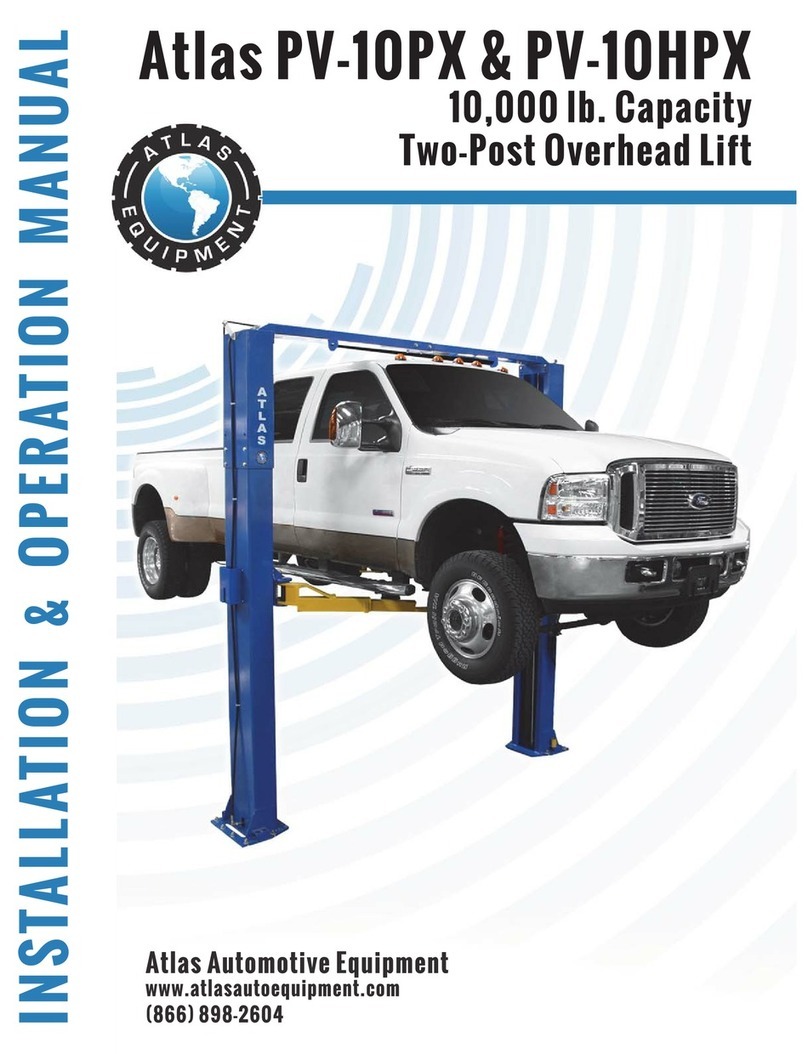

Shoreline Lift Mate User instructions

“LIFT MATE”

BOAT LIFT MOTOR

ASSEMBLY

Assembly and Operating Manual

www.boatliftmotor.com

03/26/2010

LIMITED WARRANTY

Shoreline Industries, Inc. warrants its products shall be free from defects in materials and

workmanship for a period of two years from the date of purchase as shown on the customer’s

invoice. Shoreline’s warranty is limited to products purchased new by the original owner and is

not transferable.

SHORELINE WILL AT ITS OPTION REPAIR OR REPLACE, WITHOUT CHARGE, OR

ALLOW CREDIT FOR ANY SUCH GOODS FOUND ON EXAMINATION BY SHORELINE TO

BE DEFECTIVE UNDER NORMAL USE AND SERVICE. THE BUYER’S REMEDIES WITH

RESPECT TO DEFECTIVE GOODS SHALL BE EXCLUSIVELY LIMITED AS ABOVE

PROVIDED AND IN NO EVENT SHALL THE SELLER BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES OF ANY NATURE. ALL OTHER WARRANTIES,

INCLUDING BUT NOT LIMITED TO WARRANTIES OF MERCHANTABILITY AND FITNESS

FOR A PARTICULAR PURPOSE ARE EXPRESSLY DISCLAIMED.

Shoreline’s warranty does not cover damage caused by circumstances outside its reasonable

control, including but not limited to, improper use, installation, overloading, accident, neglect or

harmful alterations or repairs made by others.

READ THROUGH THE ENTIRE MANUAL

It is recommended to read through the entire manual before beginning your installation.

Follow all steps exactly.

TOOLS NEEDED

Review the tools needed list here on this page. Gather all tools needed for the assembly of your unit

before starting the installation steps.

Adjustable Wrench

5/16” 1/2” and 15/16”

Open End Wrenches

Flat Head Screwdriver

Safety Glasses

2

20 FT. BATTERY CABLE

25 FT. BATTERY CABLE FOR PONTOONS

30 FT. BATTERY CABLE FOR PONTOONS

VMC – VINYL MOTOR COVER

Dresses up the motor and matches canopy color.

Available in six colors; burgundy, gray, tan, green,

white & blue.

REMOTE CONTROL ADD-ON KIT

Turns any Lift Mate into a “keyless remote” like

your automobile.

PONTOON KIT

3 ft. wheel extension. Moves the wheel away from

the winch.

TO ORDER

See your local retailer.

3

ACCESSORIES/OPTIONS

INSPECT SHIPMENT

Your boat lift motor was shipped complete in one

carton. Use care when handling the carton.

Remove all items from your shipping carton. Check

all items against the packing list below. Note any

items lost or damaged in shipment.

Note any damage to the shipping carton. Refer to

the exploded view and parts list in the back of the

manual for the part names and numbers of missing

or damaged items. Call retailer where purchased if

problems exist.

PACKING LIST

●Inner Arm with Bracket

●Outer Arm with Pivot Hole

●12 Volt Electric Motor OR

●110 Volt Electric Motor with GFI Outlet Cord

●15 Foot Battery Cord (12 Volt Motor Only)

●One each Parts Bag Assembly

Containing the following parts:

●One Each 9” Rubber Poly Strap.

●One Each 4 “ x 5/8

”

Hex Head Pivot Bolt.

●One Each 5/8“ Hex Head Pivot Bolt Nut.

●Two Each 31/2” x 5/16” Hex Head Bolt.

●Two Each 5/16

”

Hex Head Nuts.

●Four Each 5/16” Washers.

●Two Each S-Hooks.

●Two Each 5” Metal Band Clamps.

Do not proceed with assembly until you have a

good understanding of part identification.

4

PACKING LIST

PLAN YOUR INSTALLATION

The Lift Mate is designed to mount on most

manufacturers’ boatlifts. As a result of its

compatibility with all lifts, your first task is to review

your particular lift against the assembly instructions

included here.

