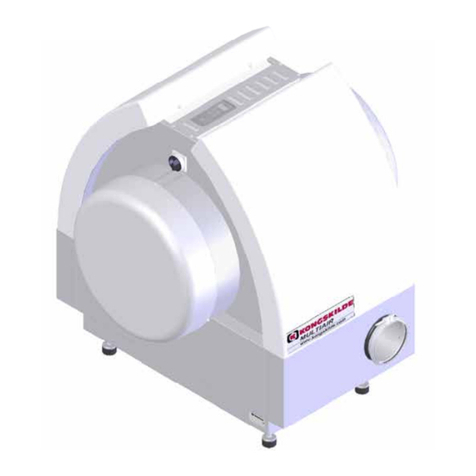

Showa Denki U2S Use and care manual

013(E)-E

Gust Blower

【U2S 】

Operation and Safety Manual

Thank you very much for purchasing this Showa Denki blower.

This Operation Manual describes the specifications for

【

Gust Blower Type U2S

】

.

Please read this Operation Manual carefully (in particular where marked with a symbol) for safe and

efficient use of this blower.

Please keep this Operation Manual accessible for future use.

013(E)-E

-1-

Application

This gust blower is suitable for handling air and other incombustible, non-corrosive, and non-explosive gases.

This gust blower is designed to allow continuous operation. However, please note that frequent or repetitive

ON/OFF operation or use in a high-temperature environment can raise the gust blower to the maximum

allowable temperature. For details, please contact us.

Remove solid matters and impurities to prevent their entry into the gust blower.

Suction and compression pressure

Using the gust blower near its maximum static pressure causes temperature rise due to the compression heat

and the overloading of the motor. Provide a pressure adjusting valve or a bypassnis hole on either the suction

or discharge side to let out the air under such usage conditions.

Temperatures

The maximum allowable ambient temperature and gas temperature at the inlet are 40℃.

The casing temperature while in operation is very high. Avoid touching to prevent burns.

Installation

The gust blower can be installed in any axial direction unless its cooling effect is impaired. Keep the

ventilation grid and openings clean. The direction of flow is indicated with an arrow.

When installing the gust blower in proximity of a wall, secure a minimum of the following clearance

between the gust blower and the wall:

U2S-40T・70T・150

:

20mm

U2S-H220・H370・H750

:

30mm

Ensure ducting does not apply pressure or cause stress deformation to the gust blower.

A built-in silencer reduces noise. To further reduce noise, use an auxiliary silencer (optional accessory).

Thin or metal plating, etc. may conduct and amplify sound; if installing, be sure to install a sound-absorbing

layer between the plate and unit.

013(E)-E

-2-

Wiring

Be sure to disconnect the power supply before starting wiring work. Wiring of the gust blower must be

performed by a qualified electrician.

Ensure that the power supply voltage and frequency are the same as those indicated on the nameplate.

※Wiring for U2S-40T・70T・150

For IE1 products, the metal plates are arranged and wired for the voltage at the time of purchase.

Check that the metal plates are arranged and wired as shown in Table 1 (Fig. 1-2) according to the model,

power supply voltage and frequency to be used.

※Wiring for U2S-H220

・

H370

・

H750

For IE3 products, the metal plate is removed at the time of product delivery.

It is included in the metal plate terminal box.

Connect the metal plates as shown in Table 2 (Figures 3 to 5) according to the voltage in use.

The metal plate may be left over, depending on the voltage used. Use it if changing the voltage.

Model with IE1

electric motor

installed

(Applicable

models:)

U2S-

40T/70T/150

No. of

terminals

50Hz

60Hz

50Hz

60Hz

200V

200/220V

380V/400V

380V/400V

6

Table 1. Connecting outlet line (IE1)

Drawing 1. Δwiring

Drawing 2. Y wiring

:

Metal plate

013(E)-E

-3-

Model with IE3

electric motor

installed

(Applicable

models:)

U2S-H220/H370/

H750

No. of

terminals

50Hz

60Hz

200V

220V

9

9

60Hz

200V

9

60Hz

380V/400V

Table 2. Connecting outlet line (IE3)

:

Metal plate

Figure 3. Δwiring

Figure 4. YY wiring

Figure 5. Y wiring

Power line inlet

Power line inlet

Power line inlet

013(E)-E

-4-

Allowable voltage range is 土5%. The rated motor current is effective at a gas inlet and ambient

temperatures of 40℃. The motor current will rise by 6% at a gas inlet and an ambient temperature of 20℃.

Set the motor protection circuit breaker to the rated current value.

Be sure to connect a grounding wire to prevent electric shock hazards.

013(E)-E

-5-

Current values

Table 3

Voltage compatibility chart for All Models

Manufacturability

Frequency

50Hz

60Hz

Voltage

200V

380V

400V

200V

220V

380V

400V

U2S-40T

〇

〇

〇

〇

〇

〇

〇

U2S-70T

〇

〇

〇

〇

〇

〇

〇

U2S-150

〇

〇

〇

〇

〇

〇

〇

U2S-H220

〇

×

×

〇

〇

〇

〇

U2S-H370

〇

×

×

〇

〇

〇

〇

U2S-H750

〇

×

×

〇

〇

〇

〇

〇:

Manufacturable

×

:

Non-manufacturable

※The wiring method is different for each voltage. Please refer to Tables 1 and 2 for schematics.

Use within the following current values depending on the model.

