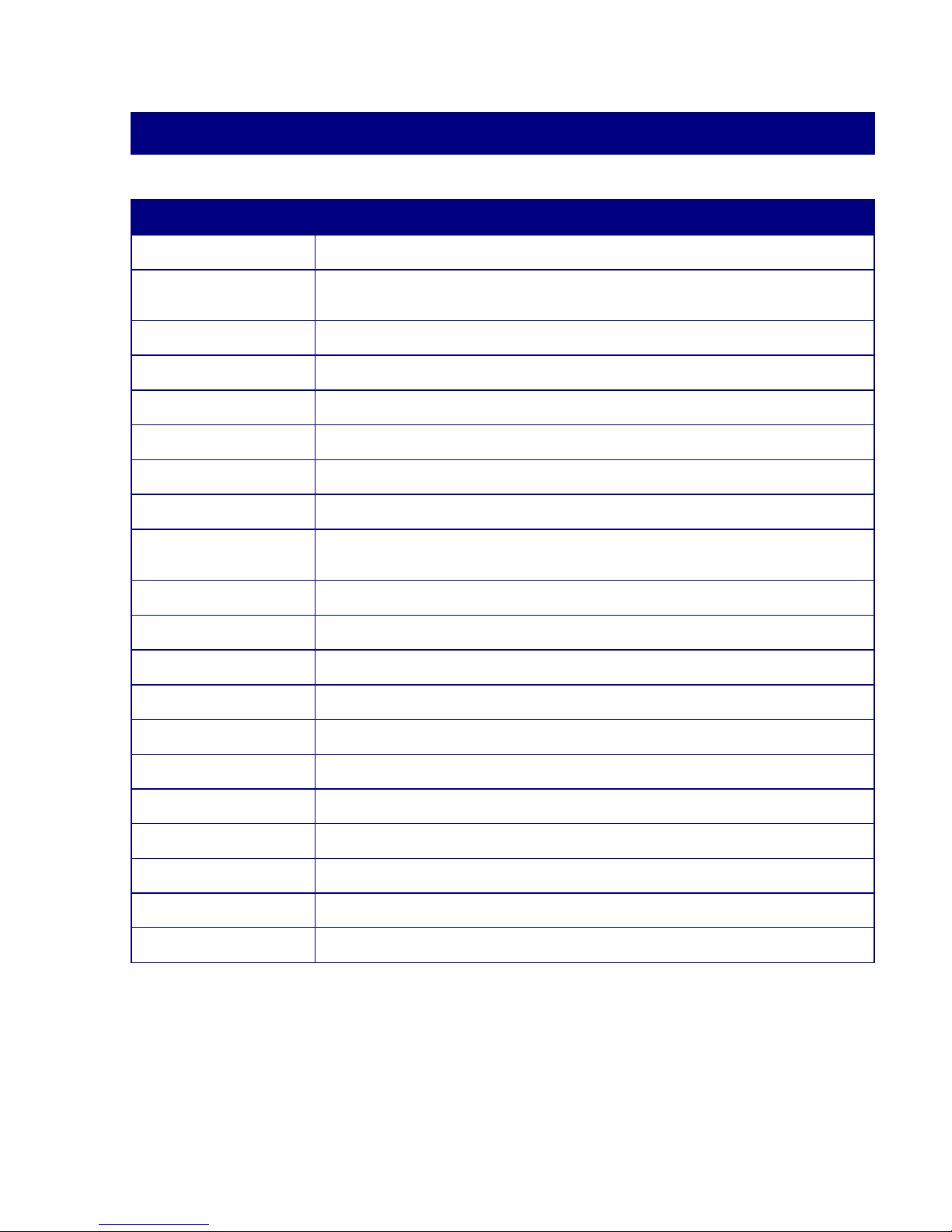

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE(S) CORRECTIVE ACTION

Grinder won’t start

1. Blown line fuse or

tripped circuit

breaker

2. Low line voltage

3.

Material wedged between wheel

and guard

4. Defective switch

5. Defective, blown capacitor

1. If fuse is blown, replace with fuse

of proper size. If breaker tripped,

reset it.

2.

Check power supply for voltage

and correct as needed

3.

Turn grinder off and remove

material

4. Replace switch

5. Replace capacitor

Excessive vibration

1.

Improper mounting of grinder or

accessories

2. Grinding wheel out of balance

3.

Dust or particles clogged on the

fan

1. Remount

2. Replace wheels

3. Clean the fan

Motor overheating

1.

Excess pressure required to

grind material

2.

Motor not turning freely (without

power)

1.

Replace sandpaper with one of

proper grit.

2.

Clean around wheels and shaft

and/or replace bearings

Fuses are being blown

or circuit breakers are

being tripped

1. Overloading due to binding

2. Defective plug

3. Defective cord

4. Defective switch

5.

Motor wired for different line

voltage

1.

Clean around wheels and shaft

and/or replace bearings

2. Replace plug

3. Replace cord

4. Replace switch

5.

Rewire motor as per wiring

diagram

Motor does not develop

proper torque

1.

Motor wired for different line

voltage

1.

Rewire motor as per wiring

diagram

Lost of suction

1. Dust bag maybe full

2. Blower fan may be clogged

3. Suction hose jammed

1. Empty it

2. Clean it

3. Clean it

MGP34 Operator Manual

Supreme Bench Sander

15

LOST OF SUCTION IN DUST COLLECTION

1. Dust bag may be full. Empty it.

2. Blower fan may be clogged. Clean it. Take apart the side cover of the

blower housing to have access to the fan.

MOTOR STOPS WITH SWITCH ON

CAUTION: Turn switch off immediately.

1. Too many equipment operated on same electrical circuit where the bench

sander is connected. Check circuit breaker or fuse box

2. Electric switch is broken. Change the switch.

MGP34 Operator Manual

Supreme Bench Sander

16

ACCESSORIES FOR BENCH SANDER

PARTS # DESCRIPTION

SMAK060 BLACK HANDLE TO ADJUST DUST PORT SUPPORT

ASB

S

HAFT BUSHING WITH SLOT

(

INCLUDED STEEL BALL SPRING

AND SCREWS

31786BAYONET MALE BAYONET FOR RUBBER WHEEL FOR RIGHT SIDE

09130019 FAN FOR DUST COLLECTING SYSTEM

31786 RUBBER WHEEL 4’’ X 3’’ (100 X 75 MM)

WAMGT34 SILVER WASHER FOR RUBBER WHEEL

WNMGT34 BUSHING FOR WASHER WAMGT34

HS64 COLLAR FOR GREY HOSE

TB4

G

REY HOSE

4’,

(100

MM

)

DIAMETER FOR DUST COLLECTING

SYSTEM

CMGP346124 KEY TO CHANGE SANDPAPER ON 4’’ X 3’’ SANDING WHEEL

CCL SPANNER WRENCH FOR BAYONET

888443 VELCRO STRAP FOR DUST BAG

SPBGNS DUST BAG

493824 REPLACEMENT SANDING SLEEVE 34 GRIT

493840 REPLACEMENT SANDING SLEEVE 40 GRIT

4938100 REPLACEMENT SANDING SLEEVE 100 GRIT

12015 SEAL FOR DUST BAG ENTRY

0700285 ON/OFF SWITCH

CA18 ALLEN KEY FOR DUST BAG POLE SCREW

31786B RUBBER WHEEL 4’’ X 3’’ ASSEMBLY ON BAYONET

MGP34 Operator Manual

Supreme Bench Sander

17

# 09130019

MGP34

Table of contents