Review the following bullets. Do not proceed with

the installation until you have a general

understanding of how you are going to install your

unit.

●The Lift Mate mounts onto the winch lift post.

Locate the winch post on your lift.

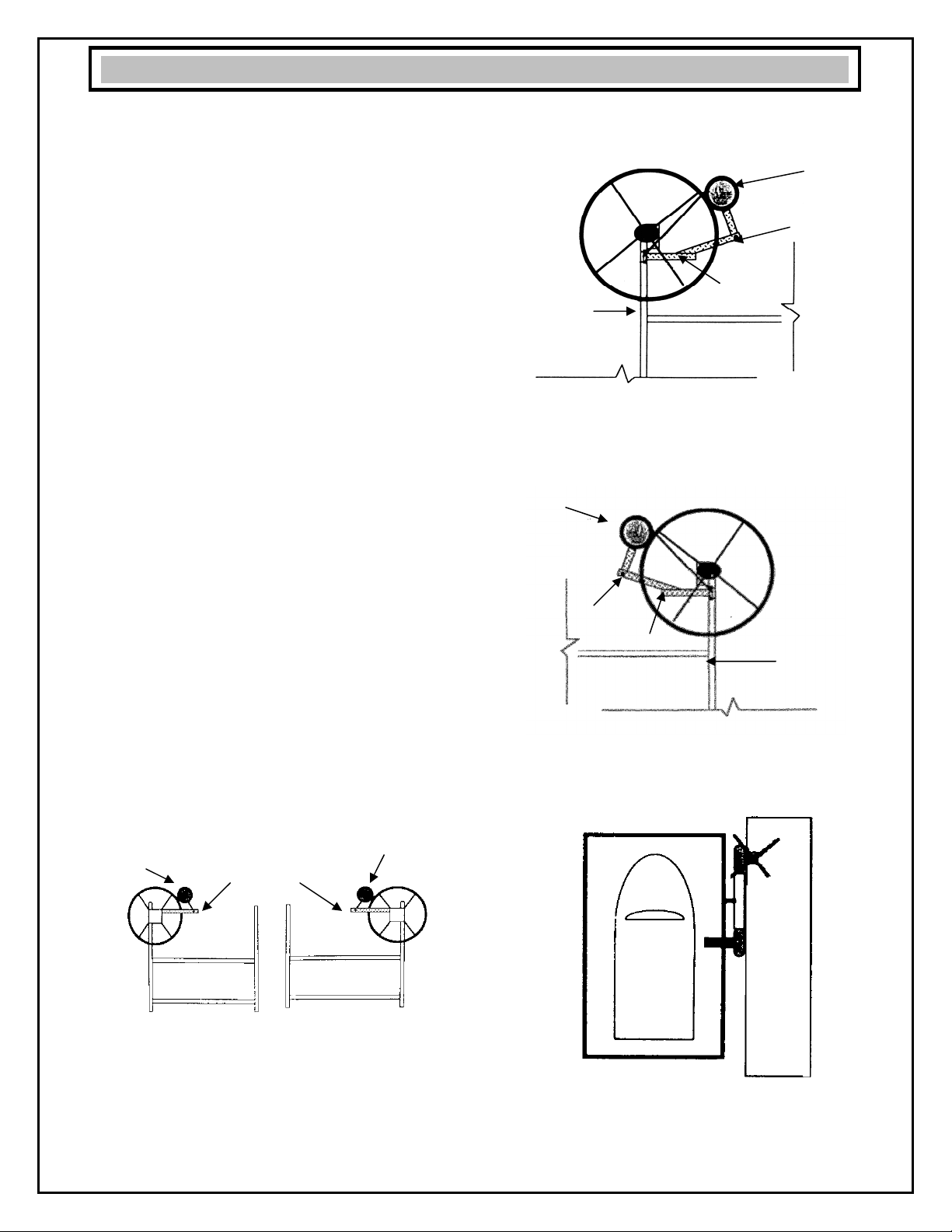

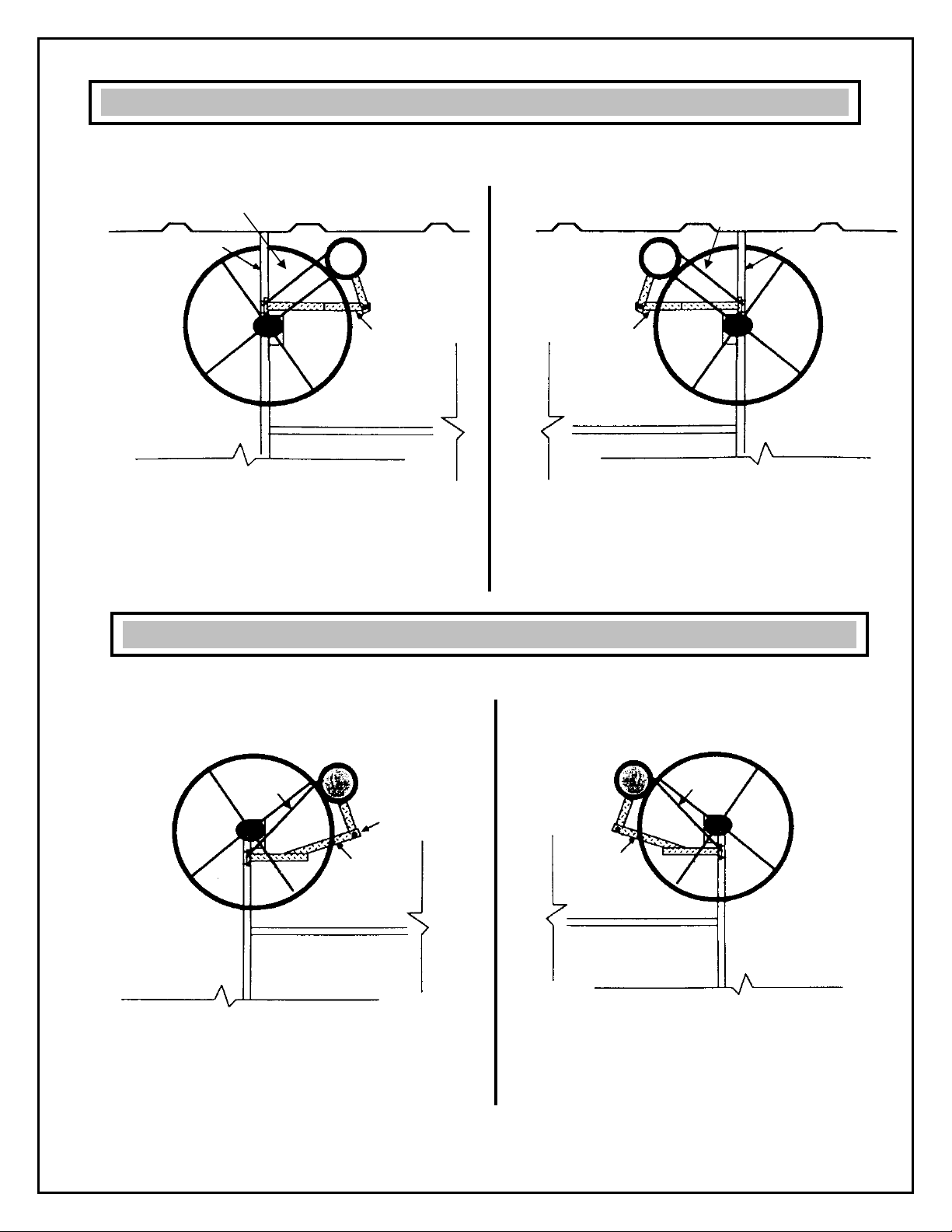

See Fig. 2 & 3.

●Stand on your dock in front of your lift. Determine if

your winch lift post is a left mount or a right mount.

See Fig. 2 & 3.

●Note that the Lift Mate motor is mounted so that it

is between the left and right lift posts.

See Fig. 1,2, & 3.

●Also note that the motor rests against the lift wheel

at roughly the 10 or 2 o’clock position. This allows

the weight of the motor to rest against the wheel

and aid in traction. See Fig. 1,2,& 3.

●Note that when properly mounted on the winch

post of the lift, the Lift Mate rubber traction wheel

is closest to the dock and the motor is closest to

the boat. See Fig. 4.

•The motor has two drain holes. The motor is

correctly mounted when the drain holes are on the

bottom side of the motor. Rainwater will seep into

the motor if the motor is mounted with drain holes

on top.

Left Winch Post Right Winch Post

Correct position of lift motor is between the left and right lift

posts in roughly the 10 or 2 O’clock position

As viewed from the dock.