Table 4

IE1 Electric Motor

(200V class)

Rated current

Schematic (IE code)

Frequency

50Hz

60Hz

Voltage

200V

200V

220V

U2S-40T

1.8

A

2.5

A

2.3

A

Fig. 1(IE1)

U2S-70T

3.0

A

4.0

A

3.8

A

Fig. 1(IE1)

U2S-150

7.0

A

8.8

A

8.5

A

Fig. 1(IE1)

Table 5

IE3 Electric Motor

(200V class)

Rated current

Wiring (IE code)

Frequency

50Hz

60Hz

Voltage

200V

200V

220V

U2S-H220

9.9

A

12.0

A

10.4

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

U2S-H370

17.1

A

19.6

A

16.9

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

U2S-H750

30.8

A

35.2

A

30.5

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

Table 6

IE1 Electric Motor

(380/400V)

Rated Current

Schematic (IE code)

Frequency

50Hz

60Hz

Voltage

380V

400V

380V

400V

U2S-40T

1.3A

1.5A

1.4A

1.3A

Fig. 2(IE1)

U2S-70T

2.0A

2.1A

2.4A

2.2A

Fig. 2(IE1)

U2S-150

4.9A

5.5

A

5.1

A

5.1

A

Fig. 2(IE1)

Table 7

IE3 Electric Motor

(380/400V)

Rated Current

Schematic (IE code)

Frequency

50Hz

60Hz

Voltage

380V

400V

380V

400V

U2S-H220

×

×

6.0

A

6.0

A

60Hz Fig. 5(IE3)

U2S-H370

×

×

9.8

A

9.8

A

60Hz Fig. 5(IE3)

U2S-H750

×

×

17.6

A

17.6

A

60Hz Fig. 5(IE3)

×

:

Non-manufacturable

013(E)-E

-6-

Current values

Depending on the model, frequency, and voltage, vibration may increase even within the rated current

value, making the product unusable.

Please use within the current value where vibration does not occur shown in the tables below.

(

Applicable models: U2S-H370, U2S-H750

)

Suction- and discharge-side current value table

Table 8

IE1 Electric Motor

(200V class)

Discharge side

Suction side

Schematic (IE code)

Frequency

50Hz

60Hz

50Hz

60Hz

Voltage

200V

200V

220V

200V

200V

220V

U2S-40T

1.8

A

2.5

A

2.3

A

1.8

A

2.5

A

2.3

A

Fig. 1(IE1)

U2S-70T

3.0

A

4.0

A

3.8

A

3.0

A

4.0

A

3.8

A

Fig. 1(IE1)

U2S-150

7.0

A

8.8

A

8.5

A

7.0

A

8.8

A

8.5

A

Fig. 1(IE1)

Table 9

IE3 Electric Motor

(200V class)

Discharge side

Suction side

Wiring(IE code)

Frequency

50Hz

60Hz

50Hz

60Hz

Voltage

200V

200V

220V

200V

200V

220V

U2S-H220

9.9

A

12.0

A

10.4

A

9.9

A

12.0

A

10.4

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

U2S-H370

17.1

A

19.6

A

16.9

A

13.1

A

18.4

A

16.9

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

U2S-H750

30.8

A

35.2

A

30.5

A

22.9

A

32.6

A

30.5

A

50Hz Fig. 3(IE3)

60Hz Fig. 4(IE3)

Table 10

IE3 Electric Motor

(380/400V)

Discharge side

Suction side

Schematic(IE code)

Frequency

50 ㎐

60 ㎐

50 ㎐

60 ㎐

Voltage

380V

400V

380V

400V

380V

400V

380V

400V

U2S-H220

×

×

6.0

A

6.0

A

×

×

6.0

A

6.0

A

60Hz Fig. 5(IE3)

U2S-H370

×

×

9.8

A

9.8

A

×

×

9.8

A

9.8

A

60Hz Fig. 5(IE3)

U2S-H750

×

×

17.6

A

17.6

A

×

×

17.6

A

17.6

A

60Hz Fig. 5(IE3)

×

:

Non-manufacturable

※

IE1 electric motors (380V/400V) not listed.

013(E)-E

-7-

Items to check during equipment commissioning

①

Power supply

①

Electromagnetic switch capacity

②

Installation

③

Connection to the power supply

④

Correct switch connection

De-energization of any one line due to

the disconnection of a power line or

poor switch connection will cause

single-phase operation, and the motor

will burn.

②

Rotational

direction

Rotational direction matches the

arrow-marked plate.

When the motor rotation is in the

reverse, change the two power supply

lines for each other.

③Operating

static pressure

and current

A pressure gage and an ammeter show

that the operating static pressure and

current are below the maximum

operating static pressure and current.

If pressure is above the maximum

operatic static pressure, provide a

bypass hole to let air out.

④

Operating status

No abnormal vibration or noise.

If any, please contact us.

Maintenance inspections

We recommend checking for any deterioration in insulation, and for abnormal vibration or noise every three

months. The motor bearing uses a sealed ball bearing requiring no lubrication. The grease life is roughly one

year, although it varies greatly depending on the operating environment.

Inquiries

For technical inquiries concerning this product, please contact the following.

For troubleshooting or repairs, please contact us using the Contact Form on our website.

http://www.showadenki.co.jp

Showa Denki Co., Ltd., Osaka Headquarters Factory, Promotion Group.

TEL

:

+81-72-870-5708

Table of contents

Other Showa Denki Blower manuals