FIG. 1

Left Winch Post Installation

As viewed from Dock

FIG. 2

Right Mount Winch Post Installation

As viewed from Dock

FIG. 3

Correct position of lift motor is when the rubber traction

wheel is closest to the dock and the lift motor is closest to

the boat

5 FIG. 4

Right

Winch

Post

Lift Motor

Lift

Motor

No

Yes

Dock

Boat

Lift

Motor

Lift

Motor

PLAN YOUR INSTALLATION

Inner Arm

Inner Arm

Inner Arm

Left

Winch

Post

Outer Arm

Outer

Arm

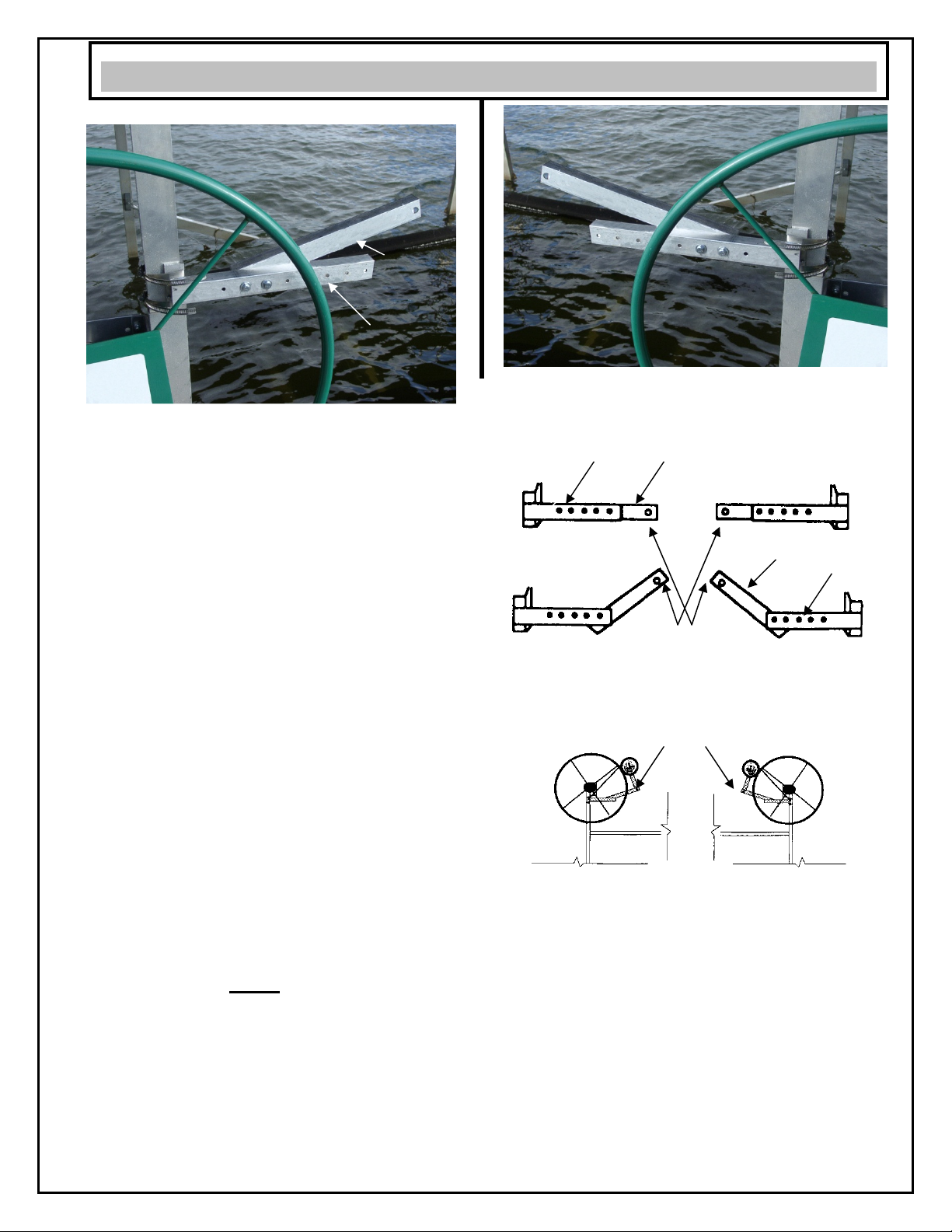

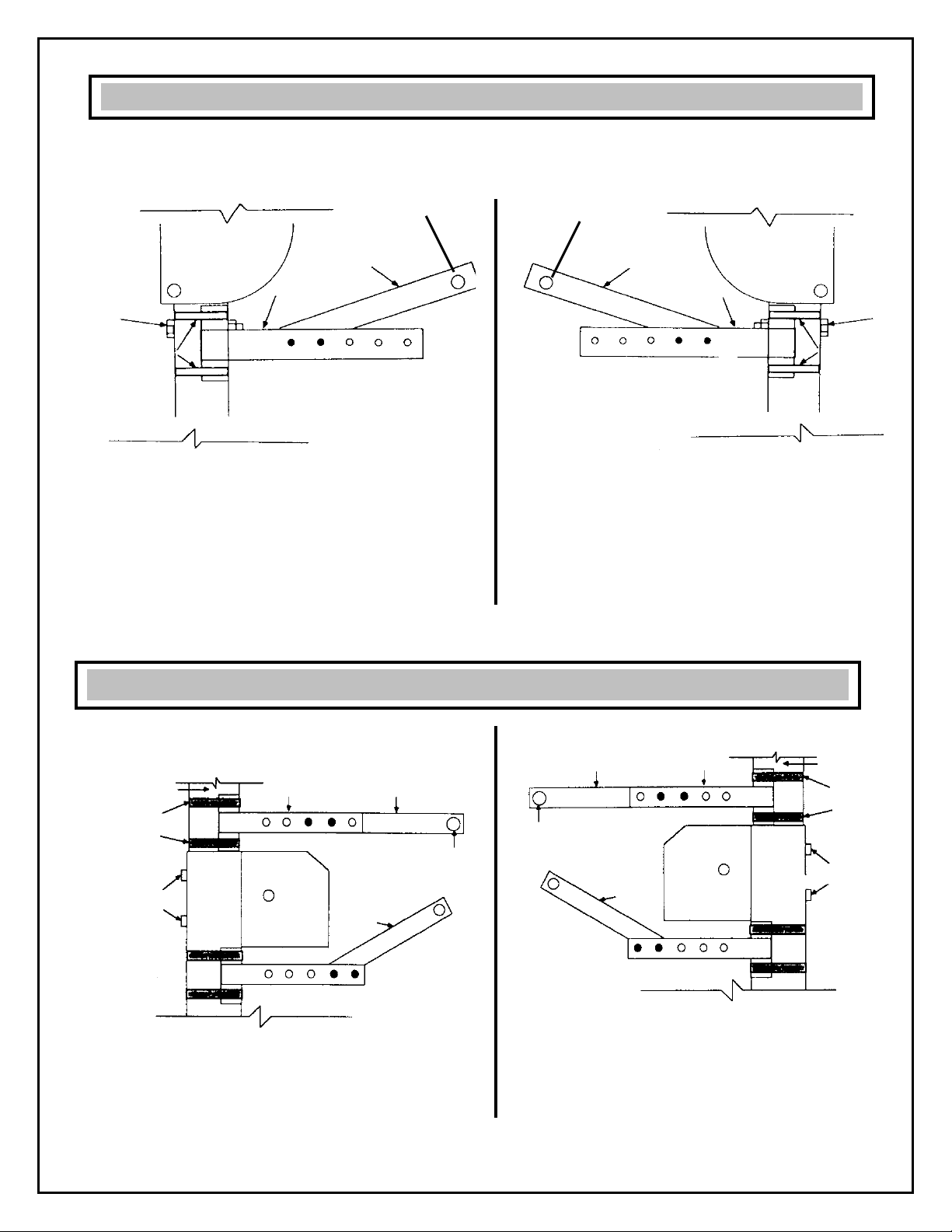

FIG 6: Left Winch Post Installation View

FIG. 8: Left Winch Post Installation View

INSTALL INNER ARM

1. Determine which type of mount you have—a left

post install or a right post install. Then refer to the

left or right install photos as you are installing the

arm.

2. Mount the inner arm with bracket to the winch

post. In this case it is just above the winch box. See

Figs. 6 or 7 depending on which type of post mount.

NOTE: The position of the inner arm will vary

from lift to lift. Refer to the miscellaneous

drawings/photos on pages 11-13 for specific arm

positions on the different types of lifts on the

market today.

FIG. 7: Right Post Winch Post Installation

FIG. 9: Right Winch Post Installation

3. Fasten the inner arm with the two band straps

over the angle bracket. Mount one band strap on top

of bracket. Mount the other band strap on bottom of

bracket. See Figs. 8 or 9.

4. Tighten just enough to hold bracket in place.

Further adjustment will occur in a later step.

6

Inner Arm Inner Arm

Band Strap

Band Strap

Band Strap

Band Strap

STEP 1: INSTALL INNER ARM WITH BRACKET ONTO WINCH POST

FIG 10: Left Winch Post Installation View

INSTALL OUTER ARM

The outer arm can be installed in a variety of

configurations. See Fig 12. The outer arm is the

transition piece between the inner arm and the lift

motor. In the next step, you will mount the lift motor

in roughly the 10 or 2 o’clock position. The outer arm

position will dictate the lift motor’s final position

against the wheel.

Note: There may be some trial and error that

occurs during this step and the next one.

1. Review Fig. 12. The outer arm can bolt on in a

variety of positions. The end goal is to mount the lift

motor arm (next step) onto this arm and have the

motor’s rubber wheel touching the lift wheel at

roughly the 10 or 2 o’clock position.

Note: On some installs, the arm may need to be

positioned downward so the motor is mounting

in the 2 or 4:00 o’clock position.

2. View the miscellaneous drawings/photos on

pages 10-12 for specific arm positions on the

different types of lifts on the market today. By

utilizing the nine holes in both the inner arm and

outer arm, you can adjust the length and angle

positioning of the arms to fit almost any boatlift. The

4 holes in the outer arm will place the outer arm at

15º or 45º.

3. Bolt the outer arm behind and to the inner arm

using the (2) 5/16” x 3 1/2” bolts, nuts, and washers.

See Fig. 10. The pivot hole on the outer arm should

be at least 3”, but not more than 8” from the outer

edge of the winch wheel.

Note: On some installs, the outer arm may need

to go in front of the inner arm. If your boat lift

requires a shorter arm length than our standard

holes allow, drill (2) 5/16” holes where needed in

and lowering the arms will help.

FIG 11: Right Winch Post Installation View

Left Winch Post

Right Winch Post

Installation View Installation View

FIG. 12

The Outer Arm can be installed in many configurations. The

outer arm is the transition piece between the inner arm and

the lift motor. In the next step, you will mount the lift motor in

roughly the 10 or 2 o’clock position. The outer arm position

will dictate where the lift motor’s final position will be.

FIG. 13

7

Outer

Arm

Inner

Arm

Outer

Arm

Inner

Arm

Inner

Arm

Outer

Arm

Outer

Arm

Inner

Arm

STEP 2: INSTALL OUTER ARM ONTO INNER ARM

Pivot

Hole

INSTALL MOTOR ARM

1. Run the 5/8” pivot bolt thru the pivot hole in the

motor arm with threads away from dock.

See Fig. 14.

2. Run the 5/8” bolt thru the pivot hole in the outer

arm and lightly screw on 5/8” nut. See Fig. 14. The

motor arm should be in front of the outer arm.

See Fig. 14.

3. Rotate the motor up and over the pivot so motor’s

rubber traction wheel rests on the boat lift wheel.

See Fig. 14.

4. The lift motor’s rubber traction wheel should be

touching the lift wheel at roughly the 10 or 2 o’clock

position. See Fig. 14. If the motor is not positioned

correctly review Step 2: Install Outer Arm Onto The

Inner Arm on the previous page. Adjust the angle of

the outer arm until the motor rests near the 10 or 2

o’clock position on the lift wheel. See Figs. 12 & 13.

5. Firmly tighten the band clamps on the winch post.

using a 5/16” wrench. See Fig. 14.

Note: Lift up on the arms while tightening the

band clamps. This will allow you to firmly

tighten the clamps.

6. Tighten the 5/8” nut until it just touches the back

side of the outer arm. See Figure 15.

Note: Do not over tighten the nut. The wheels

will not align if over tightening occurs.

Note: Each boat lift will have a different sized

space at the pivot point. Some lifts will have no

space. See Fig. 15. Even if there is some space

between the motor arm and the outer arm where

it pivots, the grooved rubber traction wheel

should follow the boat lift wheel and not jump

off. If you feel you need spacers, purchase large

nylon washers at your local hardware store and

place them between the arms and over the pivot

bolt.

6. Hook one end of the black rubber poly strap into

the top hole of the motor plate towards the winch

post. Fasten the other end to the open end of the

inner or outer arm or directly onto the winch box.

See Fig. 16.

Note: Black rubber poly strap fits most but not

all applications. Alternates may be purchased at

your local hardware store.

FIG. 14

FIG. 15

8

FIG. 16

Rubber

Wheel

Band

Straps

Motor

Arm

Pivot

Bolt

Motor

Arm

Space

Between

Arms

Outer

Arm

5/8”

Nut

Motor

Plate

Rubber

Poly

Strap

STEP 3: INSTALL MOTOR ARM ONTO OUTER ARM

Pivot

Bolt

FIG. 16

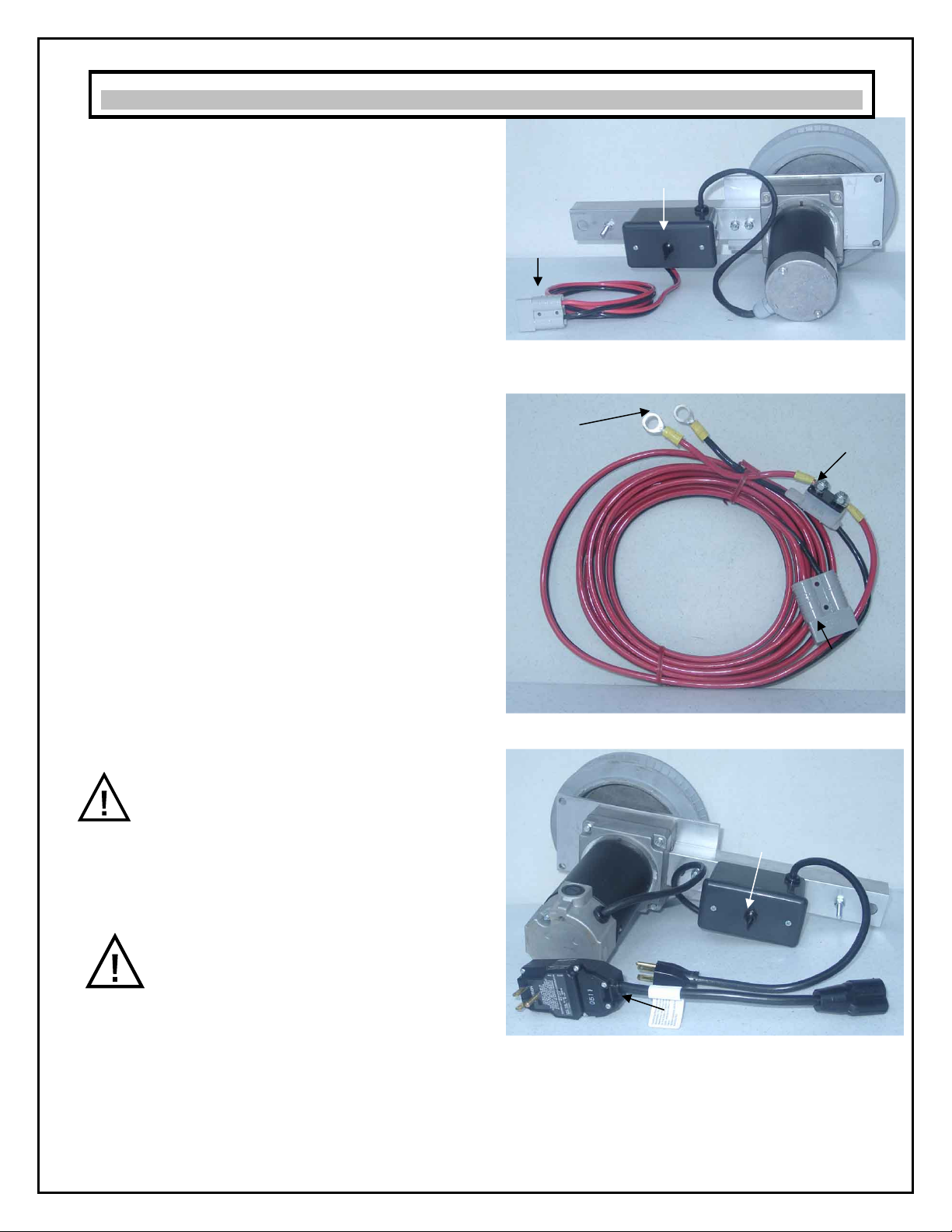

12 VOLT BATTERY WIRING:

We recommend that you hook the harness to the

boat battery on the 12 volt Lift Mate. The boat motor

is charging the battery all the time. It is unlikely that

the lift motor would drain the battery so you cannot

start your boat. Some use a separate 12v battery on

the dock. Try to hide the 15’ cable in the boat by

running it along the side channels, or below the

seats, or under the pontoon deck, or under the

carpet. See Fig. 17 & 18.

Longer cables (pontoon kits) are available at

Shoreline Industries. Refer to the parts list in the

back of the manual, the options list in the front of the

manual, or call your local retailer.

Mate the two plastic quick connects and lightly

attach the two lead ends (one with a circuit breaker

attached) to the battery poles. See Fig. 18. Flip the

motor switch “up” to see that the lift wheel rotates in

the “up” direction. If not, reverse the leads at the

battery and tighten down. See Fig. 17 & 18.

Note: The 12 volt motor is reversible by just

changing the leads at the battery.

The 60 AMP circuit breaker is attached to one of the

lead ends for safety. See Fig. 18. This breaker must

attach to the + pole.

110 VOLT WIRING

This unit uses a 110 volt 15 amp service. Make sure

the unit is connected to an outlet having the same

configuration as the plug. No adapter should be

used with this unit.

Caution: Before plugging in your unit

make sure it will be connected to a

supply circuit that is protected by a

circuit breaker.

Check with a qualified electrician if the grounding

instructions are not completely understood or you

are in doubt as to whether the motor is properly

grounded.

Caution: Always properly connect and

ground your unit. An improper

connection can cause an electrical

shock resulting in severe injury or

death. If you are unsure of the proper electrical

connections or grounding procedures, contact a

qualified electrician to perform the installation.

To reduce the risk of shock, this unit is equipped

with a ground fault interrupter (GFI) plug. See Fig.

19. The GFI plug must be plugged into a matching

outlet that is properly installed and grounded in

accordance with all local codes and ordinances.

FIG. 17

FIG. 18

FIG. 19

9

Motor

Switch

Quick

Connect

Battery

Lead

Ends

Circuit

Breakers

Quick

Connect

GFI

Switch

110 VOLT MOTOR

15 FOOT BATTERY CABLE

12 VOLT MOTOR

STEP 4: ELECTRICAL REQUIREMENTS

Motor

Switch

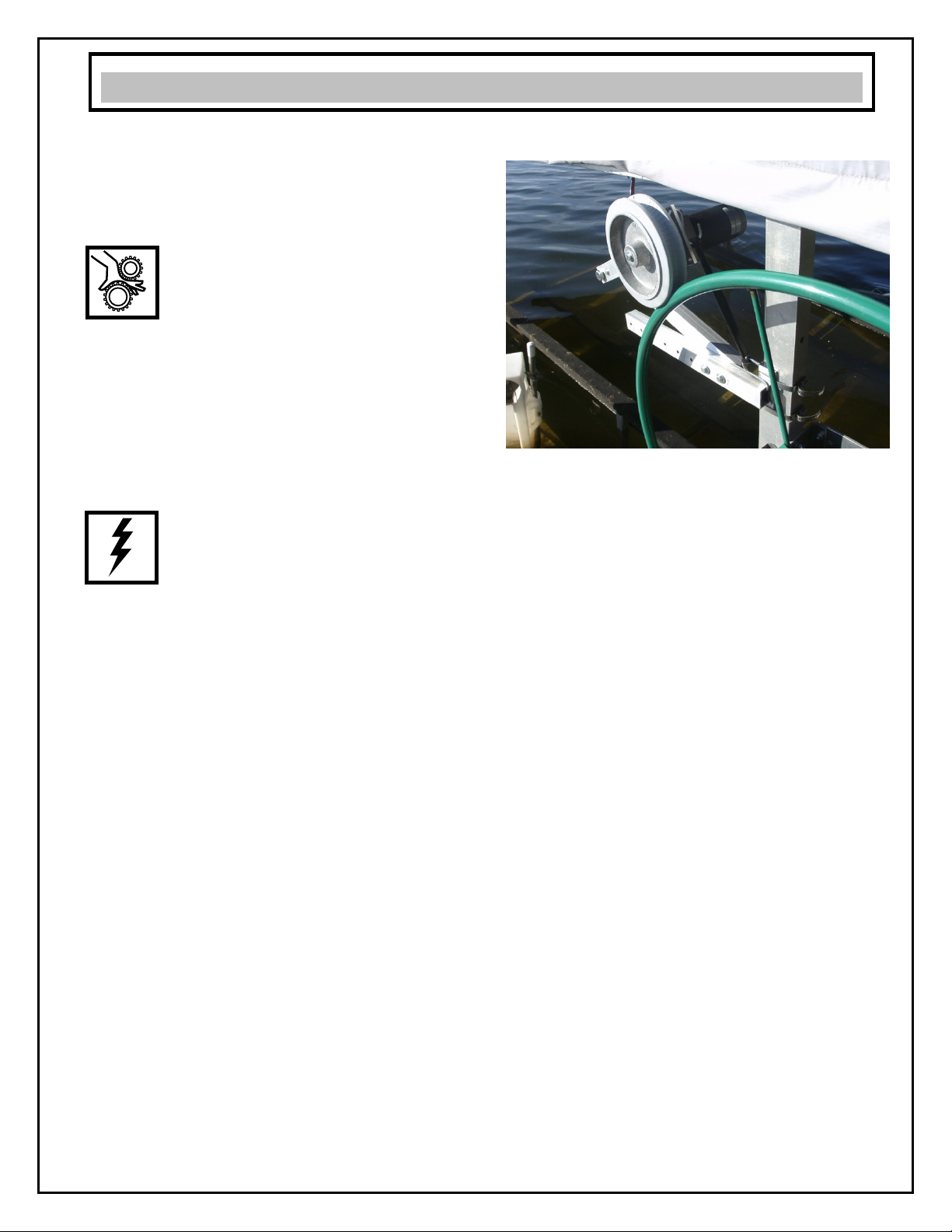

ON/OFF SWITCH

The Lift Mate has a rocker style on/off switch.

1. Hold the switch up to raise the lift.

2. Hold the switch down to lower the lift.

Caution: Stay clear of all moving

parts during raising and lowering of

the lift. There are exposed moving

parts that can pinch fingers, causing

serious injury.

If the motor wheel chatters or slips during operation,

it is just a matter of adding more tension. Adjust the

existing rubber strap to increase tension or add

additional straps.

During a rain or when the wheels are wet from dew

or spray, you will most likely experience slippage.

The operator may need to assist the big lift wheel by

turning on the lift’s crank knob.

Caution: It is recommended to

disconnect the power to Lift Mate

when not in use.

MAINTENANCE

The Lift Mate is basically maintenance free with the

exception of periodic inspections. It is recommended

to periodically inspect the complete unit. Refer to the

following Inspection List:

Caution: It is recommended to disconnect the

power to Lift Mate when performing maintenance

procedures.

1. Tighten all hardware.

2. Inspect rubber traction wheel for proper

alignment. Align if required.

3. Inspect motor brushes and replace as needed.

Caution: It is recommended to disconnect the

power to Lift Mate when performing maintenance

procedures

4. Inspect rubber poly strap for proper tension.

Repair or replace as needed.

5. Inspect electrical connections for worn or frayed

connections. Repair or replace as needed.

OFF SEASON STORAGE

It is recommended to remove the motor from the

outer arm and store in a dry place during the off

season.

FIG. 20

10

OPERATING, MAINTENANCE AND STORAGE INSTRUCTIONS

Left Winch Post Installation

Left Winch Post Installation

Right Winch Post Installation

Right Winch Post Installation

11

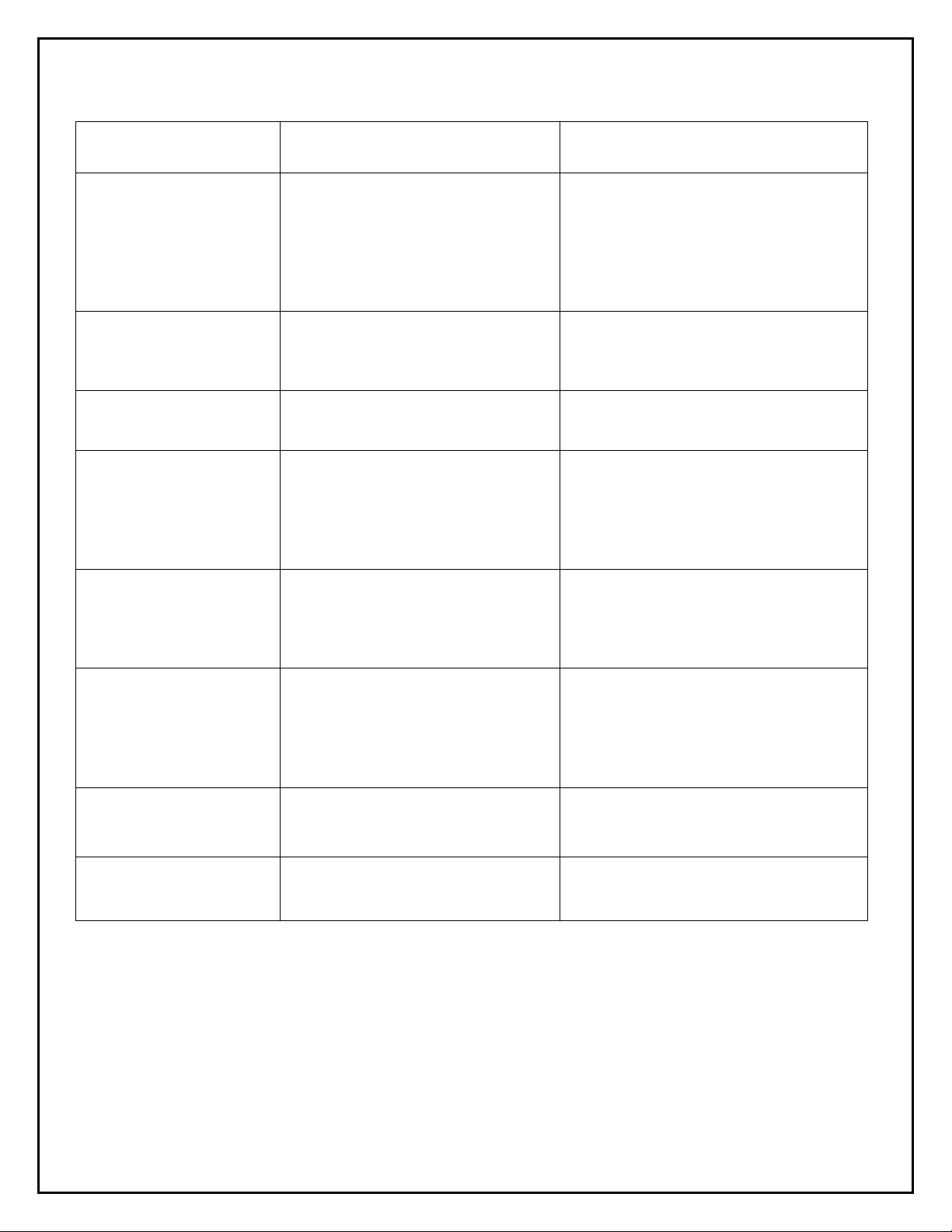

Winch Post

Pivot

Bolt

Outer Arm

Winch Post

Outer Arm

Winch Post

Rubber Strap

Rubber Strap

Outer

Arm

Strap Strap

Outer

Arm

Winch

Post

Rectangular Lift With Canopy

Rectangular Lift Without Canopy

Left Winch Post Installation

Left Winch Post Installation

Right Winch Post Installation

Right Winch Post Installation

12

Outer

Arm

Inner

Arm

Winch

Post

Bolt

Band

Straps

Outer

Arm

Inner

Arm

Winch

Post

Bolt

Band

Straps

Canopy Post

Band

Straps

Bolt

Heads

Inner Arm Outer Arm

Outer

Arm

Outer

Arm

Outer Arm Inner Arm Canopy Post

Band

Straps

Bolt

Heads

OR

Pivot

Hole

OR

Pivot

Hole

ShoreMaster Aluminum Platform Hoists

Aluminum Shore Station

Pivot

Hole

Pivot

Hole

Left Winch Post Installation

Right Winch Post Installation

13

Band

Straps

Inner

Arm Pivot

Hole

Outer

Arm

Pivot

Hole

Inner

Arm

Outer

Arm

Band

Straps

Steel Shore Station

Problem

Cause

Remedy

Motor will not run

1. Not connected to power source.

2. GFI button tripped.

3. Wiring and connections

corroded, worn, or frayed.

4. Motor brushes worn, corroded,

or need replacing.

1. Connect to power source.

2. Push in reset button on GFI.

3. Repair or Replace.

4. Repair or Replace.

12 volt Motor rotating

in the wrong direction

1. Cable leads at battery are

reversed.

1. Reverse cable leads at battery.

110 volt Motor rotating

in the wrong

direction

1. Call retailer. 1. Call retailer.

Rubber traction wheel

slipping on lift wheel

1. Wet lift wheel.

2. Rubber poly strap not tensioned

properly.

3. Incorrectly installed.

1. Dry off lift wheel.

2. Create more tension by stretching

rubber poly strap to a new

mounting

position.

3. Review installation procedures.

The groove on the

rubber traction wheel

will not stay in place

against the lift wheel

1. Rubber traction wheel not

aligned properly.

2. 5/8” pivot bolt nut over

tightened.

1. Review installation procedures.

2. Do not over tighten nut. Install and

tighten per installation instructions.

Remote does not work

Remote may be locked. Too lock and unlock your remote, press

two small blue buttons on the sides at

the same time. You will hear a tone

when affective.

Remote does not work

Batteries may be dead

Replace Batteries.

Remote does not work

Remote not synced with control

unit.

14

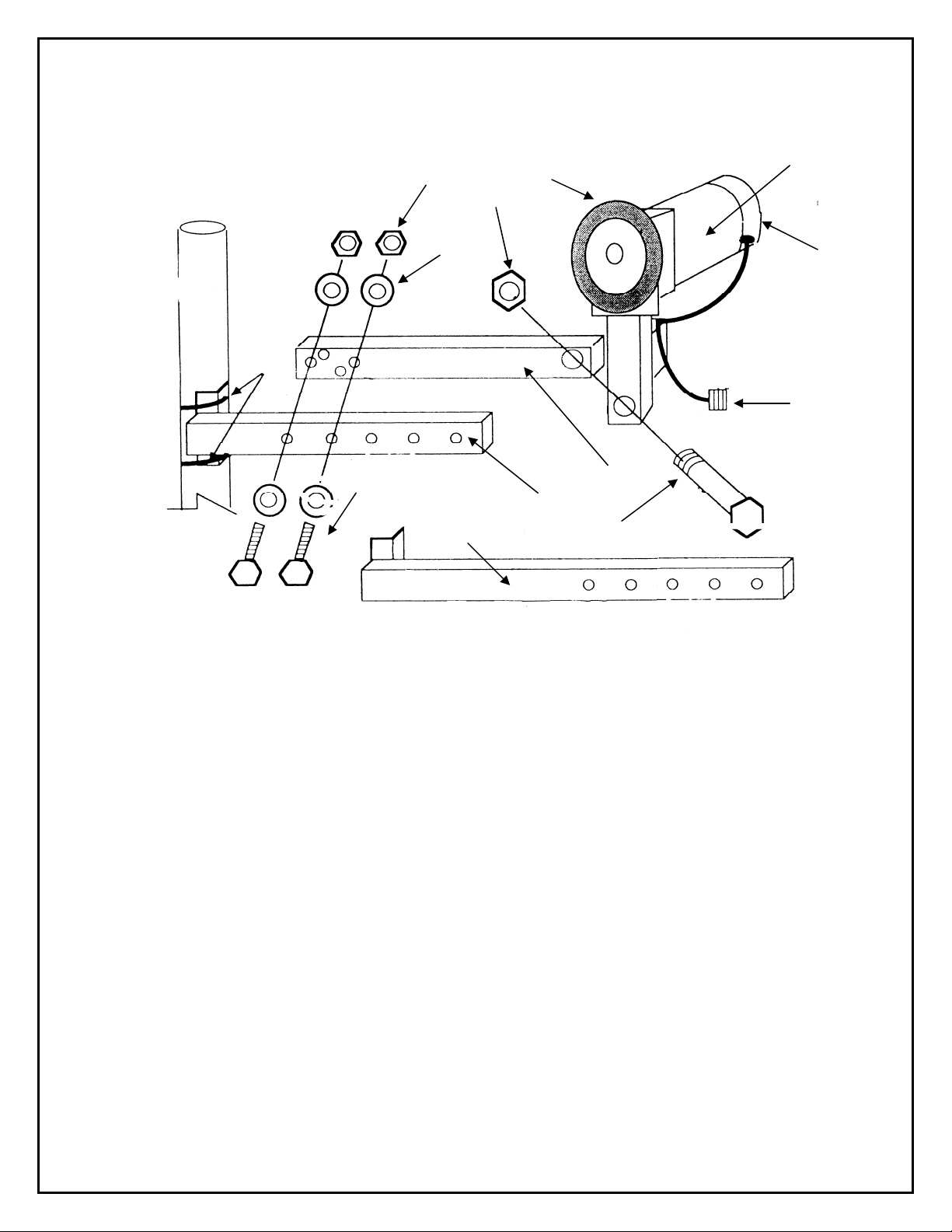

Exploded View

15

5

6

2

8

4

13

3

14

11

9, 10

15

16, 17

( Not Shown)

23

Parts List

Part

Number

Description Qty

1. 1014519 12” Rubber Poly Strap (Not Shown) 1

2. 1002614 Nut 5/8 - 11 SS Pivot Nut 1

3. 1002458 Bolt 5/8 - 11 X 4 SS Pivot Bolt 1

4. 1014432 Bolt 5/16 X 3" Zinc L/M Kit 2

5.

1014429

Nut 5/16 Zinc Steel (L/M Kit) 2

6. 1002608 5/16” Washers SS 4

7. NA 0

8. 1014564 5” Metal Band Straps 2

9.

1014328

12 Volt Motor Assy. 1

10. 1014247 110 Volt Motor 1

11. 1014376 15 Foot Battery Cable (12 Volt Only) 1

12. 1014387/1014467 18” Outlet Cord and 6” GFI Cord (Not

Shown) 1

13. 1014481 Inner Arm 1

14. 1014490 Outer Arm 1

15.

1014479

Rubber Traction Wheel & Wheel Key 1

16. 1014327 12 Volt Motor Brushes (Not Shown) 1

17. 1014276 110 Volt Motor Brushes (Not Shown) 1

Optional Equipment

18. 1015017-1012023 Motor Cover (Not Shown) 1

19.

1014224/1014318

Remote Control (Not Shown) (110V

or 12V)

1

20. 1014389

20 Ft Battery Cable (Not Shown) 1

21. 1014392

25 Ft Battery Cable (Not Shown) 1

22. 1014399

30 Ft Battery Cable (Not Shown) 1

23.

1014796

Pontoon Kit 1

24. 1014775 Overdock Kit (not shown) 1

16

Table of contents

Popular Lifting System manuals by other brands

Manutan

Manutan A170349 instructions

morse

morse 400A-60-120 Operator's manual

Blitz

Blitz GWSK operating instructions

Central Hydraulics

Central Hydraulics 1647 Assembly and operating instructions

Lippert Components

Lippert Components Power Gear owner's manual

Presto

Presto TT Series Installation, operation and service manual